Solid silicon rubber and preparation method thereof

A technology of solid silicon and silicone rubber raw rubber, applied in the rubber field, can solve the problems of weak interaction force, difficult to meet the needs of use, and low tear strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

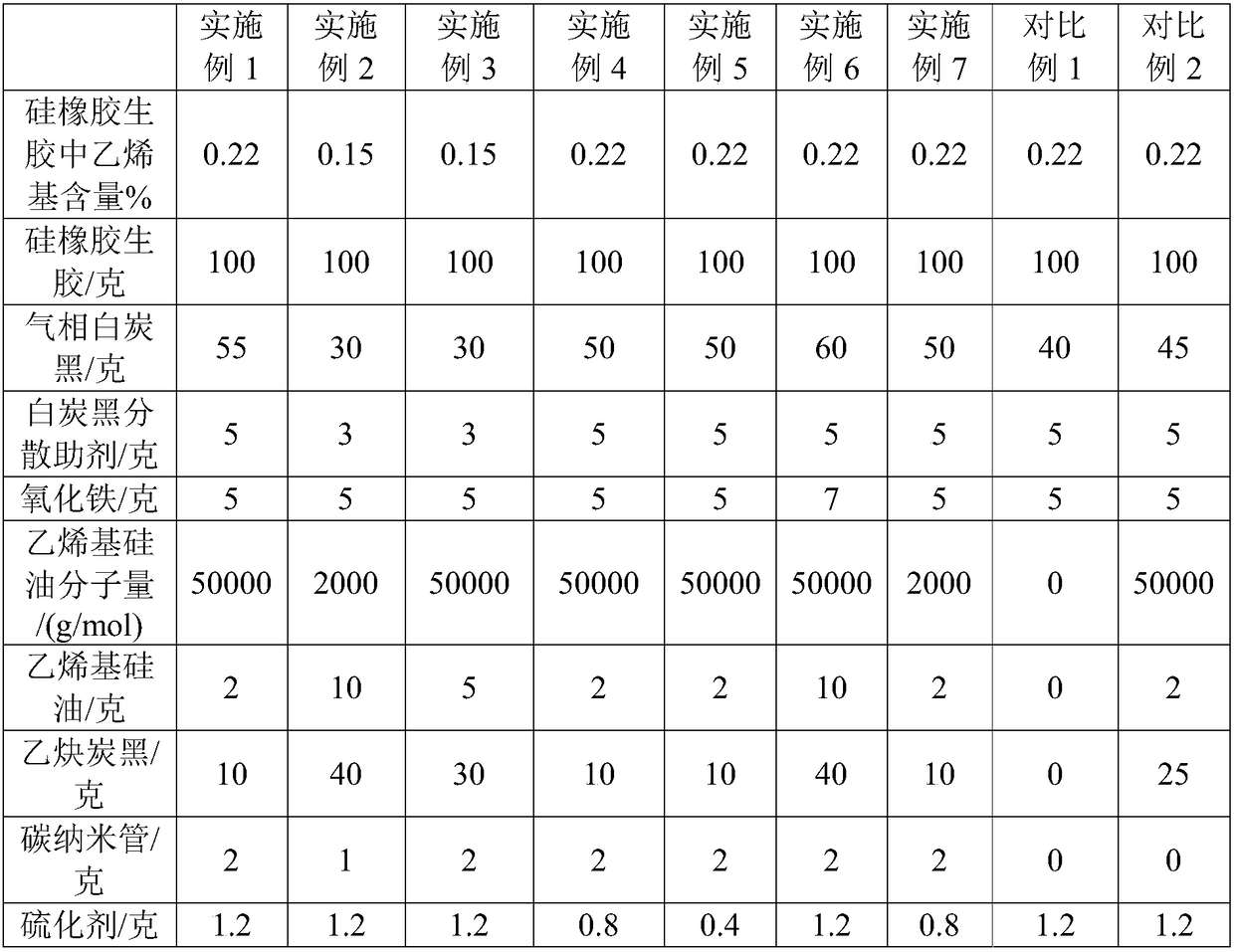

Embodiment 1

[0032] Add 100g of raw silicone rubber with a vinyl content of 0.22% (mol %), 55g of fumed white carbon black, and 5g of hydroxy silicone oil into the kneader in batches, heat to 80°C, knead until the material becomes agglomerate, and then add 5.0g Kneading was continued with 2g of iron oxide, 2g of vinyl silicone oil (average molecular weight of 50,000), and finally 10g of acetylene carbon black and 2g of carbon nanotubes were added. After the kneading is completed, discharge the rubber to the open mill, add 1.2 g of peroxide vulcanizing agent double 2,5, mix well and discharge the rubber to obtain a film. Place the film in a 2mm thick mold and vulcanize it on a plate vulcanizer at 165°C and 10.0MPa for 5 minutes to obtain a solid silicone rubber.

Embodiment 2

[0034] Add 100g of raw silicone rubber with a vinyl content of 0.15% (mole percentage), 30g of fumed white carbon black, and 3g of hydroxy silicone oil into the kneader in batches, increase the temperature to 80°C, knead until the material becomes agglomerate, and then add 5.0g Kneading of iron oxide, 10g vinyl silicone oil (average molecular weight 2000) was continued, and finally 40g acetylene carbon black and 1g carbon nanotubes were added. After the kneading is completed, discharge the rubber to the open mill, add 1.2g of peroxide vulcanizing agent double 2,5, mix evenly and discharge the rubber to obtain the film. Place the film in a 2mm thick mold at 165°C, 10.0MPa Vulcanize on a flat vulcanizer for 5 minutes to obtain solid silicone rubber.

Embodiment 3

[0036] Add 100g of raw silicone rubber with a vinyl content of 0.15% (mole percentage), 30g of fumed white carbon black, and 3g of hydroxy silicone oil into the kneader in batches, increase the temperature to 80°C, knead until the material becomes agglomerate, and then add 5.0g Kneading of iron oxide, 5g vinyl silicone oil (average molecular weight 50,000) was continued, and finally 30g acetylene carbon black and 2g carbon nanotubes were added. After the kneading is completed, discharge the rubber to the open mill, add 1.2g of peroxide vulcanizing agent double 2,5, mix evenly and discharge the rubber to obtain the film. Place the film in a 2mm thick mold at 165°C, 10.0MPa Vulcanize on a flat vulcanizer for 5 minutes to obtain solid silicone rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com