Preparation method of nitric acid industrial carbon emission reduction catalyst

A catalyst and carbon emission reduction technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve problems such as unsatisfactory thermal stability, and achieve water vapor resistance and stability Good, stable performance, simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

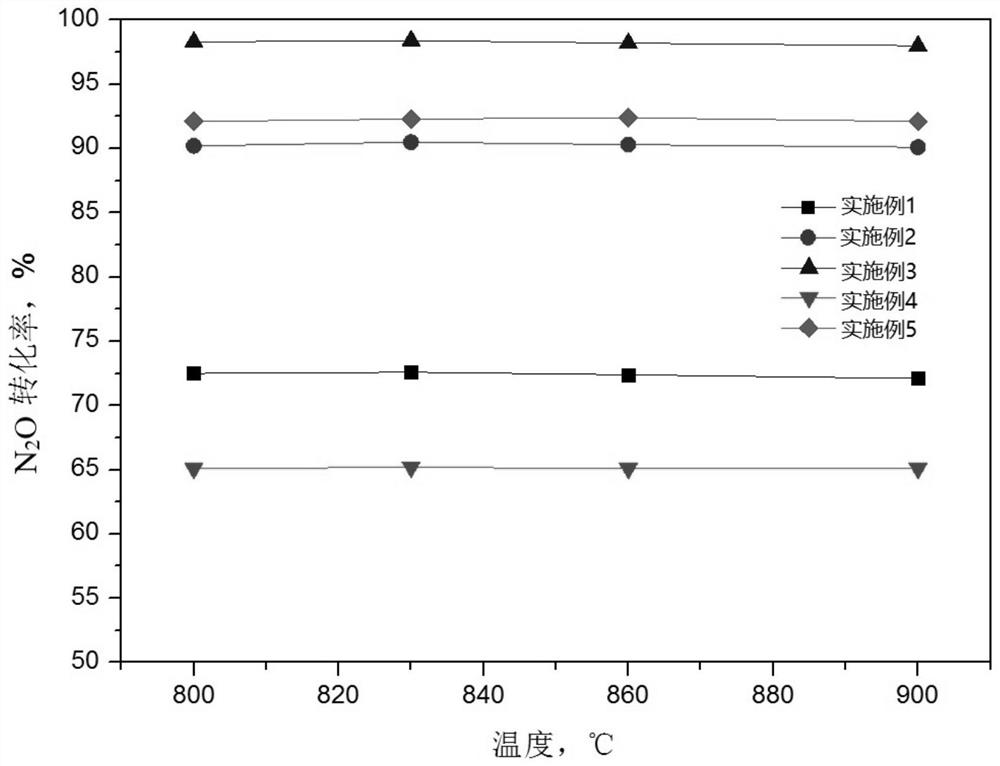

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] Step 1. Prepare impregnation solution: dissolve the active component precursor and auxiliary agent precursor in deionized water according to the mass ratio of 0.5:1 to obtain a transparent impregnation solution; the active component precursor is cobalt acetate, and the auxiliary agent The precursor is platinum nitrate;

[0033] Step 2. Preparation of catalyst precursor: at room temperature, cerium oxide powder with a particle size of less than 10 μm was added as a carrier to the impregnation solution obtained in step 1 for 2.0 hours to obtain a paste, and then the paste was placed at 80 Dry at ℃ for 24 hours to obtain a catalyst precursor; the ratio of the mass of the ceria powder to the volume of the impregnating solution is 100:20, the unit of mass is g, and the unit of volume is mL;

[0034] Step 3. Catalyst molding: mix montmorillonite, cornstarch and the catalyst precursor obtained in step 2 uniformly accordin...

Embodiment 2

[0040] This embodiment includes the following steps:

[0041] Step 1. Prepare impregnation solution: dissolve the active component precursor and auxiliary agent precursor in deionized water at a mass ratio of 10:0.01 to obtain a transparent impregnation solution; the active component precursor is cobalt and aluminum Cobalt acetate and aluminum acetate with a mass ratio of 3:1, and the precursor of the auxiliary agent is palladium nitrate;

[0042] Step 2. Preparation of catalyst precursor: at room temperature, cerium oxide powder with a particle size of less than 10 μm was added as a carrier to the impregnation solution obtained in step 1 for 1.0 h to obtain a paste, and then the paste was placed at 110 Dry at ℃ for 48 hours to obtain a catalyst precursor; the ratio of the mass of the ceria powder to the volume of the impregnating solution is 100:100, the unit of mass is g, and the unit of volume is mL;

[0043] Step 3. Catalyst molding: mix pseudo-boehmite, hydroxymethylprop...

Embodiment 3

[0048] This embodiment includes the following steps:

[0049] Step 1. Prepare impregnation solution: dissolve the active component precursor and auxiliary agent precursor in deionized water according to the mass ratio of 2.5:0.15 to obtain a transparent impregnation solution; the active component precursor is cobalt element and aluminum element Cobalt nitrate and aluminum nitrate with a mass ratio of 4:1, the additive precursor is ruthenium chloride;

[0050] Step 2. Preparation of catalyst precursor: at room temperature, cerium oxide powder with a particle size of less than 10 μm was added as a carrier to the impregnation solution obtained in step 1 for 1.0 h to obtain a paste, and then the paste was placed at 110 Dry at ℃ for 24 hours to obtain a catalyst precursor; the ratio of the mass of the ceria powder to the volume of the impregnating solution is 100:50, the unit of mass is g, and the unit of volume is mL;

[0051] Step 3. Catalyst forming: mix bentonite, hydroxymethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com