Non-sintered glaze foamed ceramic insulation board and external wall insulation board using same

A technology of external wall insulation board and glaze foaming, which is applied in the field of building materials, can solve the problems of poor insulation effect, high thermal conductivity, and high cost, and achieve the effects of low manufacturing cost, improved strength, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

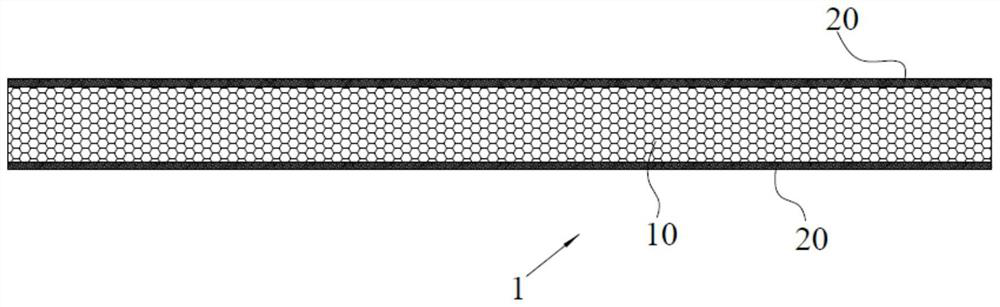

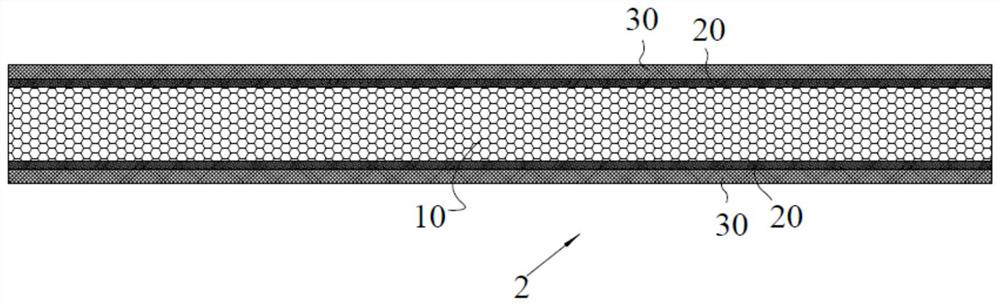

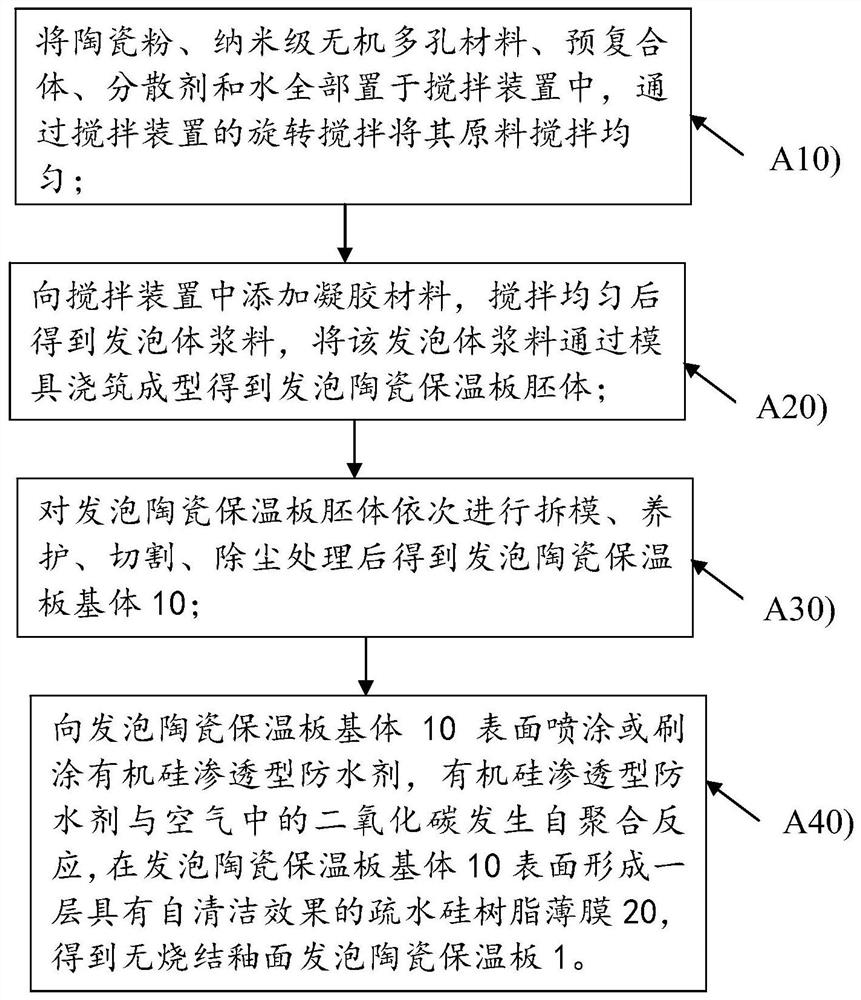

[0036] Example 1: see figure 1 As shown, a non-sintered glazed foamed ceramic thermal insulation board 1 includes a foamed ceramic thermal insulation board substrate 10 formed by a foaming process, and the foamed ceramic thermal insulation board substrate 10 includes the following raw materials in parts by weight:

[0037] 60 parts of ceramic powder;

[0038] 10 parts of gel material, as foaming agent of ceramic powder;

[0039] 0.8 parts of nano-scale inorganic porous materials; preferably, in this embodiment, active minerals adopt 5 parts of cement and / 5 parts of active minerals, wherein cement adopts one or both of sulphoaluminate cement and portland cement The active mineral is a mixture of one or more of quartz, slag, fly ash, ground natural zeolite, gypsum, silica fume and metakaolin, which is not particularly limited in this embodiment;

[0040] 0.2 parts of electrified graphene; the D90 particle size of electrified graphene is less than 50 microns;

[0041] 2 parts ...

Embodiment 2

[0057] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the difference is that this embodiment 2 proposes a non-sintered glazed foamed ceramic insulation board, and its foamed ceramic insulation board base includes the following parts by weight raw material:

[0058]

Embodiment 3

[0059] Embodiment 3: The remaining technical solutions of this embodiment 3 are the same as those of embodiment 1. The difference is that this embodiment 3 proposes a non-sintered glazed foamed ceramic insulation board, and its foamed ceramic insulation board base body includes the following parts by weight raw material:

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com