Construction waste recycled afforesting brick and preparation method thereof

A technology for construction waste and green bricks, which is applied to the field of construction waste regenerated green bricks and its preparation, can solve problems such as resource waste and environmental pollution, and achieve the effects of low cost, simple preparation method and wide social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

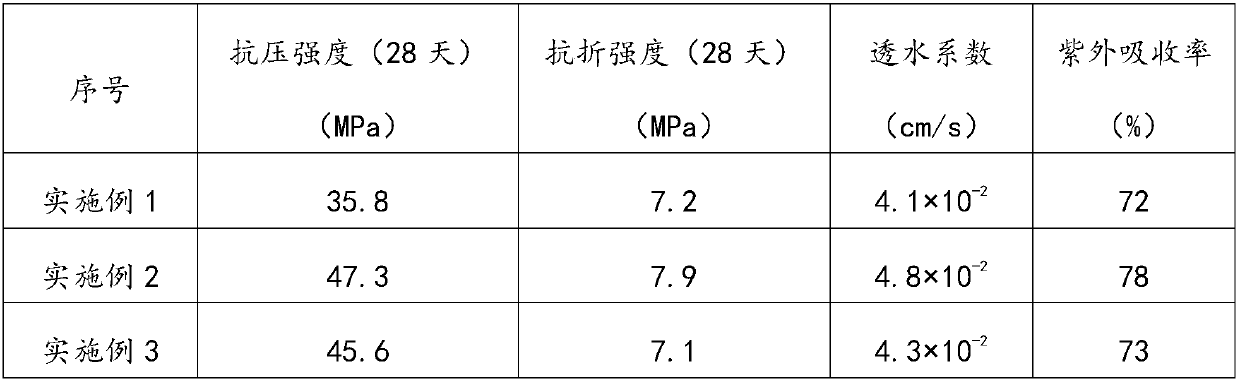

Examples

Embodiment 1

[0023] The construction waste regenerated greening brick of this embodiment is made of the following raw materials: 30 kg of construction waste regenerated aggregate, 15 kg of aggregate modifier, 6 kg of gelling agent, 12 kg of water reducing agent, 6 kg of coal gangue particles, hydroxymethylpropane 16kg of base cellulose, 6kg of slag, 15kg of bamboo fiber, 20kg of cement and 70kg of water, wherein the recycled construction waste aggregate refers to construction waste with a particle size of 2-10mm obtained after crushing, screening, and removal of impurities. , the gelling agent is a mixture of light magnesium oxide, magnesium chloride and magnesium sulfate in a mass ratio of 40:40:20.

[0024] The preparation method of the above-mentioned construction waste regenerated greening brick comprises the following steps:

[0025] (1) Take the following raw materials: 30kg of recycled construction waste aggregate, 15kg of aggregate modifier, 6kg of gelling agent, 12kg of water redu...

Embodiment 2

[0030] The construction waste regenerated greening brick of this embodiment is made of the following raw materials: 40 kg of construction waste recycled aggregate, 10 kg of aggregate modifier, 11 kg of gelling agent, 9 kg of water reducing agent, 11 kg of coal gangue particles, hydroxymethylpropane 11kg of base cellulose, 9kg of slag, 10kg of bamboo fiber, 40kg of cement and 50kg of water, wherein the recycled aggregate of construction waste refers to construction waste with a particle size of 2-10mm obtained after crushing, screening, and removal of impurities. , the gelling agent is a mixture of light magnesium oxide, magnesium chloride and magnesium sulfate in a mass ratio of 40:40:20.

[0031] The preparation method of the above-mentioned construction waste regenerated greening brick comprises the following steps:

[0032] (1) Take the following raw materials: 40kg of recycled construction waste aggregate, 10kg of aggregate modifier, 11kg of gelling agent, 9kg of water red...

Embodiment 3

[0037] The construction waste regenerated greening brick of this embodiment is made of the following raw materials: 50 kg of construction waste regenerated aggregate, 5 kg of aggregate modifier, 16 kg of gelling agent, 6 kg of water reducing agent, 16 kg of coal gangue particles, methylol propane Base cellulose 6kg, slag 12kg, bamboo fiber 5kg, cement 60kg and water 30kg, wherein, described construction waste regenerated aggregate refers to the construction waste obtained after crushing, sieving, removing foreign matter, and the particle size is 2-10mm , the gelling agent is a mixture of light magnesium oxide, magnesium chloride and magnesium sulfate in a mass ratio of 40:40:20.

[0038] The preparation method of the above-mentioned construction waste regenerated greening brick comprises the following steps:

[0039] (1) Take the following raw materials: 50kg of recycled construction waste aggregate, 5kg of aggregate modifier, 16kg of gelling agent, 6kg of water reducing agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com