Self-cleaning antireflection coating and preparation method thereof

An anti-reflection coating and self-cleaning technology, which is applied in the field of solar energy applications, can solve the problems of reducing system efficiency, increasing costs, and easy contamination of glass surfaces, and achieves the goals of reducing operation and maintenance costs, low cost, and improving environmental adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

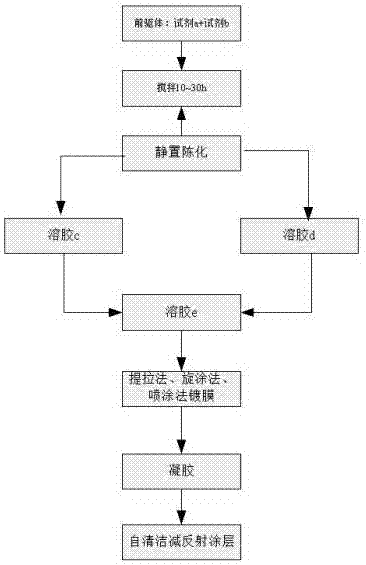

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a self-cleaning anti-reflection coating. The self-cleaning anti-reflection coating uses tetraethyl orthosilicate and ethanol as precursors, stirred for 10 hours under the condition of pH=0.4, and then left to age for 7 days , forming sol c; standing for 30 days to form sol d; mixing sol c and sol d at a ratio of 1:5 to form sol e; On the inner and outer walls of the proportional tube, the progress is that the lowering speed of the plated piece is 0.5mm / s, and the pulling speed is 0.3mm / s after standing still for 5 minutes; Dry at ℃ for 1 hour to obtain the self-cleaning anti-reflection coating; finally, the sol e is coated on the reflector of the solar collector tube and the surface of the photovoltaic panel by the spin coating method, and the spin coating speed is 0.1r / min , after being plated, it was left to stand in the air for 30 minutes to form a gel, and then dried at 400° C. for 1 hour to obtain the self-cleaning anti-reflection coating. ...

Embodiment 2

[0037] This embodiment provides a self-cleaning anti-reflection coating. The self-cleaning anti-reflection coating uses polydimethylsiloxane and methanol as precursors, stirs for 15 hours under the condition of pH=2, and then stands and ages for 5 hours. day, form sol c; stand and age for 1 day to form sol d; mix sol c and sol d at a ratio of 0.7:8 to form sol e; On the inner and outer walls of the glass tube, during immersion plating, the descending speed of the plated part is 0.3mm / s, and the pulling speed is 1.5mm / s after standing for 10 minutes; Dry at 500°C for 2 hours to obtain the self-cleaning anti-reflection coating; finally, the sol e is coated on the reflector of the solar energy collector tube and the surface of the photovoltaic cell panel by the spin coating method, and the spin coating speed is 2r / min, after being plated, it was left to stand in the air for 30 minutes to form a gel, and then dried at 500°C for 2 hours to obtain the self-cleaning anti-reflection ...

Embodiment 3

[0039]This embodiment provides a self-cleaning anti-reflection coating. The self-cleaning anti-reflection coating uses tetraethyl orthosilicate and ethanol as precursors, is stirred at pH=0.9 for 20 hours, and then left to age for 6 days. Sol c was formed; another polydimethylsiloxane and ethanol were used as precursors, stirred at pH=0.9 for 15 hours, and then left to age for 5 days to form sol d; sol c and sol d were mixed at a ratio of 0.1:6 Proportionally mixed to form sol e; then, sol e was dip-coated on the inner and outer walls of the glass tube of the solar heat collector by the pulling method. 2 mm / s; after the immersion plating is completed, let it stand in the air for 30 minutes to form a gel, and then dry it at 550 ° C for 3 hours to obtain the self-cleaning anti-reflection coating; finally, the sol e is coated by spin coating Coated on the reflector of the solar heat collector and the surface of the photovoltaic panel, the spin coating speed is 5r / min, after the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com