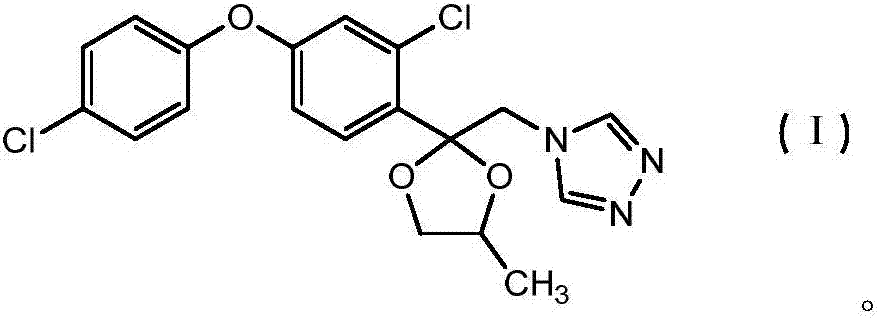

Application of tetrahydrobenzene difenoconazole to preparation of agricultural fungicide or fungicide composition and preparation method of tetrahydrobenzene difenoconazole

An agricultural fungicide, tetrahydrophenyl ether technology, applied in the field of agricultural fungicides, to achieve the effect of reducing costs, increasing yield, and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

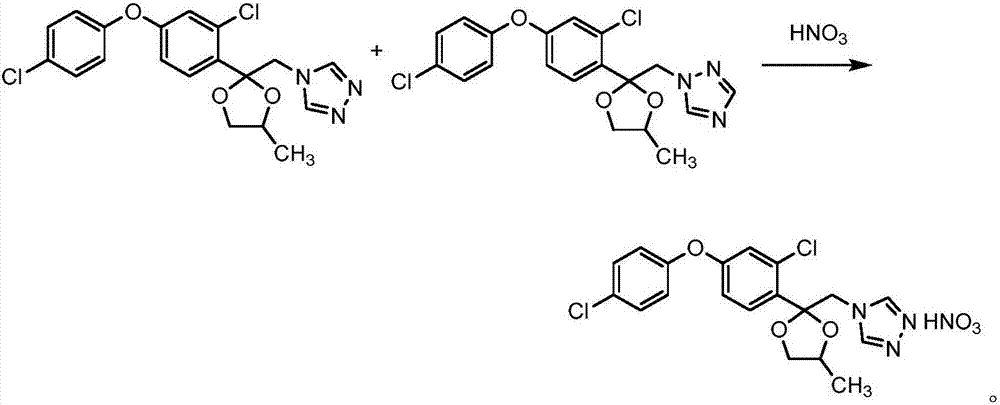

[0048] step one,

[0049] Reaction equation:

[0050]

[0051] Add 1000kg of difenoconazole scraps (difenoconazole content 36.7%, 0.903kmol, tetrahydrodifenoconazole content 33.8%, 0.832kmol) into a 5000L reactor, pump 3000kg of toluene into the kettle , heated up to about 30°C under stirring, stirred for 1 hour, and confirmed that it was completely dissolved; then 59kg (content 98%, 0.915kmol) of nitric acid (content 98%, 0.915kmol) in the preset high tank was added dropwise to the reactor, and the jacket of the reactor was cooled with water to control the nitric acid drop. The temperature of the addition process does not exceed 40°C. After the dropwise addition, stir for half an hour, then cool and crystallize, slowly cool to 17°C in 4 hours, stir and keep at 17°C for 1 hour, and then filter the reaction solution through a filter press. The filtrate was poured into another 5000L reaction kettle, and the filter cake was 420kg of tetrahydrodifenoconazole nitrate wet produc...

Embodiment 210

[0067] Embodiment 2.10% compound I (tetrahydrodifeconazole) granules:

[0068] Compound I 10%;

[0069] Dispersant 890 68%;

[0070] Dispersant CP86 3%;

[0071] Wetting agent SW 1%;

[0072] Defoamer 0.2%;

[0074] Light calcium carbonate tops up to 100%.

[0075] After the components are fully mixed, they are pulverized by a superfine pulverizer, extruded and granulated, and dried to obtain 10% granules.

Embodiment 3

[0076] Example 3. 30% compound I (tetrahydrodifeconazole) suspension concentrate.

[0077] Compound I 30%;

[0078] Nonylphenol polyethylene glycol ether 5%;

[0079] Urea 5%;

[0080] Xanthan Gum 0.2%;

[0081] Sodium Benzoate 0.3%;

[0082] Magnesium aluminum silicate 1%;

[0083] Silica 1%;

[0084] Water topped up to 100%;

[0085] Put each component into a sand mill for grinding to make a suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com