Environment-friendly nano high-flame-retardant polyester film tape and manufacturing process thereof

A technology of polyester film tape and manufacturing process, which is applied in the direction of conductors, insulators, insulated cables, etc., can solve the problems of poor flame retardancy of polyester film tape, thick flame retardant layer, and easy falling off of the flame retardant layer, and achieve flame retardant Good performance, high insulation level and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

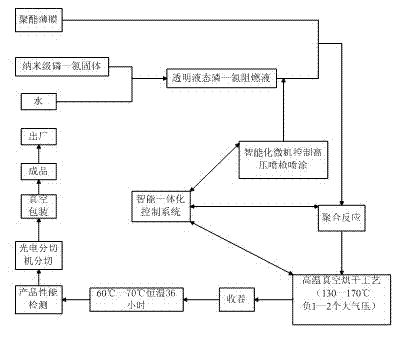

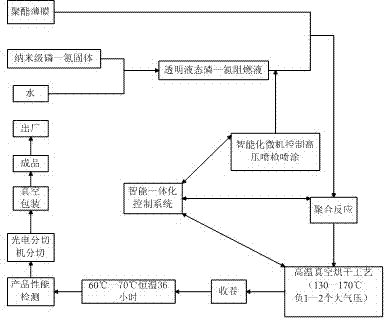

[0024] The present invention is carried out in the following steps:

[0025] (1) Dissolve nano-level phosphorus-nitrogen solid powder in water to prepare liquid nano-level phosphorus-nitrogen flame retardant with a mass concentration of 25%, and then uniformly block liquid nano-level phosphorus-nitrogen through a high-pressure spray gun system The fuel is sprayed on both sides of the polyester film;

[0026] (2) Make full use of the surface activity of the nano-phosphorus-nitrogen flame retardant to make the nano-level phosphorus-nitrogen flame retardant adhere tightly to the film surface under high temperature and high pressure;

[0027] (3) Drying: drying in a high-temperature oven at 170°C and minus 1 atmosphere;

[0028] (4) Put the above-mentioned finished product at a high temperature of 70℃ for no less than 36 hours for curing and storage;

[0029] (5) Slitting and finished products.

[0030] In the step (2), the atmospheric pressure is 2.5 atmospheres and the temperature is 120°...

Embodiment 2

[0032] The present invention is carried out in the following steps:

[0033] (1) Dissolve nano-level phosphorus-nitrogen solid powder in water to prepare liquid nano-level phosphorus-nitrogen flame retardant with a mass concentration of 30%, and then uniformly block liquid nano-level phosphorus-nitrogen through a high-pressure spray gun system The fuel is sprayed on both sides of the polyester film;

[0034] (2) Make full use of the surface activity of the nano-phosphorus-nitrogen flame retardant to make the nano-level phosphorus-nitrogen flame retardant adhere tightly to the film surface under high temperature and high pressure;

[0035] (3) Drying: drying in a high-temperature oven at 130°C under negative 2 atmospheres;

[0036] (4) Put the above-mentioned finished product at a high temperature of 60℃ for no less than 36 hours for curing and storage;

[0037] (5) Slitting and finished products.

[0038] In the step (2), the atmospheric pressure is 1.8 atmospheres and the temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com