Preparation method of novel interface phase material

An interface phase and a new type of technology, applied in the field of preparation of new interface phase materials, can solve the problems of poor oxidation resistance and inability to apply high-temperature water vapor and high-speed gas environment, etc., to achieve the effect of prolonging the service life and good high temperature resistance and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a high-temperature-resistant and anti-oxidation novel interface phase material, comprising the following steps:

[0034] Step 1. Degumming the SiC fiber preform at a temperature of 500-700° C. and nitrogen atmosphere for 0.5-1 hour.

[0035]Step 2. Mix ethyl orthosilicate and absolute ethanol in a ratio of 17:12 by volume under a magnetic heating stirrer, then add the mixture of dilute hydrochloric acid and deionized water drop by drop, and continue to stir at a constant temperature for two Hours, a stable, transparent silica sol was obtained.

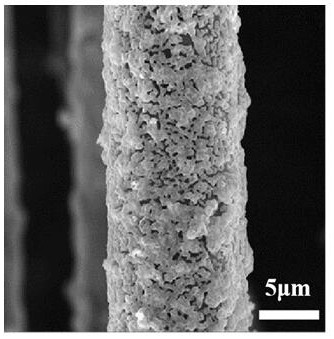

[0036] Step 3: Add an appropriate amount of SiC fibers treated in step 1 to the silica sol, impregnate, coat, and dry, and then keep it in a vacuum furnace at a constant temperature of 300~500°C for 1 hour to obtain a uniform SiO on the surface. 2 coated SiC fibers.

[0037] Step 4: Take 322.82g of concentrated phosphoric acid, add deionized water to dilute, and use a 500mL volumetric flask to constant v...

Embodiment 2

[0045] A method for preparing a high-temperature-resistant and anti-oxidation novel interface phase material, comprising the following steps:

[0046] Step 1. Degumming the SiC fiber preform at a temperature of 500-700° C. and nitrogen atmosphere for 0.5-1 hour.

[0047] Step 2. Mix ethyl orthosilicate and absolute ethanol in a ratio of 17:12 by volume under a magnetic heating stirrer, then add the mixture of dilute hydrochloric acid and deionized water drop by drop, and continue to stir at a constant temperature for two Hours, a stable, transparent silica sol was obtained.

[0048] Step 3: Add an appropriate amount of SiC fibers treated in step 1 to the silica sol, impregnate, coat, and dry, and then keep it in a vacuum furnace at a constant temperature of 300~500°C for 1 hour to obtain a uniform SiO on the surface. 2 coated SiC fibers.

[0049] Step 4: Take 322.82g of concentrated phosphoric acid, add deionized water to dilute, and use a 500mL volumetric flask to constant ...

Embodiment 3

[0057] A method for preparing a high-temperature-resistant and anti-oxidation novel interface phase material, comprising the following steps:

[0058] Step 1. Degumming the SiC fiber preform at a temperature of 500-700° C. and nitrogen atmosphere for 0.5-1 hour.

[0059] Step 2. Mix ethyl orthosilicate and absolute ethanol in a ratio of 17:12 by volume under a magnetic heating stirrer, then add the mixture of dilute hydrochloric acid and deionized water drop by drop, and continue to stir at a constant temperature for two Hours, a stable, transparent silica sol was obtained.

[0060] Step 3: Add an appropriate amount of SiC fibers treated in step 1 to the silica sol, impregnate, coat, and dry, and then keep it in a vacuum furnace at a constant temperature of 300~500°C for 1 hour to obtain a uniform SiO on the surface. 2 coated SiC fibers.

[0061] Step 4: Take 322.82g of concentrated phosphoric acid, add deionized water to dilute, and use a 500mL volumetric flask to constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com