Transparent packaging film and preparation method thereof

A transparent packaging and film layer technology, applied in the field of packaging materials, can solve the problems of high temperature resistance, machine adaptability, and crimping of food packaging films that cannot meet the requirements, and achieve high food hygiene safety and quality stability. Improved peel strength and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions in the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

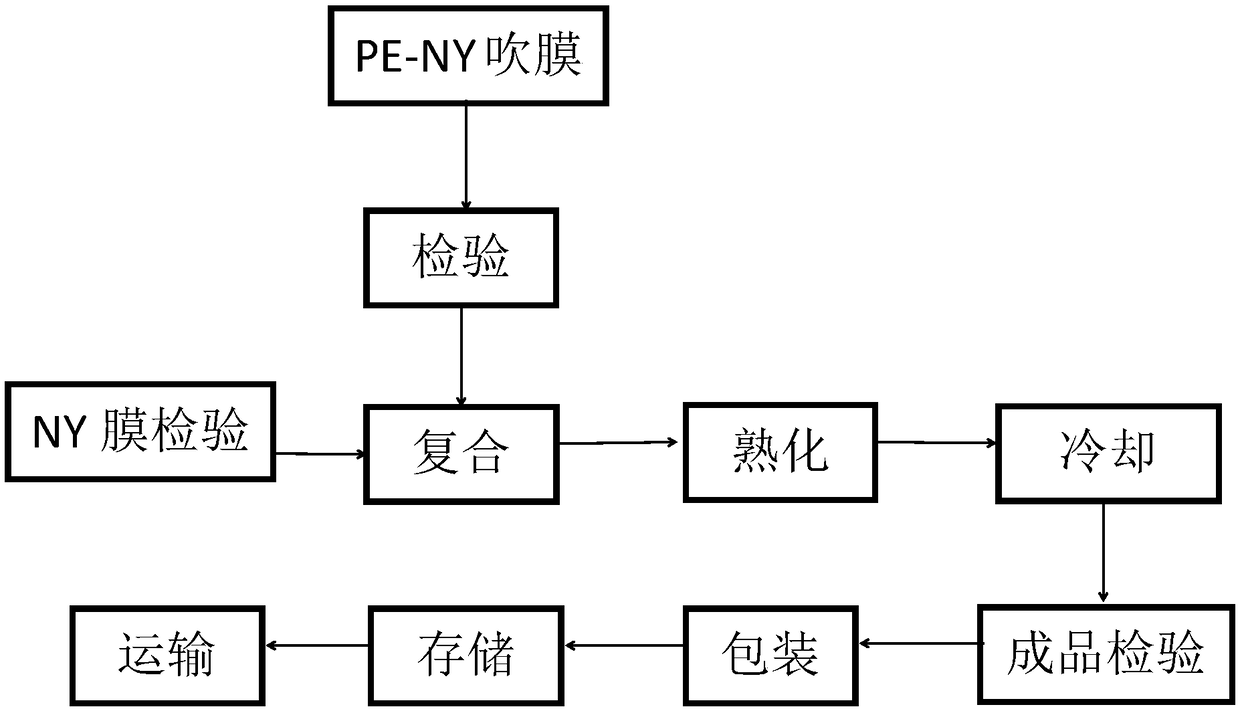

[0041] The preparation method of transparent packaging film of the present invention is as follows:

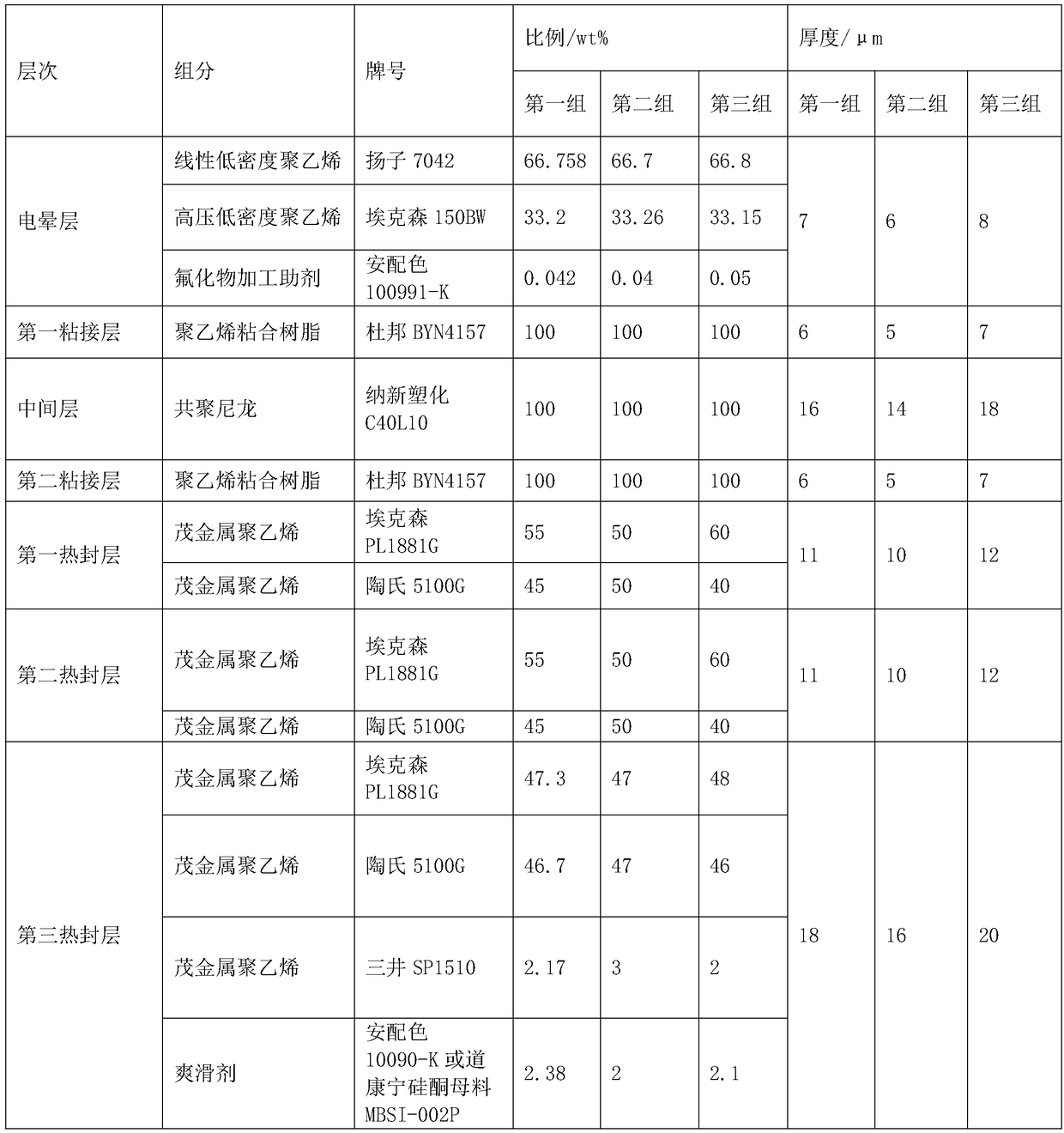

[0042] Step 1, prepare PE-NY co-extrusion film in 3 groups, and the formula of the PE-NY co-extrusion film layer is shown in Table 1 below:

[0043] Table 1

[0044]

[0045]

[0046] Add the particles contained in the corona layer, the first adhesive layer, the middle layer, the second adhesive layer, the first heat-sealing layer, the second heat-sealing layer and the third heat-sealing layer into the seven-layer W&H blown film equipment respectively Among them, the extrusion temperature settings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com