A kind of airgel fireproof heat insulation coating and preparation method thereof

A technology for thermal insulation coatings and aerogels, applied in fire-resistant coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor adhesion, instability, and structural damage, reduce heat loss, improve The effect of fire resistance and heat insulation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

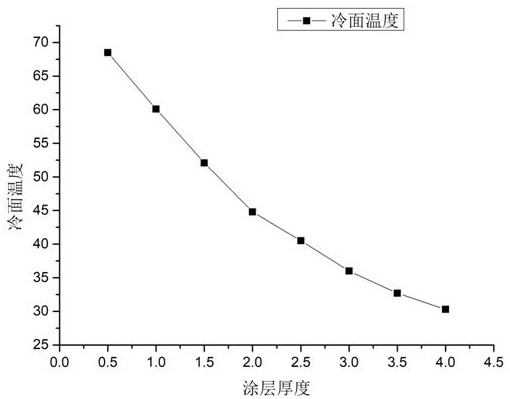

Image

Examples

Embodiment 1

[0041] An aerogel fireproof and heat-insulating coating, comprising the following raw materials in parts by weight: water-based polyurethane emulsion 20, water-based epoxy resin emulsion 15, graphene aerogel 25, 2-hydroxybenzophenone derivatives 2. Piperidine derivatives 2, sodium hexametaphosphate 3, ethylene glycol 3, ammonium borate 4, amino resin 5, zirconia ceramic powder 18, hydroxyethyl cellulose 4, tributyl phosphate 2.5, sodium benzoate 2 , Silicone series leveling agent 4, titanium dioxide 2, silicone defoamer 2.5, deionized water 30.

[0042] The preparation method of the aerogel fireproof and thermal insulation coating of the present embodiment comprises the following steps:

[0043] (1) Preparation of modified aerogel slurry:

[0044] a. Heating the aerogel powder for 30min-2h at a heating temperature of 200-500℃ for surface hydrophilic modification, without destroying its three-dimensional network structure, modify the surface of the aerogel powder into Hydroph...

Embodiment 2

[0051] An aerogel fireproof and heat-insulating coating is prepared from the following raw materials in parts by weight: water-based polyurethane emulsion 40, LiO aerogel 24, 2-hydroxybenzophenones 3, fatty alcohol polyoxyethylene ether 2, Glycerol 2, Pentaerythritol 2, Ammonium Phosphate 7, Silica Ceramic Powder 12, Sodium Carboxymethyl Cellulose 2, Aluminum Hydroxide 0.5, Expanded Graphite 0.5, Sodium Benzoate 1.5, Acrylate Leveling Agent 0.5, Fluorine Modification Leveling agent 0.5, titanium dioxide 2, zinc oxide 2, silicone defoamer 3, deionized water 20.

[0052] The preparation method of the aerogel fireproof and thermal insulation coating of the present embodiment comprises the following steps:

[0053] (1) Preparation of modified aerogel slurry:

[0054] a. Heating the aerogel powder for 30min-2h at a heating temperature of 200-500℃ for surface hydrophilic modification, without destroying its three-dimensional network structure, modify the surface of the aerogel powd...

Embodiment 3

[0057] An aerogel fire-proof and heat-insulating coating, comprising the following raw materials in parts by weight: water-based epoxy resin emulsion 45, TiO 2 Aerogel powder 15, imidazolidinone derivatives 1, fatty alcohol polyoxyethylene ether 1.5, ethylene glycol 2, ammonium borate 6, zirconia ceramic powder 14, lithium bentonite 1.5, expanded graphite 3, sodium citrate 3.5 , acrylate leveling agent 3, zinc oxide 1.5, silicone defoamer 1, deionized water 40.

[0058] The preparation method of the aerogel fireproof and thermal insulation coating of the present embodiment comprises the following steps:

[0059] (1) Preparation of modified aerogel slurry:

[0060] a. Heating the aerogel powder for 30min-2h at a heating temperature of 200-500℃ for surface hydrophilic modification, without destroying its three-dimensional network structure, modify the surface of the aerogel powder into Hydrophilic to obtain aerogel powder with surface hydrophilic modification;

[0061] Other ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com