Epoxidized soybean oil plasticized ethyl cellulose membrane and method for preparing the same

A technology of epoxidized soybean oil and ethyl cellulose, which is applied in the field of natural polymer film materials, can solve the problems such as no public reports of epoxidized soybean oil plasticized ethyl cellulose film materials, etc., and achieve excellent comprehensive use performance, Good mechanical properties, simple and easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

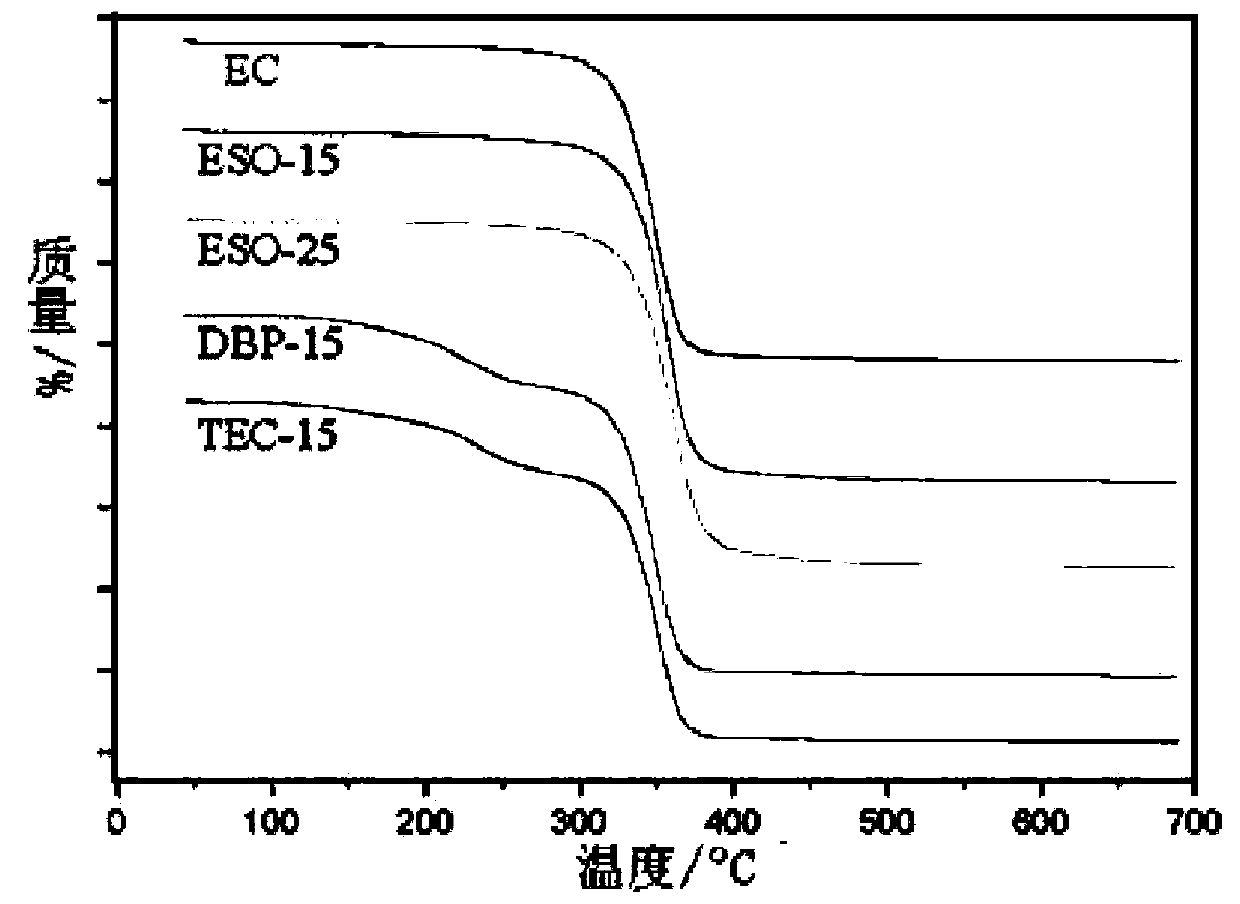

[0026] Dissolve 1.9g of ethyl cellulose in 20mL of acetone, stir to dissolve; add 0.1g of epoxidized soybean oil (epoxy value 3.0) into the above-mentioned dissolved ethyl cellulose solution, stir and mix evenly; pour the mixed solution into Put into a polytetrafluoroethylene plate, and cast to prepare a film by casting method. The film forming temperature is room temperature (25° C.) to obtain an ethyl cellulose film plasticized with epoxy soybean oil.

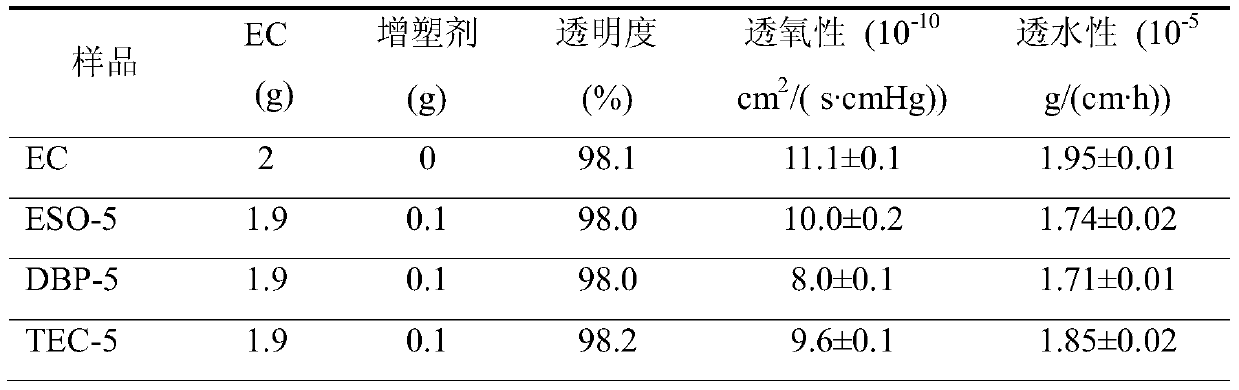

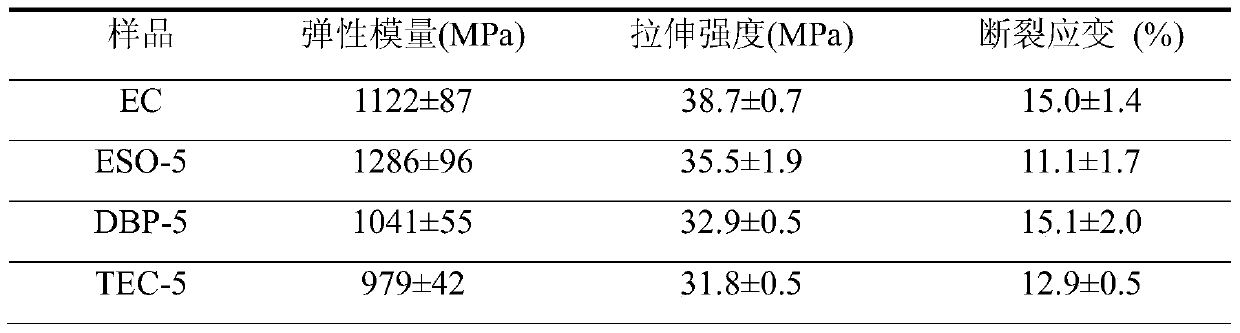

[0027] The ethyl cellulose film (ESO-5) plasticized by the epoxidized soybean oil obtained in this embodiment and the ethyl cellulose film (DBP-5) plasticized by dibutyl phthalate prepared under the same conditions, lemon The ethyl cellulose film plasticized with triethyl acetate (TEC-5) and the pure ethyl cellulose film (EC) without plasticizer were compared. The properties of the film are shown in Table 1 and Table 2.

[0028] Table 1 Comparison of film transparency and gas permeability

[0029]

[0030] Table 2 Compari...

Embodiment 2

[0034] Dissolve 1.5g of ethyl cellulose in 20mL of acetone, stir to dissolve; add 0.5g of epoxidized soybean oil (epoxy value 6.5) into the above-mentioned dissolved ethyl cellulose solution, stir and mix evenly; pour the mixed solution into Put into a polytetrafluoroethylene plate, and cast to prepare a film by casting method. The film forming temperature is 40° C. to obtain an ethyl cellulose film plasticized with epoxy soybean oil.

[0035] The ethyl cellulose film (ESO-25) of the epoxy soybean oil plasticization that the present embodiment obtains and the dibutyl phthalate plasticization ethyl cellulose film (DBP-25) prepared under the same conditions, lemon The ethyl cellulose film plasticized with triethyl acetate (TEC-25) and the pure ethyl cellulose film (EC) without plasticizer were compared. The properties of the film are shown in Table 3 and Table 4.

[0036] Table 3 Transparency and gas permeability of the film

[0037]

[0038] Note: "—" indicates that due to ...

Embodiment 3

[0044] Dissolve 1.4g of ethylcellulose in 20mL of acetone, stir and dissolve; add 0.6g of epoxidized soybean oil (epoxy value 6.5) into the above-mentioned dissolved ethylcellulose solution, stir and mix evenly; pour the mixed solution into Put into a polytetrafluoroethylene plate, cast and cast a film to prepare a film, and the film forming temperature is 70° C. to obtain an ethyl cellulose film plasticized with epoxy soybean oil.

[0045] The ethylcellulose film (ESO-30) plasticized by the epoxy soybean oil obtained in this embodiment is compared with the pure ethylcellulose film (EC) without plasticizer, and the performance of the film is shown in Table 5 and Table 6 shown.

[0046] Table 5 Transparency and gas permeability of the film

[0047]

[0048] Table 6 Mechanical properties of membranes

[0049]

[0050] From the results of Table 5 and Table 6, it can be seen that the ethyl cellulose film added with 30% epoxidized soybean oil has lower oxygen permeability a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com