Foamed glass insulation board for buildings, and preparation method thereof

A foamed glass and thermal insulation board technology, applied in the field of building materials, can solve the problems of difficult addition, poor durability, poor crack resistance, etc., achieve excellent thermal insulation and fire resistance, improve compactness and mechanical strength, and save energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

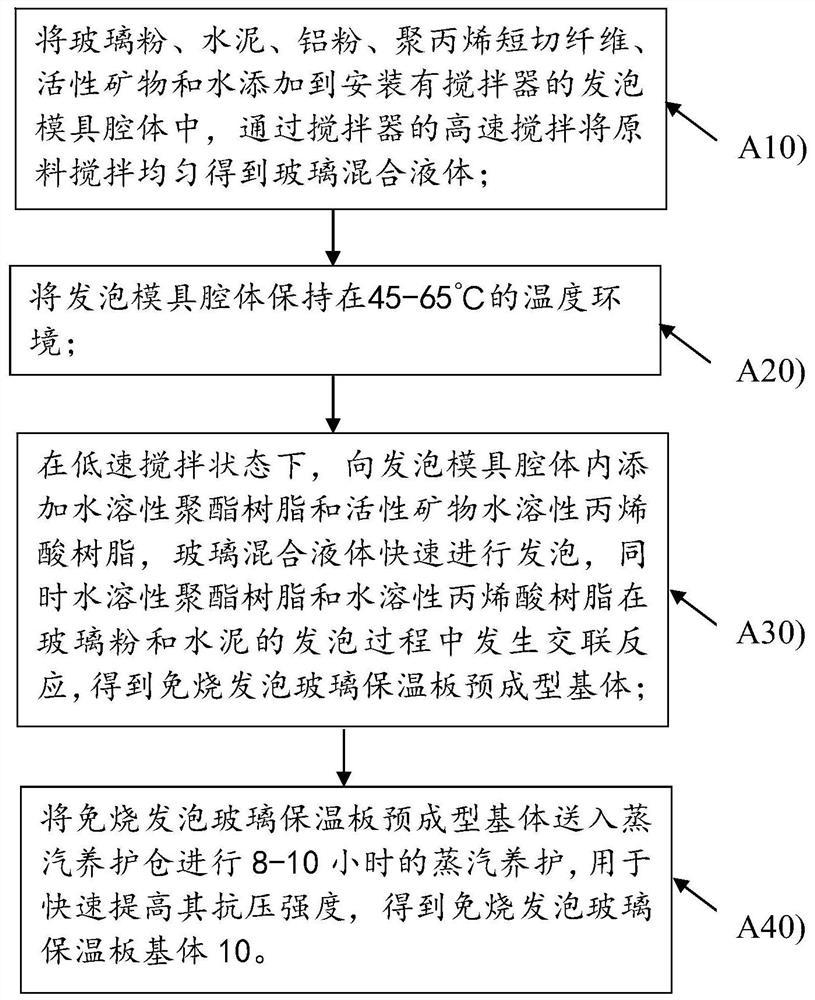

[0036] The embodiment of the present invention also discloses a method for preparing the foamed glass insulation board for construction as described above, which includes the following steps:

[0037] A10), add glass powder, cement, nano-scale inorganic porous material, polypropylene chopped fiber and water into the cavity of the foaming mold equipped with a stirrer, and stir the raw materials evenly through the high-speed stirring of the stirrer to obtain a glass mixed liquid ;

[0038] A20), foaming mold cavity is kept on the temperature environment of 45-65 ℃;

[0039] A30), under low-speed stirring state, add water-soluble polyester resin and water-soluble acrylic resin in the foaming mold cavity, the glass mixed liquid foams rapidly, simultaneously water-soluble polyester resin and water-soluble acrylic resin are mixed in glass powder and A cross-linking reaction occurs during the foaming process of cement, and the preformed matrix of the non-fired foamed glass insulatio...

Embodiment 1

[0042] Example 1: see figure 1 As shown, a foamed glass thermal insulation board for construction includes a non-fired foamed glass thermal insulation board substrate 10 formed by a foaming process, and the non-fired foamed glass thermal insulation board substrate 10 includes the following raw materials in parts by weight:

[0043]

[0044] As a foam enhancer;

[0045]

[0046] Specifically, a mixture of quartz and fly ash is used, and of course other active mineral components such as slag, ground natural zeolite, gypsum, silica fume and metakaolin can also be used;

[0047]

[0048]

[0049] see further figure 2 As shown, in this embodiment, the preparation method of the non-fired foamed glass insulation board substrate 10 includes the following steps:

[0050] A10), add glass powder, cement, aluminum powder, polypropylene chopped fibers, active minerals and water into the foaming mold cavity equipped with a stirrer, and stir the raw materials evenly through th...

Embodiment 2

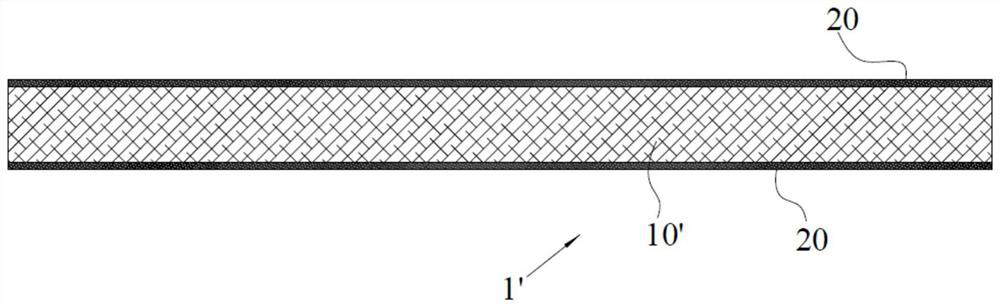

[0054] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the difference is that please refer to image 3 As shown, the present embodiment 2 proposes a foamed glass insulation board 1' for building, and its non-fired foamed glass insulation board base 10' comprises the following raw materials in parts by weight:

[0055]

[0056]

[0057] In this embodiment, a surface enhancer is used to perform penetration-enhancing coating treatment on the surface of the non-burning foamed glass insulation board substrate 10', which is used to form a layer of hydrophobic protective film on the surface of the non-fired foamed glass insulation board substrate 10'; Preferably, in this embodiment, the surface enhancer is a silicone penetrating waterproofing agent, and the silicone penetrating waterproofing agent is coated on the surface of the foamed glass insulation board substrate 10' and undergoes a self-polymerization reaction wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com