Environmental-friendly ultraviolet-resistant sheath material and cable

A technology of UV resistance and sheath material, which is applied in the field of sheath material and cables, can solve the problems of unsatisfactory UV resistance and achieve the effects of sun protection, good insulation performance, and good forming and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0020] Each raw material was weighed according to the data corresponding to Examples 1-5 in Table 1. The raw materials are mixed on a high-speed mixer for 8 minutes, and then plasticized and granulated on a two-stage screw extruder with an extrusion temperature of 150°C to obtain the environmentally friendly UV-resistant sheath material of the present invention.

[0021] Then the environment-friendly UV-resistant sheath material was molded on a press at 170°C for 15 minutes to make test pieces for experimentation.

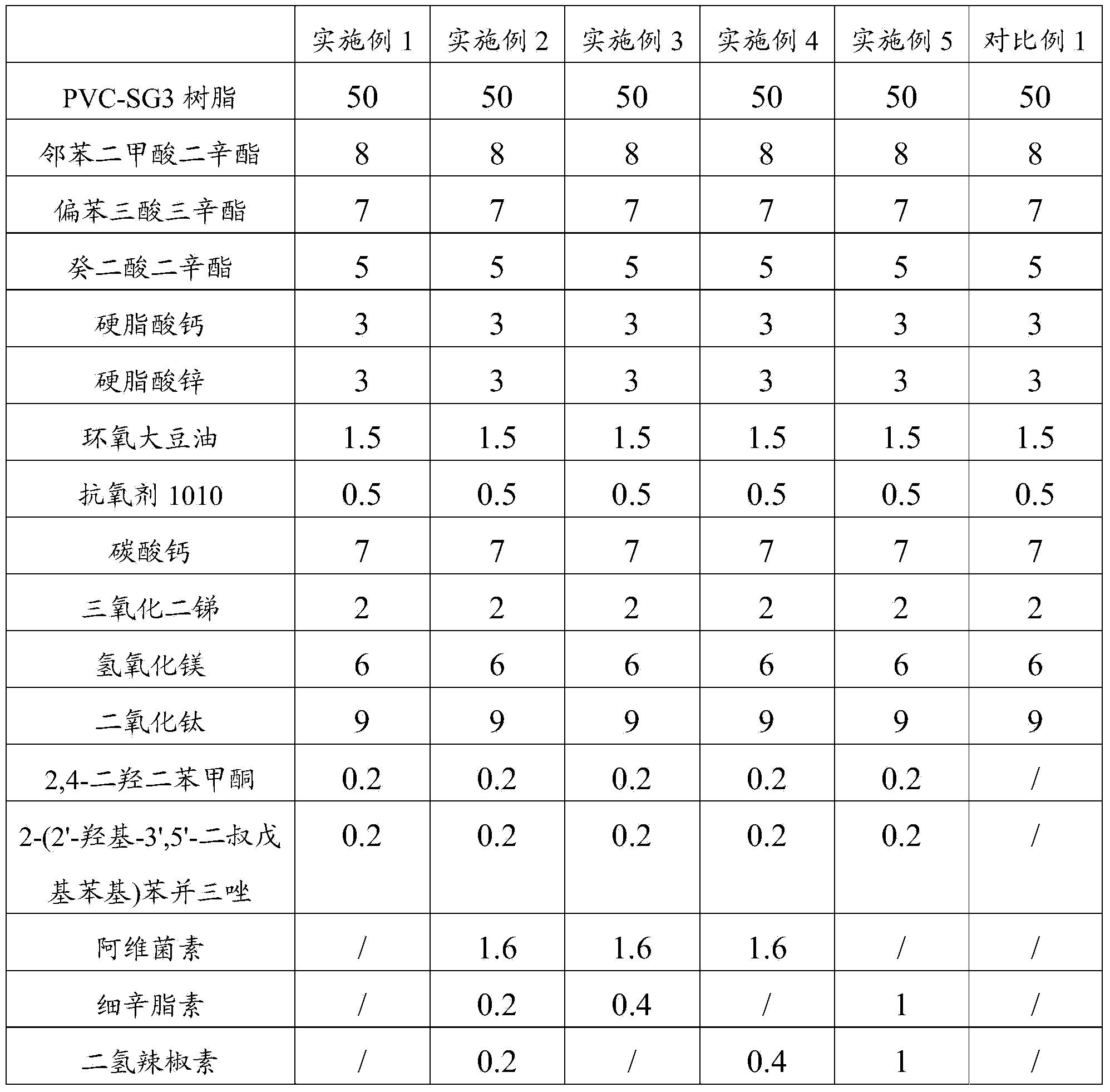

[0022] Table 1: Formula table of environmental protection UV resistant sheathing material Unit: kg

[0023]

Embodiment 6

[0025] The cable is prepared by a general method in the field, and the environmental protection UV-resistant sheath material of Examples 1-5 is prepared as the sheath of the cable.

[0026] Specifically, coaxial cables can be prepared. The coaxial cable is composed of an inner conductor, an insulating layer, an outer conductor, and an environment-friendly UV-resistant sheath made of the materials of Examples 1-5 from the inside to the outside.

Embodiment 2

[0028] The sheath material of embodiment 2, oxygen index 36%, volume resistivity 3.1 * 10 13 Ω.m.

[0029] The sheath materials of Examples 1-5 all passed the heat aging test at 145°C×168h. The sheath material of Comparative Example 1 failed the heat aging test at 145°C×168h.

[0030] It can be seen that the environment-friendly UV-resistant sheathing material of the present invention is environmentally friendly and resistant to sunlight in the use environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com