A kind of solar photovoltaic cell module transparent back plate composite film and preparation method thereof

A technology of photovoltaic cells and composite membranes, applied in the field of composite membranes, can solve problems such as pollution, expensive imports, and shortened service life of battery components, and achieve the effects of good chemical stability, excellent performance, and good water vapor transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

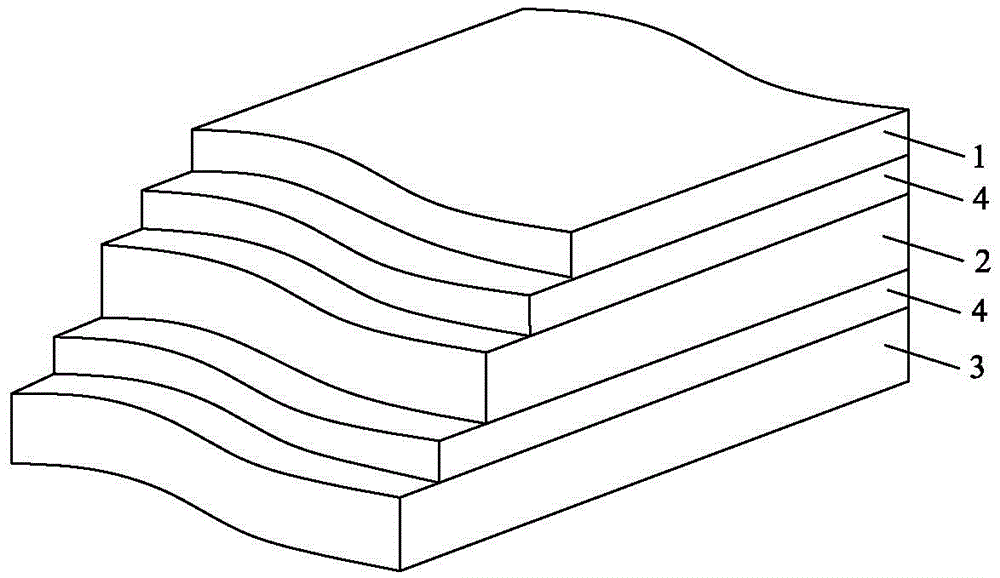

[0056] Such as figure 1 As shown, the solar photovoltaic cell module transparent backboard composite film of this embodiment includes the first weather-resistant layer, the second weather-resistant layer and the base layer in sequence from top to bottom, between the first weather-resistant layer and the second weather-resistant layer, the second weather-resistant layer An adhesive layer is arranged between the second weather-resistant layer and the base layer, and the two adhesive layers are transparent glue adhesive layers 4, and the thickness of the two transparent glue adhesive layers 4 is 11 μm; the first weather-resistant layer is transparent weather-resistant PC (polycarbonate) film 1 with a thickness of 25 μm; the second weather-resistant layer is transparent weather-resistant PET (polyethylene terephthalate) film 2 with a thickness of 150 μm; the base layer is transparent linear low-density LLDPE ( Polyethylene) film 3 with a thickness of 50 μm;

[0057] The two trans...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that: the thickness of the two transparent glue bonding layers 4 of this embodiment is 14 μm; the thickness of the transparent weather-resistant PC film 1 is 100 μm; the thickness of the transparent weather-resistant PET film 2 is 300 μm; the thickness of the transparent linear low-density LLDPE film 3 is 150 μm.

[0067] The two transparent glue bonding layers 4 both include 0.5 part of ultraviolet absorber UV-326.

[0068] The preparation method of the transparent backplane composite film of the solar photovoltaic cell module of the present embodiment comprises the following preparation steps:

[0069] a, the modified polymer resin LLDPE-g of 95 parts of polycarbonate, 5 parts of UV absorber UV-326, 5 parts of ZnO, 0.4 parts of light hindered amine light stabilizer 770, 3 parts by weight - MAH is mixed and stirred evenly to obtain a modified PC mixture, and the modified PC mixture is prepared by a casting met...

Embodiment 3

[0077] The difference between this embodiment and Embodiment 1 is that: the thickness of the two transparent glue bonding layers 4 of this embodiment is 12.5 μm; the thickness of the transparent weather-resistant PC film 1 is 50 μm; the thickness of the transparent weather-resistant PET film 2 The thickness is 250 μm; the thickness of the transparent linear low-density LLDPE film 3 is 90 μm.

[0078] Both transparent glue bonding layers 4 include 1 part of UV absorber UV-1577.

[0079] The preparation method of the transparent backplane composite film of the solar photovoltaic cell module of the present embodiment comprises the following preparation steps:

[0080] a, the parts by weight are 100 parts of polycarbonate, 1 part of UV absorber UV-1577, 1 part of TiO 2 , 0.6 parts of light hindered amine light stabilizer 622, 5 parts of modified polymer resin DBAE-g-PE are mixed and stirred evenly to obtain a modified PC mixture, and the modified PC mixture is prepared by casting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com