Adhesive pressing platform of textile machinery

A technology of mechanical pressing and countertops, applied in textile processing machine accessories, textile and papermaking, textile materials processing and other directions, can solve the problems of low flatness of worktops, short service life, easy corrosion and aging, etc., and achieve a smooth and smooth surface. , long service life, good high temperature resistance and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

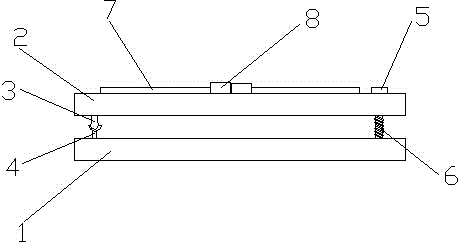

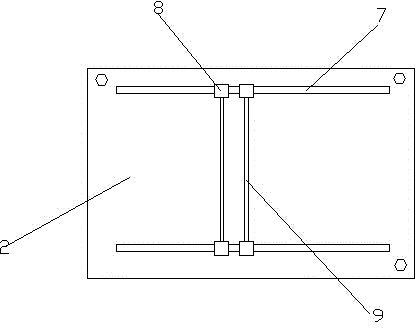

[0014] combine figure 1 , figure 2 , the present invention discloses a rubberized table top for textile machinery, comprising a table base 1, a table body 2, a slider 8 and a cross bar 9; , the table base 1 is equipped with a concave spherical support 4 cooperating with the spherical foot 3, and the spherical foot 3 is installed on the concave spherical support 4; the other triangle of the table body 2 is adjusted by the adjusting bolt 5 is fixed on the table base 1; the adjusting bolt 5 is covered with a spring 6, and the spring 6 is located between the table body 2 and the table base 1; A set of slide rails 7 is provided; two slide rails 7 are equipped with a pair of slide blocks 8 , and a pair of slide blocks 8 on different slide rails 7 are connected through the cross bar 9 . The number of the sliders 8 is preferably two pairs.

[0015] In order to improve the smoothness of the surface of the table body 2 and its high temperature resistance and anti-oxidation performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com