Patents

Literature

55results about How to "Long-lasting protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

DNA vaccines encoding antigen linked to a domain that binds CD40

InactiveUS7118751B1Improve abilitiesEasy to demonstrateAntibody mimetics/scaffoldsVirus peptidesPeptide antigenEukaryotic plasmids

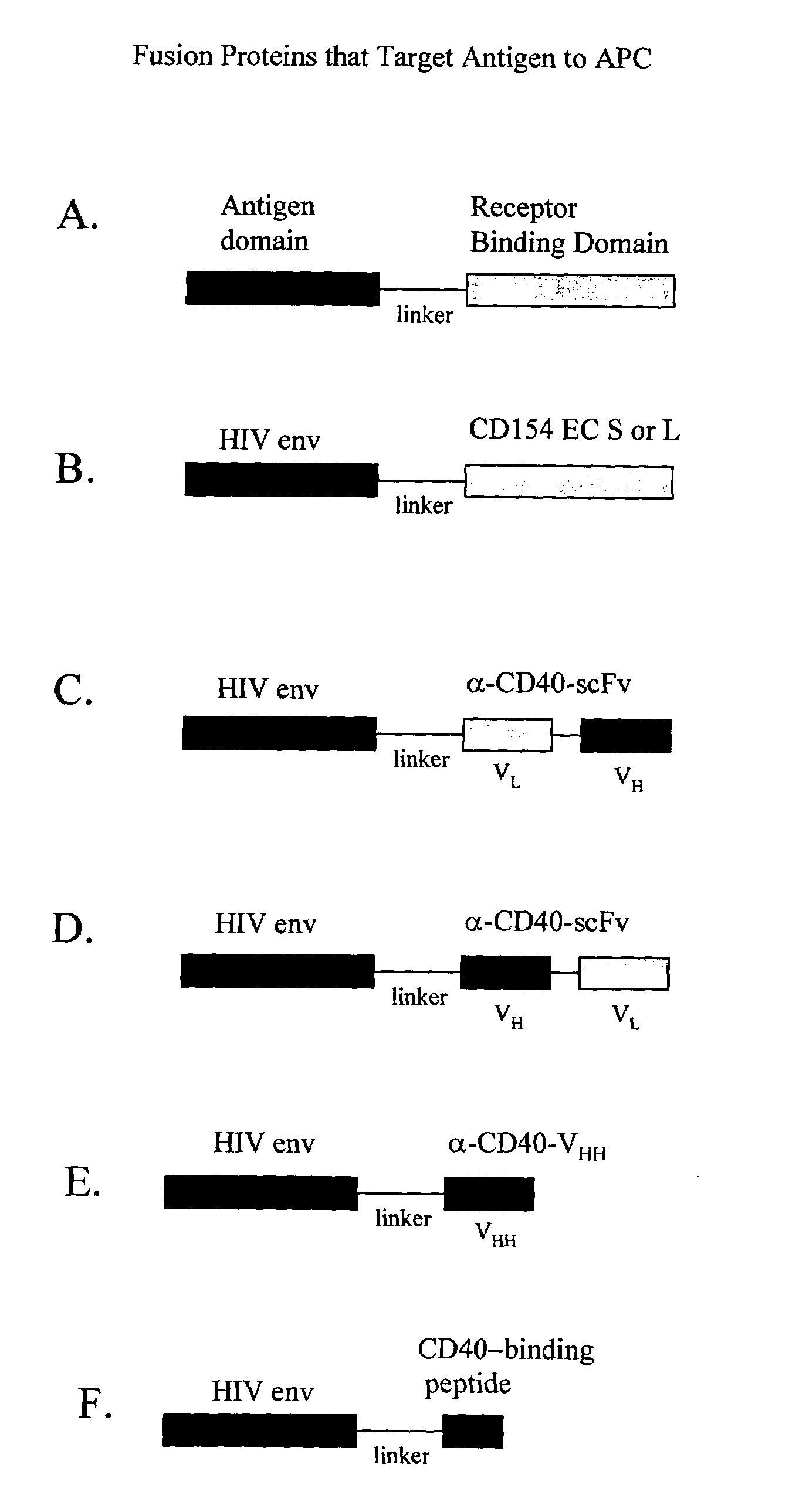

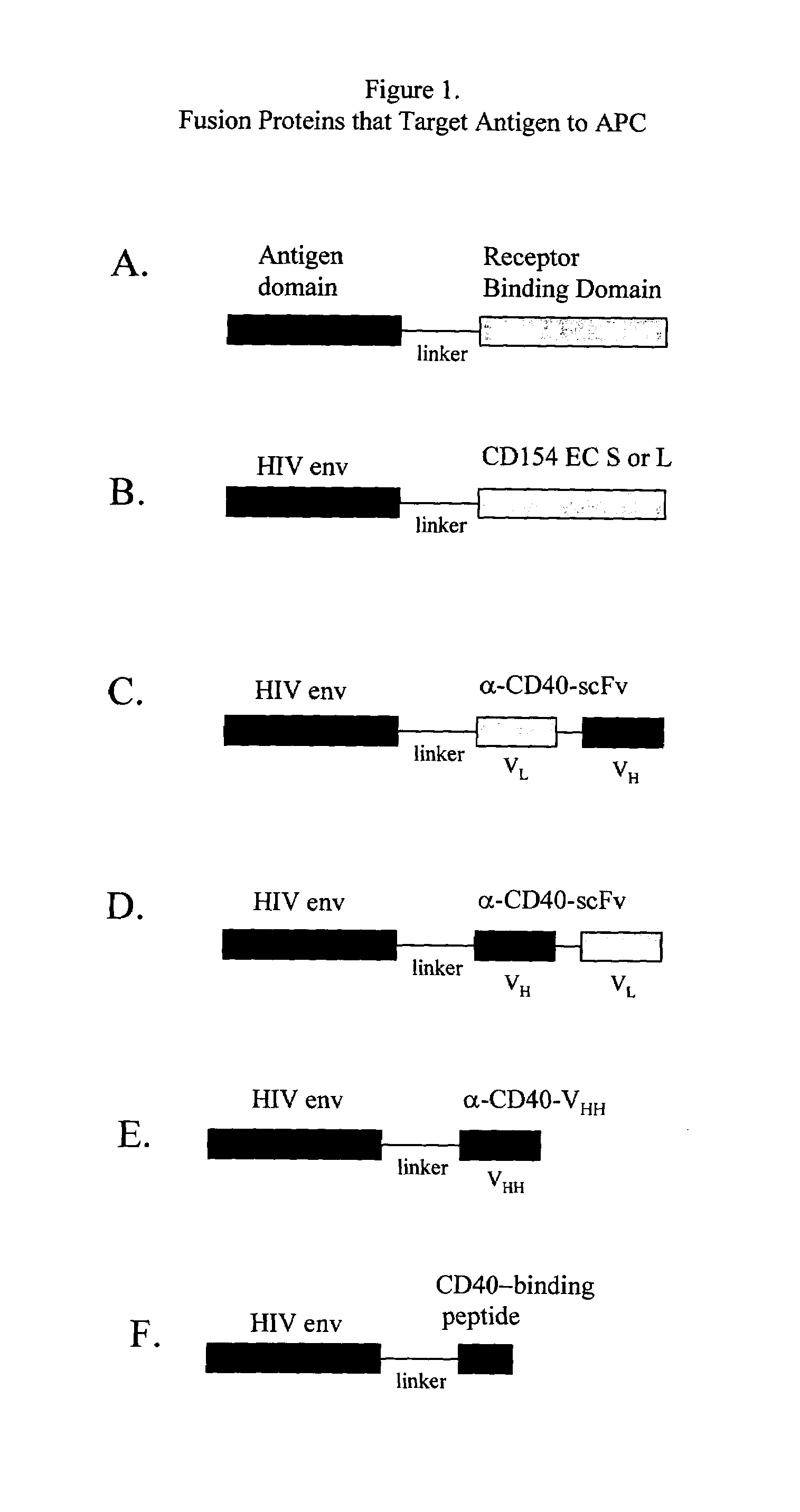

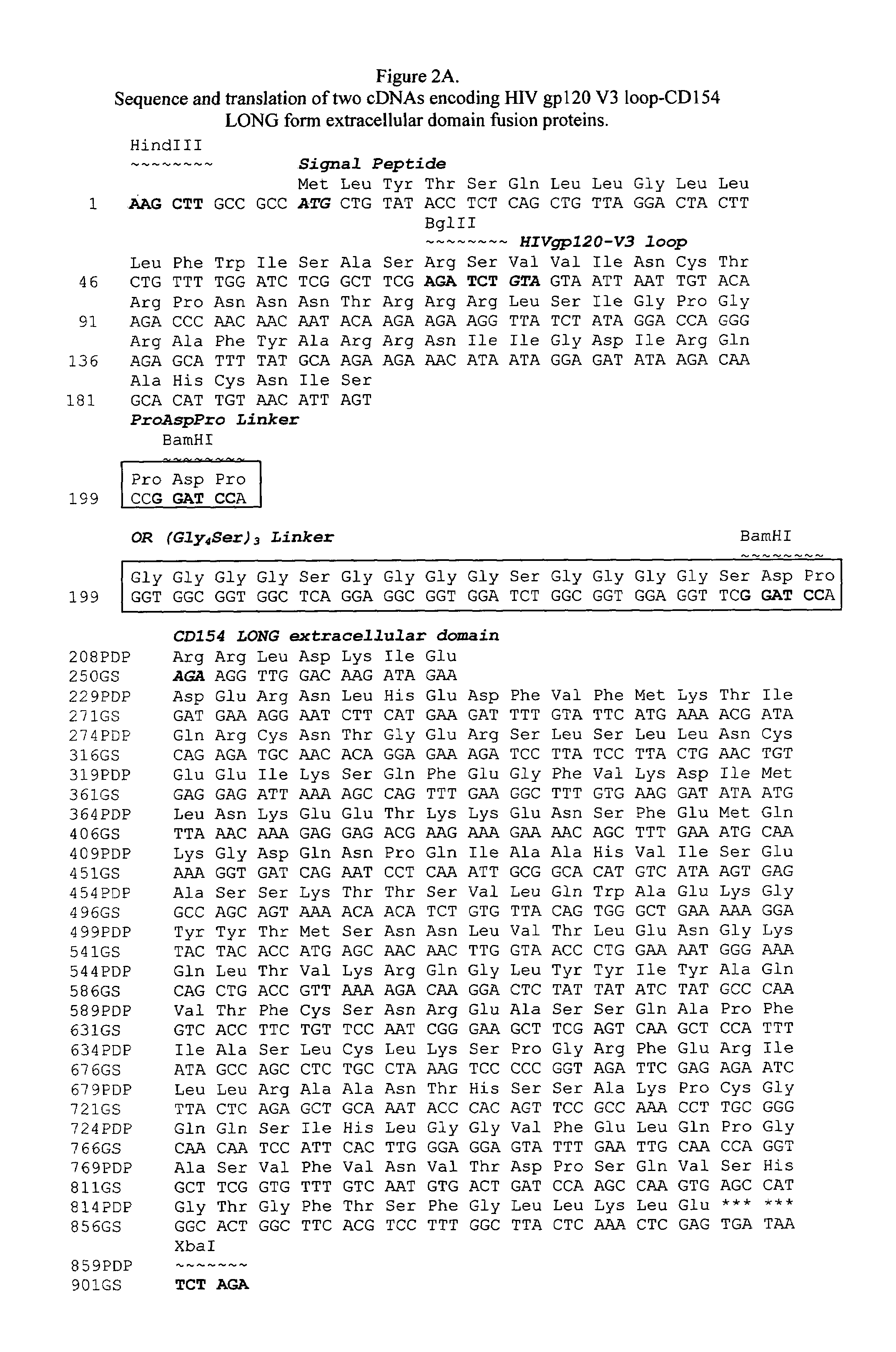

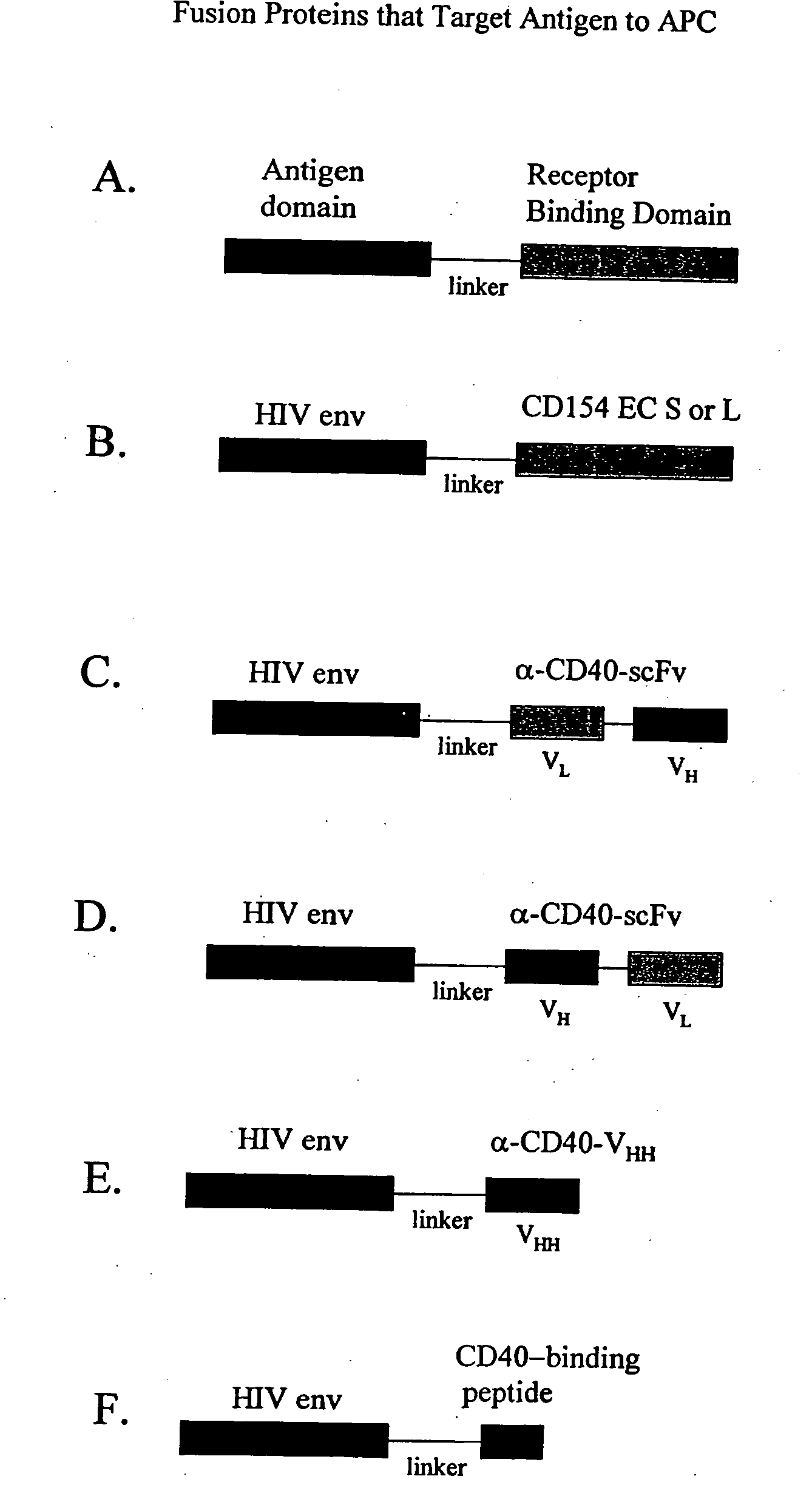

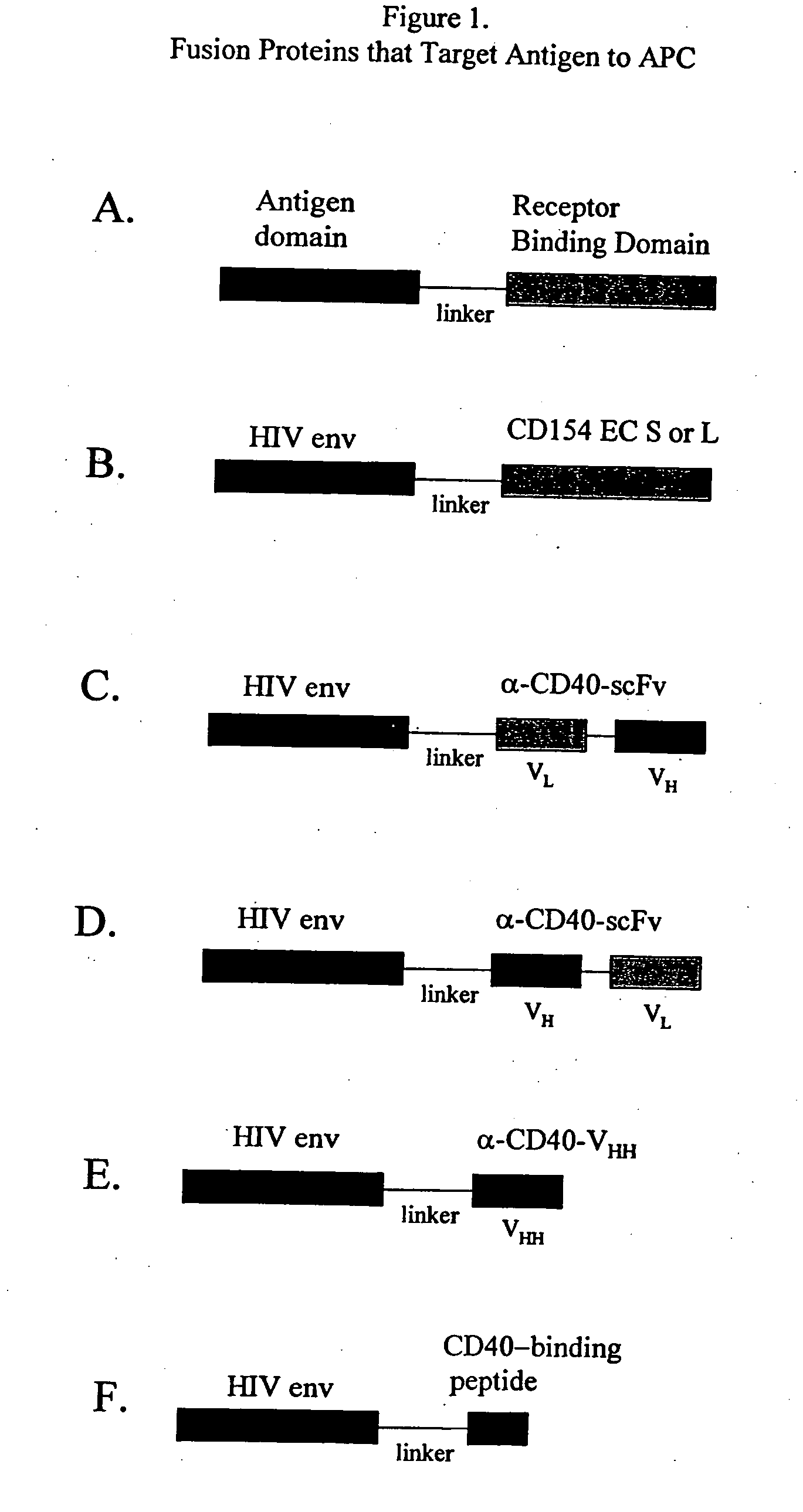

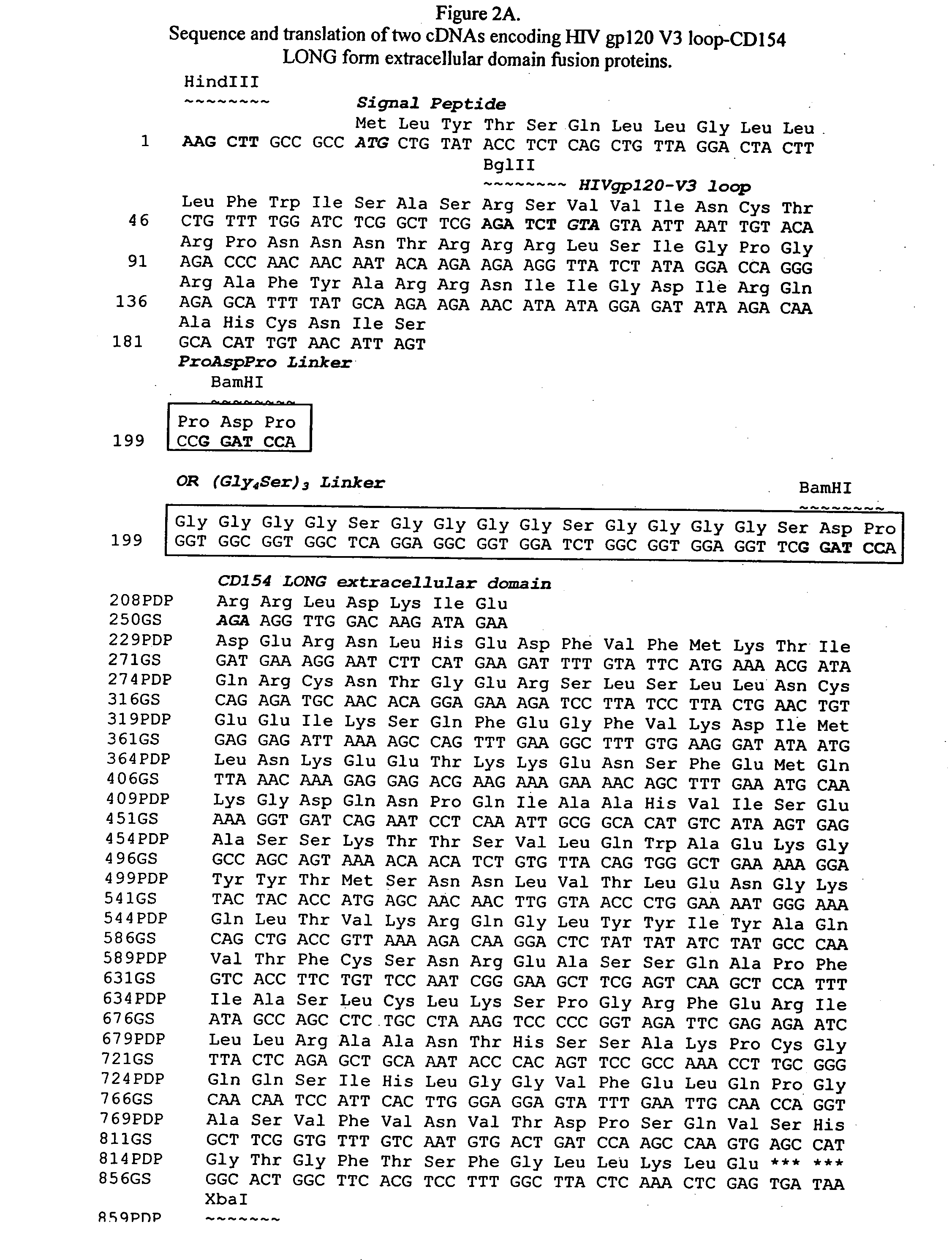

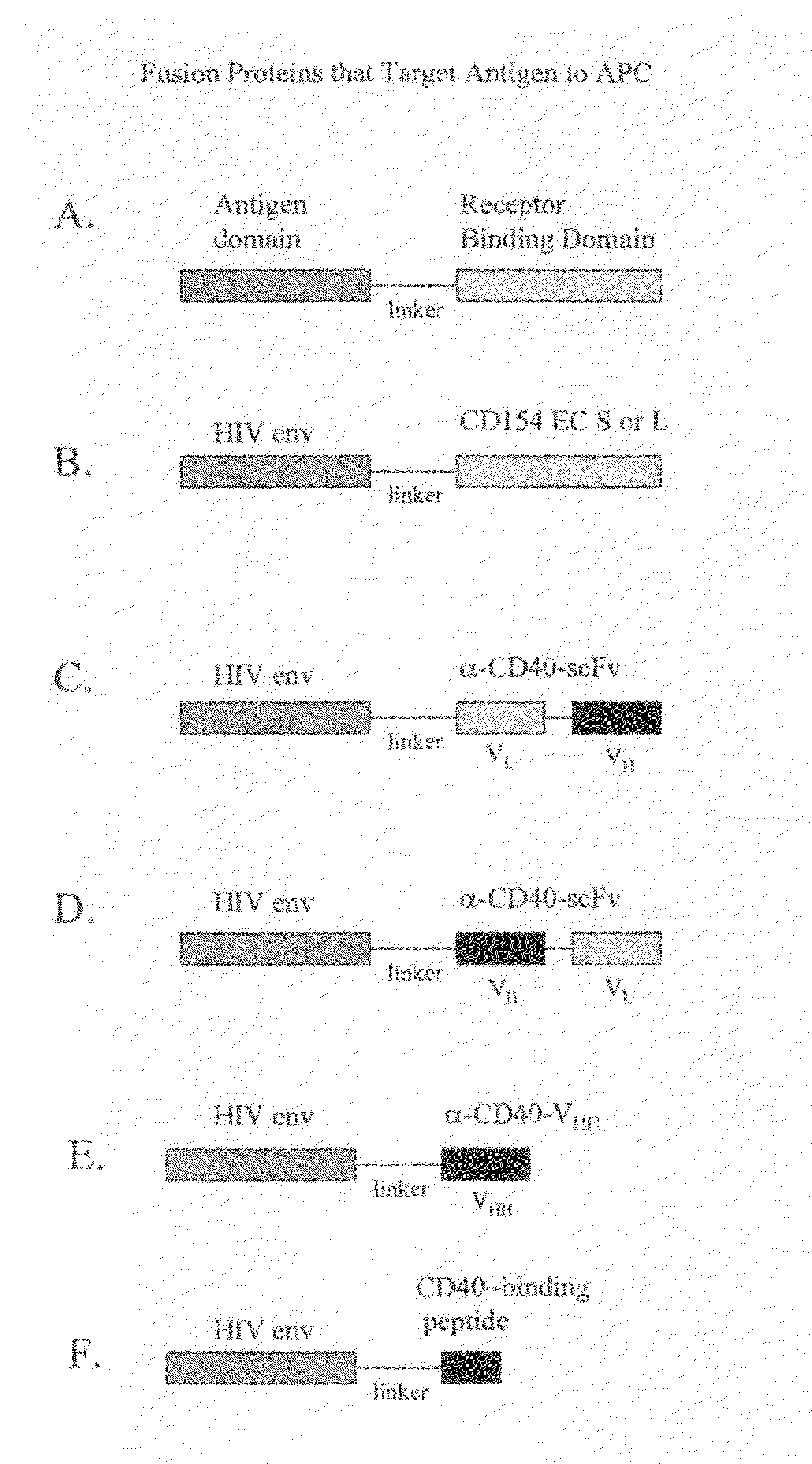

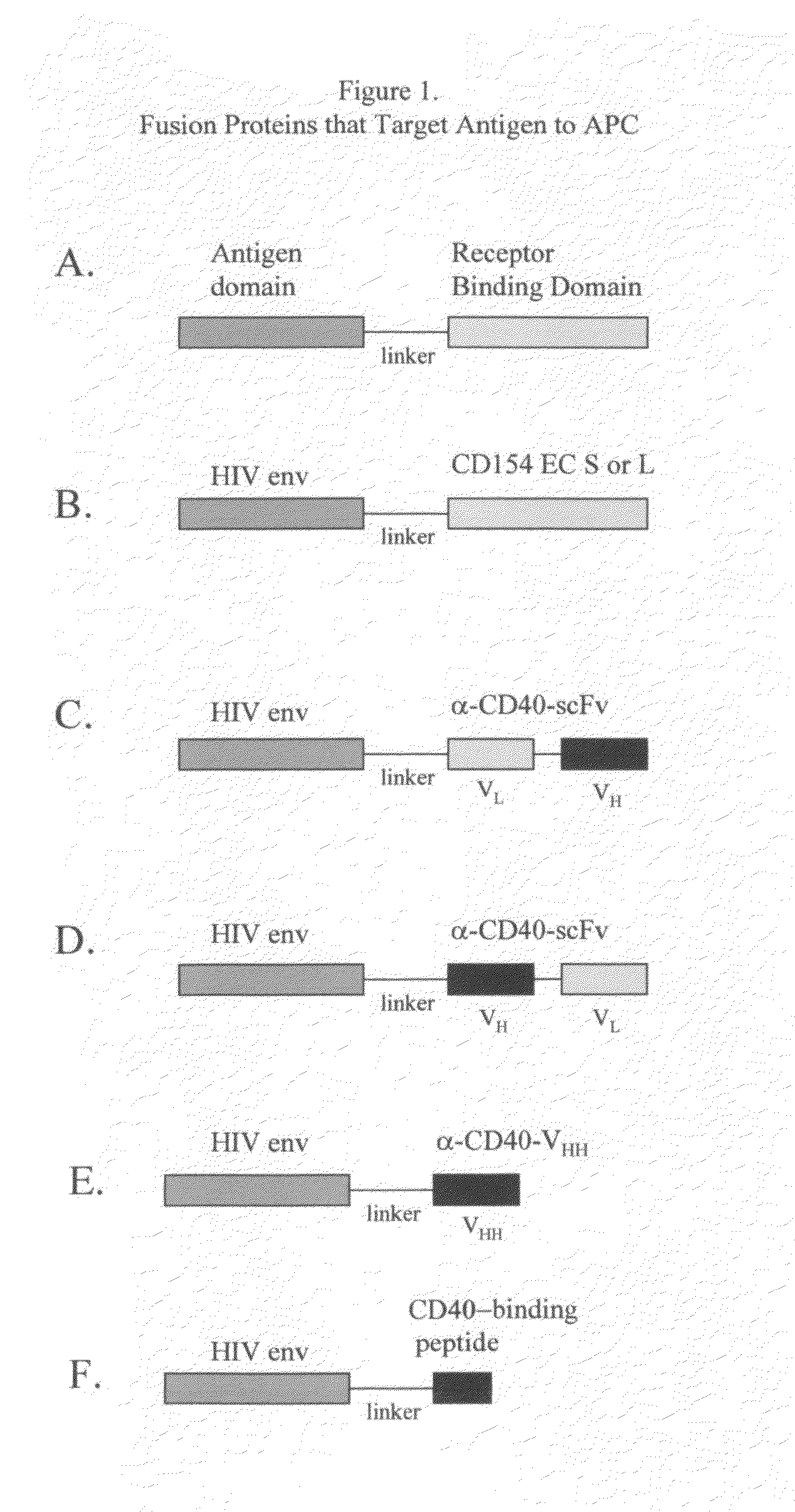

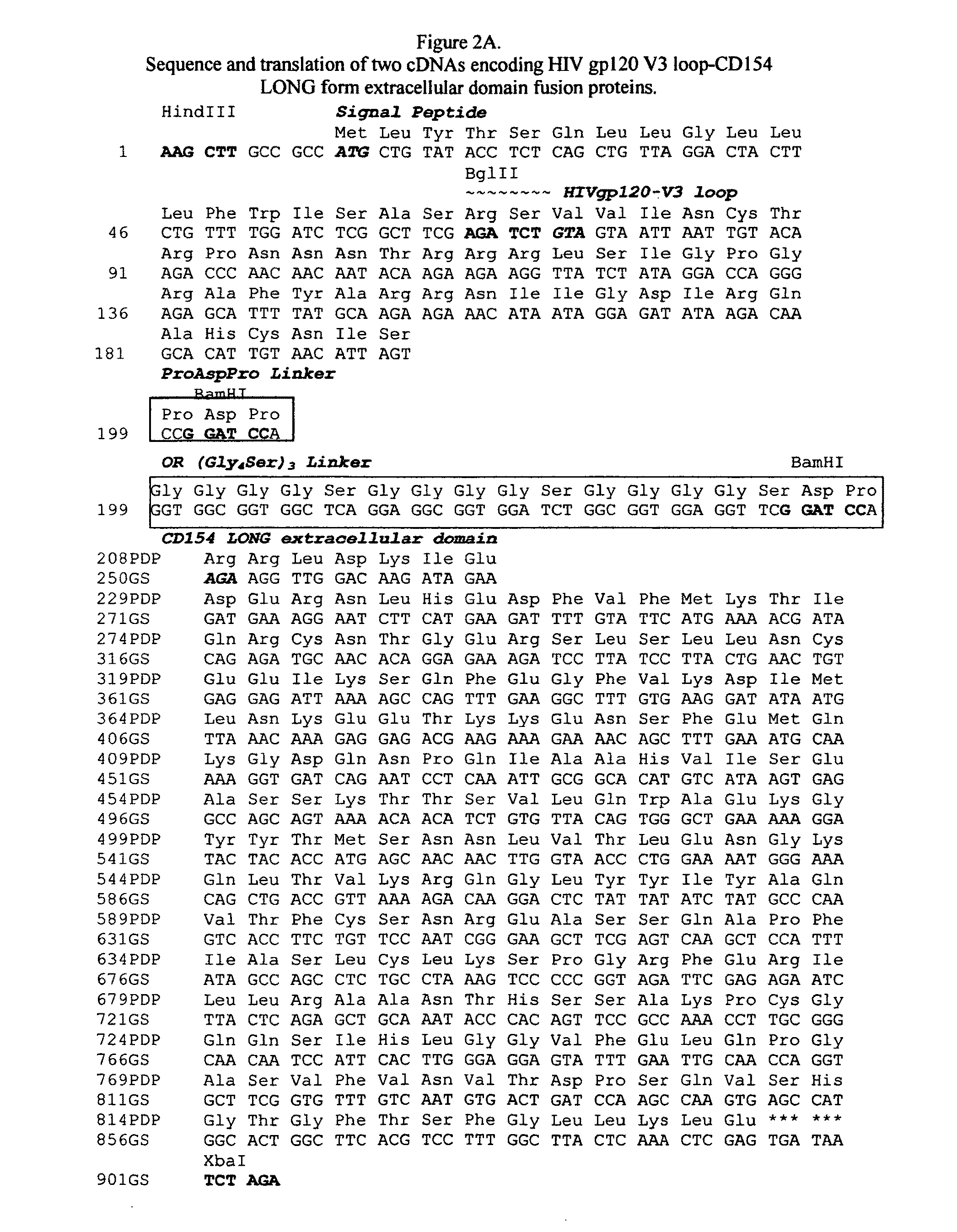

Vaccines that target one or more antigens to a cell surface receptor improve the antigen-specific humoral and cellular immune response. Antigen(s) linked to a domain that binds to a cell surface receptor are internalized, carrying antigen(s) into an intracellular compartment where the antigen(s) are digested into peptides and loaded onto MHC molecules. T cells specific for the peptide antigens are activated, leading to an enhanced immune response. The vaccine may comprise antigen(s) linked to a domain that binds at least one receptor or a DNA plasmid encoding antigen(s) linked to a domain that binds at least one receptor. A preferred embodiment of the invention targets HIV-1 env antigen to the CD40 receptor, resulting in delivery of antigen to CD40 positive cells, and selective activation of the CD40 receptor on cells presenting HIV-1 env antigens to T cells.

Owner:HAYDEN LEDBETTER MARTHA S +1

DNA vaccines encoding antigen linked to a domain that binds CD40

InactiveUS20070025982A1Improve abilitiesEasy to demonstrateAntibody mimetics/scaffoldsVirus peptidesPeptide antigenEukaryotic plasmids

Vaccines that target one or more antigens to a cell surface receptor improve the antigen-specific humoral and cellular immune response. Antigen(s) linked to a domain that binds to a cell surface receptor are internalized, carrying antigen(s) into an intracellular compartment where the antigen(s) are digested into peptides and loaded onto MHC molecules. T cells specific for the peptide antigens are activated, leading to an enhanced immune response. The vaccine may comprise antigen(s) linked to a domain that binds at least one receptor or a DNA plasmid encoding antigen(s) linked to a domain that binds at least one receptor. A preferred embodiment of the invention targets HIV-1 env antigen to the CD40 receptor, resulting in delivery of antigen to CD40 positive cells, and selective activation of the CD40 receptor on cells presenting HIV-1 env antigens to T cells.

Owner:LEDBETTER JEFFREY A +1

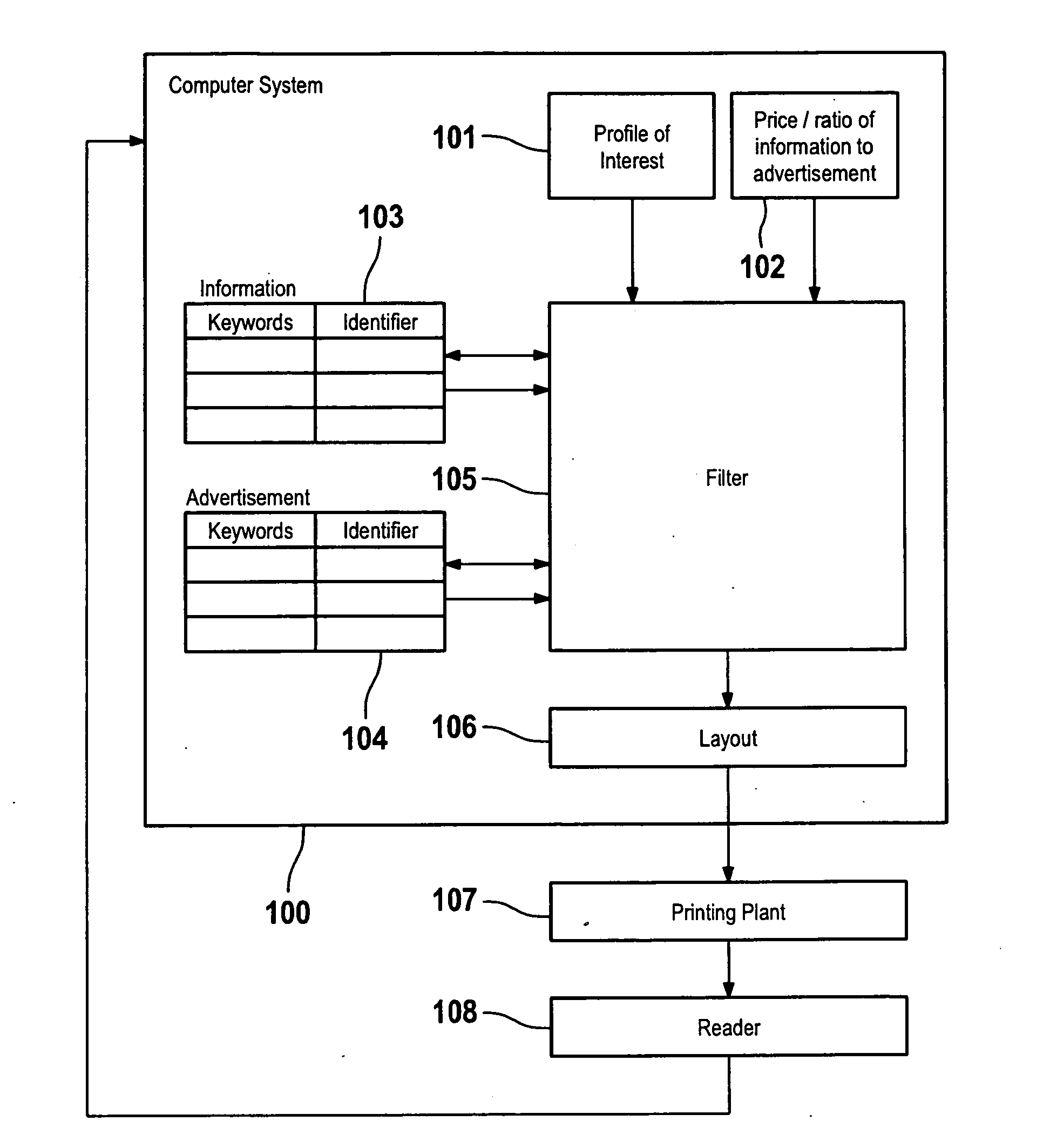

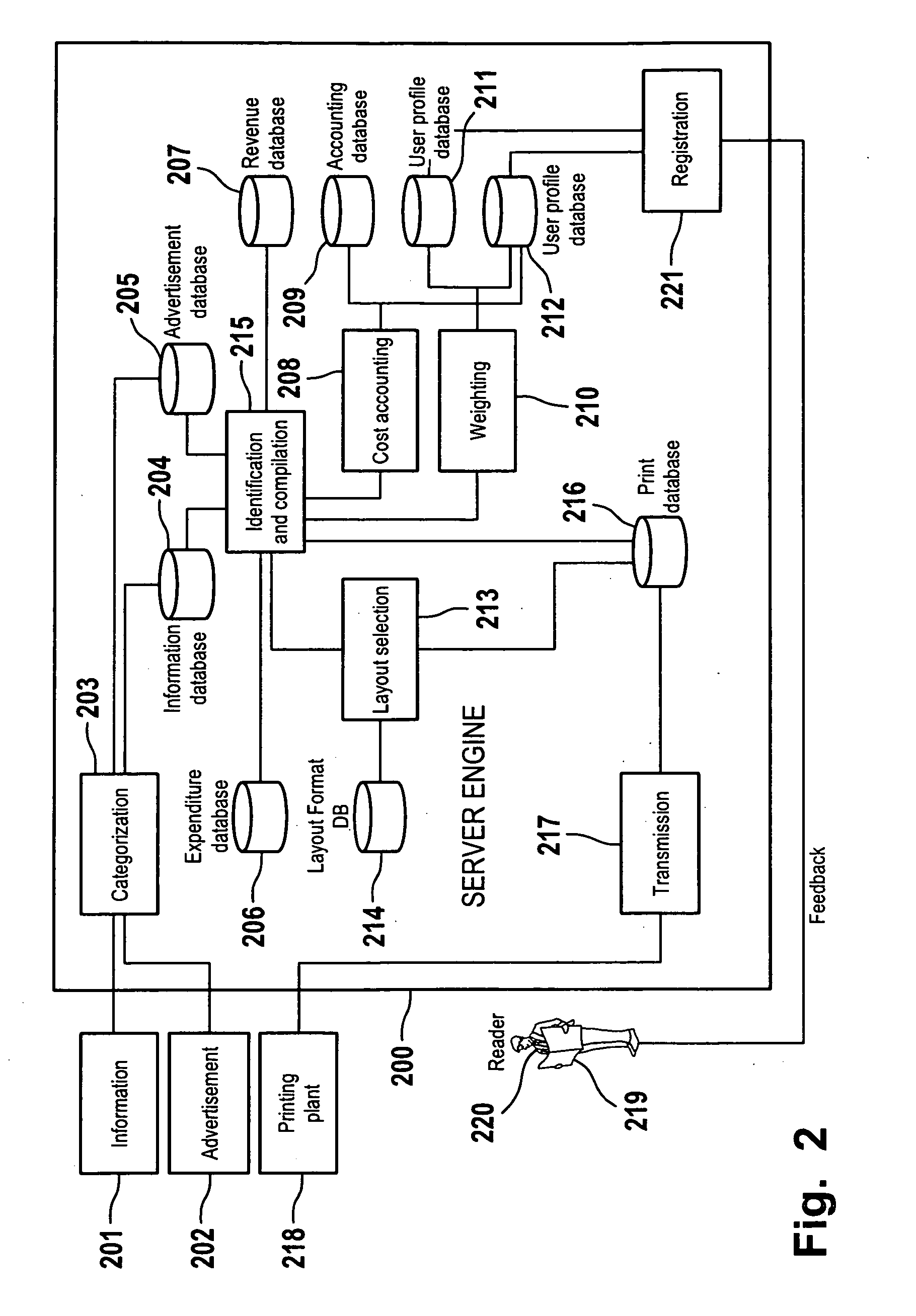

System and process for the production of a customer individualized print product

ActiveUS20050021404A1Avoid wastingLong-lasting protectionMarket predictionsSpecial data processing applicationsPaymentPrint media

A system and method for production of a printed product individualized for the customer, which offers the customer a selection of information content, depending on the variable payment (price) and the profile of interests thereof. Based on the price decision of the customer, a customer-specific relationship of optionally edited information content to customer-specific advertisement is generated. A dynamic matching of the profile of interests is carried out by feedback. The form of the printed product is determined by the selection of the information and the advertisements and the combination thereof according to the customer-specific relationship and profile of interests by means of an inventive layout. The printed product produced is suitable for traditional processing by print media, customer-specific in price, quality and quantity, achieves the interests of the advertisers with targeted advertising and the interests of the producers of the printed product with regard to achievable margins by providing a highly-attractive customer-specific product.

Owner:SCHODER DETLEF +1

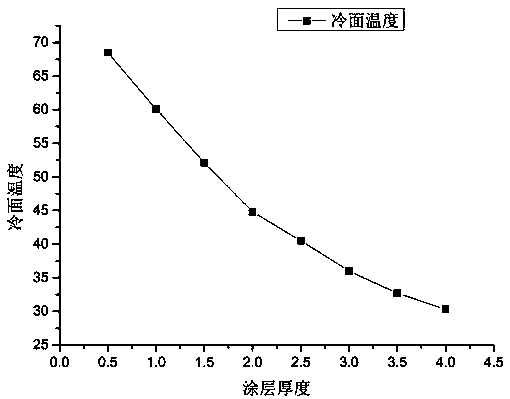

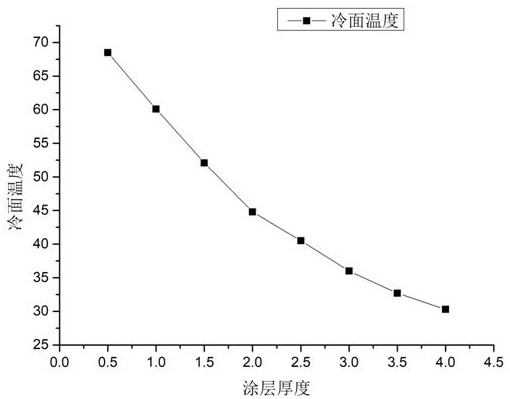

Aerogel waterproof and heat-insulating coating as well as preparation method thereof

ActiveCN108997911AImprove insulation performanceImprove comfortFireproof paintsPolyurea/polyurethane coatingsHeat conductingMetallic materials

The invention discloses an aerogel waterproof and heat-insulating coating as well as a preparation method thereof. The coating with fireproof and heat-insulating properties is prepared by adding aerogel powder and ceramic powder which are subjected to hydrophilic modification as well as adding aids and fillers according to different formula proportions, and the coating is prepared by utilizing theproperty characteristic of a three-dimensional network structure of the aerogel, so that the defect that the existing coating is only fireproof and is not heat-insulating is solved and the coating has the heat-insulating characteristic. Meanwhile, nanometer ceramic powder is added in the coating, the nanometer ceramic powder in the coating is heated to be ceramic, one expanded ceramic film is formed on the surface of a base material, one air layer is arranged between the film and the base material, contact between flame and the surface of a vehicle metal material product is isolated, and heatis prevented from being transmitted to the surface of the metal by depending on the low heat-conducting coefficient characteristic of the aerogel in the coating. Through fireproof and heat-insulatingsynergistic effect, good barrier effect on heat and flame is guaranteed to be achieved no matter normal use of the metal part in the vehicle or occurrence of extreme fire accidents, and the fireproofproperty of the coating is enhanced.

Owner:河南爱彼爱和新材料有限公司

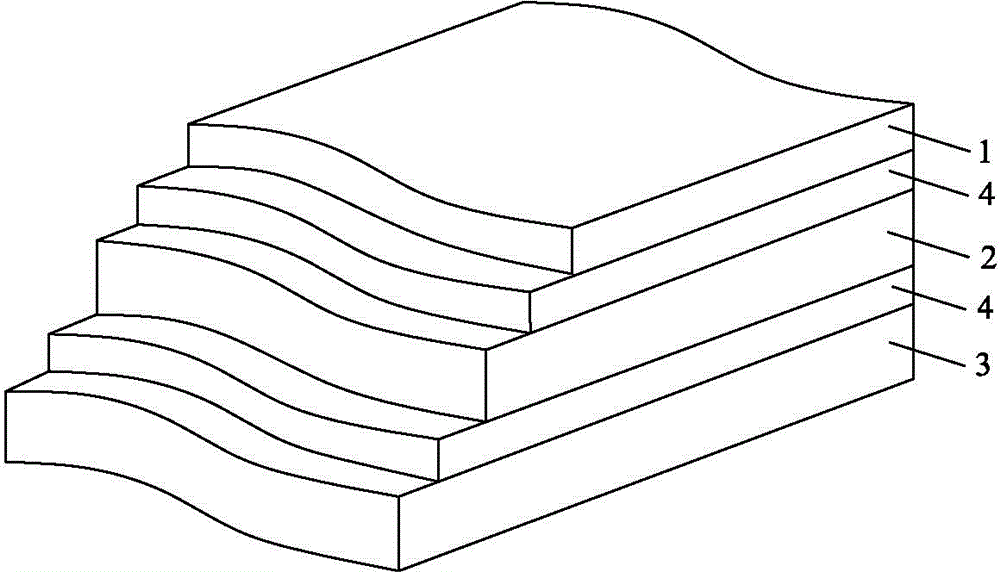

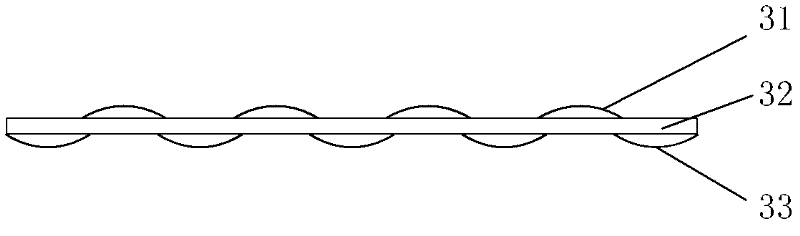

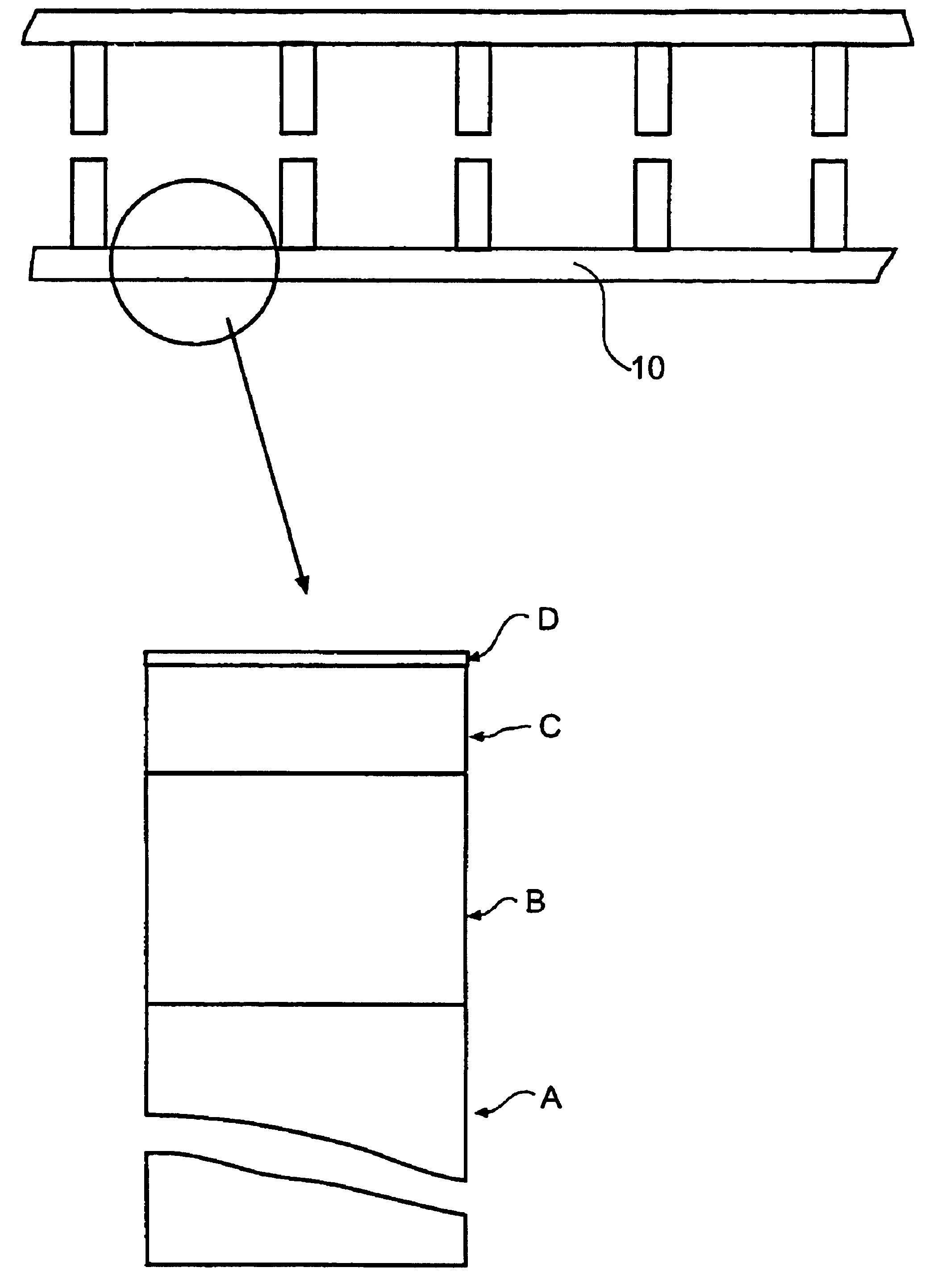

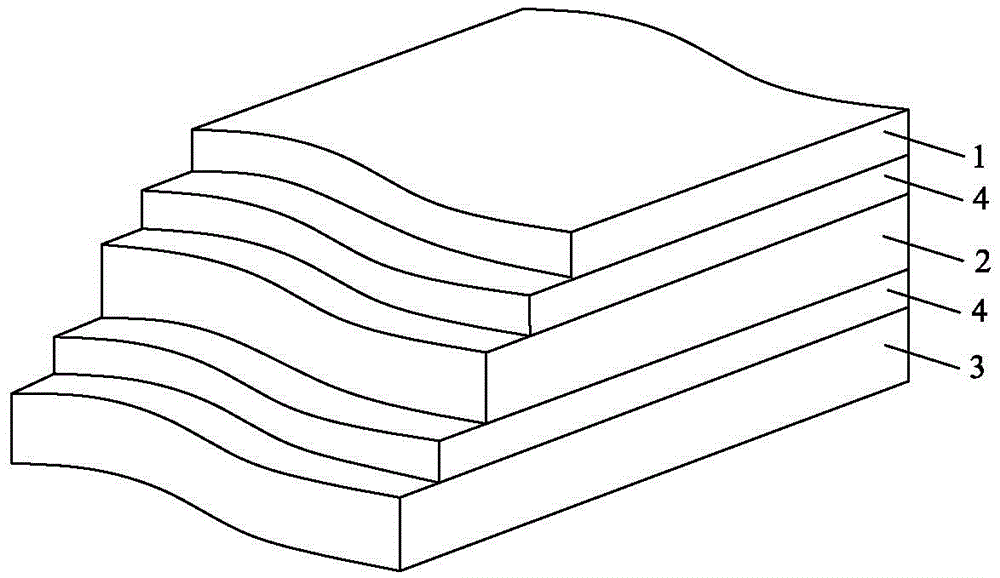

Solar photovoltaic battery assembly transparent backboard composite film and preparation method thereof

ActiveCN105428445AGood weather resistanceImprove aging resistanceFinal product manufactureSynthetic resin layered productsPolyesterWeather resistance

The invention relates to the technical field of a composite film, and particularly to a solar photovoltaic battery assembly transparent backboard composite film and a preparation method thereof. The solar photovoltaic battery assembly transparent backboard composite film comprises a first weather-resistant layer, a second weather-resistant layer and a substrate layer, wherein the first weather-resistant layer, the second weather-resistant layer and the substrate layer are successively arranged from top to bottom. The first weather-resistant layer is a transparent weather-resistant polycarbonate (PC) film and has a thickness of 25-100 [mu]m. The second weather-resistant layer is a transparent weather-resistant polyester (PET) film and has a thickness of 150-300 [mu]m. The substrate layer is a transparent linear low-density polyethylene (LLDPE) film and has a thickness of 50-150 [mu]m. According to the solar photovoltaic battery assembly transparent backboard composite film, a traditional poly(vinylidene fluoride) (PVDF) film is replaced by the transparent weather-resistant PC film, and weather resistance and light transmittance of the back board on which the solar photovoltaic battery assembly transparent backboard composite film is applied. Not only is cost reduced, but also environment pollution caused by a fluoride film is greatly reduced. Furthermore the solar photovoltaic battery assembly transparent backboard composite film has excellent binding property with a polyethylene vinylacetate (EVA) film.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

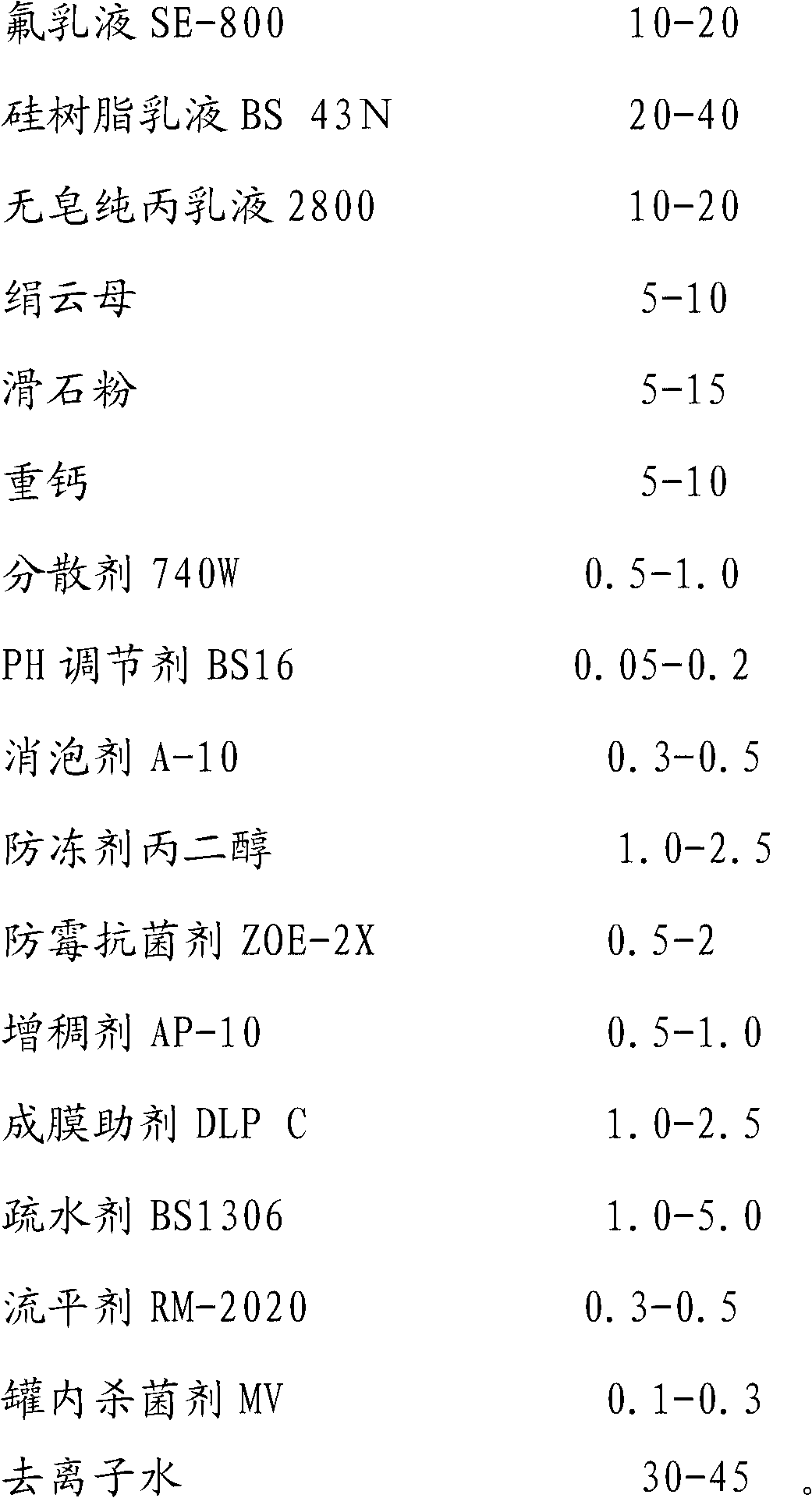

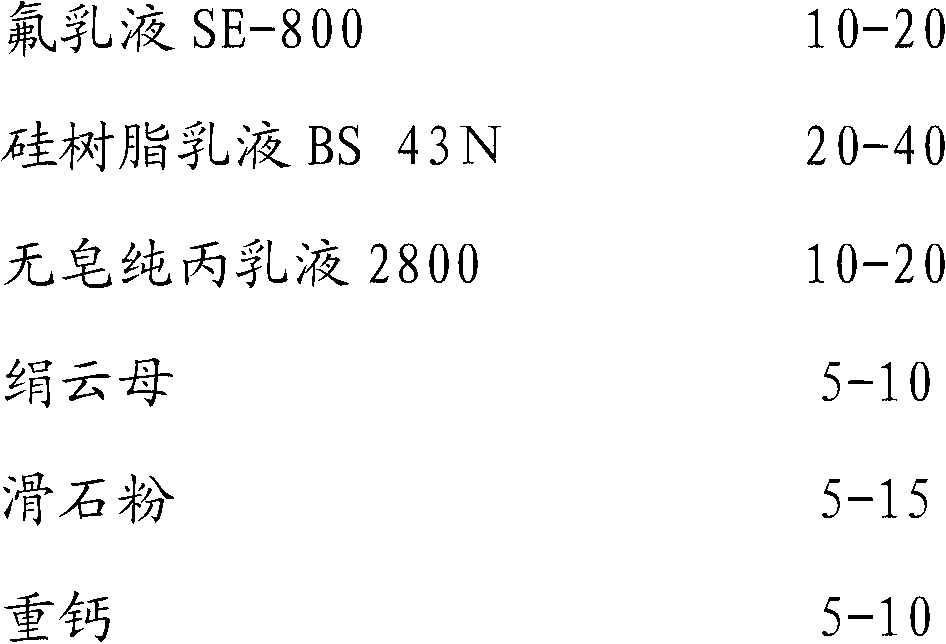

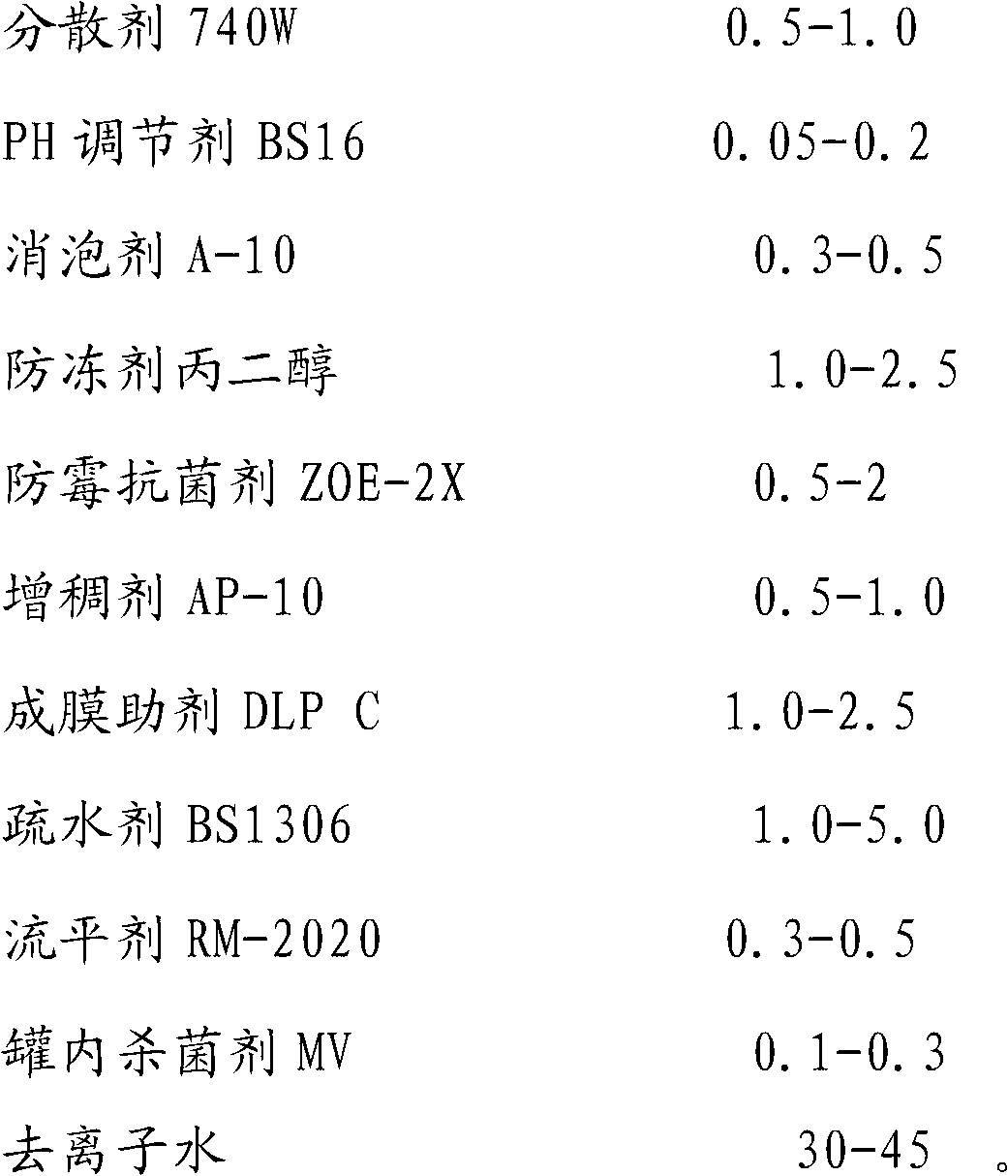

Waterborne fluorine silicone resin modified acrylic acid concrete protective coating

ActiveCN102993946AGood weather resistanceImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesDefoaming AgentsMaterials science

The invention relates to a waterborne fluorine silicone resin modified acrylic acid concrete protective coating. The concrete protective coating comprises 10-20 parts of a fluorine emulsion, 20-40 parts of a silicone resin emulsion, 10-20 parts of a soap-free pure acrylic emulsion, 5-10 parts of sericit, 5-15 parts of talcum powder, 5-1 parts of ground calcium carbonate, 0.5-1.0 part of a dispersing agent, 0.05-0.2 part of a pHregulator, 0.3-0.5 part of a defoaming agent, 1.0-2.5 parts of propylene glycol, 0.5-2 parts of an antifungus and anti-mildew agent, 0.5-1.0 part of a thickening agent, 1.0-2.5 parts of a film-forming agent, 1.0-5.0 parts of a water repellent agent, 0.3-0.5 part of a flatting agent, 0.1-0.3 part of a tank bactericide and 30-45 parts of deionized water. The waterborne fluorine silicone resin modified acrylic acid concrete protective coating has the beneficial effects of weatherability, alkali resistance, washability, air permeability and mildew resistance. The concrete protective coating has a long-term protective effect for the concrete.

Owner:天津灯塔涂料工业发展有限公司

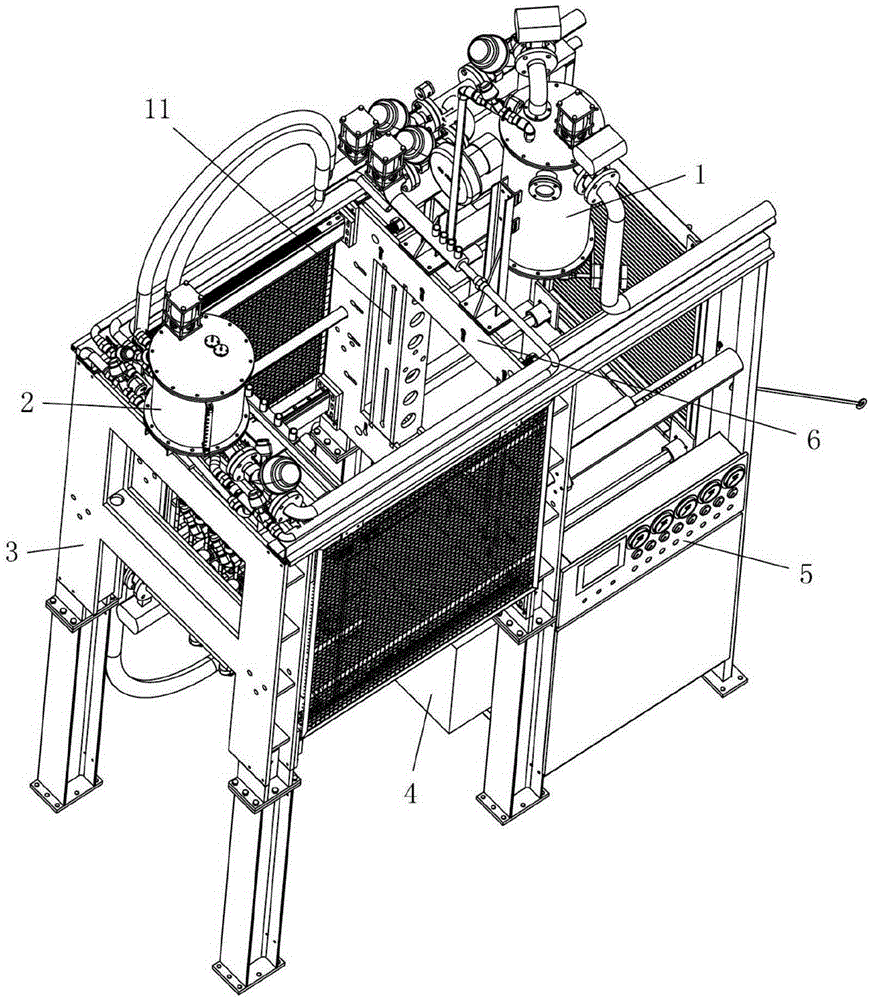

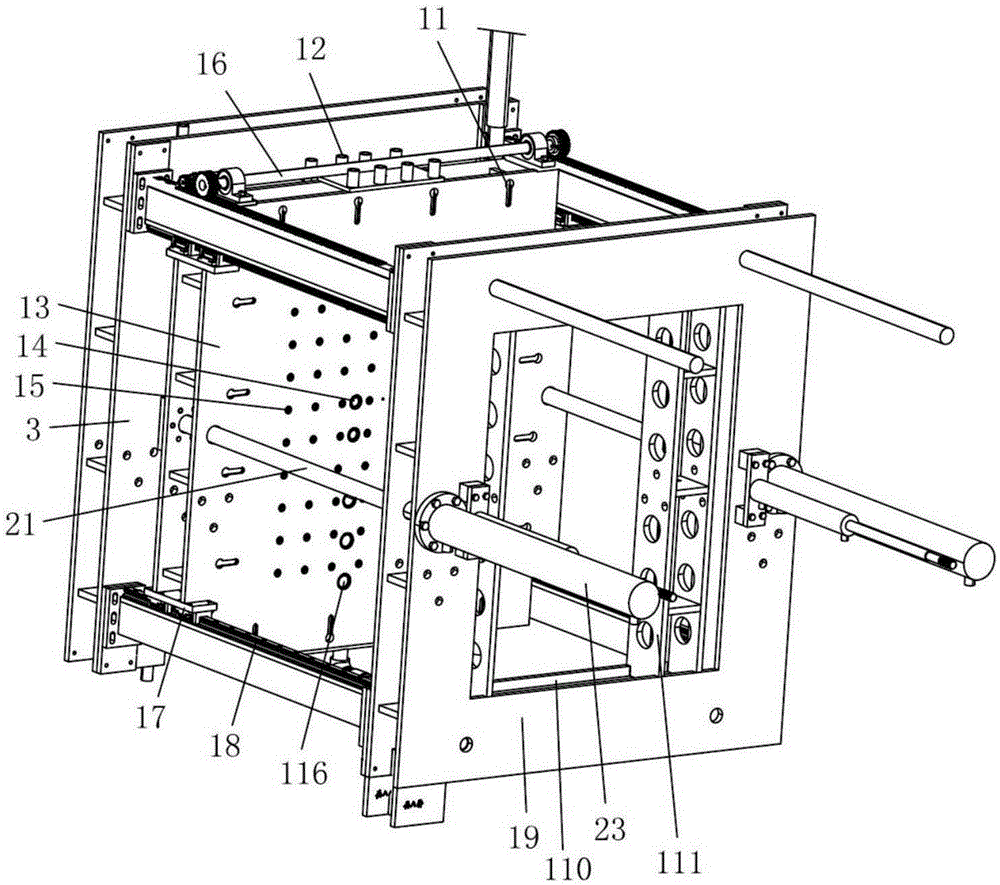

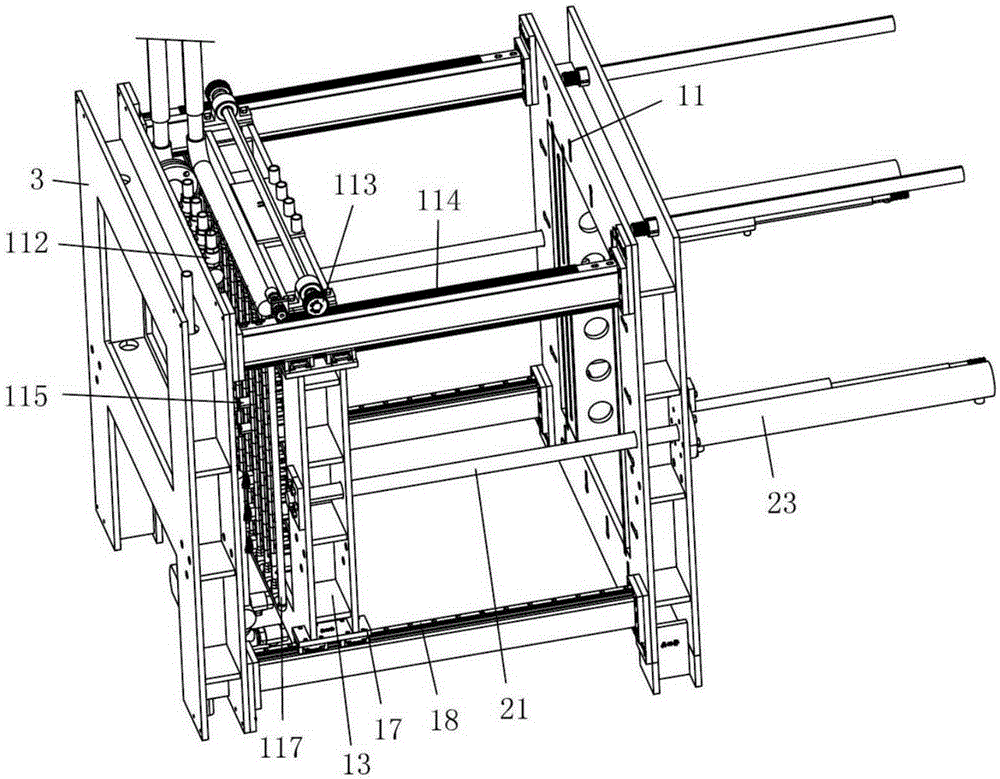

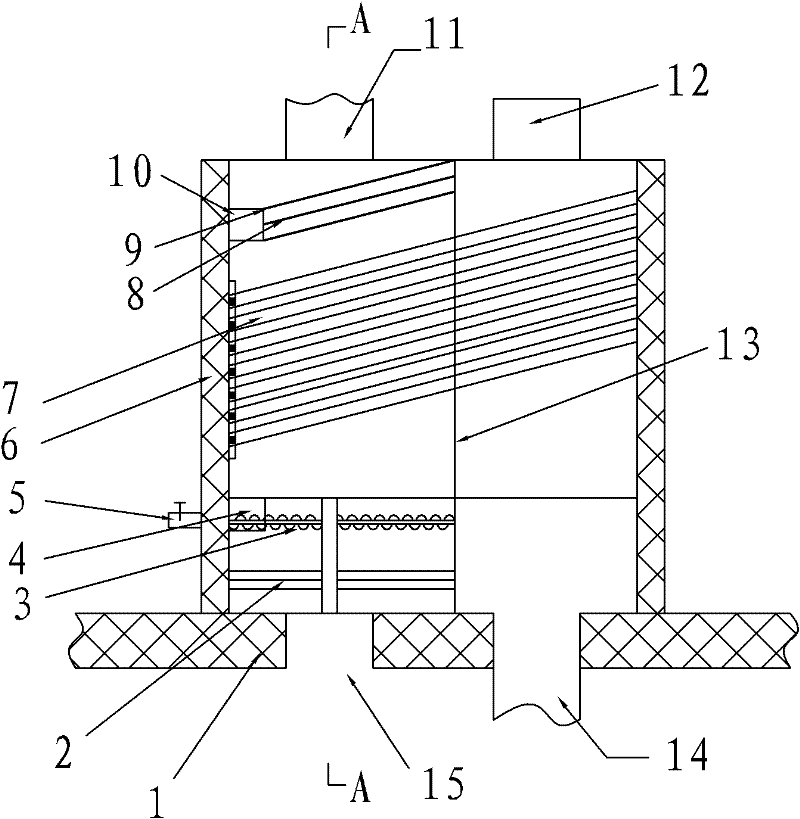

Novel foam forming machine and foam forming method

The invention proposes a novel foam forming machine and a foam forming method. The machine comprises a frame; the frame is provided with a feeding system, a mold mounting mechanism, a steam heating system, a cooling water system, a demolding mechanism and an electric automatic control system; the mold mounting mechanism includes a fixed template and a movable template; the movable template and the fixed template are arranged on the same one horizontal line; an oil cylinder drives the movable template to move left and right on the frame to form an opening / closing structure with the fixed template; the movable template and the fixed template are respectively communicated with the steam heating system and the cooling water system; and the demolding mechanism is behind the fixed template. The foam forming machine can adapt to molds with different sizes, and the movable template is connected with a composite material plate and a stainless steel plate layer, so that the equipment use performance at high temperature is improved; and the foam forming machine has the advantages of low mold investment, generality of semi-automatic and full-automatic mechanical molds, convenience to change the molds, high production flexibility and low manual dependence.

Owner:浙江武义速达包装材料有限公司

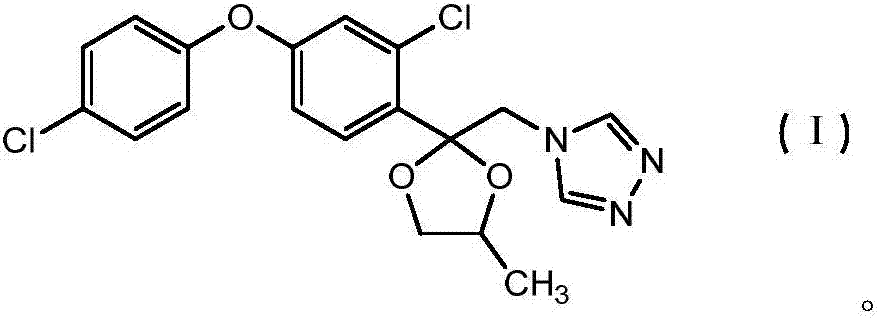

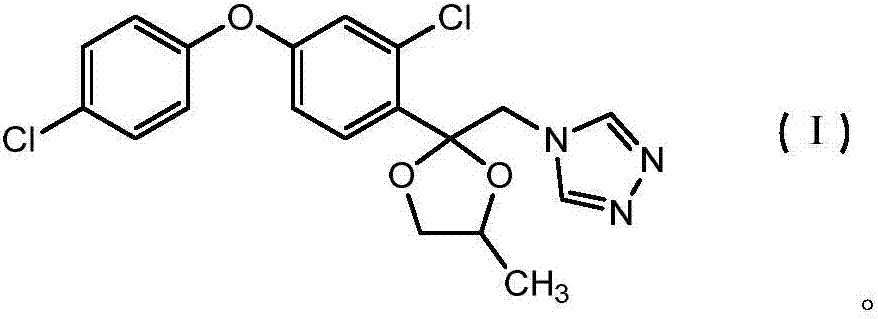

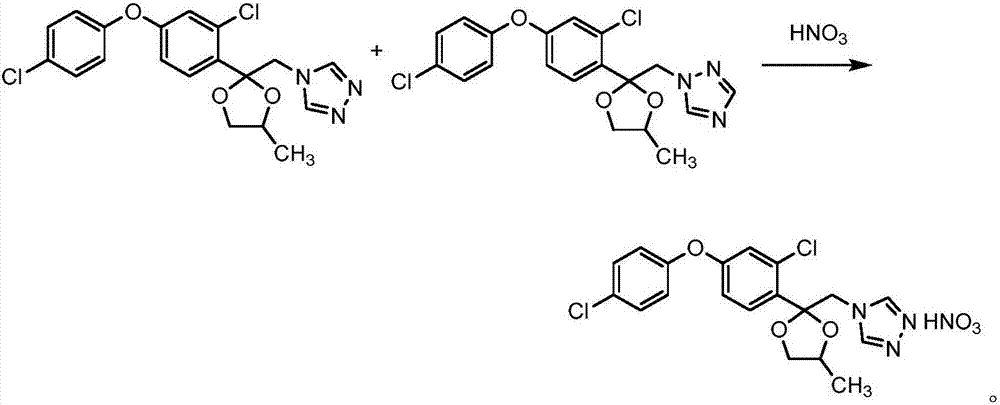

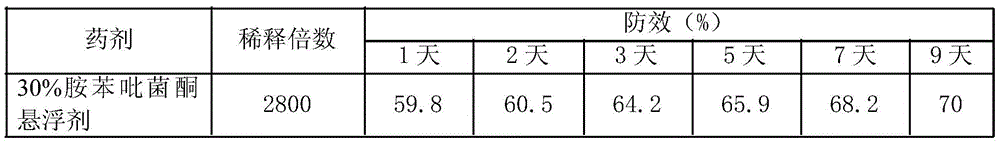

Application of tetrahydrobenzene difenoconazole to preparation of agricultural fungicide or fungicide composition and preparation method of tetrahydrobenzene difenoconazole

InactiveCN107306965AImprove biological activityLong-lasting protectionBiocideOrganic chemistryFungicideStructural formula

The invention discloses an application of tetrahydrobenzene difenoconazole to preparation of an agricultural fungicide or fungicide composition and a preparation method of the tetrahydrobenzene difenoconazole, and further discloses an application of a 4-((-(2-chlorine-4-(4-chlorophenoxy) phenyl)-4-methyl-1, 3-dioxolane-2-base) methyl)-4H-1, 2, 4-triazole (tetrahydrobenzene) compound to agricultural fungicide. The structural formula of the compound is as shown in the specification. According to the application, 35-40% of tailings serving as hazardous organic waste solids in the production process of agricultural fungicide difenoconazole are changed into useful pesticides, emission of the hazardous organic waste solids is greatly decreased, and environmental protection pressure of production enterprises is relieved. According to the preparation method, the yield of the difenoconazole can be increased, and cost is reduced.

Owner:JIANGSU GENGYUN CHEM CO LTD

Dispersion type waterborne epoxy zinc-alkene rusty, anti-rust and heavy anti-corrosion primer

ActiveCN108531033AEvenly dispersedFull and effective integrationAnti-corrosive paintsEpoxy resin coatingsEpoxyWater dispersible

The invention discloses a dispersion type waterborne epoxy zinc-alkene rusty, anti-rust and heavy anti-corrosion primer. The dispersion type waterborne epoxy zinc-alkene rusty, anti-rust and heavy anti-corrosion primer is a waterborne heavy anti-corrosion primer composed of three components, wherein a component A is composed of waterborne epoxy dispersion, dispersant, defoamer, zinc oxide, rust converter, water dispersible graphene, graphene-specialized dispersant, flash rust inhibiting auxiliaries, waterborne rheological auxiliaries and water; a component B is zinc powder; a component C is composed of waterborne epoxy curing agent and water. The dispersion type waterborne epoxy zinc-alkene rusty, anti-rust and heavy anti-corrosion primer has no volatilization of organic solvent, and by taking water as dispersion medium, can convert rust on steel into stable substance, give play to anti-corrosion capability of the graphene, the zinc oxide and epoxy resin and provide continuous negativeelectrode protecting ability for the surface of base materials.

Owner:湖北铁神新材料有限公司

Corrosion-resistant coating for metals and preparation method for corrosion-resistant coating

InactiveCN103509430AIncrease usageStrong adhesionAnti-corrosive paintsPolyether coatingsEpoxyEmulsion

The invention discloses a corrosion-resistant coating for metals, which comprises the following ingredients in parts by weight: 55-65 parts of an epoxy resin emulsion, 35-45 parts of alloy powder, 20-25 parts of chlorinated polyether resin, 10-20 parts of fluororesin, 5-10 parts of cosolvents, and 20-40 parts of water. The corrosion-resistant coating has the benefits as folllows: according to the corrosion-resistant coating for the metals and the preparation method for the corrosion-resistant coating, the coating has strong adhesion force, long continuous protective time and a good protecting effect on corrosion such as acid / alkali liquid corrosion, electrical erosion and the like in the conventional production; the experiments in factories show that the utilization rate of the metals coated with the corrosion-resistant coating is increased by 30%.

Owner:唐山威克涂料化工有限公司

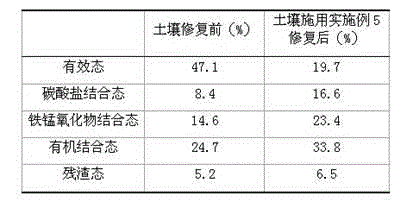

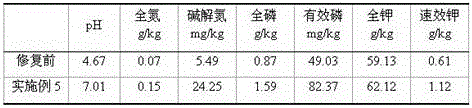

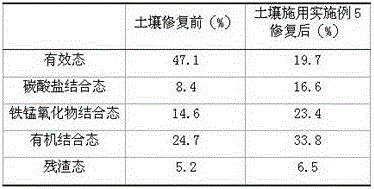

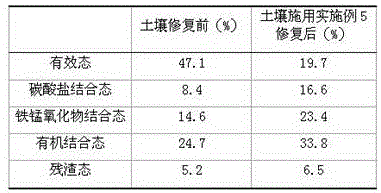

Soil restoration agent with heavy metal pollution treatment function and fertilizing function and preparation process of soil restoration agent

InactiveCN104311335AReduced mobilityReduce adsorptionBiocideAgriculture tools and machinesMicrobial agentSoil heavy metals

The invention discloses a soil restoration agent with a heavy metal pollution treatment function and a fertilizing function and a preparation process of the soil restoration agent. The soil restoration agent is mainly prepared from the following raw materials in parts by weight: 260 to 310 parts of organic fertilizer, 25 to 31 parts of microbial agent, 0.03 to 0.07 part of difenoconazole, 0.05 to 0.1 part of pyrethrum, 0.03 to 0.09 part of rotenone, 0.04 to 0.08 part of chlorothalonil and 0.02 to 0.06 part of lactobacillus plantarum. The organic fertilizer is used as a main raw material, the microbial agent, insecticidal and sterilized vegetable drug and chemicals capable of alleviating the harm of soil heavy metal are added, so that not only can the fertilizer effect of the soil be improved, but also the soil restoration agent can enter the soil deeply to improve the heavy metal pollution and prevent the disease and insect pests.

Owner:广州市正思环保科技有限公司

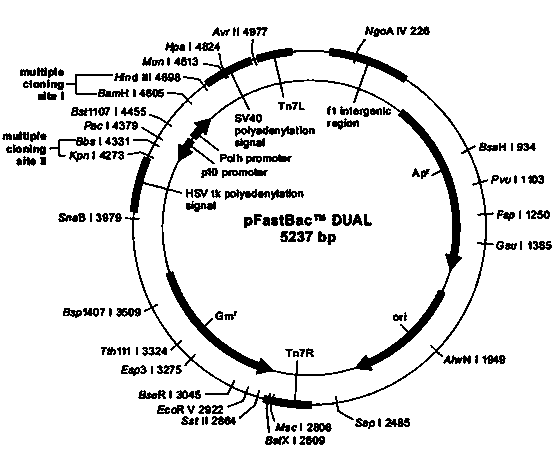

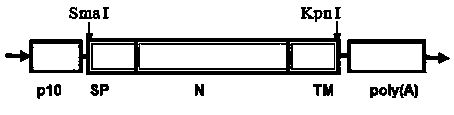

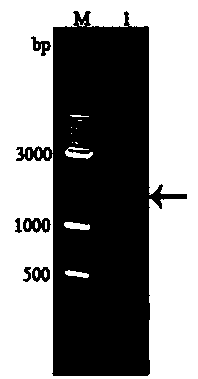

Recombinant protein containing SARS virus N antigen and baculovirus displaying N protein

ActiveCN104292338AHigh clinical application valueSuitable for mass productionGenetic material ingredientsAntiviralsSequence signalSurface display

The invention discloses a recombinant protein containing an SARS virus N antigen and a baculovirus displaying an N protein. The recombinant protein SP-N-TM is formed by connecting an N- end of the N protein of an SARS virus with a signal peptide SP of a baculovirus envelope protein GP64, and connecting a C- end with a transmembrane domain TM of the baculovirus envelope protein GP64. The recombinant baculovirus having the surface displaying the SARS antigen N protein is the recombinant baculovirus obtained by the steps of inserting a cording gene of the SP-N-TM into a donor plasmid, carrying out homologous recombination with a genome of a shuttle vector Bacmid through transposition to obtain a recombinant baculovirus genome, then transfecting a bombyx mori cell with the recombinant baculovirus genome, and packaging in the cell to obtain the recombinant baculovirus. The recombinant baculovirus allows an N protein gene of the SARS virus to be fused with a bombyx mori baculovirus envelope protein GP64 gene, realizes display of the N protein on the surface of a viral capsid, and has good immunogenicity and large application value.

Owner:特菲(天津)生物医药科技有限公司

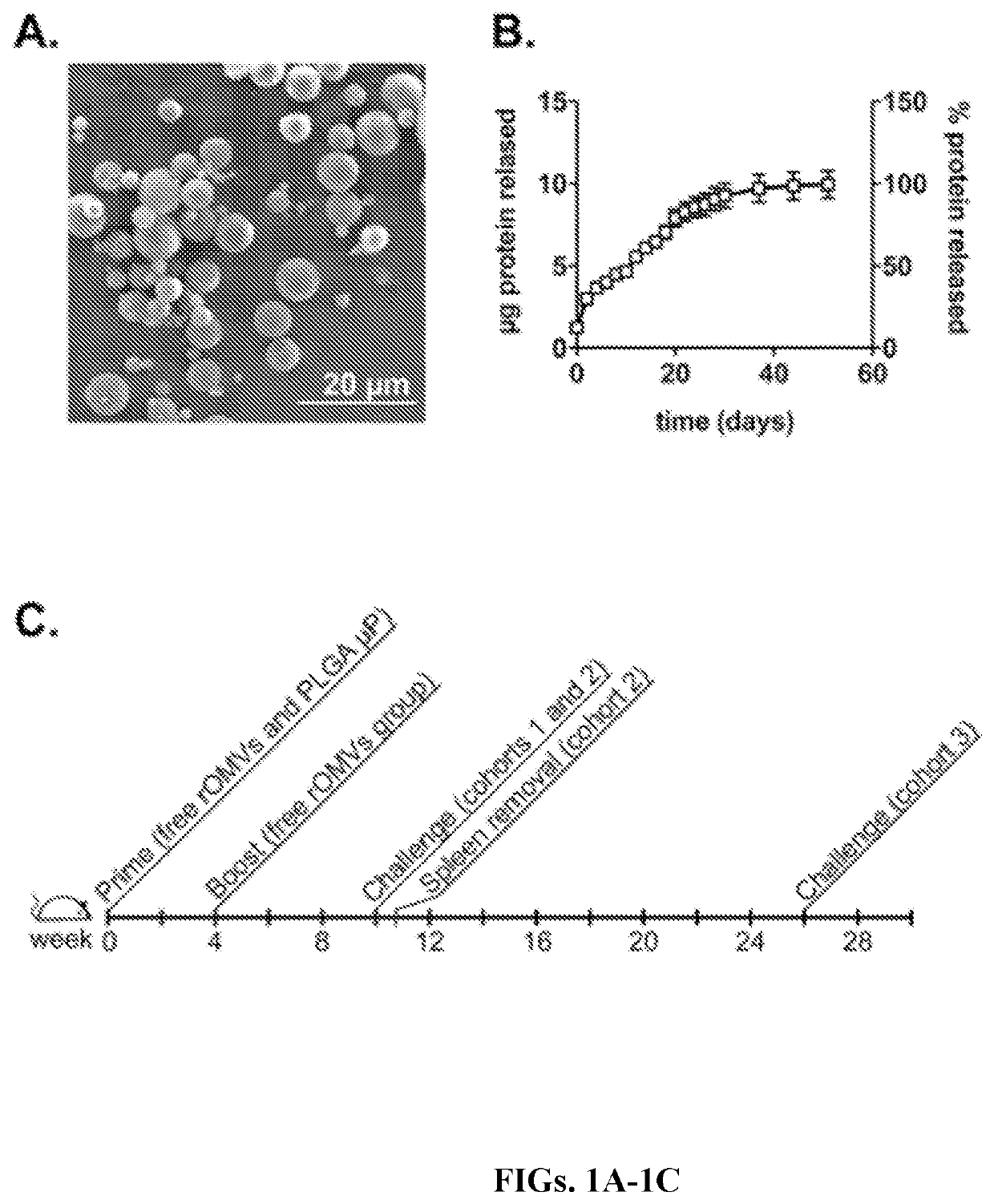

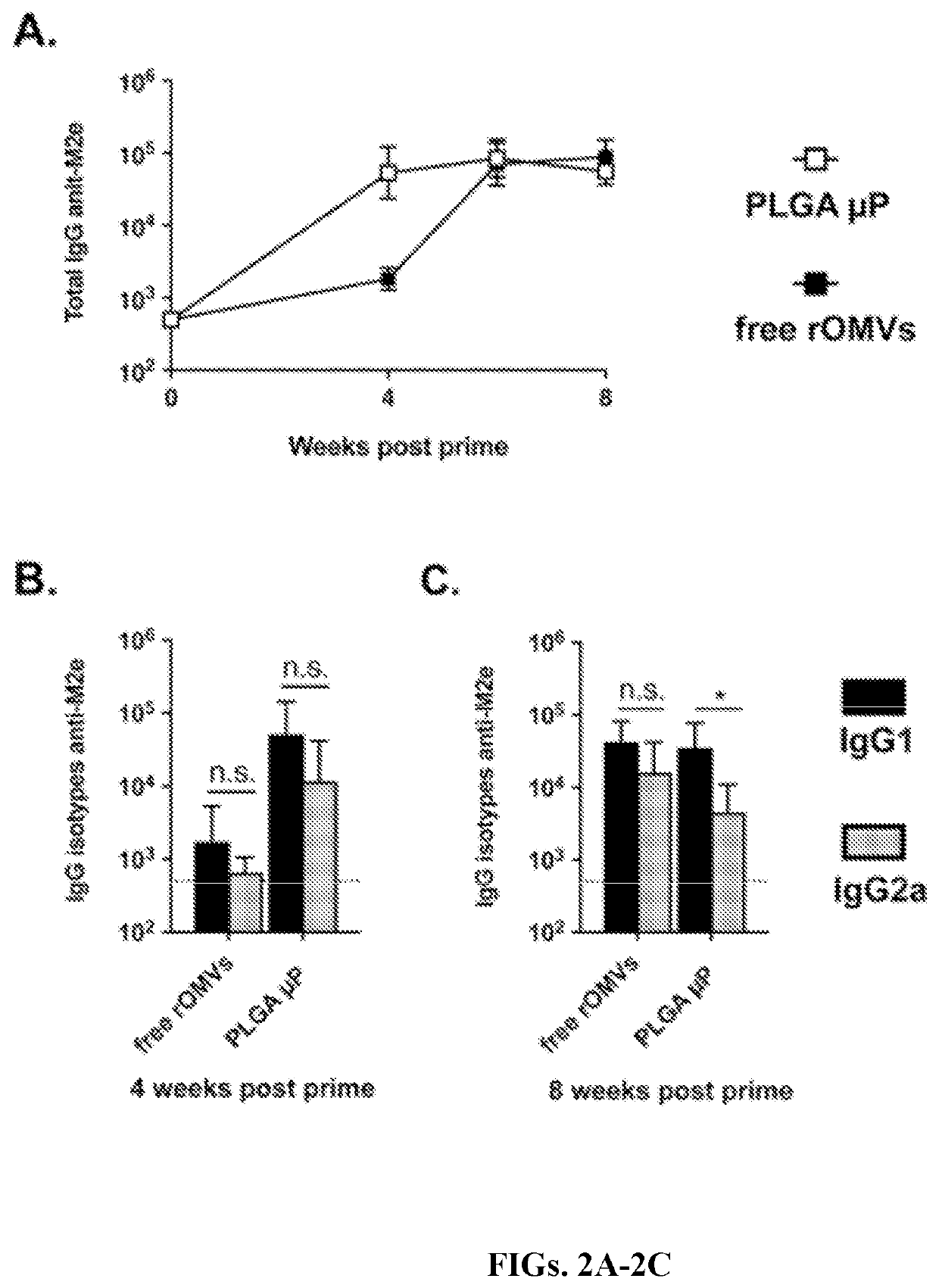

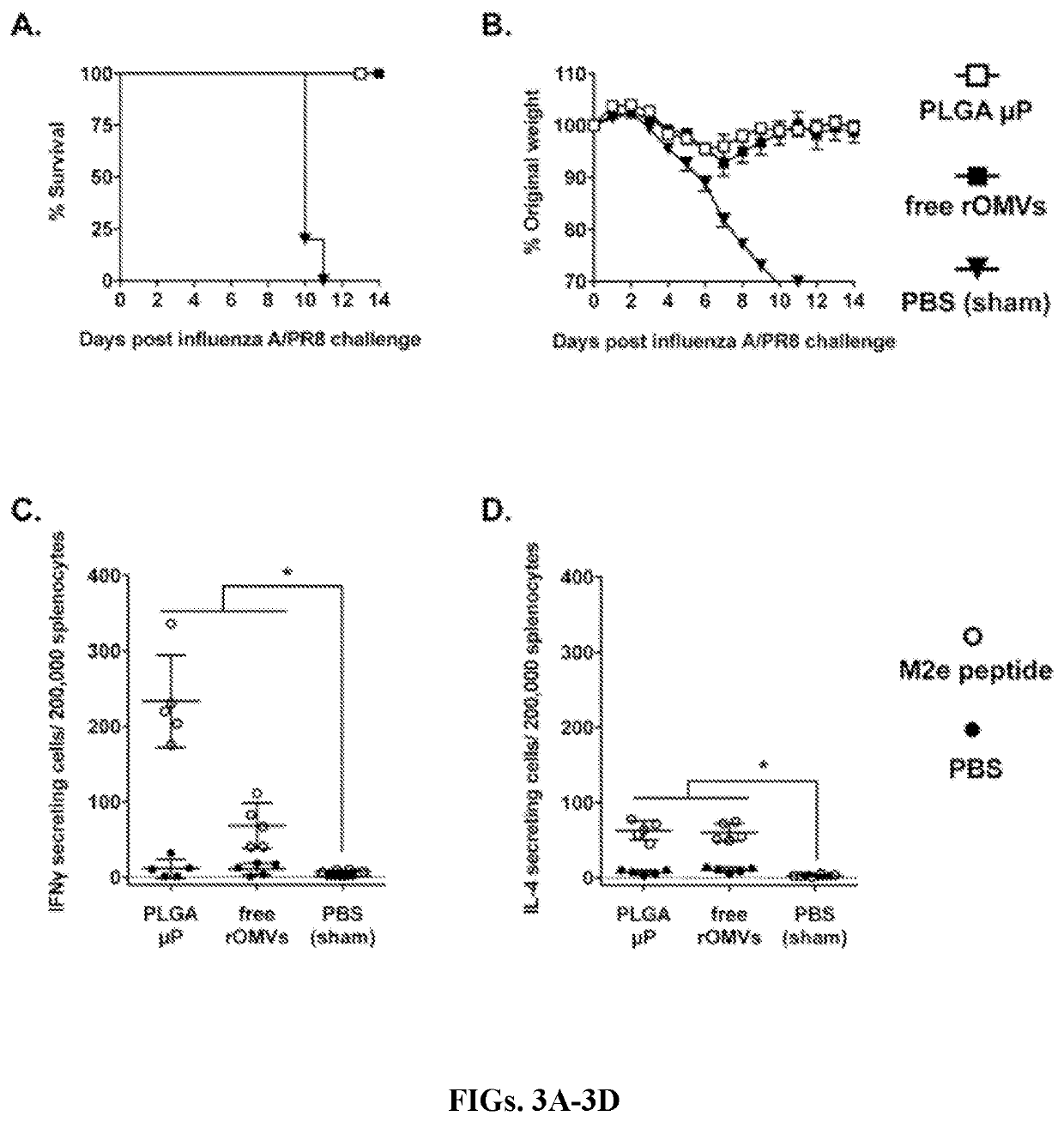

Formulation for protection through controlled release of microparticles containing recombinant outer membrane vesicles

InactiveUS20200054571A1Rapid titer productionLong-lasting protectionSsRNA viruses negative-sensePeptide/protein ingredientsControlled releaseImmunity response

The present invention relates to a microparticle. The microparticle includes one or more recombinant outer membrane vesicles, at least some of which display a fusion protein, where the fusion protein comprises at least a portion of a transport protein coupled to at least a portion of one or more antigenic proteins or peptides, and a polymeric coating over the one or more recombinant outer membrane vesicles. The present invention further relates to a method of eliciting an immune response in a mammal and a method of making encapsulated outer membrane vesicles displaying a fusion protein.

Owner:CORNELL UNIVERSITY

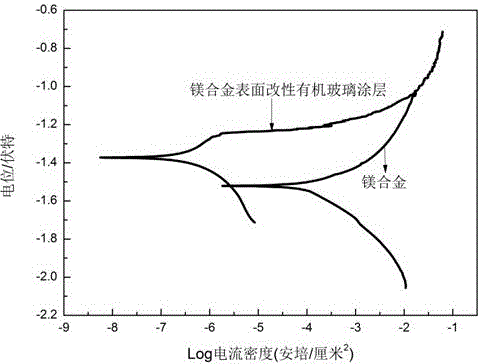

Method for preparing modified polymethyl methacrylate anticorrosive coating on magnesium alloy surface

InactiveCN105862014AImprove corrosion resistanceImprove bindingLiquid/solution decomposition chemical coatingWater bathsN dimethylformamide

The invention discloses a method for preparing a modified polymethyl methacrylate anticorrosive coating on a magnesium alloy surface. The method comprises the steps of treating the magnesium alloy surface; mixing a tetraethyl orthosilicate solution with a gamma-methacryloxy propyl trimethoxyl silane solution, adding a catalyst, and heating to form sol; adding an ethanol solution in which zirconium oxychloride is dissolved into the sol, continuously heating, dropwise adding a sodium hydroxide alkaline solution, and controlling the reaction rate to form SiO2-ZrO2 hybrid sol; adding methyl methacrylate in which AIBN is dissolved, N-N-dimethylformamide and a cerous nitrate aqueous solution, and heating in the water bath environment to prepare modified PMMA-SiO2-ZrO2 hybrid sol; and smearing the PMMA-SiO2-ZrO2 hybrid sol on the surface of a magnesium alloy surface base material through rotation, drying, keeping the temperature, and cooling to prepare the modified polymethyl methacrylate anticorrosive coating on the magnesium alloy surface. According to the method, different catalysts and chemical additives are added, so that the corrosion resistance of a sol gel film on the magnesium alloy surface is improved.

Owner:TAIYUAN UNIV OF TECH

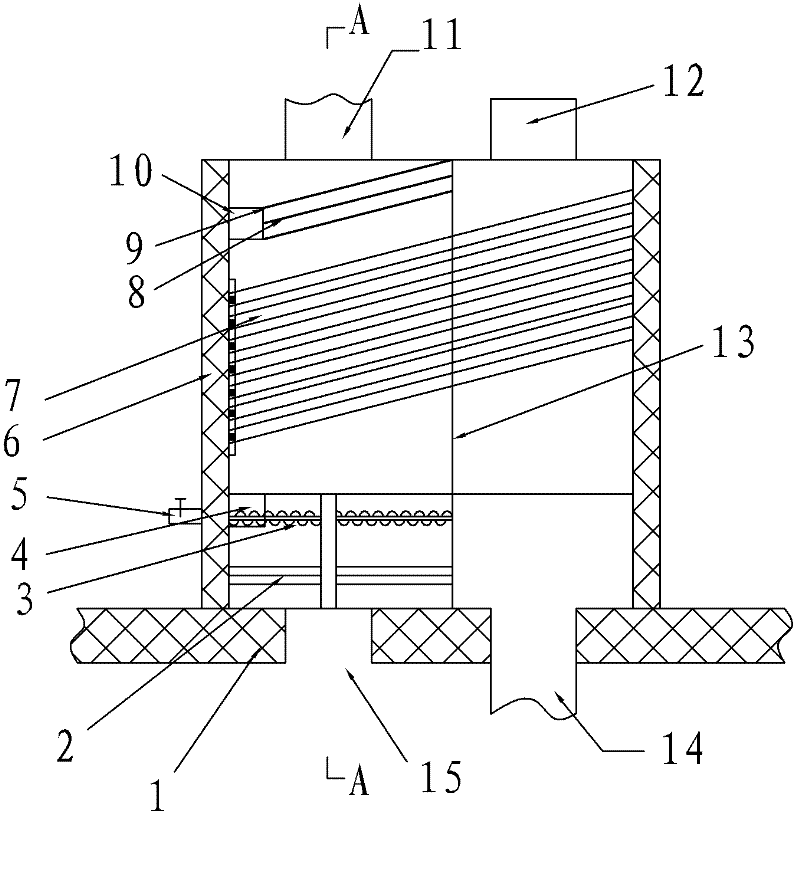

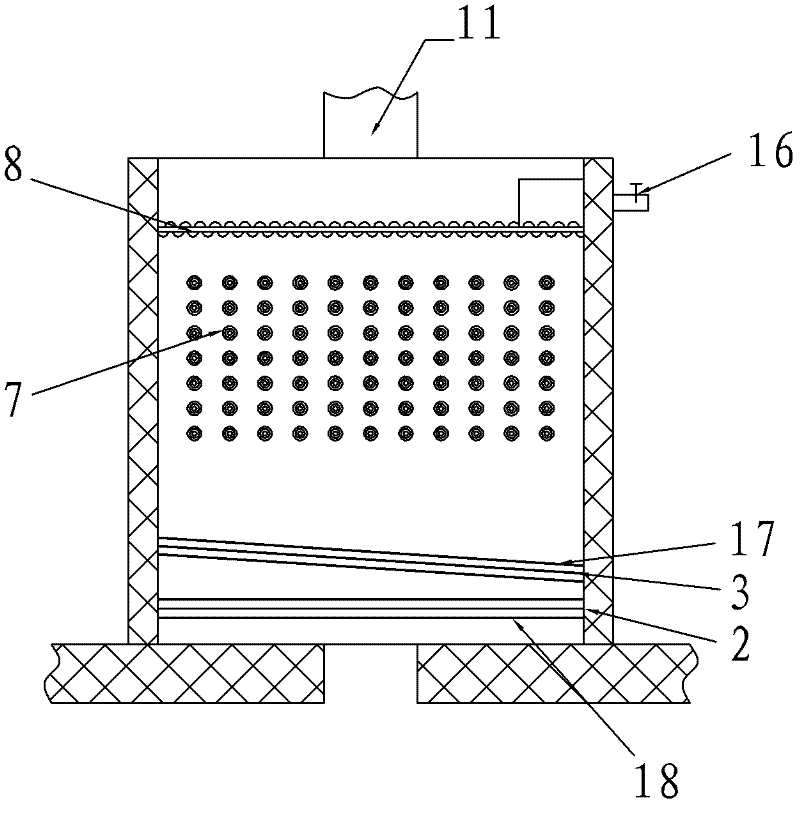

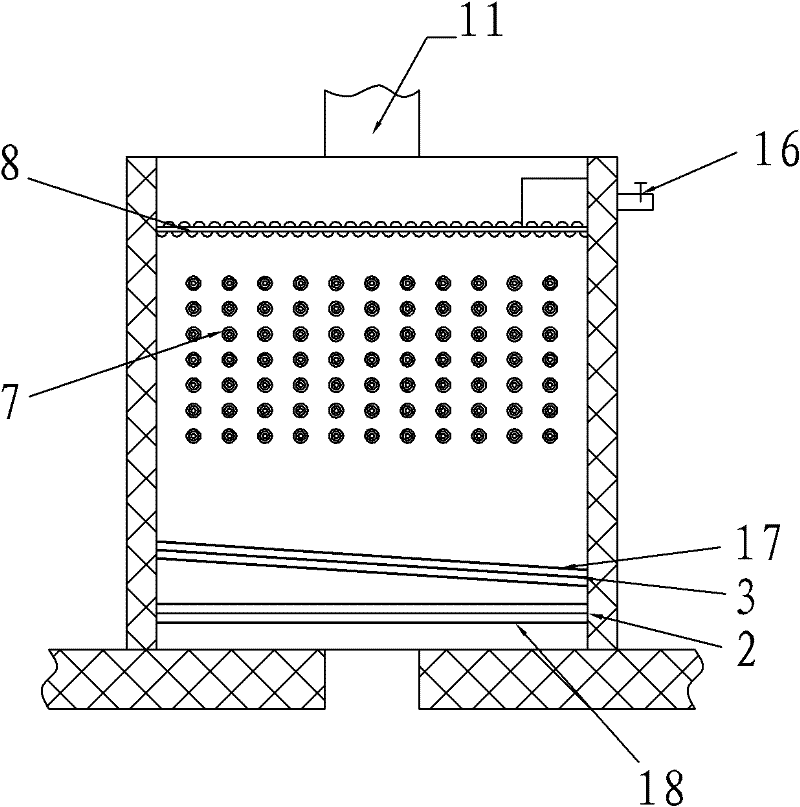

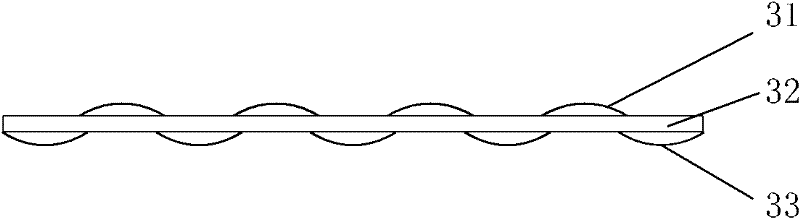

Dryer with oil removing and collecting energy-saving device

InactiveCN102330306AReduce oil fume concentrationGuarantee unimpededHeating/cooling textile fabricsIndirect heat exchangersFresh airHeat pipe

The invention discloses a dryer with an oil removing and collecting energy-saving device, which comprises the oil removing and collecting energy-saving device. The oil removing and collecting energy-saving device comprises a box body. The box body is divided into two left and right independent spaces through a sealing diaphragm; the left part of the box body is used as a waste gas passage; the right part of the box body is used as a fresh air passage; a waste gas inlet is arranged in the box body and below the waste gas passage; a waste gas discharge outlet is arranged in the box body and above the waste gas passage; a filter screen, a lower oil removing and collecting device, a heat pipe and an upper oil removing and collecting device are sequentially arranged in the waste gas passage from bottom to top; the heat pipe passes through the sealing diaphragm to enter the fresh air passage; a fresh air inlet is arranged in the box body and above the fresh air passage; a fresh air outlet is arranged in the box body and below the fresh air passage; the heat pipe is arranged in the fresh air passage; the waste gas inlet of the oil removing and collecting energy-saving device is communicated with a waste gas port of the dryer; and the fresh air outlet of the oil removing and collecting energy-saving device is communicated with an air inlet of the dryer. Due to the adoption of the technical scheme, the adverse impact of oil substances in waste gas on a heat exchange surface is solved.

Owner:DEQING HENGXIN ENERGY SAVING TECH

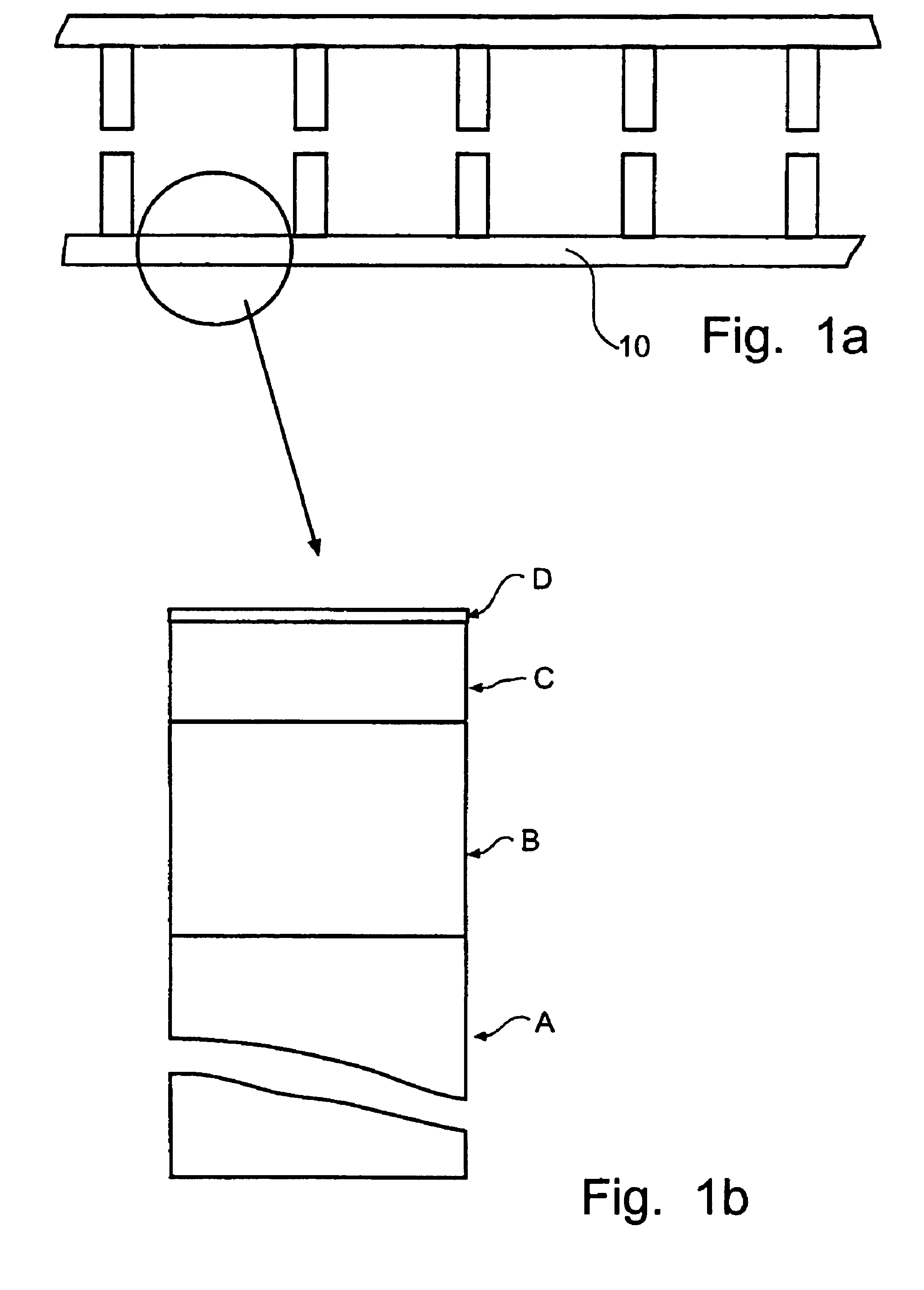

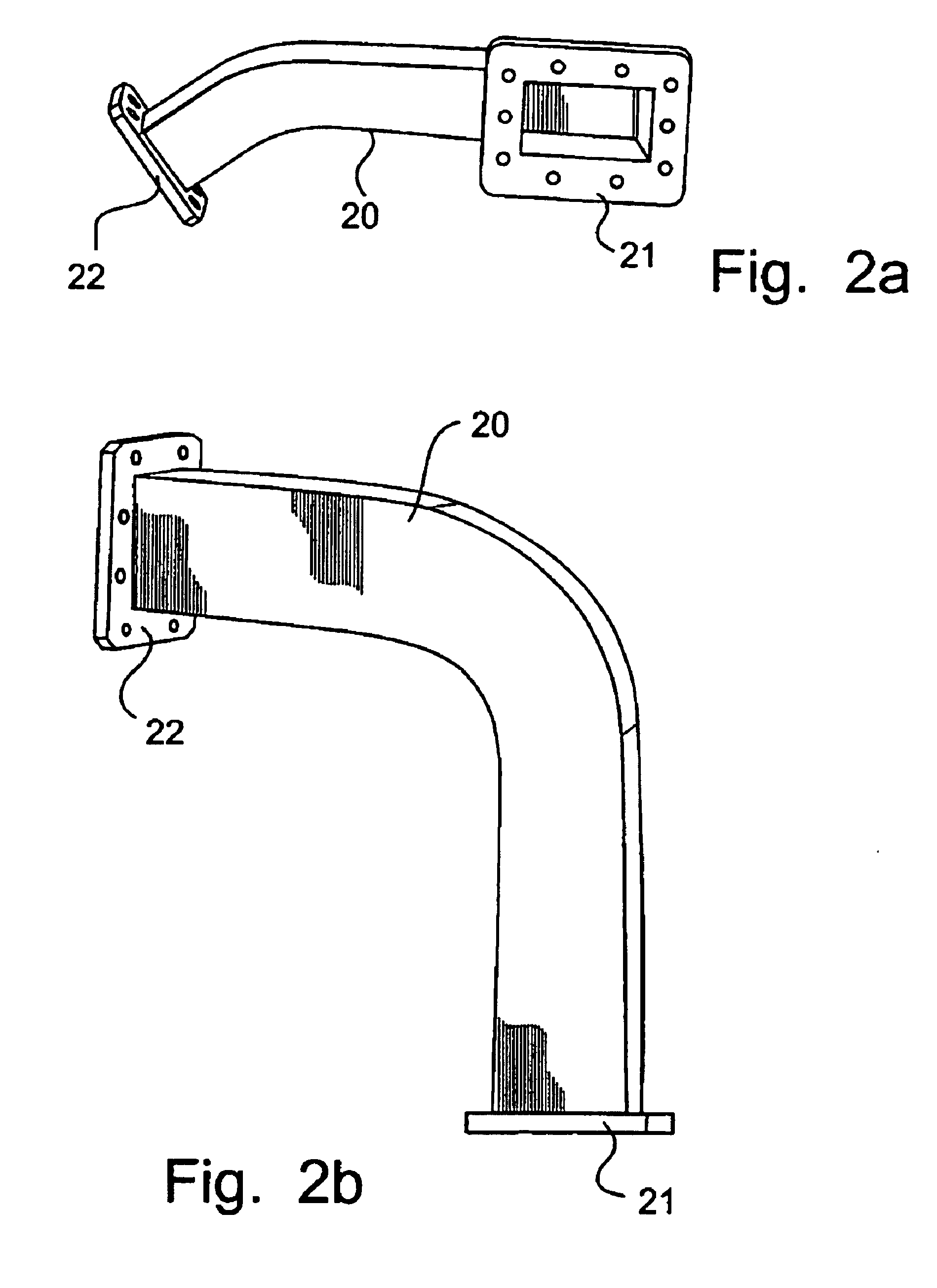

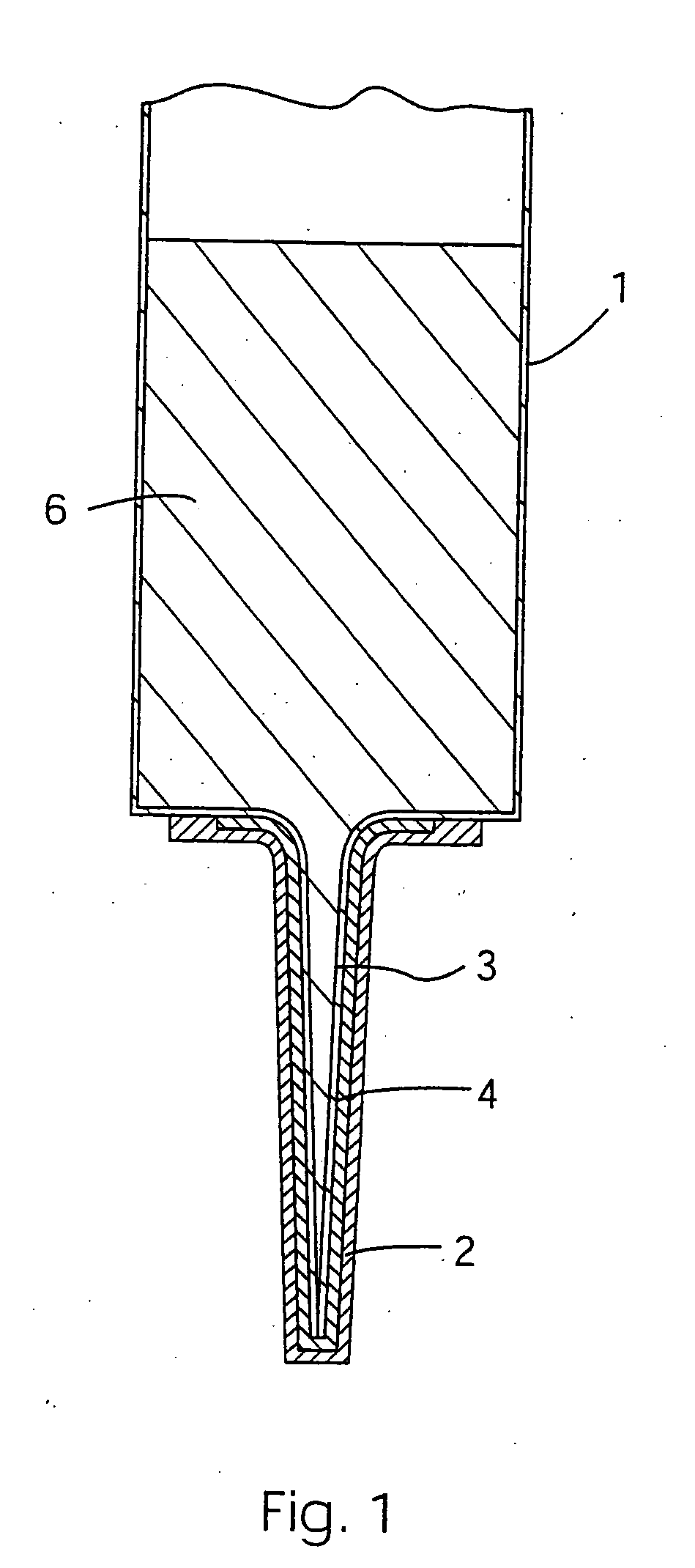

Microwave components

InactiveUS6809696B1Long-lasting protectionConvenient ArrangementWaveguide hornsWaveguidesEngineeringHorn antenna

A microwave component with an at least partially enclosed cavity, such as a microwave filter, a waveguide or a horn antenna, includes an outer support structure and an electric layer which is made of pulse-plated silver and which is arranged on the inside of the support structure and faces the cavity. The microwave component further includes a first inner protective layer of chemically precipitated gold, the protective layer being arranged on the electric layer and facing the cavity.

Owner:POLYMER KOMPOSITER I GOTEBORG

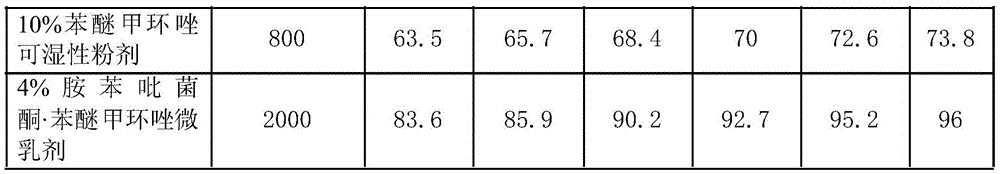

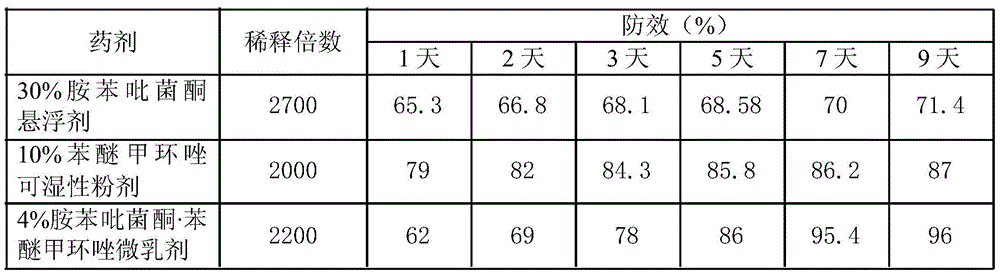

Antifungal composition comprising fenpyrazamine and difenoconazole

The invention belongs to the technical field of compound pesticides and particularly relates to antifungal composition comprising fenpyrazamine and difenoconazole. The fenpyrazamine and the difenoconazole are taken as the effective ingredients and account for 1%-80% by weight of the composition, and the weight ratio of the fenpyrazamine to the difenoconazole is 50:1-1:10. The composition can be prepared in one of the forms including an emulsifiable concentrate, wettable powder, a suspension, granules, a microemulsion, an emulsion in water and water dispersible granules. The antifungal composition is used for controlling crop diseases and has the characteristics of broad antifungal spectrum, high efficiency, low toxicity, low residues, obvious synergistic effect, reduction of use cost and the like.

Owner:JINGBO AGROCHEM TECH CO LTD

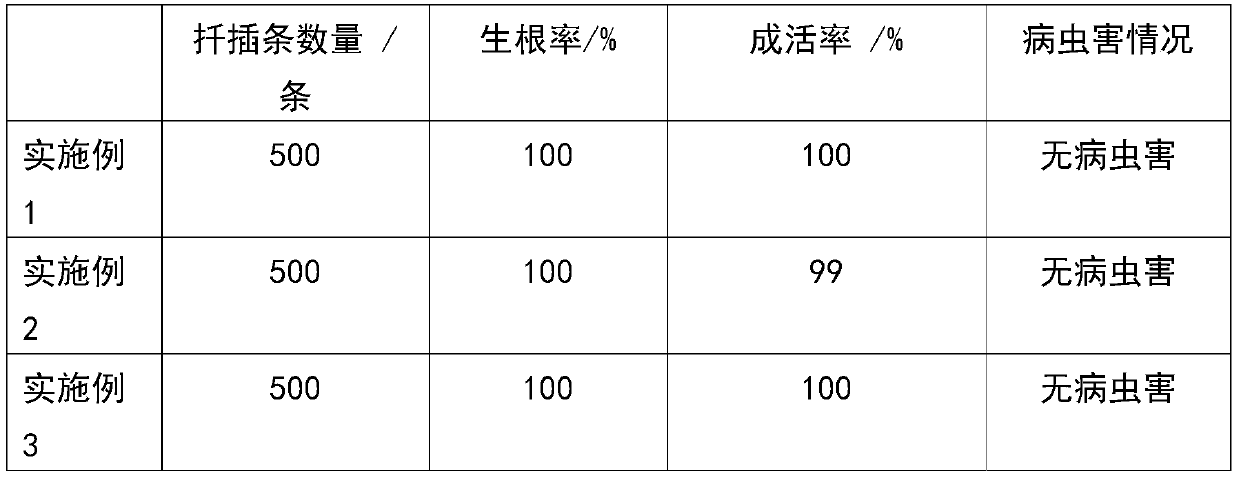

Mesona chinensis cutting seedling method

InactiveCN110313318AIncrease the rate of lignificationIncrease profitPlant growth regulatorsBiocideDiseaseEcological environment

The invention discloses a mesona chinensis cutting seedling method. The method is characterized by comprising the following steps of collection of cutting seedlings, preparation of a seedbed, cuttingand field management. In the cutting breeding process, lignification treatment before collection of cuttings, composite rooting inducing solution soaking treatment of the cuttings and environment-friendly ecological seedbed disease and insect pest prevention and treatment are carried out. The rooting rate of the cuttings reaches 100%, the survival rate is up to 99% or above, and diseases and insect pests are avoided. Environment-friendly raw materials are used, so that no harmful effect is caused to the ecological environment, and green ecological seedling culture of mesona chinensis is realized.

Owner:黔东南州林业投资开发有限公司

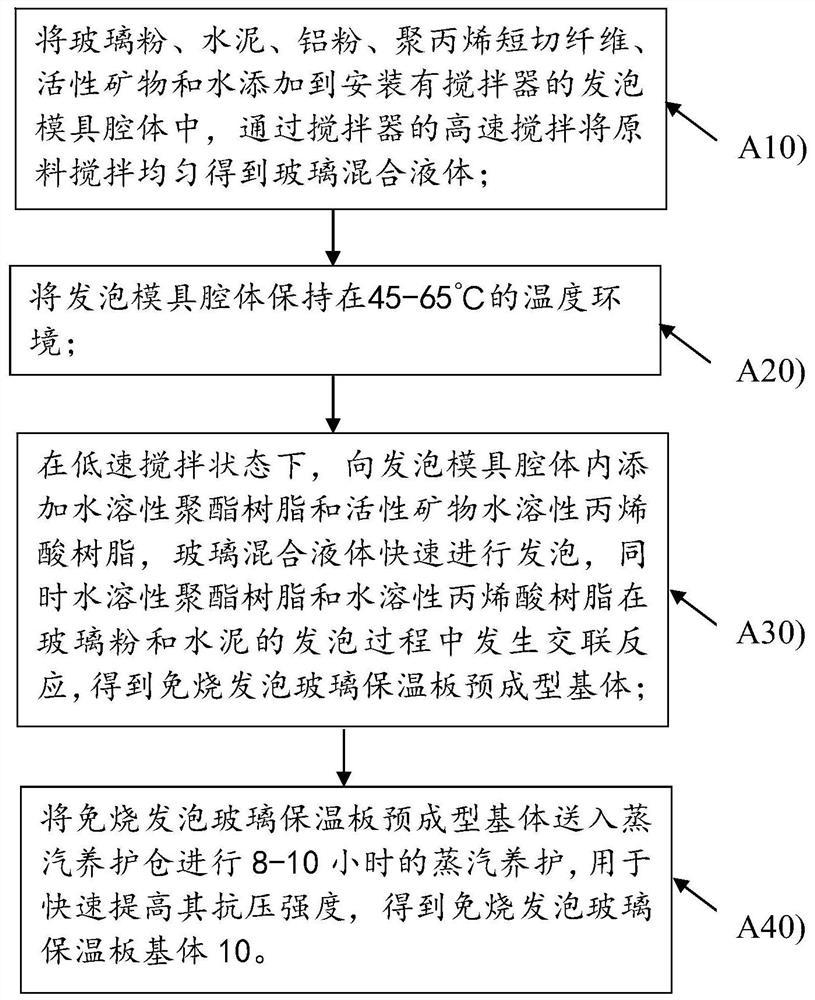

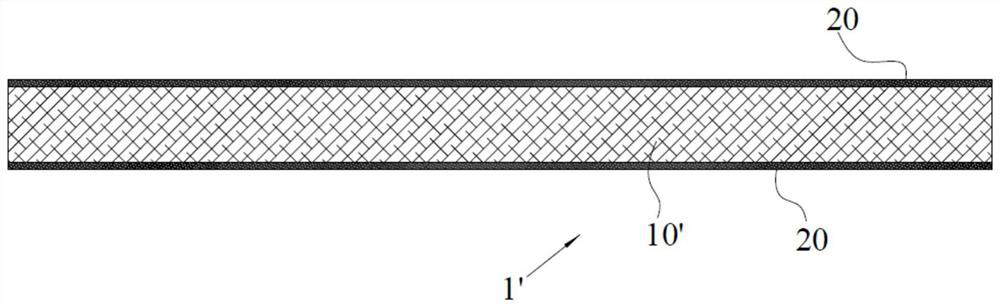

Foamed glass insulation board for buildings, and preparation method thereof

The invention discloses a foamed glass insulation board for buildings, and a preparation method thereof. The foamed glass insulation board comprises an unfired foam glass insulation board base body, which comprises, by weight, 20-30 parts of glass powder; 20-45 parts of cement; 2-5 parts of a nanoscale inorganic porous material; 4-8 parts of polypropylene chopped fibers; 5-10 parts of a water-soluble polyester resin; 5-10 parts of water-soluble acrylic resin; and the balance of water, wherein the cement can be subjected to polymerization reaction with the glass powder, the nanoscale inorganicporous material is used as a foaming enhancer, and the water-soluble polyester resin and the water-soluble acrylic resin are subjected to cross-linking reaction in the foaming process of polymerization of the glass powder and the cement, so that the compactness and the mechanical strength of the baking-free foamed glass insulation board matrix are improved. According to the invention, on the premise of having excellent heat preservation and fireproof performance, the foamed glass insulation board is low in manufacturing cost and light in weight, high-temperature sintering is not needed in thepreparation process, energy consumption is greatly reduced, and the building material conforms to the technical development direction of energy conservation and low-carbon management of building materials.

Owner:江苏银辉生态科技有限公司

Soil remediation agent for treating heavy metal contaminated soil

InactiveCN105860977AReduce releaseQuick releaseBiocideAgriculture tools and machinesDiseaseSoil heavy metals

The invention discloses a soil remediation agent for treating heavy metal contaminated soil. The soil remediation agent is prepared from, by mass, 260-310 parts of organic fertilizer, 25-31 parts of microorganism bacterium agent, 0.03-0.07 part of difenoconazole, 0.05-0.1 part of pyrethrum, 0.03-0.09 part of trifoliate jewelvine roots or stems, 0.04-0.08 part of chlorothalonil and 0.02-0.06 part of lactobacillus plantarum. According to the soil remediation agent for treating the heavy metal contaminated soil, the organic fertilizer serves as the main raw material, the microorganism bacterium agent capable of reducing soil heavy metals and the vegetable drug and chemicals capable of killing insects and achieving sterilization are added, not only can the soil fertilizer efficiency be improved, but also the soil remediation agent can penetrate into the soil, heavy metal contamination is improved, and diseases and insect pests are prevented and treated.

Owner:苗庆龄

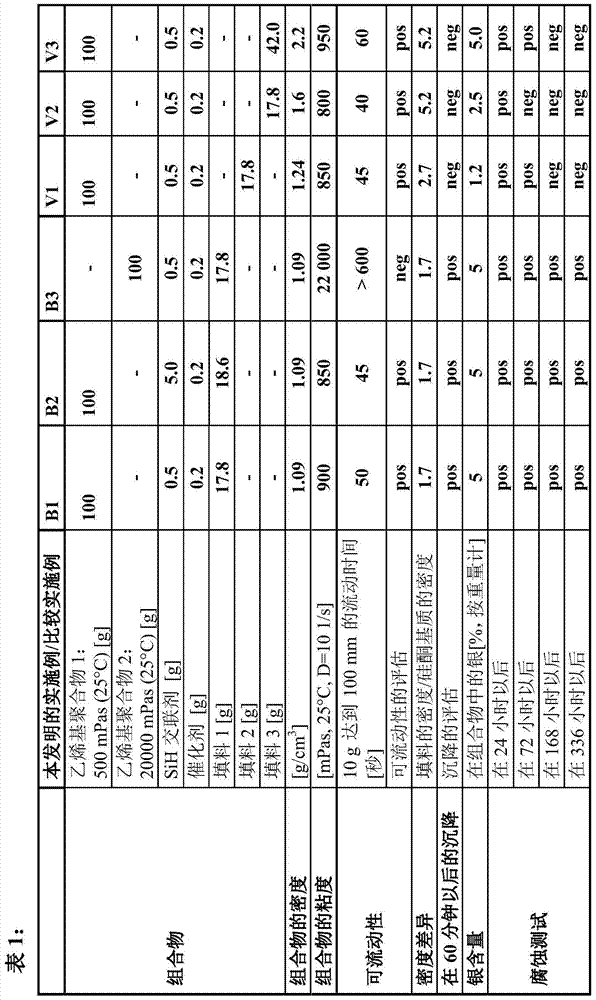

Filler-containing silicone compositions

Owner:WACKER CHEM GMBH

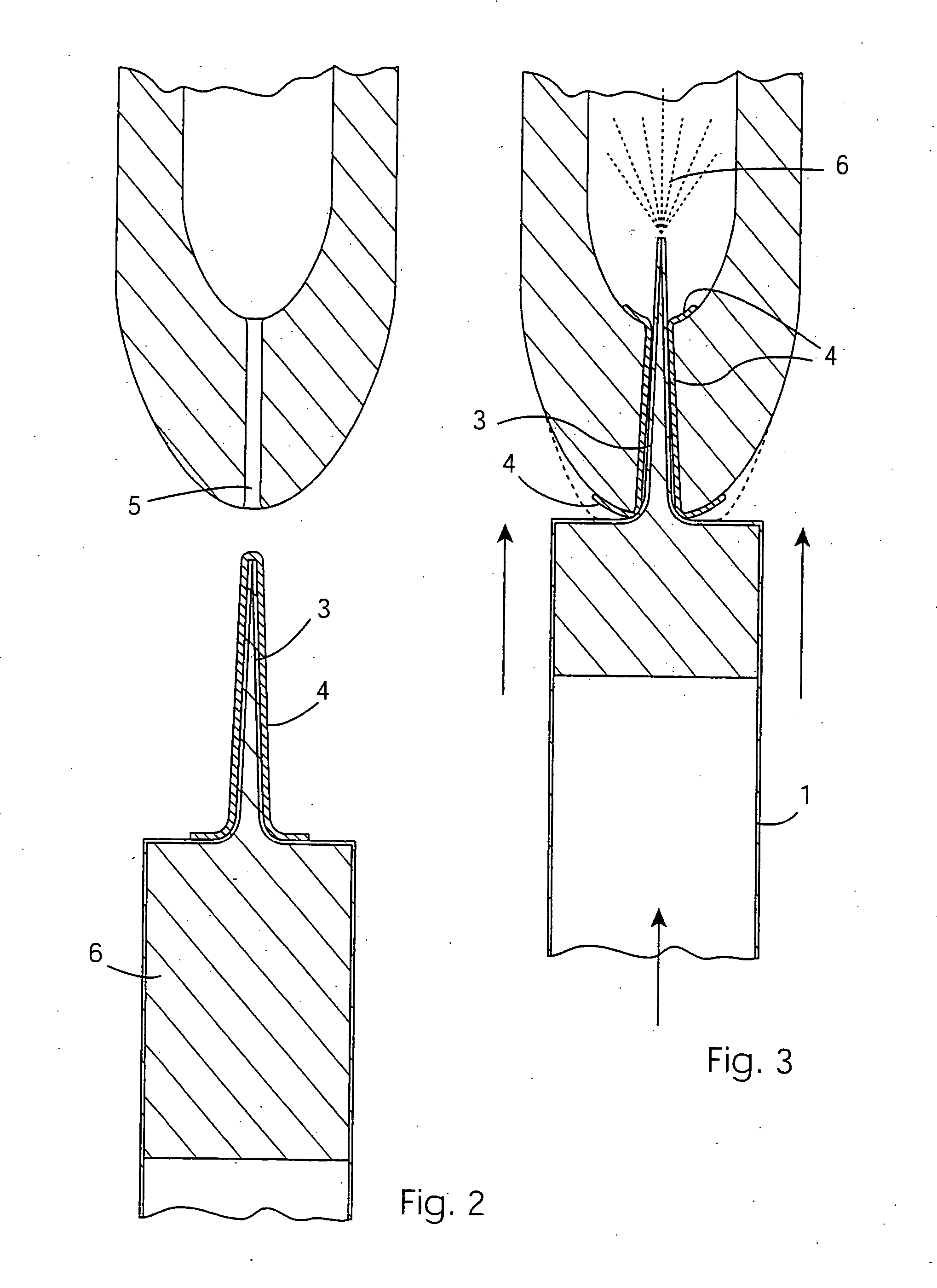

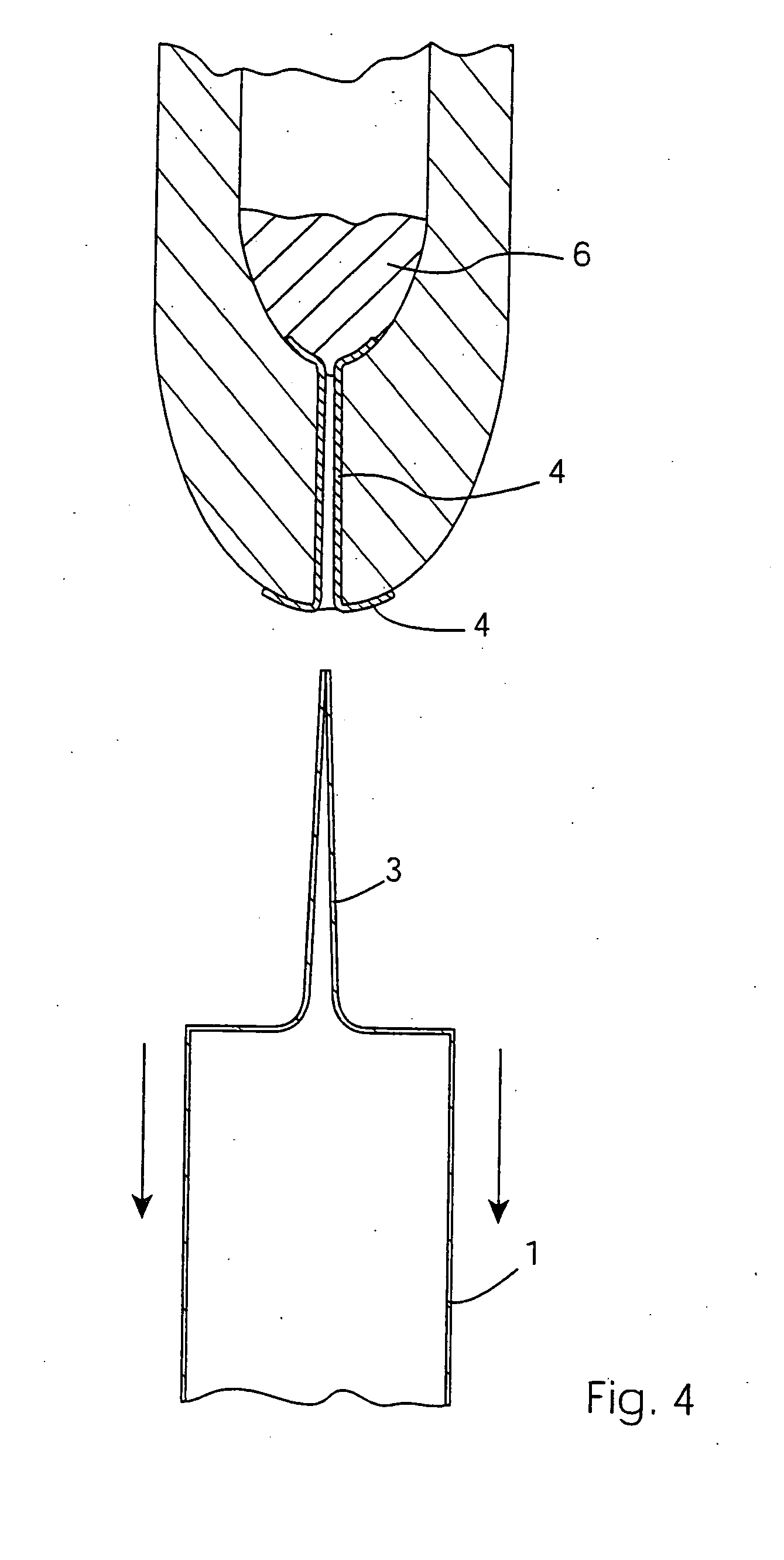

Bio-security system

InactiveUS20070093421A1Prevent and reduce riskReduce morbidityAntibacterial agentsBiocideEngineeringSecurity system

A method for preventing contamination of a teat during administration of a sealant comprises the steps of introducing / delivering a sterilising agent into the teat and subsequently delivering the sealant into the teat. A sealant injector 1, has a nozzle 3, with a removable protective cap 2. A sterilising agent 4 such as a bacteriocin is provided between the nozzle 3 and the contents of the sealant injector 1.

Owner:BIMEDA RES & DEV

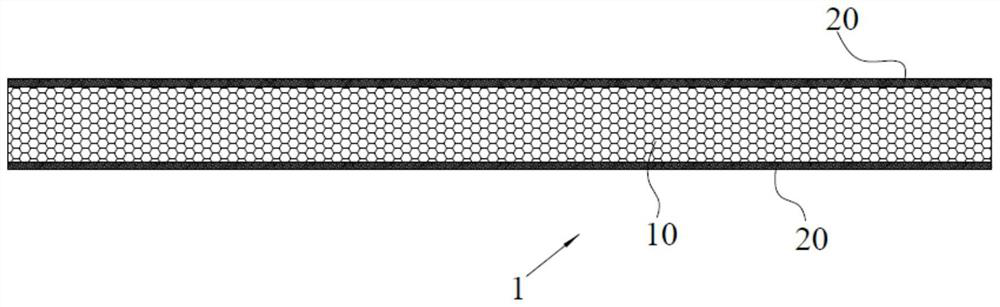

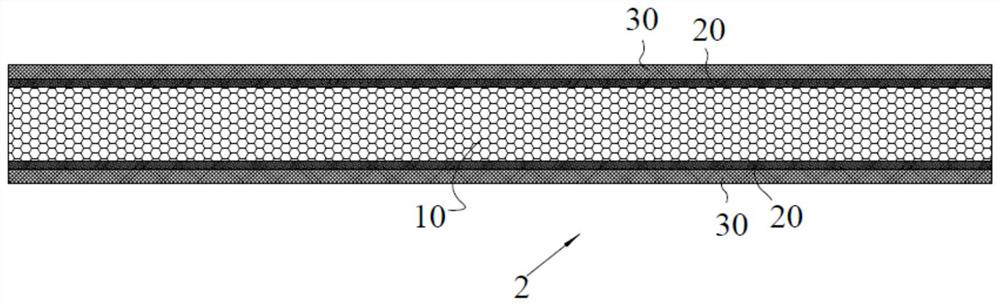

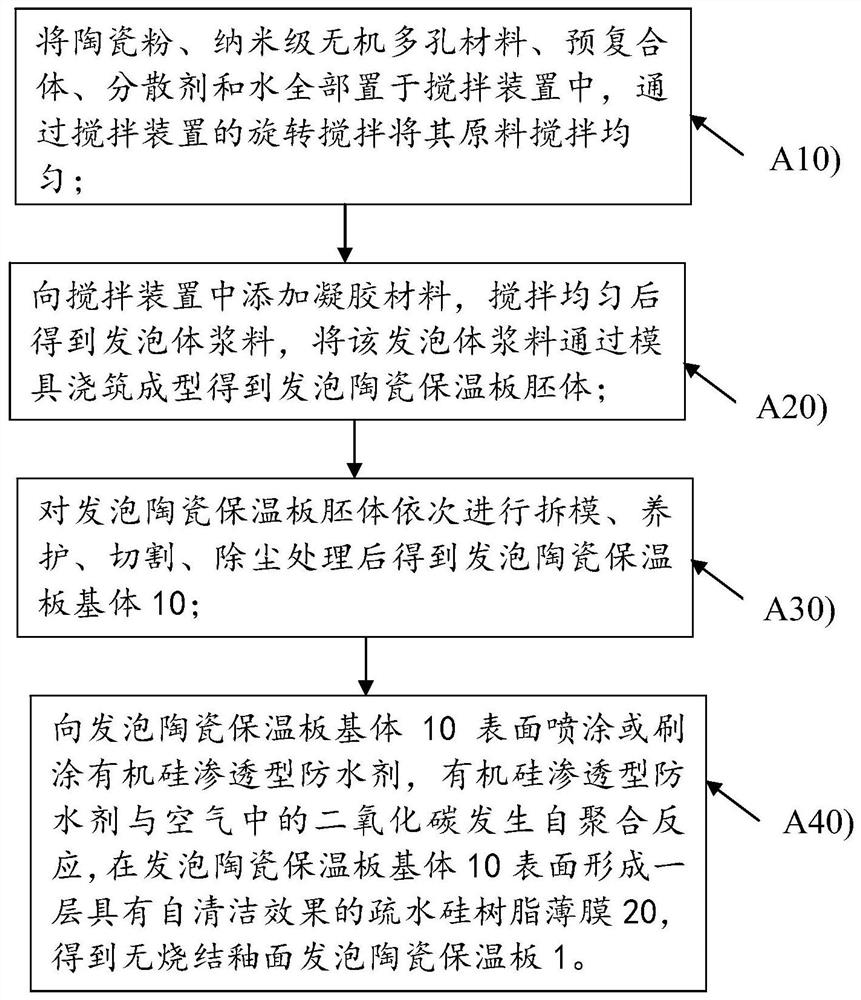

Non-sintered glaze foamed ceramic insulation board and external wall insulation board using same

InactiveCN111635208AGood compatibilityConducive to increasing the powder effectHeat proofingBuilding insulationsFiberFoaming agent

The invention discloses a non-sintered glaze foamed ceramic insulation board and an external wall insulation board using the same. The non-sintered glaze foamed ceramic insulation board comprises a foamed ceramic insulation board matrix formed by a foaming process, and the foamed ceramic insulation board matrix comprises the following raw materials by weight: 50-70 parts of ceramic powder, 10-15 parts of a gel material which is used as a foaming agent of the ceramic powder, 0.5-1 part of a nanoscale inorganic porous material, 0.1-3 parts of energized graphene, wherein the D90 particle size ofthe energized graphene is less than 50 microns, 1-3 parts of reinforcing fibers, 0.1-1 part of a dispersing agent and 20-40 parts of water. A surface enhancer is adopted to conduct permeation enhancing coating treatment on the surface of the foamed ceramic insulation board matrix, and a hydrophobic protective film is formed on the surface of the foamed ceramic insulation board matrix. On the premise of excellent heat preservation and fire prevention performance, the external wall insulation board is low in manufacturing cost and light in weight, has good hydrophobicity and durability, and haslasting weather-proof protection and decoration effects on the external wall insulation board.

Owner:江苏银辉生态科技有限公司

Oil removal and collection apparatus with function of energy saving

InactiveCN102330309AReduce oil fume concentrationGuarantee unimpededHeating/cooling textile fabricsDrying solid materialsExhaust gas emissionsFresh air

The invention discloses an oil removal and collection apparatus with the function of energy saving. The apparatus is characterized in that: the apparatus comprises a casing, the casing is divided into two relatively independent spaces by a seal separator, the left space is an exhaust gas channel, and the right space is a fresh air channel; the casing is provided with an exhaust gas inlet at the lower side of the exhaust gas channel, the upper side of the exhaust gas channel is provided with an exhaust gas outlet, a filter screen, a lower oil removal and collection apparatus, heat tubes, and an upper oil removal and collection apparatus are successively arranged in the exhaust gas channel from the bottom to the top, and the heat tubes enter the fresh air channel through traversing the sealseparator; and the casing is provided with a fresh air inlet at the upper side of the fresh air channel, the lower side of the fresh air channel is provided with a fresh air outlet, and the heat tubes are arranged in the fresh air channel. Above technical scheme allows the negative influence of oily substances in the exhaust gas to heat exchange surfaces to be solved.

Owner:DEQING HENGXIN ENERGY SAVING TECH

A kind of solar photovoltaic cell module transparent back plate composite film and preparation method thereof

ActiveCN105428445BGood weather resistanceImprove aging resistanceFinal product manufactureSynthetic resin layered productsComposite filmWeather resistance

The invention relates to the technical field of composite films, in particular to a composite film for a transparent back plate of a solar photovoltaic cell module and a preparation method thereof. The solar photovoltaic cell module transparent backboard composite film of the present invention comprises a first weather-resistant layer, a second weather-resistant layer and a base layer in sequence from top to bottom, and the first weather-resistant layer is a transparent weather-resistant PC film with a thickness of 25-100 μm; The second weather-resistant layer is a transparent weather-resistant PET film with a thickness of 150-300 μm; the base layer is a transparent linear low-density LLDPE film with a thickness of 50-150 μm. The present invention replaces the traditional PVDF film with a transparent weather-resistant PC film, which improves the weather resistance and light transmittance of the backboard it is applied to, not only reduces the cost, but also greatly reduces the environmental pollution caused by the fluorine film. EVA film has excellent adhesion.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

Automobile engine cabin coating agent and preparation method thereof

InactiveCN111205764AIncrease brightnessHigh hardnessAntifouling/underwater paintsPaints with biocidesControl theoryPollution prevention

The invention discloses an automobile engine cabin coating agent and a preparation method thereof. The automobile engine cabin coating agent is prepared from the following raw materials in percentageby weight: 70 to 90 percent of isopropanol, 1 to 3 percent of a leveling agent, 1 to 3 percent of a wetting dispersant, 7 to 23 percent of organic silicon resin and 0.1 to 1 percent of a preservative.According to the automobile engine cabin coating agent, organic silicon resin is used as a carrier, the automobile engine cabin coating agent can be cured at normal temperature, and has the characteristics of high film brightness, high hardness, good durability, excellent antifouling effect and the like; long-acting lasting protection is provided for the outer surface of an engine cabin, the constructed cabin surface has the characteristics of brightness, smoothness and pollution prevention, cabin aging, yellowing, cracking and the like are delayed, the later maintenance cost is reduced, thecabin can be bright as new only through simple washing, a formed film layer is transparent after being cured, and the original color and glossiness of the cabin are not affected.

Owner:GUANGZHOU HELIOSON CAR CARE

A kind of airgel fireproof heat insulation coating and preparation method thereof

ActiveCN108997911BImprove insulation performanceImprove comfortFireproof paintsPolyurea/polyurethane coatingsNanoceramicMetallic materials

The invention discloses an aerogel waterproof and heat-insulating coating as well as a preparation method thereof. The coating with fireproof and heat-insulating properties is prepared by adding aerogel powder and ceramic powder which are subjected to hydrophilic modification as well as adding aids and fillers according to different formula proportions, and the coating is prepared by utilizing theproperty characteristic of a three-dimensional network structure of the aerogel, so that the defect that the existing coating is only fireproof and is not heat-insulating is solved and the coating has the heat-insulating characteristic. Meanwhile, nanometer ceramic powder is added in the coating, the nanometer ceramic powder in the coating is heated to be ceramic, one expanded ceramic film is formed on the surface of a base material, one air layer is arranged between the film and the base material, contact between flame and the surface of a vehicle metal material product is isolated, and heatis prevented from being transmitted to the surface of the metal by depending on the low heat-conducting coefficient characteristic of the aerogel in the coating. Through fireproof and heat-insulatingsynergistic effect, good barrier effect on heat and flame is guaranteed to be achieved no matter normal use of the metal part in the vehicle or occurrence of extreme fire accidents, and the fireproofproperty of the coating is enhanced.

Owner:河南爱彼爱和新材料有限公司

Soil remediation agent with heavy metal pollution treatment and fertilization effects and preparation method thereof

InactiveCN105802633AReduced mobilityReduce adsorptionBiocideAgriculture tools and machinesMicrobial agentDisease damage

The invention discloses a soil remediation agent with the heavy metal pollution treatment and fertilization effects and a preparation method thereof.The soil remediation agent is mainly prepared from, by mass, 260-310 parts of organic fertilizer, 25-31 parts of a microbial agent, 0.03-0.07 part of difenoconazole, 0.05-0.1 part of pyrethrum, 0.03-0.09 part of derris, 0.04-0.08 part of chlorothalonil and 0.02-0.06 part of lactobacillus plantarum.According to the soil remediation agent, the organic fertilizer serves as a main raw material, the microbial agent capable of reducing heavy metal in soil and the plant pesticides and chemicals capable of killing pests and bacteria are added, and thus the soil remediation agent can improve the fertilizer effect of soil and can also penetrate deep into soil to relieve heavy metal pollution and prevent and treat pest and disease damage.

Owner:苗庆龄

DNA Vaccines Encoding Antigen Linked to a Domain That Binds CD40

InactiveUS20090074814A1Improve abilitiesEasy to demonstrateAntibody mimetics/scaffoldsVirus peptidesPeptide antigenA-DNA

Vaccines that target one or more antigens to a cell surface receptor improve the antigen-specific humoral and cellular immune response. Antigen(s) linked to a domain that binds to a cell surface receptor are internalized, carrying antigen(s) into an intracellular compartment where the antigen(s) are digested into peptides and loaded onto MHC molecules. T cells specific for the peptide antigens are activated, leading to an enhanced immune response. The vaccine may comprise antigen(s) linked to a domain that binds at least one receptor or a DNA plasmid encoding antigen(s) linked to a domain that binds at least one receptor. A preferred embodiment of the invention targets HIV-1 env antigen to the CD40 receptor, resulting in delivery of antigen to CD40 positive cells, and selective activation of the CD40 receptor on cells presenting HIV-1 env antigens to T cells.

Owner:JEFFREY A LEDBETTER

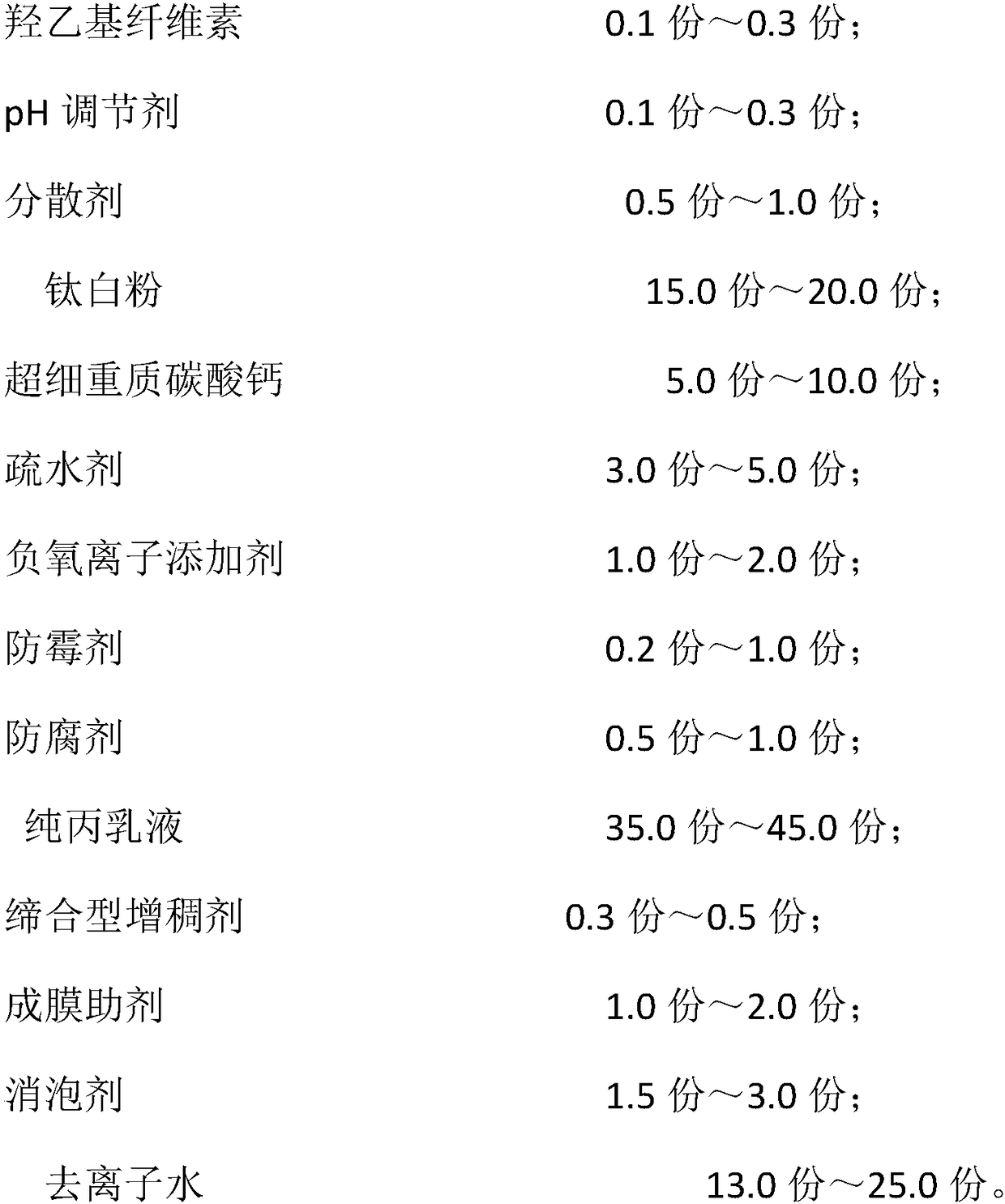

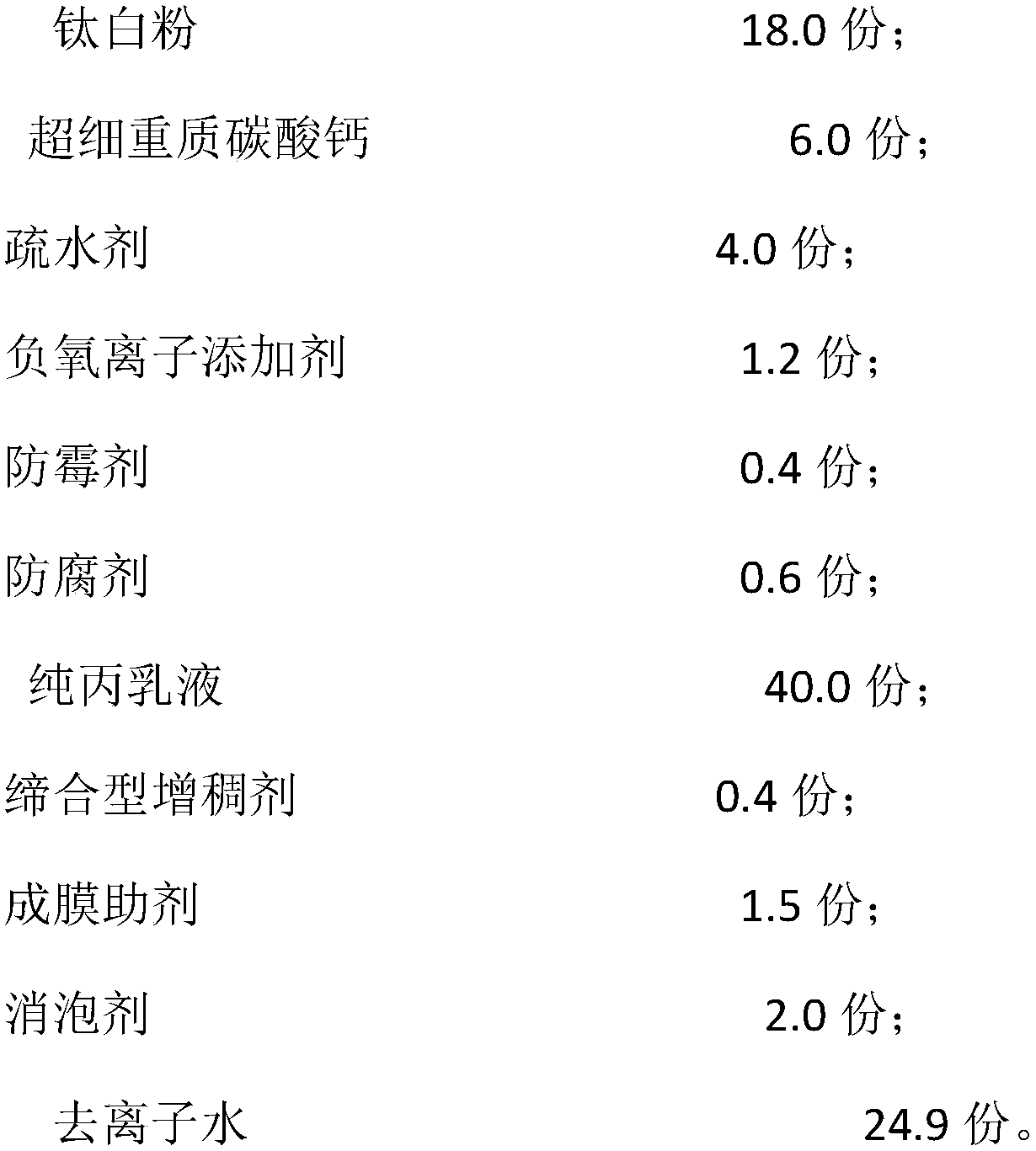

Waterborne forest negative oxygen ion exterior wall coating and preparation method thereof

InactiveCN108102497AGood weather resistanceLong-lasting protection and decorationAntifouling/underwater paintsPaints with biocidesChemistryEmulsion

The invention belongs to the technical field of negative oxygen ion exterior wall coating and provides waterborne forest negative oxygen ion exterior wall coating and a preparation method thereof in order to solve the technical problem that the existing exterior wall coating cannot sustainably release negative oxygen ions. The exterior wall coating comprises the following raw materials in parts byweight: 0.1-0.3 part of hydroxyethyl cellulose, 0.1-0.3 parts of a pH regulator, 0.5-1.0 part of a dispersing agent, 15.0-20.0 parts of titanium dioxide, 5.0-10.0 parts of ultrafine ground calcium carbonate, 3.0-5.0 parts of a water repellent agent, 1.0-2.0 parts of a negative oxygen ion additive, 0.2-1.0 part of a mildew preventive, 0.5-1.0 part of a preservative, 35-45.0 parts of pure acrylic emulsion, 0.3-0.5 parts of an associated thickening agent, 1.0-2.0 parts of a film forming additive, 1.5-3.0 parts of a defoaming agent and 13.0-25.0 parts of deionized water. The preparation method comprises the following steps: preparation of hydroxyethyl cellulose liquid, preparation of defoaming liquid, preparation of negative oxygen ion mixed solution and exterior wall coating. The exterior wall coating provided by the invention has the characteristics of sustainably releasing negative oxygen ions and removing peculiar smell of the coating.

Owner:吕跃文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com