Flame-retardant anti-corrosion insulated rubber tape

A technology of anti-corrosion insulation and tape, applied in the direction of adhesive, adhesive type, film/sheet adhesive, etc., can solve the problems of asphalt construction and protection that are difficult to meet the requirements of engineering quality, uniformity, poor sealing, etc. Achieve the effect of improving the safety of use, good compactness, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

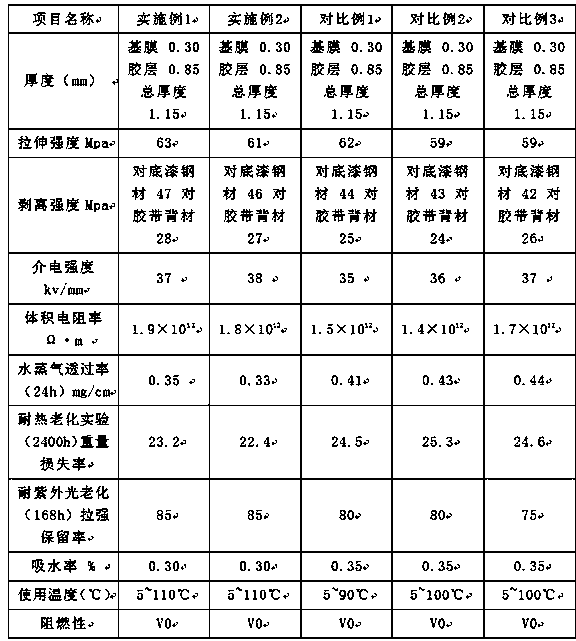

Examples

Embodiment 1

[0020] A flame-retardant and anti-corrosion insulating tape, consisting of a polyvinyl chloride base film and an adhesive layer, the thickness of the polyvinyl chloride film is 0.2-0.5mm, wherein the adhesive layer components are calculated in parts by weight, Including: 33 parts of nitrile rubber, 13 parts of vinyl acetate resin, 7 parts of neoprene rubber, 7 parts of rosin resin, 3 parts of ethyl acetate, 9 parts of graphite powder, 9 parts of dimethyldimethoxysilane, stearic acid 0.5 parts, 2.5 parts of diphenylsilanediol, 0.2 parts of antioxidant, and 15 parts of inorganic fillers.

[0021] Further, the antioxidant is a mixture of antioxidant 168, antioxidant 1010, and antioxidant DLTP.

[0022] Further, the inorganic filler is wollastonite, calcium carbonate and quartz powder, and the weight ratio of the three is 1:2~3:4~5.

[0023] Further, the particle size of the wollastonite is 0.3-2 μm, the particle size of the calcium carbonate is 1250 mesh, and the particle size o...

Embodiment 2

[0030] A flame-retardant and anti-corrosion insulating tape, consisting of a polyvinyl chloride base film and an adhesive layer, the thickness of the polyvinyl chloride film is 0.2-0.5mm, wherein the adhesive layer components are calculated in parts by weight, Including: 30 parts of nitrile rubber, 15 parts of vinyl acetate resin, 10 parts of neoprene rubber, 9 parts of rosin resin, 3 parts of ethyl acetate, 9 parts of graphite powder, 10 parts of dimethyldimethoxysilane, stearic acid 0.5 parts, 3 parts of diphenylsilanediol, 0.3 parts of antioxidant, 17 parts of inorganic fillers.

[0031] Further, the antioxidant is a mixture of antioxidant 168, antioxidant 1010, and antioxidant DLTP.

[0032] Further, the inorganic filler is wollastonite, calcium carbonate and quartz powder, and the weight ratio of the three is 1:2~3:4~5.

[0033] Further, the particle size of the wollastonite is 0.3-2 μm, the particle size of the calcium carbonate is 1250 mesh, and the particle size of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com