Patents

Literature

47results about How to "Resistant to UV radiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyimide ultra-short fiber and preparation method thereof

ActiveCN107675288AGood insulationAchieve decentralizationHeating/cooling textile fabricsMonocomponent synthetic polymer artificial filamentTemperature treatmentSlurry coating

The invention discloses a polyimide ultra-short fiber and a preparation method thereof and relates to the field of fiber preparation. According to the preparation method disclosed by the invention, batch preparation of polyimide fiber products with a fiber diameter nanoscale and a length micro scale can be realized. For the polyimide ultra-short fiber disclosed by the invention, the length of thefiber is 2 to 500mu m, the diameter of the fiber is 0.1 to 50mu m, and specific area is 2 to 30m<2> / g. By utilizing the physical and chemical properties at different heat treatment temperatures in thepreparation process of the polyimide fiber, dispersion and ultrashort properties of the fiber are realized more easily by adopting physical and mechanical methods in a state that the polyimide fiberis incompletely imidized; then complete imidization of the polyimide fiber is realized by high-temperature treatment; finally, the polyimide ultra-short fiber is obtained by a method of mechanical pulverization, lapping and shifting. The polyimide ultra-short fiber obtained by the preparation method disclosed by the invention has the characteristics of high and low temperature resistance, ultraviolet irradiation resistance, good insulating property and the like, and can be used for preparing a slurry coating solution, reinforcing resin, rubber and the like, forming pulp and the like.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

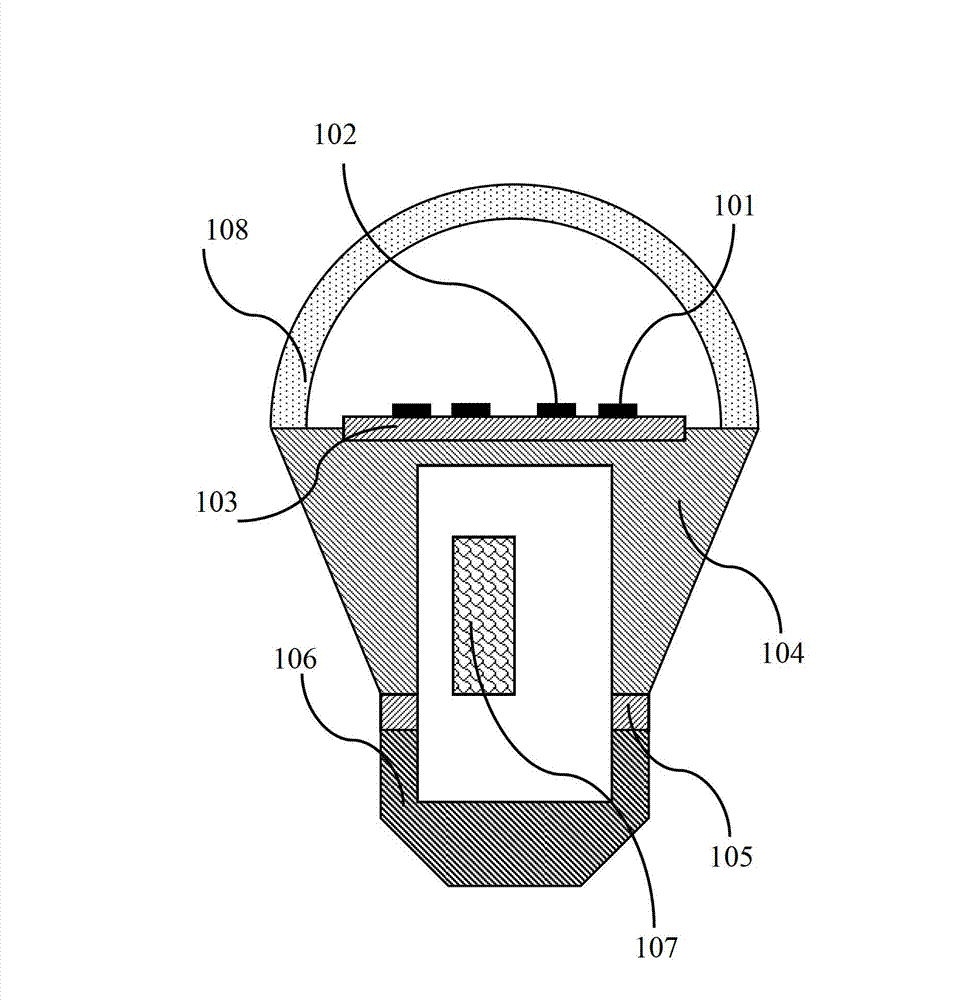

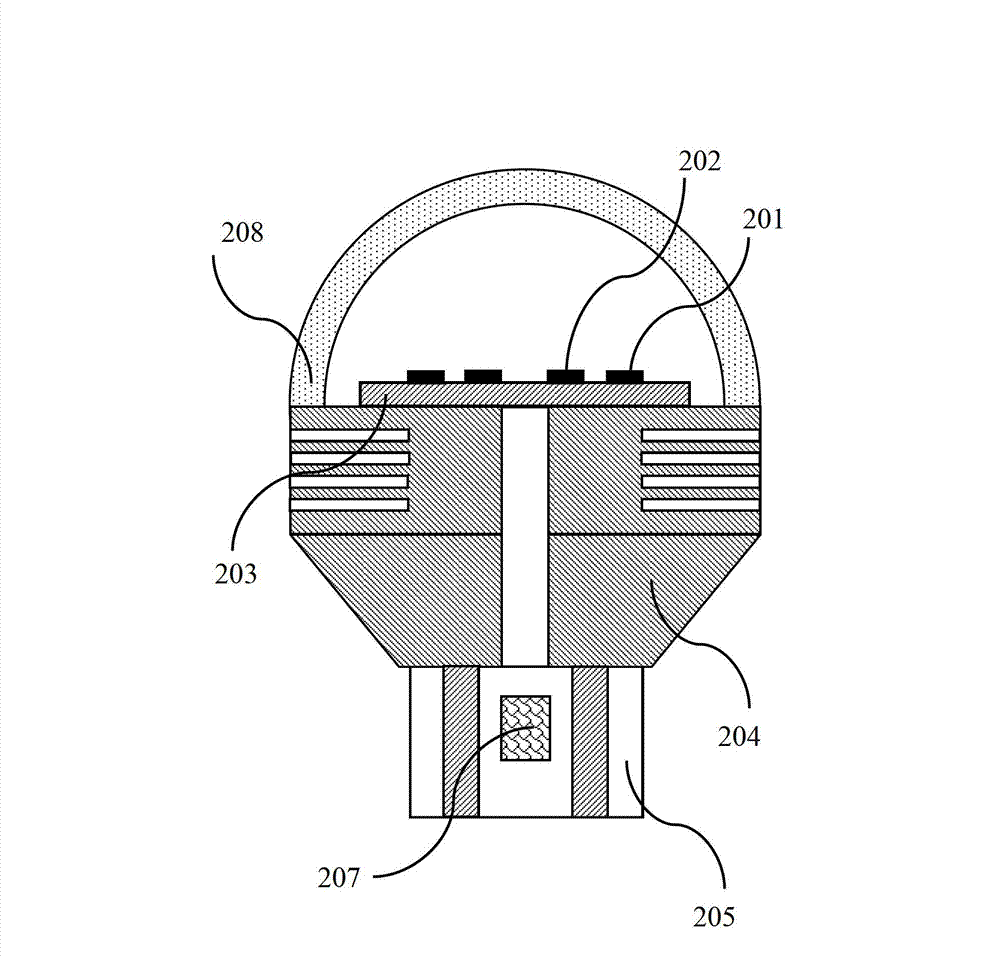

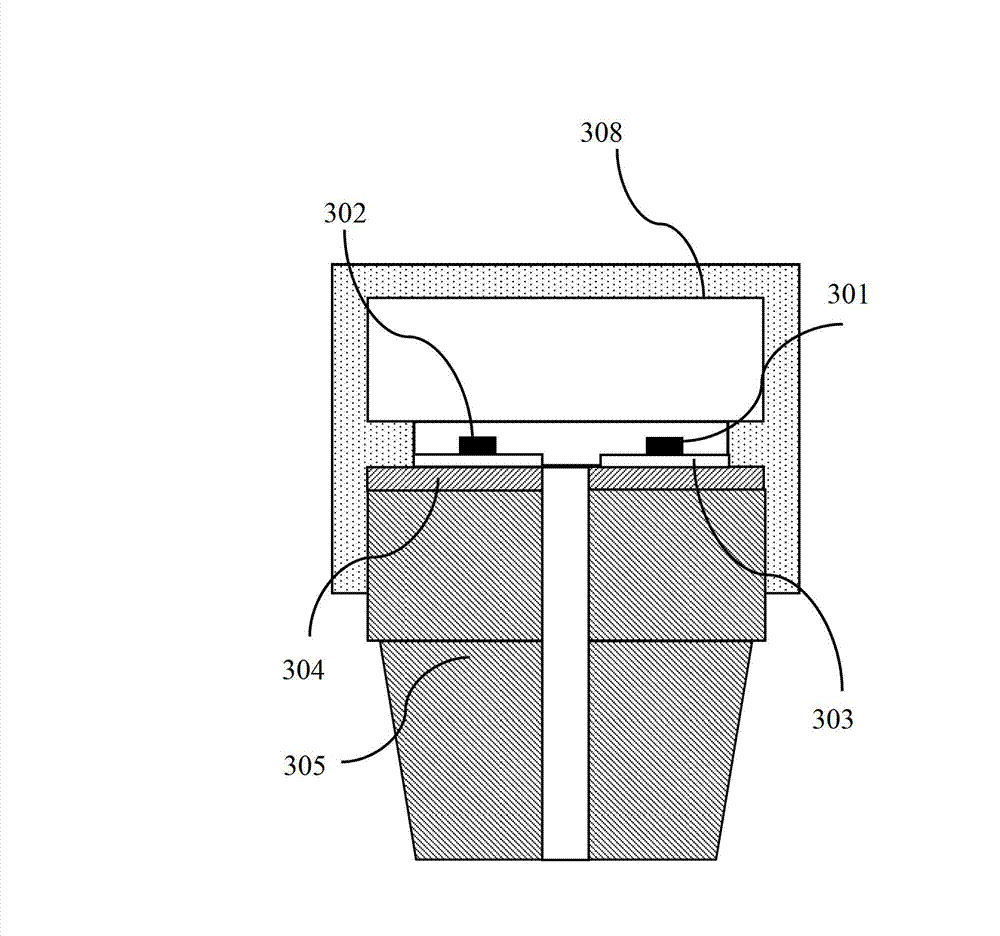

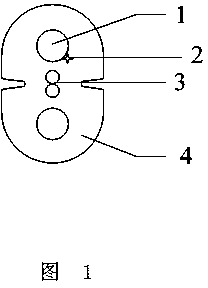

LED (Light Emitting Diode) bulb structure

InactiveCN103032722ASimple structureEasy to manufacturePoint-like light sourceLighting heating/cooling arrangementsEngineeringLight head

The invention relates to an LED (Light Emitting Diode) bulb structure which is characterized by comprising at least one substrate, at least one heat conductive liner arranged on at least one surface of the substrate, a radiator, at least one LED light source conductively arranged one surface of the heat conductive liner, at least one lamp hood covering the periphery of the LED light source, a heat conductive structure, an installation lamp holder, and a drive power supply which supplies power to the LED light source and / or a control circuit which controls the LED light source. The substrate separates the heat conductive liner from the radiator, and transfers heat of the heat conductive liner to the radiator through the heat conductive structure. The heated, heat conductive and radiating path is formed by the heat conductive liner, the heat conductive structure and the radiator provided by the invention has the advantages of good heated, heat conductive and radiating effects. In addition, the substrate separates the heat conductive liner from the radiator, so that the insulating system formed has the advantages of simple structure, convenience in manufacturing, low cost, and good insulating performance.

Owner:李刚

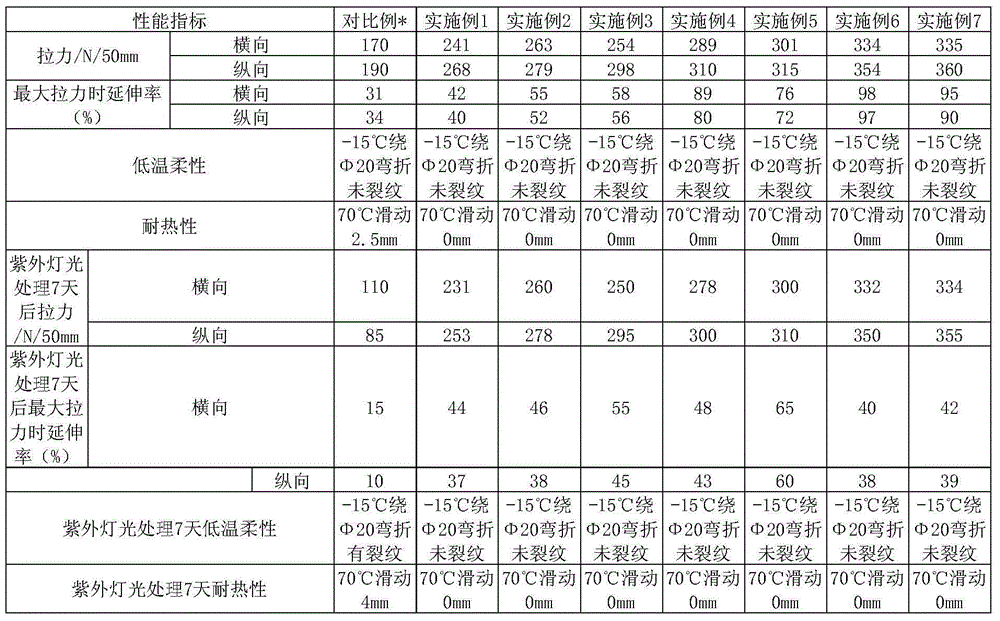

Super weather-proof composite waterproof roll material

InactiveCN104553185AWith super weather resistanceResistant to UV radiationLamination ancillary operationsSynthetic resin layered productsHigh resistanceEnvironmental resistance

The invention relates to the field of waterproof roll materials, and particularly relates to a super weather-proof composite waterproof roll material. The super weather-proof composite waterproof roll material comprises a bonding and sealing adhesive layer and an isolating film protection layer, and also comprises a super weather-proof polymeric film layer, wherein the super weather-proof polymeric film layer, the bonding and sealing adhesive layer and the isolating film protection layer are sequentially arranged from top to bottom and are adhered into a whole in a hot pressing way. The hot pressing temperature is 30 to 220 DEG C, includes but is not limited to 30 to 220 DEG C, and can be adjusted according to factors such as specific production equipment and a hot pressing technology. The bonding and sealing adhesive layer is compounded with the a super weather-proof polymeric film structure, so that the structure has high environmental resistance, corrosion resistance, high strength and high toughness, good dimensional stability, and high impact resistance and puncture resistance, does not need to be protected by cement and mortar, and can be constructed in various environments.

Owner:HANGZHOU FUMO NEW MATERIAL TECH

Ginkgo leaf extracting technology and ginkgo black tea processing method

InactiveCN102630776ASuitable for selectionPreserve the flavorPre-extraction tea treatmentGlucose highGinkgo biloba

The invention discloses a ginkgo leaf extracting technology and a ginkgo black tea processing method. The ginkgo black tea processing method is characterized in that ginkgo leaf is extracted to obtain juice concentrate, and then the juice concentrate and black tea are prepared into ginkgo black tea, wherein the mass ratio of the ginkgo leaf juice concentrate to black tea is 1:20-30. The processing method comprises the following steps of: evenly spraying the ginkgo leaf juice on the black tea in proportion so that the juice is sufficiently and evenly absorbed; carrying out thermostatic drying at the temperature of 55 DEG C+ / -2 DEG C till the water content is less than 5%; and carrying out vacuum package to obtain a ginkgo leaf black tea product. Or the processing method comprises the following steps of: smashing black tea into 10-30-mesh powder; mixing with the ginkgo leaf juice in proportion so that the juice is sufficiently and evenly absorbed; carrying out thermostatic drying at the temperature of 50 DEG C+ / -2 DEG C till the water content is less than 4%; and packing with bagged tea packing paper to obtain a bagged ginkgo black tea product, wherein each bag is 2.5-5.0g. The tea product provided by the invention is high in the content of tea polysaccharide, high in activity and more suitable for the patients who suffer from hyperlipidemia and hyperglycemia, and has more obvious effect of restraining the increase of abdominal fat as compared with other tea products.

Owner:徐州绿之野生物食品有限公司 +1

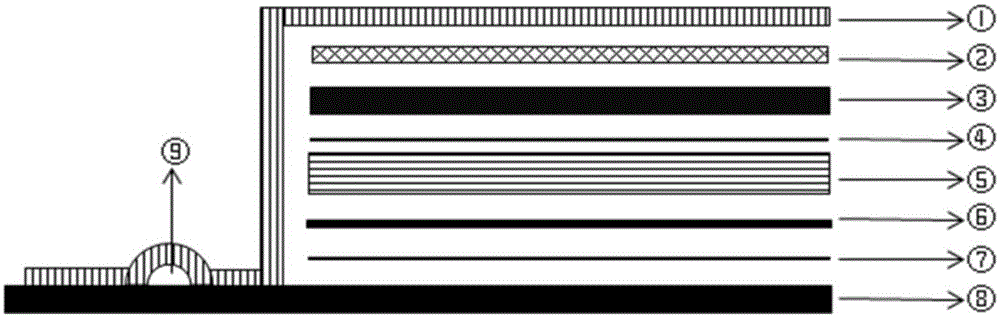

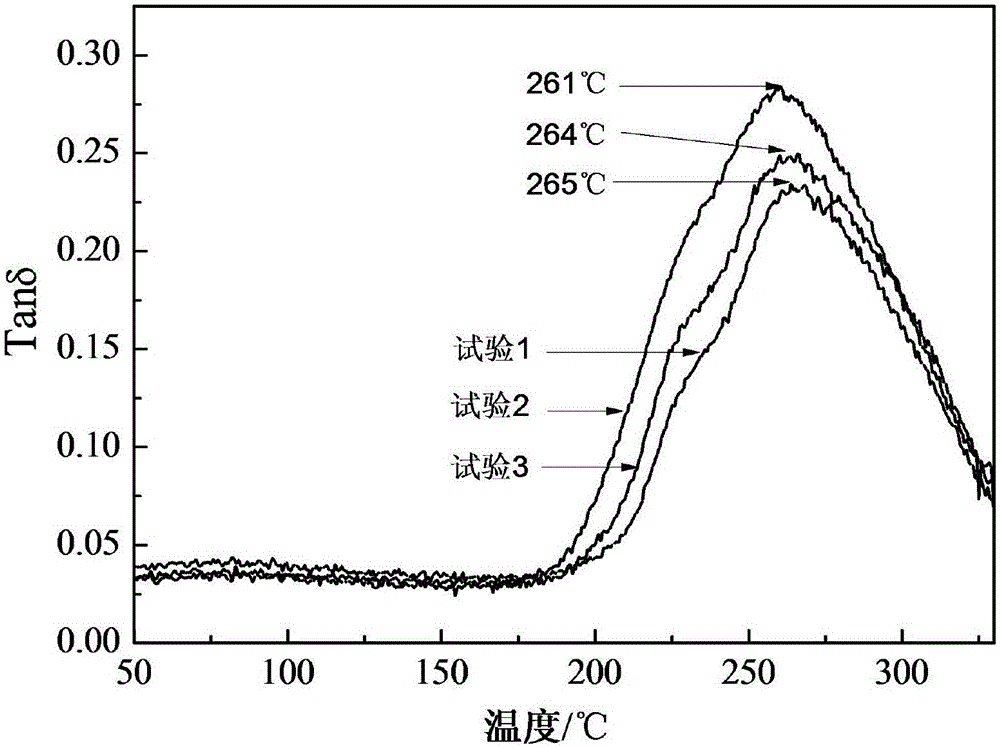

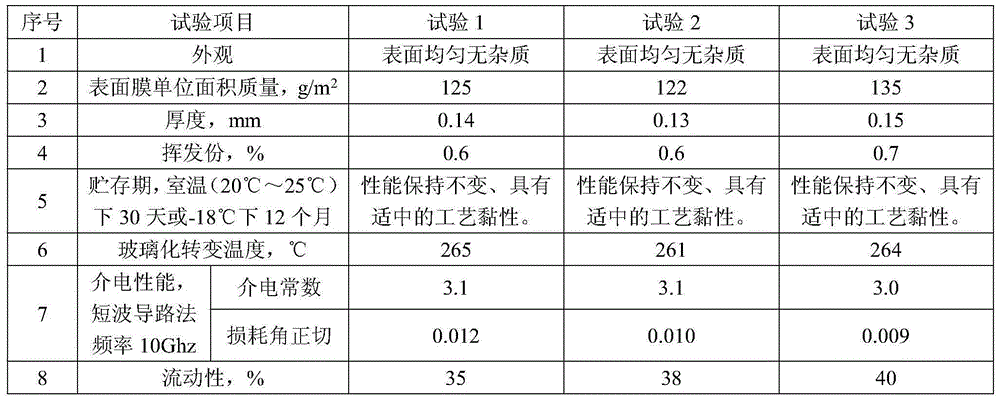

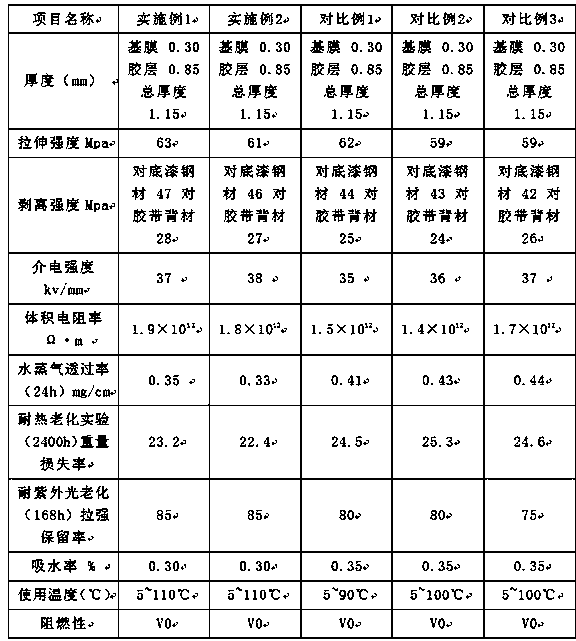

Modified cyanate ester resin surface film and preparation method thereof

ActiveCN105131827ALow dielectric constantImprove the bonding strength of the interfaceCoatingsAdhesiveToughening

The invention provides a modified cyanate ester resin surface film and a preparation method thereof, relates to a resin surface film and a preparation method thereof, and solves the problems that an existing epoxy composite surface film and cyanate ester resin prepreg are not matched well, as a result, the curing temperature is inconsistent, the long-term working service temperature is low, the dielectric property of a workpiece cannot meet the standard and the like. The cyanate ester resin surface film comprises cyanate ester resin, a polymerization process modifier, a toughening modifier, a curing accelerator, a coupling agent, inorganic filler, UV (ultraviolet) stabilizer and a carrier. The preparation method of the cyanate ester resin surface film comprises steps as follows: cyanate ester resin and the modifier are kneaded, and copolymerized and modified cyanate ester resin is obtained; the toughening modifier, the coupling agent, the inorganic filler and the UV stabilizer are added and mixed, and a modified cyanate ester resin surface film adhesive is obtained; a three-roller rotating coating film making machine is adopted for film forming. The modified cyanate ester resin surface film is used for improving the surface quality of a cyanate ester resin composite structural member.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

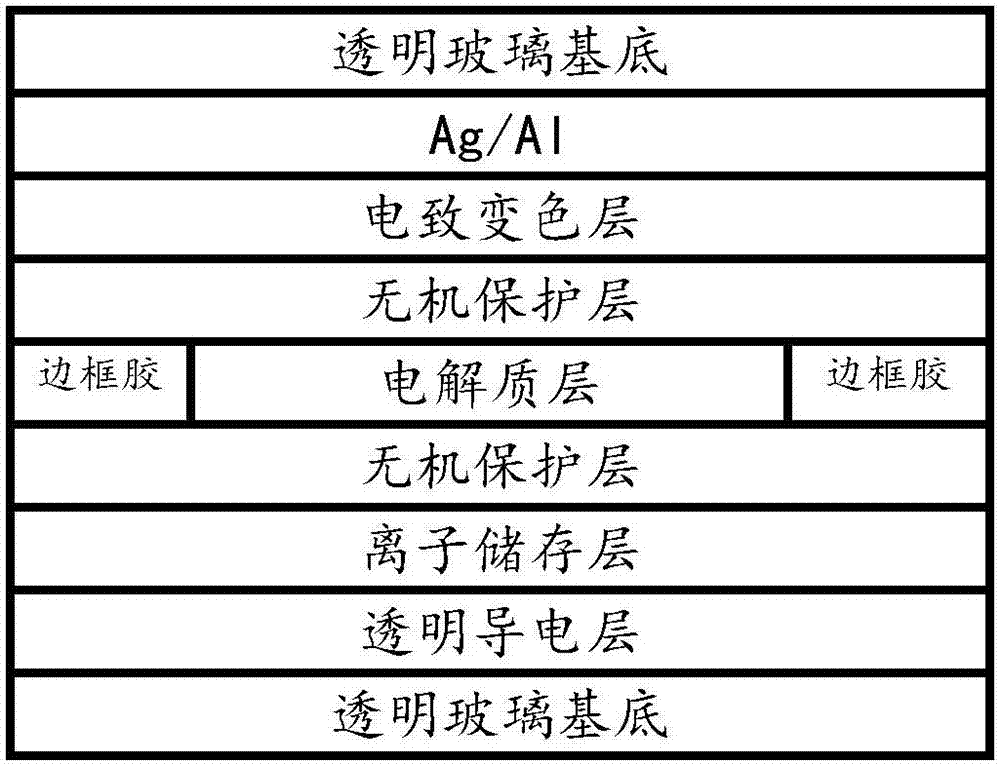

Electrochromic device and application thereof in field of rearview mirror preparation

InactiveCN106896612AResistant to UV radiationUniform discolorationNon-linear opticsOptical viewingChemistryRear-view mirror

The invention relates to the field of electrochromism and particularly relates to an organic silicon modified acrylate based electrochromic device and application thereof in the field of rearview mirror preparation. The electrochromic device comprises an electrolyte layer, and the electrolyte layer is formed by organic silicon modified gel electrolyte available for ultraviolet curing and border adhesives used for packaging devices surrounding the gel electrolyte. The electrochromic device has advantages of cheapness, high conductivity, high response speed, solar radiation resistance, high permeability and the like, and a preparation process is simple. Electrochromic rearview mirrors manufactured by adoption of the electrochromic device are high in electrochromic speed, uniform in electrochromism and high in cycling stability and have a promising application prospect in the field of automobile rearview mirrors.

Owner:JISHENG PHOTOELECTRIC SHENZHEN CO LTD

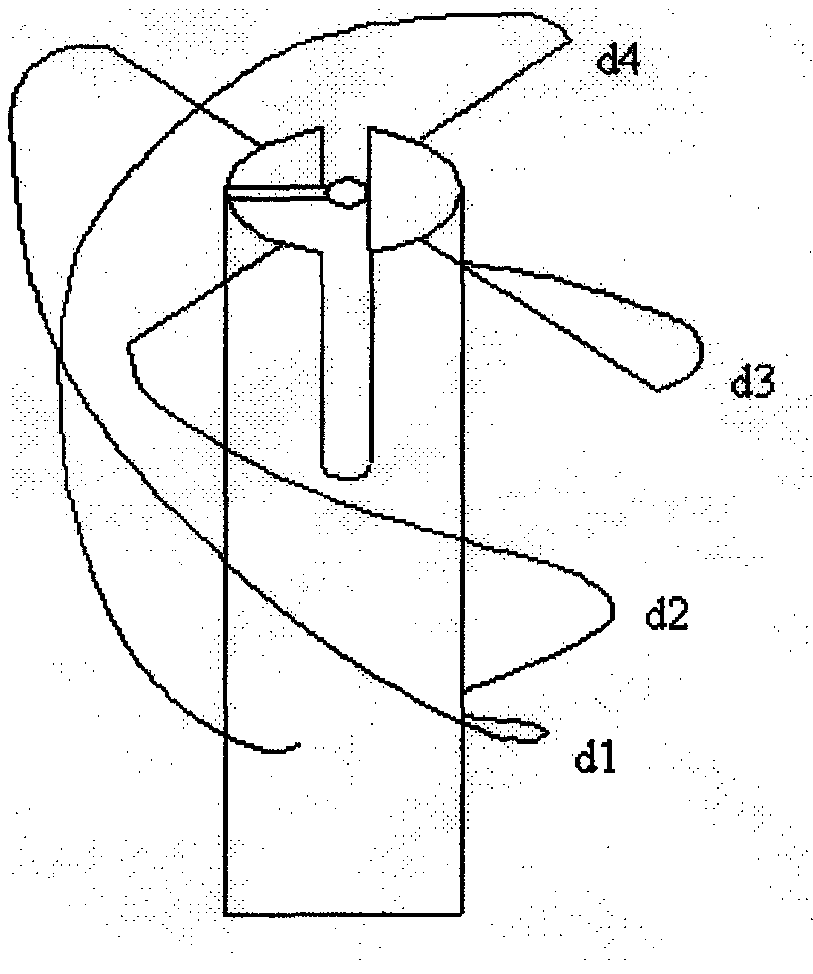

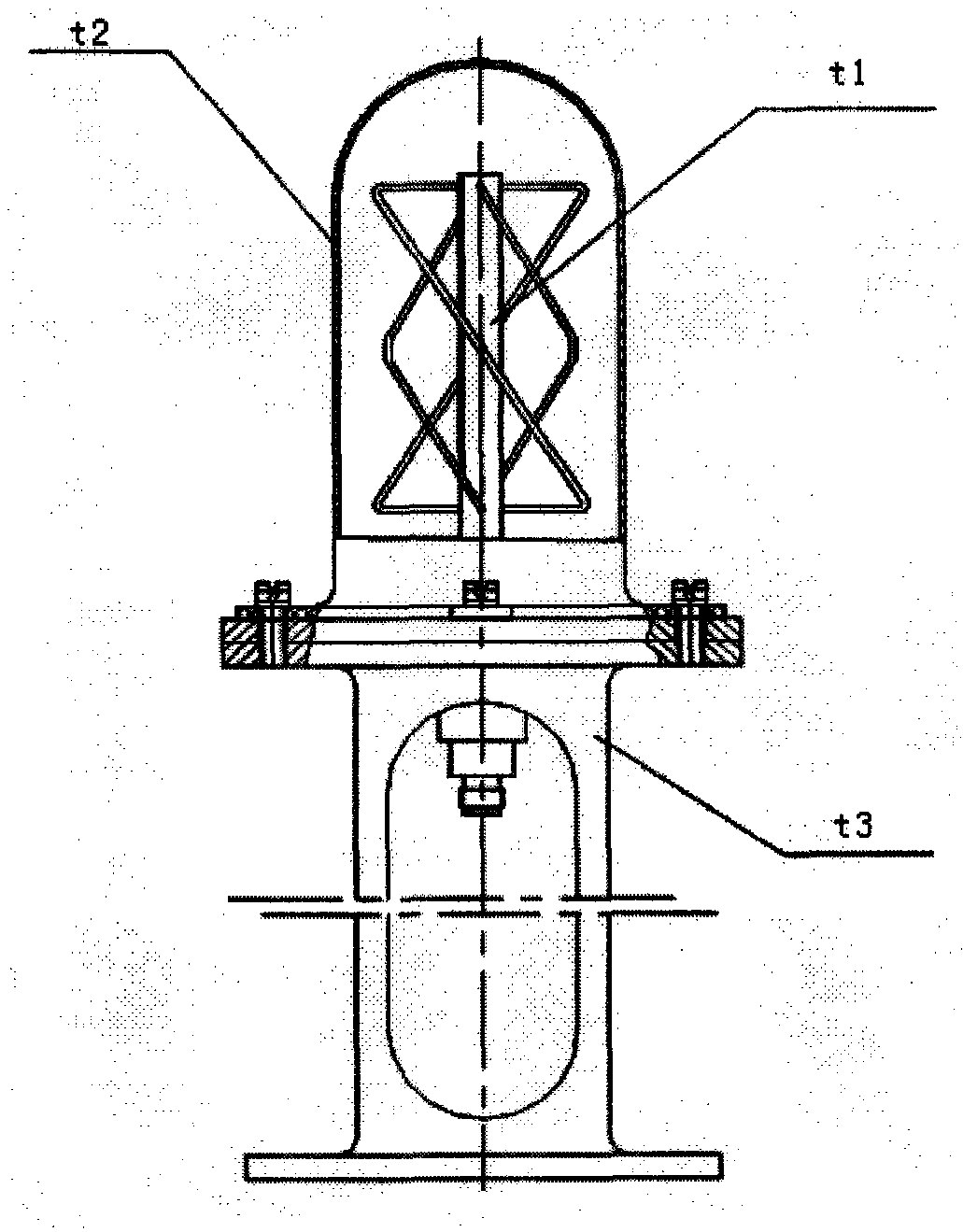

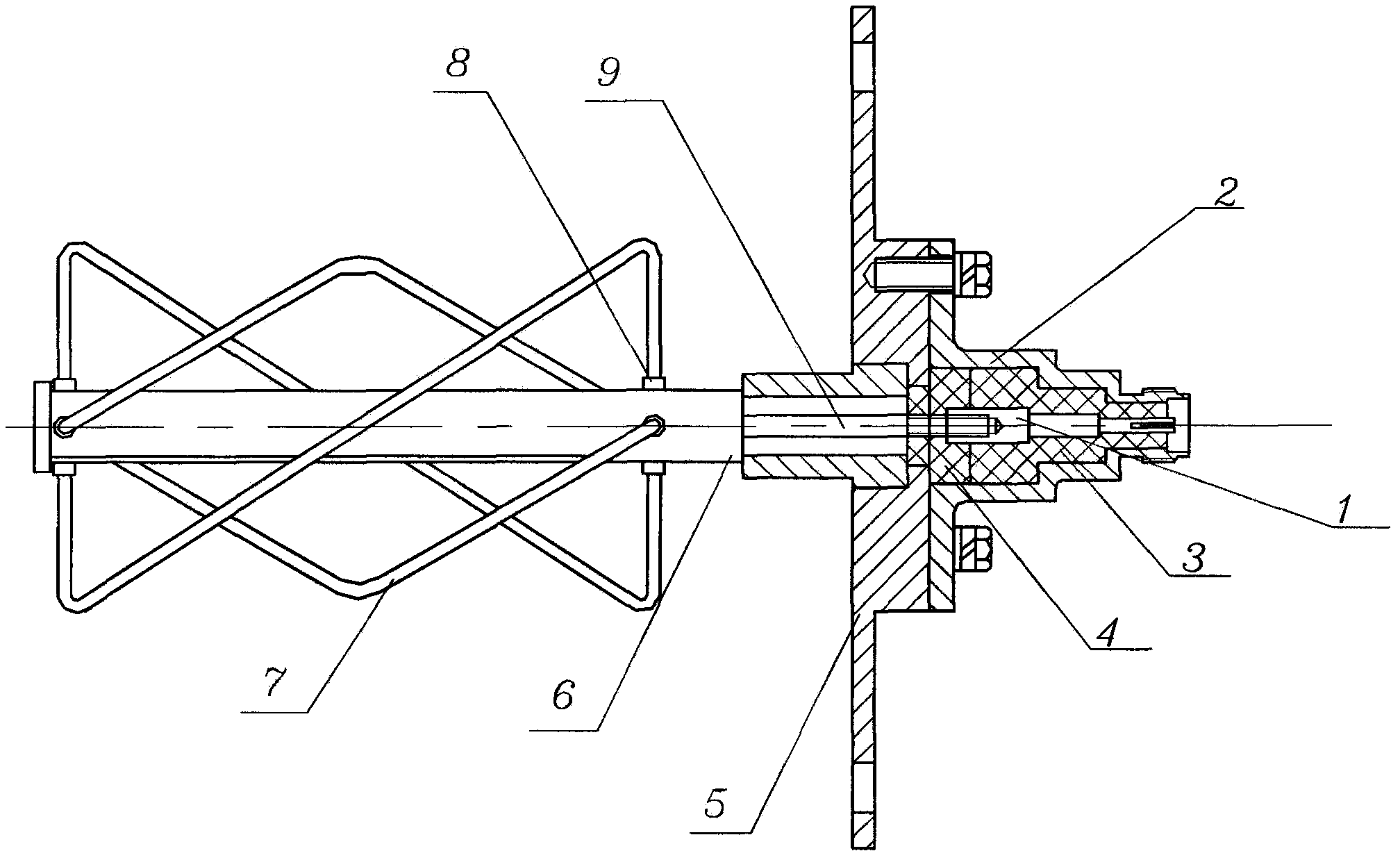

Self-feed four-arm helical gps satellite signal receiving antenna

InactiveCN105659920BCompact structureImprove reliabilityLogperiodic antennasRadiating elements structural formsElectrical conductorSystem structure

The invention discloses a self-feeding four-arm spiral GPS satellite signal receiving antenna, which comprises: a feeding rod, a socket, a dielectric sleeve, a mounting flange, a feeding pipe, a helical wire, an inner conductor; two ends of the helical wire and the feeding pipe Welded together; the rear end of the feed pipe is inserted into the round hole of the mounting flange; the inner conductor located in the center of the feed pipe, the left end is welded on the feed pipe, and the right end is connected to the feed rod through threads; the feed rod rests on the medium in the socket The sleeve is fixed in the socket; the socket is the feed port of the antenna, and the high-frequency cable is connected to feed the antenna. The invention simplifies the system structure and improves the system reliability.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Construction waste recycled pavement brick and preparation method thereof

The invention belongs to the technical field of construction materials and discloses a construction waste recycled pavement brick and a preparation method thereof. The construction waste recycled pavement brick is prepared from, by weight, 20-40 parts of construction waste recycled aggregate, 10-20 parts of a reinforcing agent, 10-16 parts of a water reducing agent, 5-15 parts of talcum powder, 10-20 parts of unsaturated polyester resin, 5-15 parts of clay, 10-20 parts of a hydroxyl silicon seal curing agent, 20-60 parts of coal gangue particles, 20-60 parts of water and 20-30 parts of polyamide. The construction waste recycled pavement brick has advantages of high strength, high abrasion resistance, stable quality, long service life, low cost, waste recyclability, environmental friendliness, energy saving, high economic benefits and extensive social benefits.

Owner:GUILIN CHUNXIAO ENVIRONMENTAL PROTECTION TECH CO LTD

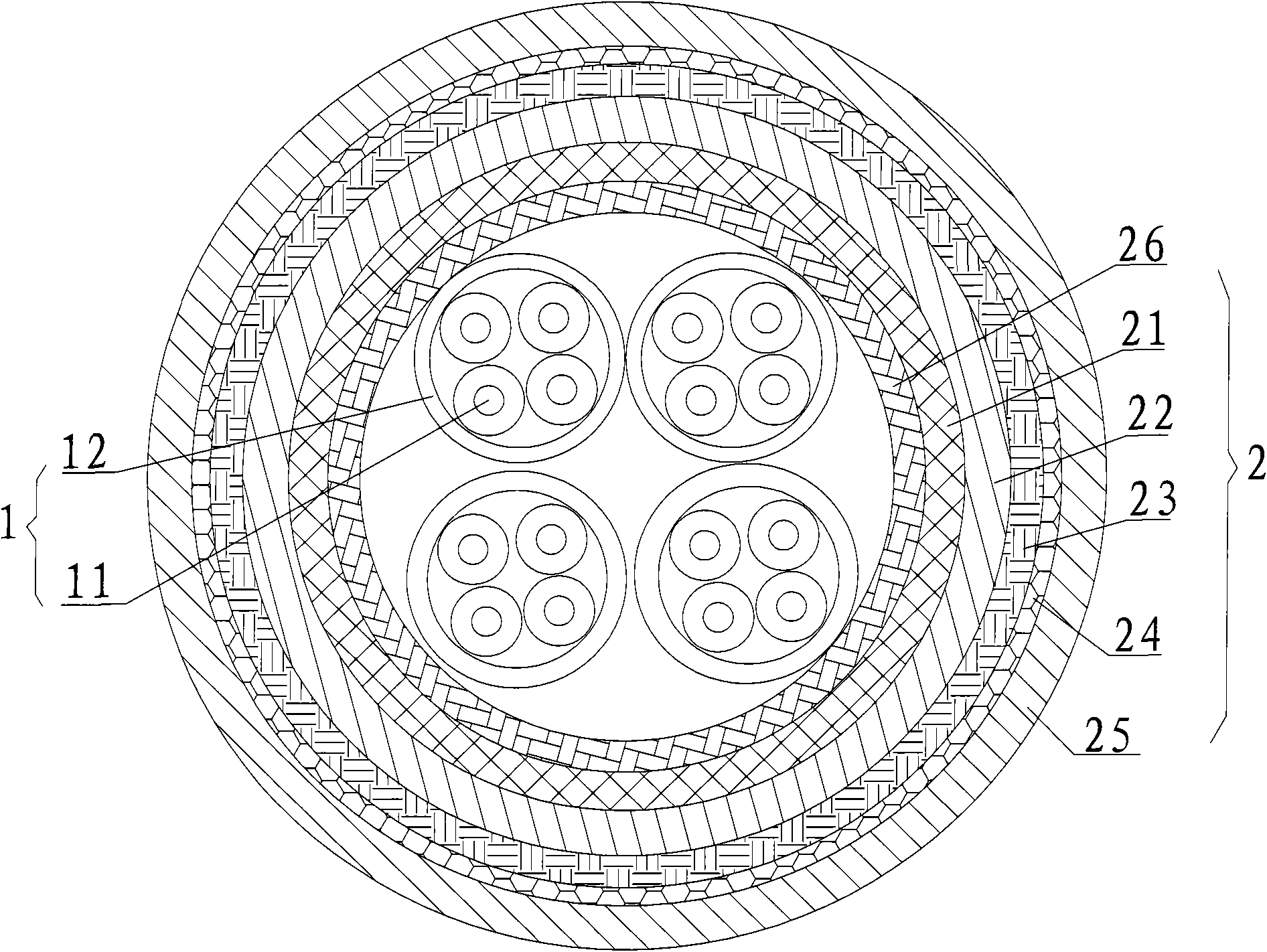

Anti-cracking railway digital signal cable

InactiveCN102110496AExtended service lifeAvoid damageInsulated cablesCommunication cablesDiphenyl etherUltraviolet

The invention relates to an anti-cracking railway digital signal cable which comprises a plurality of cable units and a jacket wrapped at the periphery of the cable units, wherein the jacket sequentially comprises an alloy aluminum protective layer which is longitudinally wrapped and welded at the periphery of the cable units, a high-density polyethylene inner protective layer extruded outside the alloy aluminum protective layer, a steel belt wrapped at the periphery of the high-density polyethylene inner protective layer, a diphenyl ether weftless belt wrapped at the periphery of the steel belt and a high-density polyethylene outer protective layer extruded outside the weftless belt. By using the high-density polyethylene materials as the inner protective layer and the outer protective layer of the cable, the railway digital signal cable has the characteristics of environmental stress crack resistance, low temperature resistance, wear resistance and ultraviolet irradiation resistance, and can be used in all regions. Simultaneously, the diphenyl ether weftless belt is used outside the steel belt, thereby preventing the steel belt from damaging the outer protective layer, and further prolonging the service life of the cable.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

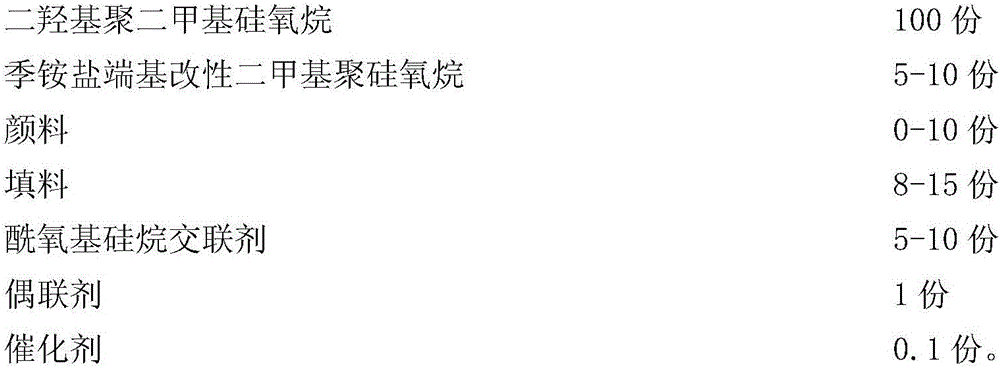

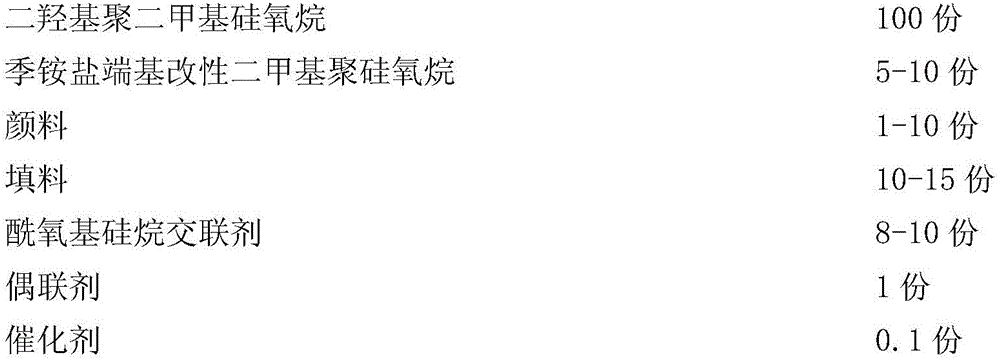

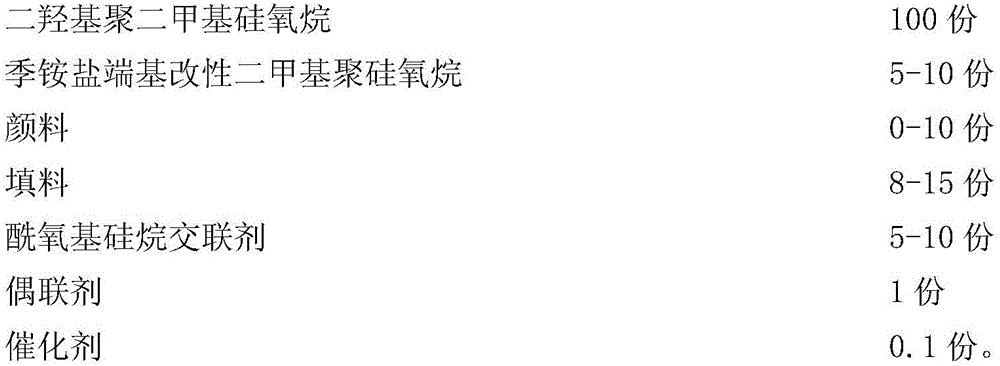

Single-component anti-bacteria anti-yellowing colored silicone sealant for fish tank and preparation method of single-component anti-bacteria anti-yellowing colored silicone sealant

InactiveCN106520061ARich color systemOrnamentalNon-macromolecular adhesive additivesEnd-groupAdhesive

The invention relates to a single-component anti-bacteria anti-yellowing colored silicone sealant for a fish tank and a preparation method of the single-component anti-bacteria anti-yellowing colored silicone sealant. The sealant is composed of, by weight, 100 parts of dihydroxy polydimethyl siloxane, 5-10 parts of quaternary ammonium salt end group modified dimethyl polysiloxane, 0-10 parts of pigments, 8-15 parts of fillers, 5-10 parts of acyloxy silane crosslinking agent, 1 part of coupling agent and 0.1 part of catalyst. By adding the bright-colored pigments, the attractiveness and practicability of the product are improved, and the product is easier to meet the demands of the market. By selection and matching of the viscosity of the 107 adhesive and addition of the coupling agent, a system is further reinforced, the elongation is controlled within a reasonable range, and the adverse effect on the sealant properties due to addition of the pigments is avoided. The method that an original silicone sealant adopts common dimethicone is changed to the method which adopts quaternary ammonium salt end group modified dimethyl polysiloxane so that the silicone sealant for the fish tank can keep colored for a long time, moreover, mildewing and bacteria breeding are not prone to occurring, the sealant is environmentally friendly, and the fish tank can keep clean and attractive for a long time.

Owner:山东宝龙达新材料有限公司

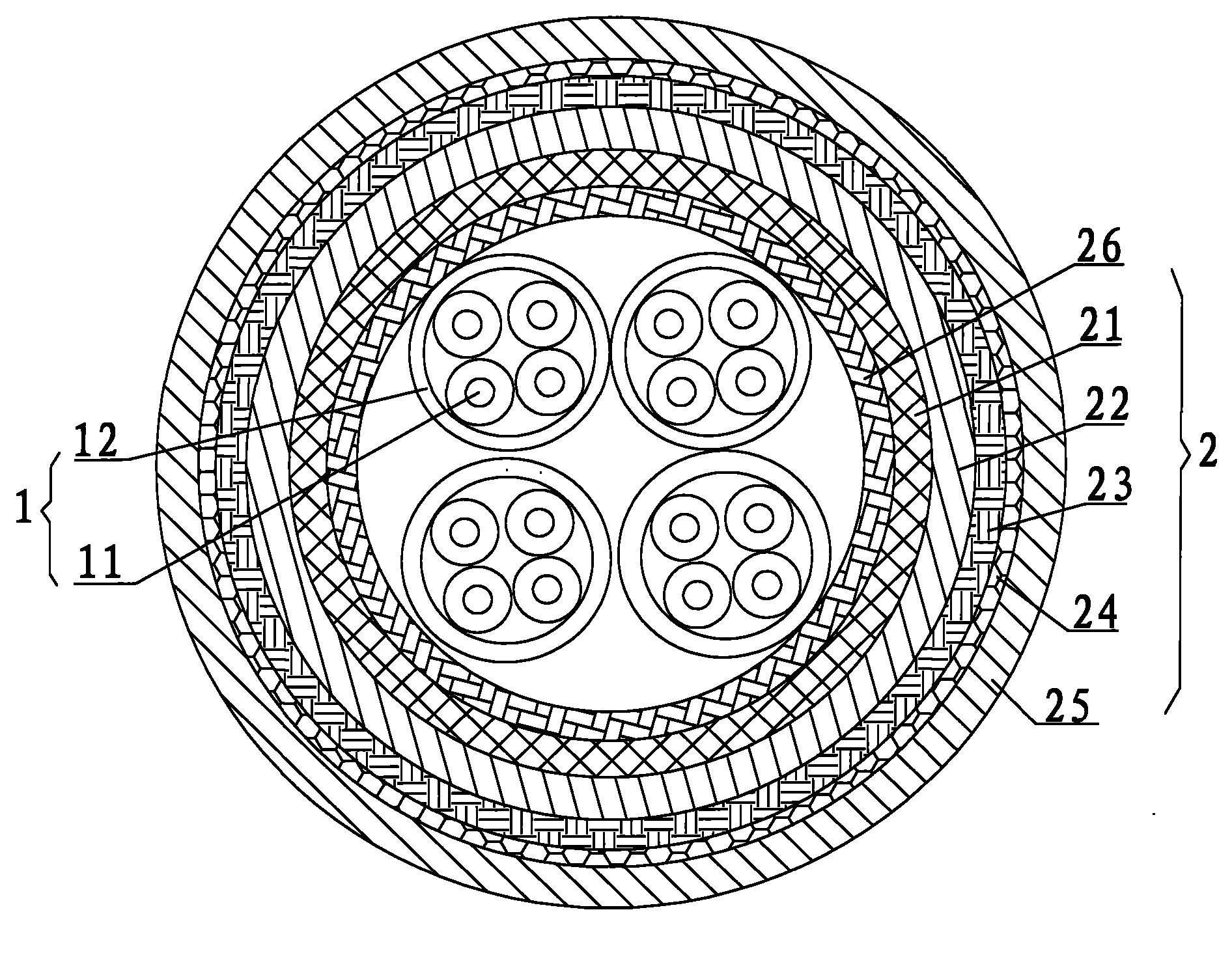

Photoelectric composite cable

InactiveCN103700441AConvenient and anti-bending constructionIncrease the bending resistance coefficientInsulated cablesPower cablesLow smoke zero halogenElectrical conductor

The invention relates to a photoelectric cable and particularly relates to a photoelectric composite cable which mainly comprises optical fibers, conductors, a conductor identification rope and a sheath. The sheath is in the shape of a butterfly and made of low-smoke halogen-free polyethylene material; the number of the conductors is two, and the two conductors are respectively positioned at the centers on the two sides of the butterfly shape and made of copper. The optical fibers are positioned at the center of the butterfly-shape part, can comprise 1 core or 2 cores or 4 cores and are of full-dry type structures. The photoelectric composite cable has the beneficial effects that a variety of power utilization requirements and signal transmission requirements of equipment can be solved once, the space of a pipeline is saved, the cost is reduced, and the installation is facilitated. Furthermore, the full-dry type structure is adopted for the photoelectric composite cable provided by the invention, relative sliding between all elements and the sheath can be avoided, the sheath is soft, the optical fibers are bending-resistant and the construction is convenient; the conductors adopt bunch strand and single conductor ways, so that the flexibility is good; the G.657 optical fiber is adopted for the optical fibers to increase the flexural coefficient of the composite cable; by using the conductor identification rope, a neutral wire and a live wire can be identified; the sheath has the advantages of resisting ultraviolet radiation, prolonging the service life, realizing insulation performance and the like.

Owner:肖国华

Uvioresistant plastic for outdoor use

An uvioresistant plastic for outdoor use is prepared from the following raw materials in parts by weight: 1-2 parts of a lubricating agent, 8-13 parts of aluminium hydroxide, 10-15 parts of a plasticizer, 3-9 parts of antimonous oxide, 4-5 parts of triphenyl phosphite, 2-3 parts of chromium oxide, 1-3 parts of a dripping agent, 2-4 parts of acetyl citrate, 3-6 parts of a colorant, 2-6 parts of barium stearate, 10-21 parts of polyimide resin, 1-3 parts of tetraethylthiuram disulfide, 2-5 parts of stearic acid, 5-6 parts of a coupling agent, 2-5 parts of glass fiber and 4-7 parts of an anti-ultraviolet agent. The uvioresistant plastic for outdoor use, provided by the invention, has the benefits that the plastic is high temperature resistant and has fire-resistance, chromaticity, anti-ultraviolet function and inoxidizability.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

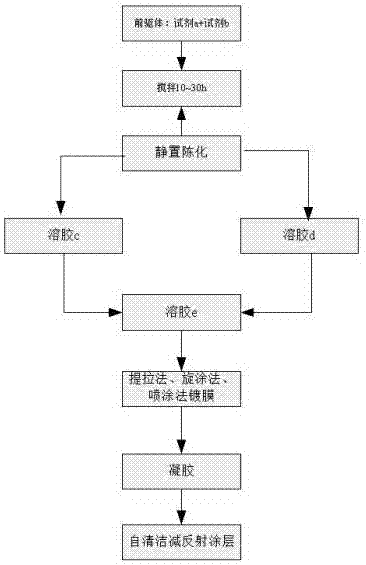

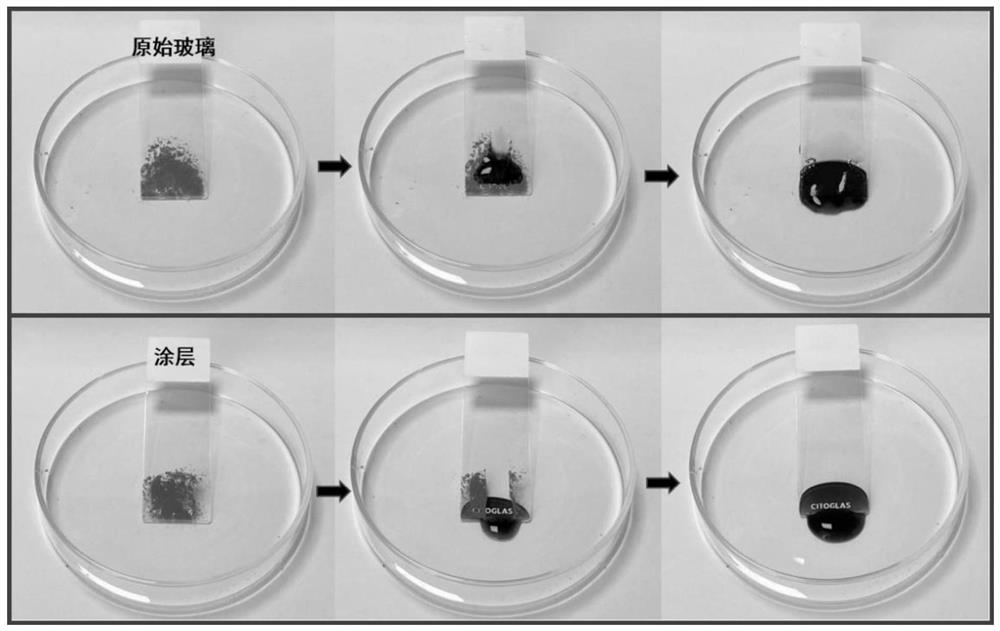

Self-cleaning antireflection coating and preparation method thereof

InactiveCN106928759AImprove anti-reflection effectEasy to prepareFireproof paintsPretreated surfacesEngineeringTemperature resistance

The invention discloses a self-cleaning antireflection coating and a preparation method thereof. The contact angle of the self-cleaning anti-reflection coating is >150°, and the rolling angle is <10°. Mirrors and photovoltaic panels have self-cleaning properties. On the basis of greatly improving the system efficiency of solar thermal collectors and photovoltaic panels, they can greatly improve their environmental adaptability, weather resistance and service life; at the same time, they can also greatly reduce The operation and maintenance cost of the power station, the preparation method of the self-cleaning anti-reflection coating is simple, the requirement for the shape of the substrate is low, the cost is low, and it is non-toxic and non-polluting; the self-cleaning anti-reflection coating has excellent high temperature resistance and can withstand 400 °C Above high temperature, it also has acid and alkali corrosion resistance, cold and heat shock resistance, ultraviolet radiation resistance, and its hardness and wear resistance are high.

Owner:CANGZHOU TRX SOLAR TECH

Production method of elastic fiber

InactiveCN103046152AChlorine resistantResistant to UV radiationFilament forming substance formingArtificial thread manufacturing machinesPolypropyleneMethods of production

Owner:CHANGSHU CHANGSHENG CLOTHING

Anti-radiation preparation and application thereof

InactiveCN108524352ADownregulation of proliferation rateResistant to UV radiationCosmetic preparationsToilet preparationsAdditive ingredientSkin Care Product

The invention relates to an anti-radiation preparation and application thereof, and belongs to the technical field of cosmetics using ingredients as features or similar preparations for makeup. The anti-radiation preparation is prepared from pearl essence extracts and green tea extracts through being compounded with water. The concentration of a solution formed by compounding the materials is 0.1to 8.0mg / ml; in addition, the addition ratio of the pearl essence extracts to the green tea extracts is (0 to 1):(1 to 0). The anti-radiation preparation has the advantages of good anti-radiation effect, high safety and the like when being applied to capsule medicine, skin care products or cosmetics.

Owner:SHAOXING UNIVERSITY

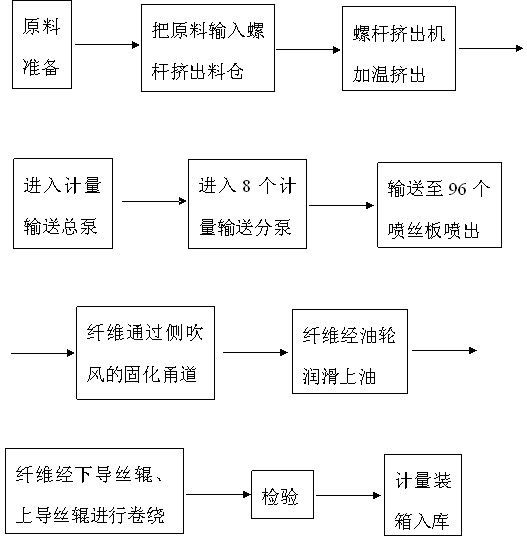

Method for producing thermoplastic elastic fibers

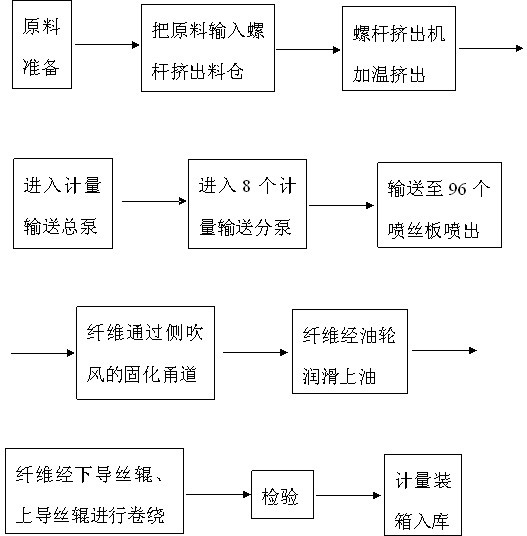

InactiveCN102660788ARaise the gradeImprove product qualityFilament forming substance formingSpinning head liquid feederFiberThermoplastic elastomer

The invention relates to a method for producing thermoplastic elastic fibers. The method comprises the following steps of: 1, preparing thermoplastic elastomers serving as raw materials; 2, conveying the raw materials into a feed bin of a screw extruder; 3, extruding melt materials from the raw materials in the feed bin of the screw extruder at four different heating temperature areas in the screw extruder; 4, conveying the extruded melt materials into a metering conveying total pump to perform metering conveying by a pipeline in a spinning box; 5, conveying sprayed fibers to a curing passageway; 6, winding the fibers by using a winder at the winding speed of 650 meters / minute; 7, detecting; and metering and boxing for warehousing. The method has the advantages that a production process is simple, short in flow and low in production energy consumption, and non-pollution discharge is realized during production; the products have the performance of chlorine resistance, ultraviolet radiation resistance, acid resistance, alkali resistance, abrasion resistance, high air permeability and the like, the quality of the products is superior to that of products of BASF in Germany and Dupont in America, and the price is 30 to 40 percent lower than that of the products of BASF and Dupont; the grade of textile industry, clothing industry and industry of industrial elastic fibers and the like is improved, and the products are upgraded.

Owner:苏立平

Flexible heat-resistant ultraviolet-aging-resistant high-efficiency light-emitting high polymer material and preparation method thereof

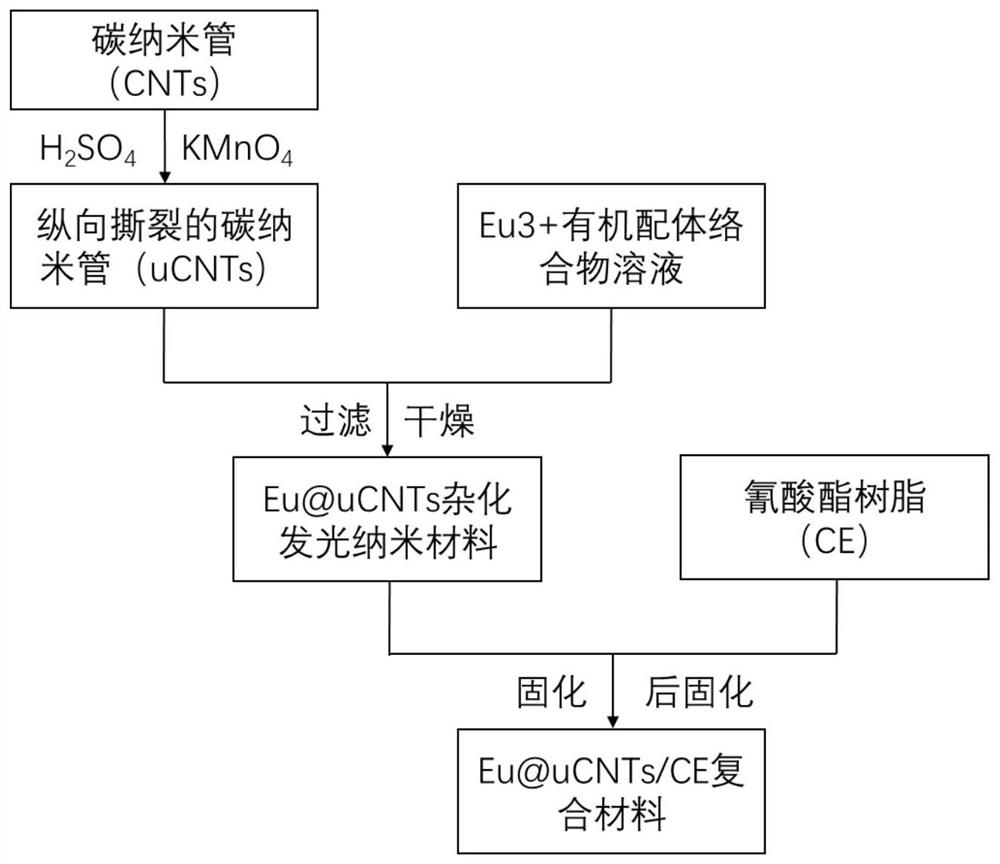

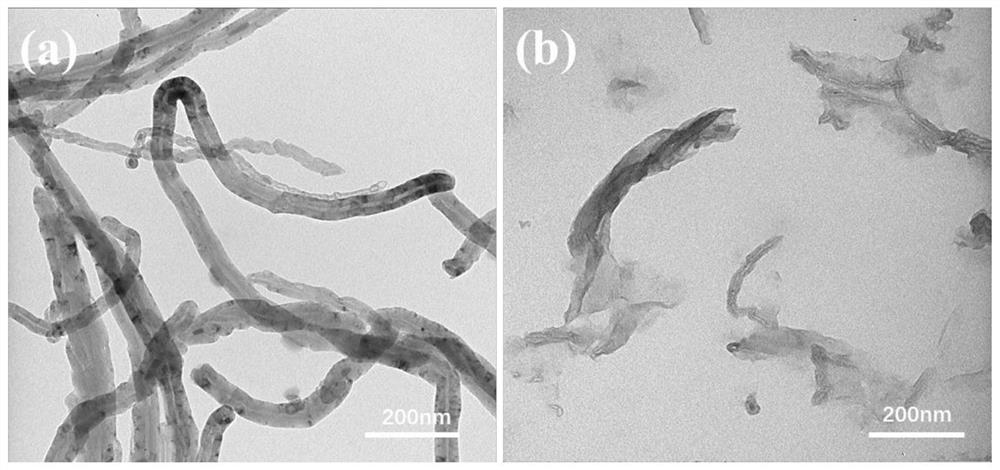

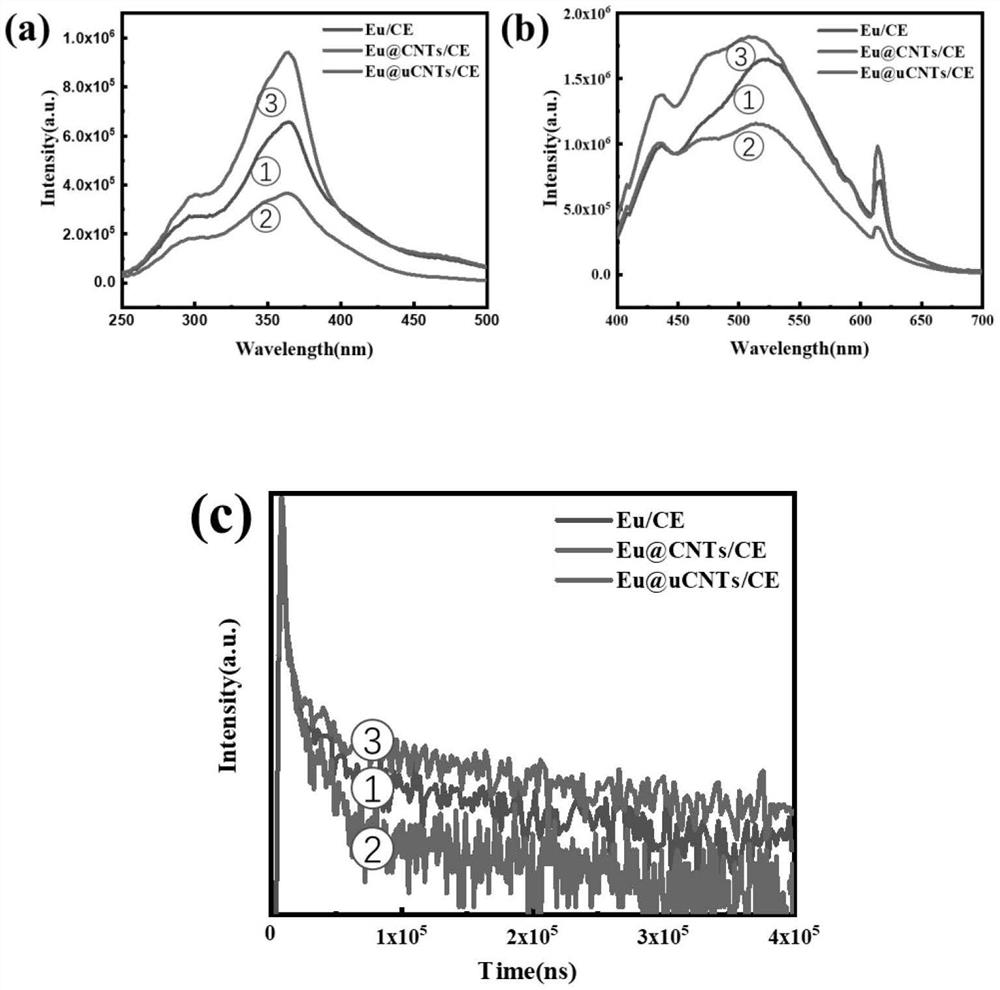

The invention discloses a flexible heat-resistant ultraviolet-aging-resistant efficient light-emitting high polymer material and a preparation method thereof, and the preparation method comprises the following steps: (1) performing oxidation unzipping on a carbon nano tube, and longitudinally tearing and cutting to open the wall of the carbon nano tube to obtain an unzipped carbon nano tube; (2) adding a phen solution, an EuCl3 solution and a TTA solution into the unzipped carbon nanotubes for compounding, and obtaining the luminescent nano material Eu@uCNTs; and (3) adding the Eu@uCNTs luminescent nano material into a cyanate resin monomer, uniformly stirring, pouring into a mold, and carrying out gradient heating curing-obtain the polycyanate hybrid luminescent composite material. According to the invention, based on the heat resistance and chemical reagent resistance of cyanate ester, the preparation of the heat-resistant and ultraviolet-aging-resistant high-efficiency luminescent high polymer material is realized by combining with a longitudinal unzipping carbon nanotube luminescent technology. It can be foreseen that the high-temperature-resistant and ultraviolet-aging-resistant polymer hybrid luminescent material will be widely applied to the fields of sensing, detection, hazard prediction and the like.

Owner:QINGDAO UNIV

Environmental-friendly ultraviolet-resistant sheath material and cable

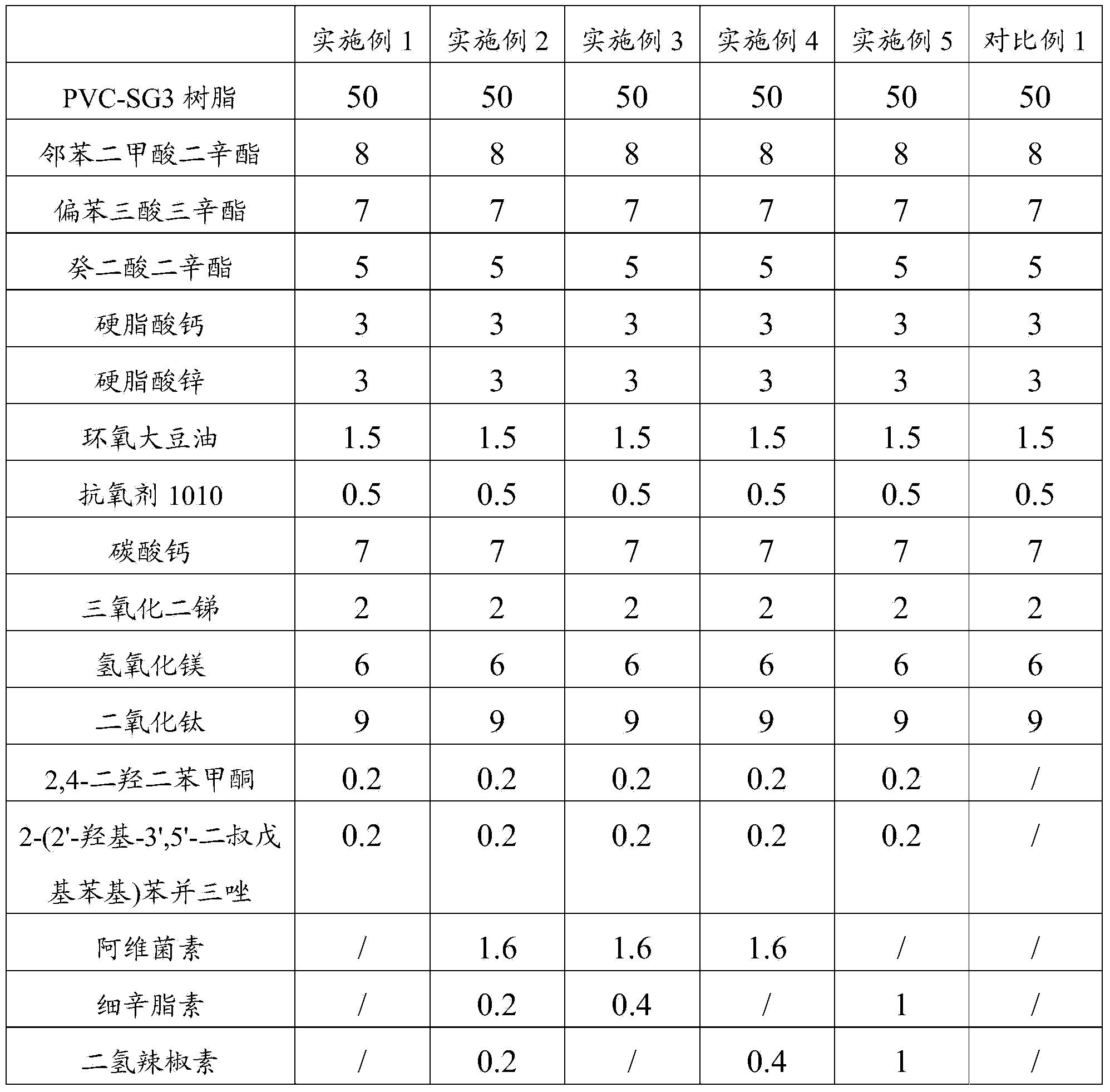

The invention discloses an environmental-friendly ultraviolet-resistant sheath material and a cable. The sheath material comprises following raw materials by weight: 50 parts of PVC resin, 6-10 parts of dioctyl phthalate, 4-10 parts of trioctyl trimellitate, 4-6 parts of dioctyl sebacate, 2-4 parts of calcium stearate, 2-4 parts of zinc stearate, 0.5-2.5 parts of epoxy soybean oil, 0.2-0.8 part of an anti-oxidant, 4-10 parts of calcium carbonate, 1-3 parts of antimony oxide, 4-8 parts of magnesium hydroxide, 8-10 parts of titanium dioxide, 0.1-0.3 part of 2,4-dihydroxybenzophenone and 0.1-0.3 part of 2-(2H-benzotriazol-2-yl)-4,6-bis(1,1-dimethylpropyl)-phenol. The sheath material has characteristics of good solarization resistance, good insulation properties and good shaping and processing properties.

Owner:广东金胜电缆有限公司

Preparation method of whitening toner

InactiveCN106852873AStrong antioxidantGood antibacterial effectCosmetic preparationsToilet preparationsVitamin CPropolis

The invention relates to a preparation method of whitening toner. The invention is based on arbutin, glabridin, licorice flavonoids, licorice flavonoids liquid, apple extract, dipotassium glycyrrhizic acid salt, cactus extract, tranexamic acid, aloe extract, yeast extract, rhodiola rosea extract , Honeysuckle Extract, Horse Chestnut Extract, Propolis Extract, Grape Seed Extract, Atractylodes Rhizome Extract, Gynostemma Gynostemma Extract, Kochia Seed Extract, Luffa Extract, Clove Extract, Pearl Hydrolyzate, Glabridin Solution , vitamin C, 100% hyaluronic acid stock solution, hyaluronic acid powder, polyglutamic acid powder, Luba oil, imported water-soluble olive oil, oligomeric hyaluronic acid, trehalose, fragrance, and water are mixed to form a whitening toner. Moisturizes the skin and prevents dryness and cracking of the skin, accelerates yellowing and depigmentation, so as to achieve the effect of nourishing and moisturizing the skin and whitening the skin.

Owner:CHANGSHA XIEHAOJI BIOENG CO LTD

Antioxidant whitening cream containing dandelion and tea extract and preparation method of antioxidant whitening cream

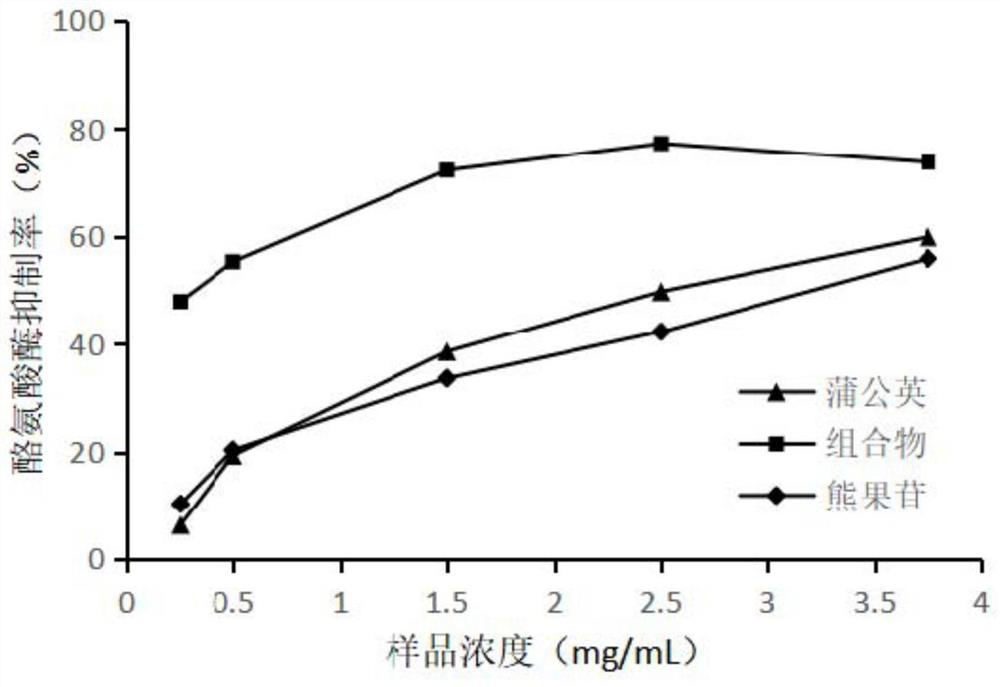

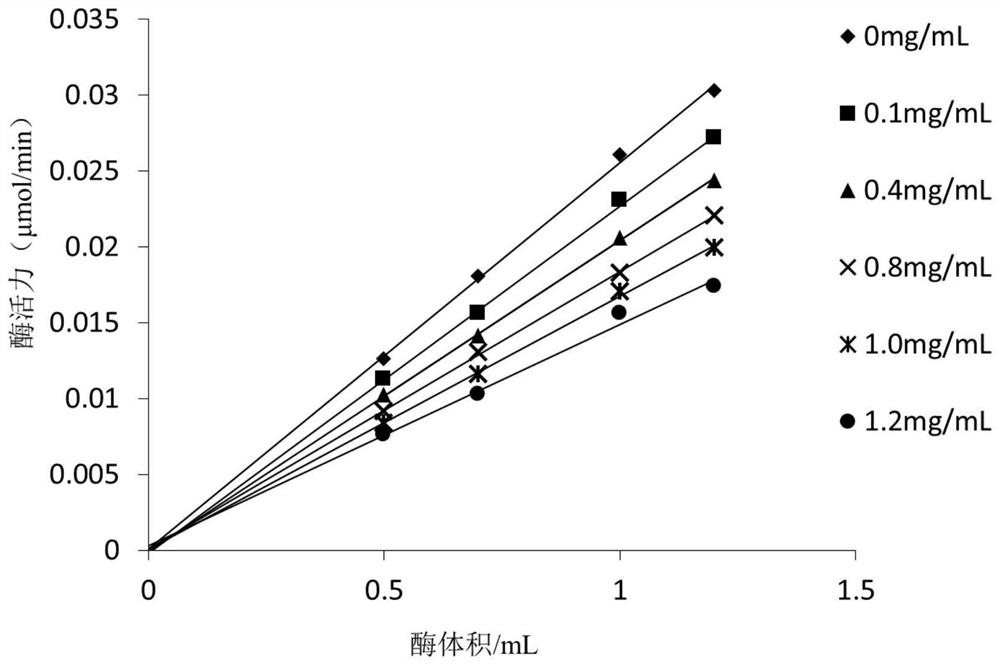

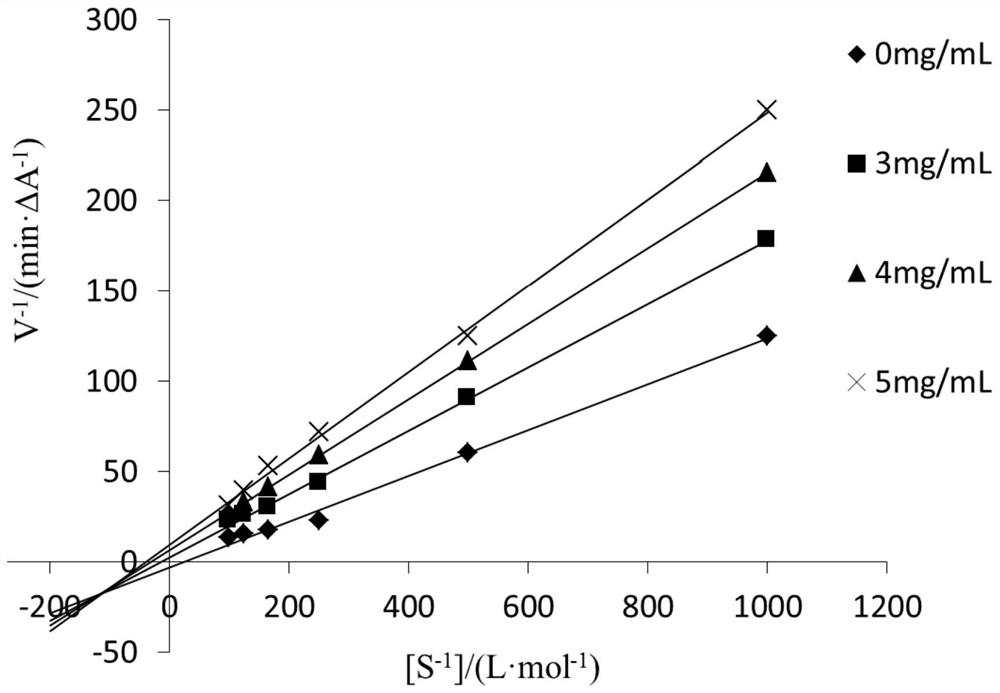

ActiveCN112006959AEnhanced inhibitory effectImprove cleanlinessCosmetic preparationsAntipyreticBiotechnologyTyrosine

The invention relates to antioxidant whitening cream containing dandelion and tea extract and a preparation method of the antioxidant whitening cream. The whitening cream comprises the following components in percentage by mass: 1 to 5 percent of herba taraxaci extract, 1 to 5 percent of tea leaf extract, 3 to 13 percent of auxiliary agent, 4.5 to 14 percent of emulsifying agent, 4 to 16 percent of skin moistening grease, 0.002 to 0.02 percent of thickening agent and the balance of ultrapure water. Compared with the prior art, the dandelion extract and the tea leaf extract are used as functional substances, and the two extracts are compounded according to different proportions, so that the obtained compound has good tyrosinase inhibition activity and antioxidant activity, and can be used as a whitening antioxidant functional component to be applied to cosmetics.

Owner:SHANGHAI INST OF TECH

Antifouling paint, antifouling coating and preparation method thereof

ActiveCN113444430ADoes not affect appearanceDoes not change glossAnti-corrosive paintsPolyurea/polyurethane coatingsMelamine formaldehyde resinP-Toluenesulfonic acid

The invention provides an antifouling paint, an antifouling coating and a preparation method thereof, and relates to the technical field of functional materials. The antifouling paint is prepared from the following raw materials: a hexamethylene diisocyanate tripolymer, amino-terminated polydimethylsiloxane, N, N-dimethylformamide, methylated melamine formaldehyde resin and a p-toluenesulfonic acid aqueous solution. The antifouling paint provided by the invention has the advantages of easily available raw materials, simple preparation method, low cost, no fluoride harmful to the environment, and environmental friendliness; The antifouling paint is wide in application range and can be applied to various types of base materials, and the obtained coating is high in transparency and does not affect the appearance of the base materials. The antifouling coating provided by the invention has wide liquid repellency and good self-cleaning performance, pollutants such as dust on the surface of the coating can be easily washed away by water and some oily liquid drops, and the antifouling coating has the advantages of high transparency, high smoothness, high hardness, flexibility, wear resistance, acid, alkali and salt resistance, corrosion resistance, ultraviolet radiation resistance and good environmental durability.

Owner:LANZHOU UNIVERSITY

Flame-retardant anti-corrosion insulated rubber tape

InactiveCN109054668AImprove adhesionImprove compactnessNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAcrylonitrile

The invention relates to the technical field of rubber tape production, in particular to a flame-retardant anti-corrosion insulated rubber tape. The flame-retardant anti-corrosion insulated rubber tape is composed of a modified polyvinyl chloride base film and an adhesive layer, wherein the adhesive layer is prepared from the following components in parts by weight: butadiene-acrylonitrile rubber,chloride vinegar resin, chloroprene rubber, rosin resin, ethyl acetate, graphite micro powder, dimethyl dimethoxy silicane, stearic acid, diphenyl silanediol, an anti-oxidant and an inorganic filler.The rubber tape is good in adhesion force and compactness, has good tensile strength, good peel strength, chemical corrosion resistance, mildew corrosion resistance, oxidization resistance, is fireproof and flame-retardant; and the adhesive layer can achieve the wateproof effect, so that the insulation property is better.

Owner:阜南县力韦包装材料有限公司

Anticorrosion waterborne aluminum pigment for reinforcing UV reflection ability

InactiveCN106221304AImprove corrosion resistanceGood dispersionPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPhosphateCordierite

The invention discloses an anticorrosion waterborne aluminum pigment for reinforcing UV reflection ability. The pigment is prepared from the following raw materials by weigh: 40-45 parts of flake aluminum powder, 100-110 parts of isopropanol, 0.3-0.35 part of copper sulfate crystal, a proper amount of deionized water, 4-4.5 parts of phenol ether-type phosphate ester, a proepr amount of absolute ethyl alcohol, 9-10 parts of ethyl orthosilicate, 6-7 parts of ethylsiloxane, 9-10 parts of ammonia with concentration of 20wt%, 200-220 parts of butyl acetate, 5-6 parts of acrylic acid, 5-6 parts of methacrylic acid, 0.6-0.65 part of dibenzoyl peroxide, 13-15 parts of propylene glycol monomethyl ether, 0.5-0.6 part of lignocellulose, 0.7-0.8 part of polyethylene pyrrolidone, 4-5 parts of cordierite powder, 3-4 parts of far infrared ceramic powder, 3-4 parts of urea aqueous solution with concentration of 20wt%, and 1.5-2 parts of poly olefin wax. The product has high ultraviolet reflectivity.

Owner:HEFEI SUNRISE PIGMENTS

Construction waste recycled afforesting brick and preparation method thereof

InactiveCN107793117AHigh strengthGood wear resistanceSolid waste managementCoal gangueConstruction aggregate

The invention belongs to the technical field of construction materials and discloses a construction waste recycled afforesting brick and a preparation method thereof. The construction waste recycled pavement brick is prepared from, by weight, 30-50 parts of construction waste recycled aggregate, 5-15 parts of an aggregate modifying agent, 6-16 parts of a gelatinizing agent, 6-12 parts of a water reducing agent, 6-16 parts of coal gangue particles, 6-16 parts of hydroxymethyl propyl cellulose, 6-12 parts of slag, 5-15 parts of bamboo fibers, 20-60 parts of cement and 30-70 parts of water. The construction waste recycled afforesting brick has advantages of high strength, high abrasion resistance, stable quality, long service life, low cost, waste recyclability, environmental friendliness, energy saving, high economic benefits and extensive social benefits.

Owner:GUILIN CHUNXIAO ENVIRONMENTAL PROTECTION TECH CO LTD

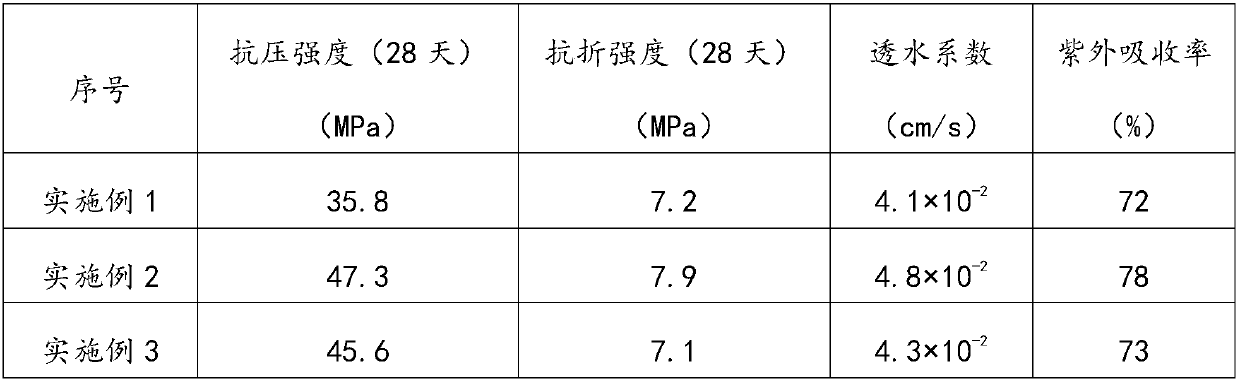

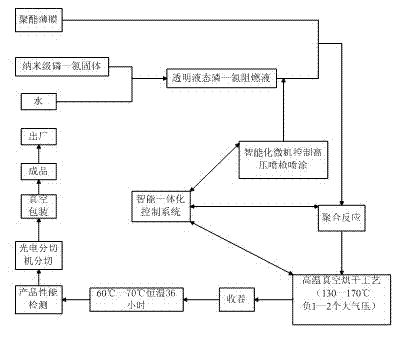

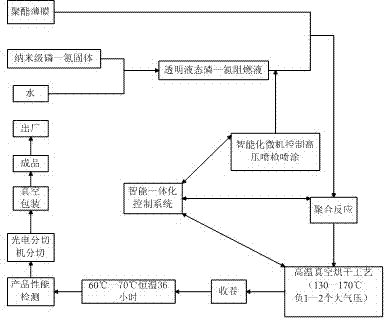

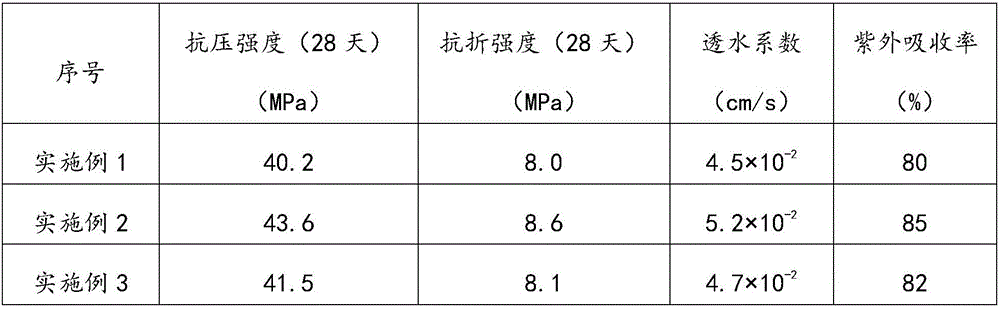

Environment-friendly nano high-flame-retardant polyester film tape and manufacturing process thereof

InactiveCN102651260ASimple preparation processImprove flame retardant performanceInsulated cablesInsulating bodiesPolyesterNitrogen

The invention relates to an environment-friendly nano high-flame-retardant polyester film tape and a manufacturing process thereof. The environment-friendly nano high-flame-retardant polyester film tape comprises a polyester film and nano phosphorus-nitrogen fire retardant attached on the upper surface and the lower surface of the polyester film. The manufacturing process comprises the following steps of: (1) dissolving solid nano phosphorus-nitrogen powder in water to prepare the liquid nano phosphorus-nitrogen fire retardant, and then uniformly spraying the liquid nano phosphorus-nitrogen fire retardant on both sides of the polyster film with a high-pressure spray gun system, (2) allowing the nano phosphorus-nitrogen fire retardant to be tightly attached to the surfaces of the film at high temperature and high pressure, (3) drying in a high temperature oven at 130 DEG C - 170 DEG C and 1-2 negative atmosphere, (4) solidifying and storing the above product at 60 - 70 DEG C for no less than 36 hours, and (5) slitting the product to form a finished product. The environment-friendly nano high-flame-retardant polyester film tape is good in flame resistance, light in gram weight and relatively small in thickness.

Owner:宝应中欧电缆电器材料研发中心

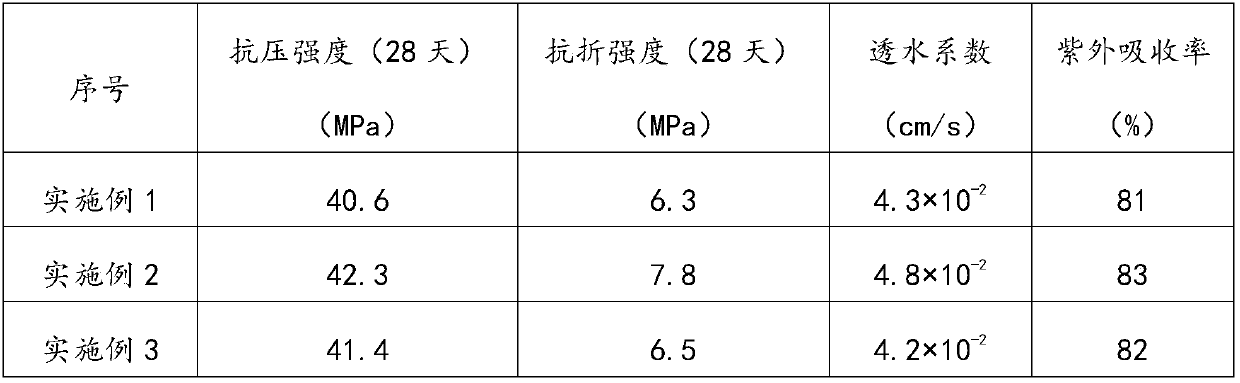

Building rubbish regeneration pavior brick and preparation method thereof

The invention discloses a building rubbish regeneration pavior brick and a preparation method thereof, and belongs to the technical field of building materials. The pavior brick is prepared from the following raw materials, in parts by weight: 20-30 parts of building rubbish regeneration aggregate, 10-20 parts of an aggregate modifier, 5-15 parts of a gelling agent, 10-20 parts of a water reducing agent, 4-10 parts of coal gangue particles, 3-9 parts of fly ash, 4-10 parts of a hydroxy silicon seal curing agent, 3-9 parts of nano silicon dioxide, 50-100 parts of cement, 80-120 parts of water and 5-15 parts of polyamide. The building rubbish regeneration pavior brick is high in strength, good in wear resistance, stable in quality, long in service life, low in costs, and friendly to environment, saves energy, can turn wastes into wealth, and has extremely good economic benefits and wide social benefits.

Owner:侯玉德

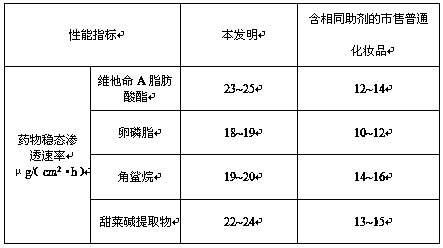

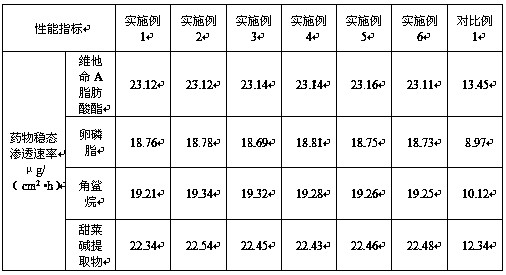

Permeation type face-beautifying and nourishing cosmetic and preparation method

InactiveCN108852889AImprove permeabilityPromote absorptionCosmetic preparationsToilet preparationsGallic acid esterIrritation

The invention relates to the field of cosmetics, and discloses a permeation type face-beautifying and nourishing cosmetic and a preparation method. The preparation method comprises the following stepsof (1) adding microcrystalline cellulose into an aqueous solution of sulfuric acid, so as to obtain the hydrolyzed microcrystalline cellulose; (2) mixing the hydrolyzed microcrystalline cellulose andwater, and homogenizing at high pressure, so as to obtain an aqueous dispersion of nanocrystalline cellulose; (3) adding functional additives into the aqueous dispersion, and freeze-drying, so as toobtain an aerogel; (4) adding glycerin monostearate, glycerin, sipan, methylparaben, polydimethylsiloxane and gallic acid into the aerogel, and uniformly dispersing, so as to obtain the permeation type face-beautifying and nourishing cosmetic. The prepared permeation type face-beautifying and nourishing cosmetic has the advantages that the irritation is avoided, the permeability of skin is good, and the absorbing is easy; the effects of resisting aging, resisting oxidizing, resisting ultraviolet radiation, whitening, nourishing the face and the like are realized; the permeation type face-beautifying and nourishing cosmetic can be used as an additive to be added into conventional day creams, night creams, masks, sunscreens, moisturizers and the like.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Regenerated bricks and preparation method thereof

The invention discloses regenerated bricks and a preparation method thereof and belongs to the technical field of building materials. The regenerated bricks are prepared from the following raw materials in parts by weight: 20 to 40 parts of construction waste recycled aggregate, 5 to 15 parts of an aggregate modifier, 5 to 15 parts of a gelatinizing agent, 10 to 20 parts of a water reducer, 10 to20 parts of magnesia carbon brick regenerated grains, 10 to 20 parts of steel fibers, 5 to 15 parts of zeolite powder, 5 to 15 parts of furnace slag, 30 to 70 parts of cement, 30 to 90 parts of waterand 5 to 15 parts of polyamide. The regenerated bricks disclosed by the invention have the advantages of high strength, good wearing resistance, stable quality, long service life and low cost; wastescan be changed into valuable things, and environment protection and energy saving are realized; the regenerated bricks have very good economic benefits and wide social benefits.

Owner:GUILIN CHUNXIAO ENVIRONMENTAL PROTECTION TECH CO LTD

Skin care material and preparation method thereof

InactiveCN109820767AEasy to operateRaw materials are easy to getCosmetic preparationsToilet preparationsIon exchangeIon

The invention discloses a preparation method of a skin care material. The method comprises the following steps of (1) preparing amino-silicone-oil-modified beeswax; (2) preparing ionized O-[2-(ethylnenoxy)ethyl] hydroxylamine; (3) preparing the care material; (4) performing ion exchange. The invention also discloses the skin care material prepared according to the preparation method of the skin care material. The skin care material has the advantages of being remarkable in skin care effect and bacterial and infective resistance effect, high in biocompatibility, excellent in comprehensive performance and safe and environmentally friendly during use.

Owner:黄丽娜

Recycled pavement brick and preparation method thereof

The invention discloses a recycled pavement brick and a preparation method thereof, and belongs to the technical field of building materials. The recycled pavement brick is prepared from the followingraw materials in parts by weight: 10-40 parts of recycled aggregate of construction wastes, 10-20 parts of gravel, 5-15 parts of a gelling agent, 10-20 parts of a water reducer, 5-15 parts of coal gangue particles, 5-15 parts of steel fiber, 5-15 parts of polypropylene fiber, 5-15 parts of quick lime, 20-80 parts of cement, 60-120 parts of water and 10-20 parts of polyamide. The recycled pavementbrick provided by the invention has the advantages of being high in strength, good in abrasion resistance, stable in quality, long in service life, low in cost, and capable of turning waste into treasure, protecting the environment and saving energy, thereby having good economic benefits and extensive social benefits.

Owner:GUILIN CHUNXIAO ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com