Light emitting diode (LED), printed circuit board (PCB), plug hole metal-based copper coating plate and fabrication method of plug hole metal-based copper coating plate

A technology of metal substrate and manufacturing method, which is applied in the manufacture of printed circuits, printed circuits connected with non-printed electrical components, printed circuits, etc. and other problems, to achieve the effect of having both insulation performance and heat dissipation performance, improving production efficiency, and combining firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The plugged metal-based copper-clad laminate provided by the present invention and its manufacturing method will be further described below in conjunction with the accompanying drawings. It should be pointed out that the technical solution and design principle of the present invention will be described in detail below with an optimized technical solution.

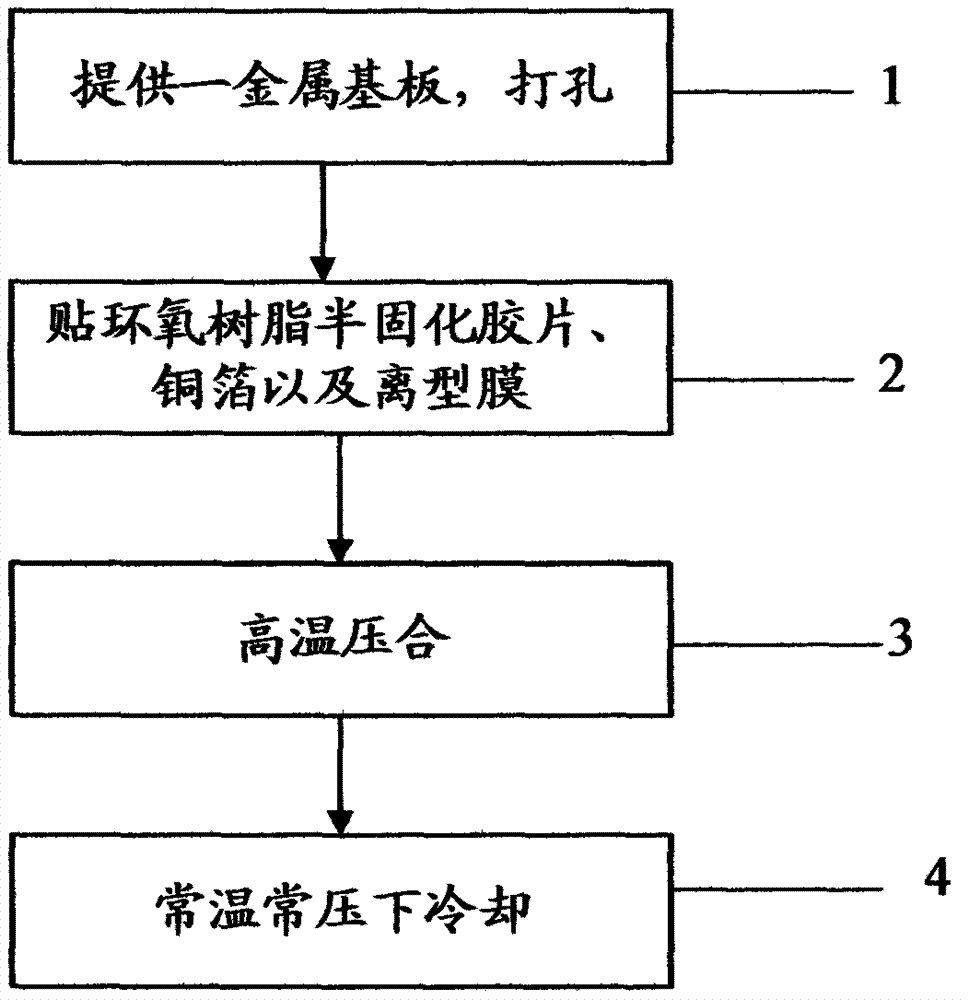

[0027] Such as figure 1 As shown, the method for manufacturing a plugged metal-based copper clad laminate provided by a preferred embodiment of the present invention includes: step 1, providing a metal substrate, drilling holes; step 2, pasting epoxy prepreg, copper foil and release film ; Step 3, high-temperature pressing; and Step 4, cooling under normal temperature and pressure to obtain a metal-based copper-clad laminate with plugged holes.

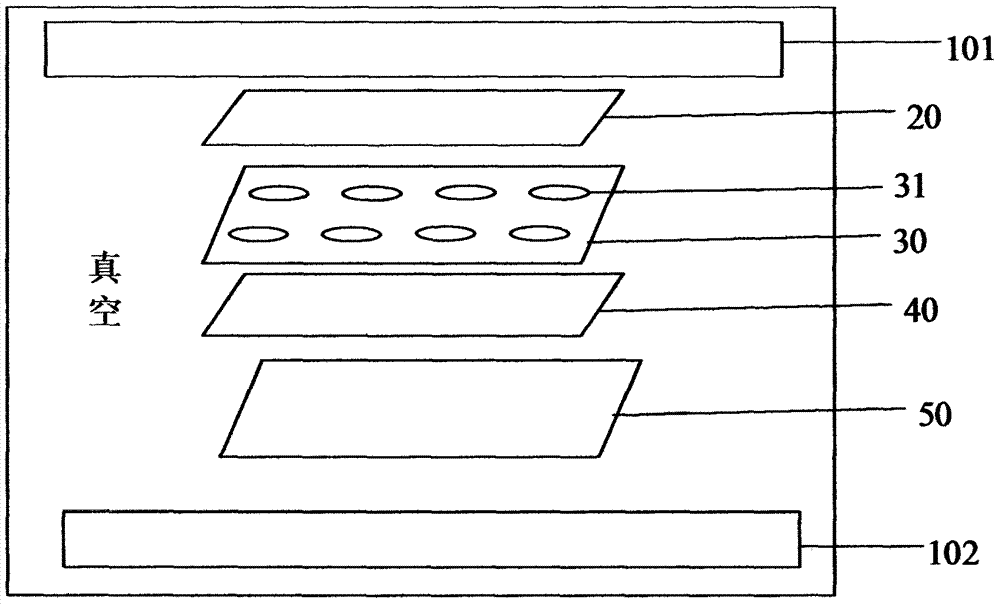

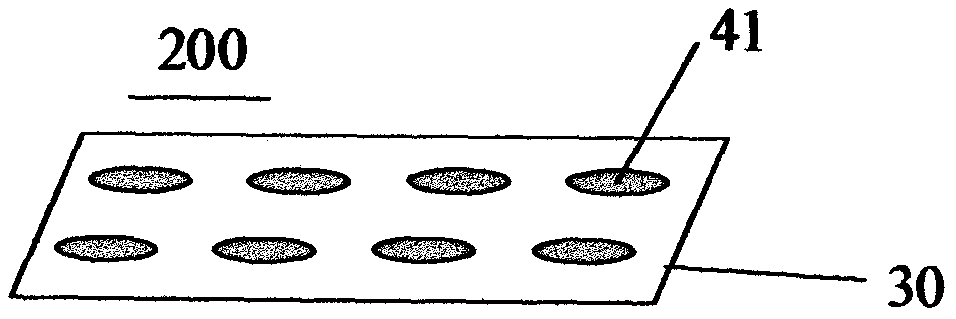

[0028] combine figure 2 As shown, in step 1, drilling refers to forming a predetermined number and layout of through holes 31 on the metal substrate 30 . In this embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com