Porous carbon in situ composite lithium iron phosphate cathode material and preparation method thereof

A lithium iron phosphate, in-situ composite technology, applied to battery electrodes, electrical components, circuits, etc., can solve problems such as agglomeration, wide distribution, and large particle size of lithium iron phosphate, and achieve uniform size, simple operation, and low equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

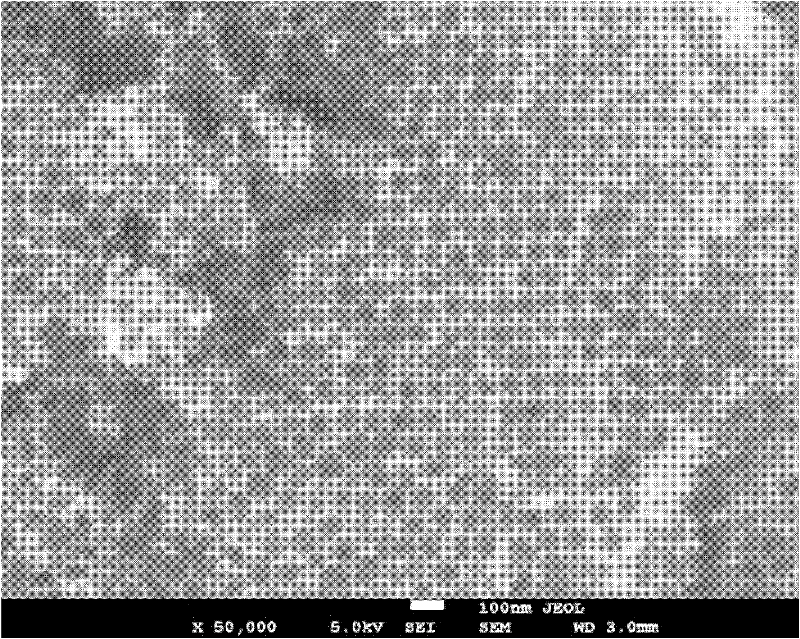

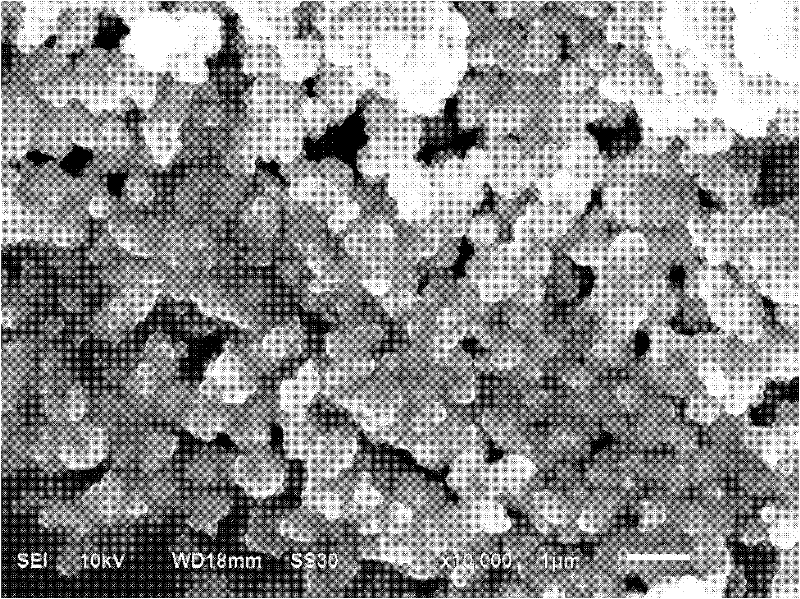

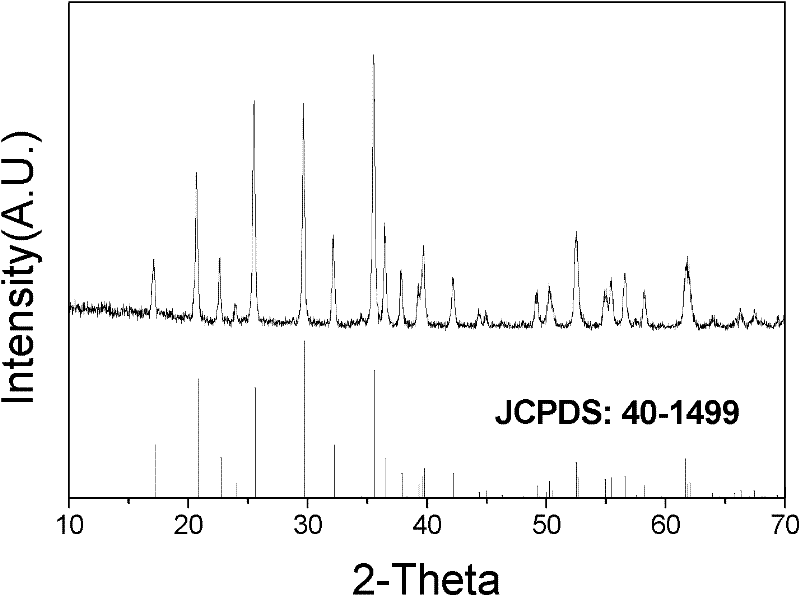

[0031] (1) Select porous carbon with a carbon pore diameter of 80 nm, weigh 1 g and put it into 1 L of deionized water, stir vigorously for 4 hours, and ultrasonically disperse for 1 hour to finally obtain a suspension of porous carbon.

[0032] (2) Dissolve ferric nitrate and phosphoric acid in deionized water and make a 0.05mol / L solution.

[0033] Mix the ferric nitrate and phosphoric acid solution of the above concentration at a volume ratio of 1:1, and send it into the continuously stirred porous carbon suspension with a peristaltic pump at a feed rate of 2ml / min, and at the same time, send it into a certain concentration of ammonia water with a peristaltic pump To ensure that the pH value of the reaction system during the entire peristaltic titration process is maintained at 2.1, wait until the titration of the mixed solution of iron and phosphorus is completed, then continue to stir for 2 hours, then wash the precipitate with deionized water to neutrality, filter, and dr...

Embodiment 2

[0037] (1) Select porous carbon with a carbon pore diameter of 100 nm, weigh 10 g and put it into 5 L of deionized water, stir vigorously for 4 hours, and ultrasonically disperse for 5 hours to finally obtain a suspension of porous carbon.

[0038] (2) Dissolve ferric chloride and ammonium dihydrogen phosphate with deionized water and make a 0.1mol / L solution.

[0039] Mix the ferric chloride and ammonium dihydrogen phosphate solution of the above concentration at a volume ratio of 1:1, and send it into the continuously stirred porous carbon suspension with a peristaltic pump at a feed rate of 20ml / min. Add a certain concentration of ammonia water to ensure that the pH value of the reaction system during the entire peristaltic titration process is maintained at 2.1. After the titration of the mixed solution of iron and phosphorus is completed, continue to stir for 4 hours, and then wash the precipitate with deionized water to neutrality and filter. Dry at 100°C for 12h.

[00...

Embodiment 3

[0045] (1) Select porous carbon with a carbon pore diameter of 80 nm, weigh 5 g and put it into 3 L of a mixed solution of deionized water and absolute ethanol with a volume ratio of 1:1, stir vigorously for 5 h, and ultrasonically disperse for 2 h to obtain Suspensions of porous carbon.

[0046] (2) Dissolve ferric citrate and ammonium phosphate with deionized water and make a 0.05mol / L solution.

[0047] According to the volume ratio of 1:1.05, the ferric source of the above concentration and the phosphorus source solution are mixed, and the peristaltic pump is used to send it into the continuously stirred porous carbon suspension at a feed rate of 10ml / min. concentration of ammonia water to ensure that the pH value of the reaction system throughout the peristaltic titration process is maintained at 2.05. After the titration of the mixed solution of iron and phosphorus is completed, continue to stir for 5 hours, then wash the precipitate with deionized water until it is neut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com