Super weather-proof composite waterproof roll material

A waterproofing membrane, super weather-resistant technology, applied in the direction of synthetic resin layered products, lamination, layered products, etc., can solve the problems of limited corrosion resistance, environmental aging resistance, inability to withstand corrosion, etc., and achieve dimensional stability. Good properties, good chemical resistance, strong puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

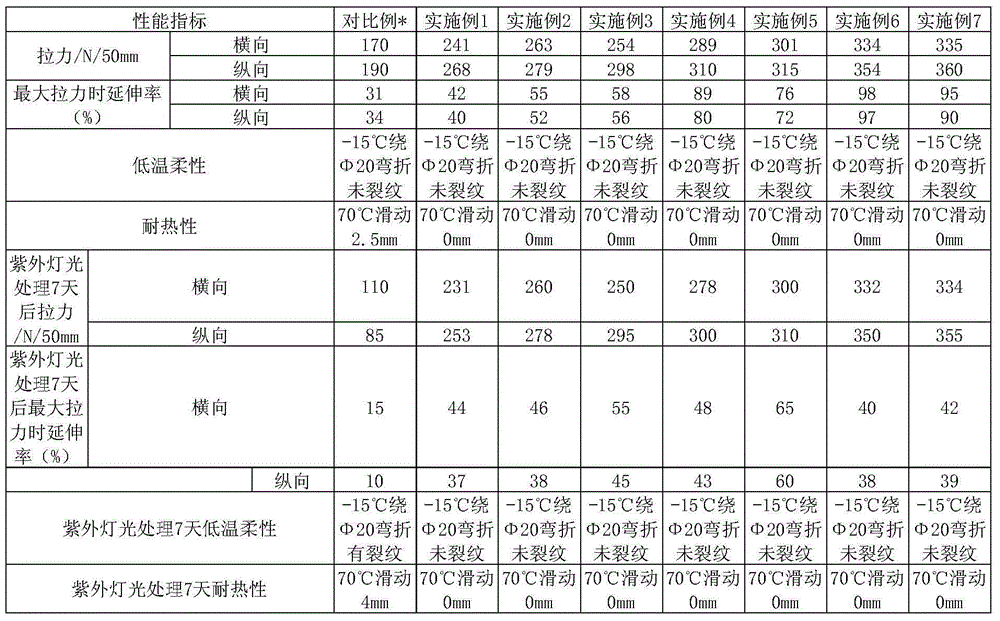

Examples

Embodiment 1

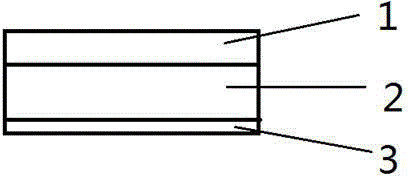

[0019] Depend on figure 1 The super-weather-resistant composite waterproof roll material shown includes: super-weather-resistant polymer film layer 1, adhesive sealant layer 2, and its interlayer structure is: the surface layer is super-weather-resistant polymer film layer 1, and the middle layer is adhesive sealant Layer 2, the bottom layer is the isolation film layer 3, and these three layers are integrated by heat-compression bonding during the production process. The adhesive sealant layer of the waterproof membrane forms a physical adsorption and mortise and tenon action with cement and concrete through pressing force to form an interface layer with strong adhesion, waterproof, tear and puncture resistance, and chemical corrosion resistance, thus forming a firm bonding.

[0020] In this embodiment, the surface layer is a 10 μm PVDF film layer 1, the middle layer is a butyl rubber layer 2, and the bottom layer is a polyethylene film layer 3, and the three are bonded by he...

Embodiment 2

[0022] A super weather-resistant composite waterproof membrane, the surface layer is a 280μm thick PVDF / PET composite film layer 1, the middle layer is a SBR modified asphalt layer 2, and the bottom layer is a polyethylene film layer 3. The three are bonded by heat and pressure, specifically Composite method is with embodiment 1.

[0023] The PVDF / PET composite film layer is composed of PVDF and PET two-layer film by double-layer co-extrusion blown film or casting process, and the PET layer is in contact with SBR modified asphalt.

Embodiment 3

[0025] A super weather-resistant composite waterproof membrane, the surface layer is a 140μm PVDF / PE composite film layer 1, the middle layer is a butyl rubber layer 2, and the bottom layer is a polyethylene film layer 3; the PVDF / PE composite film is composed of two layers of PVDF and PE The film is composited, and the PE layer is located at the bottom layer in contact with the SBS and SBR blended modified asphalt layer 2.

[0026] The PET film layer 1, the APP modified asphalt layer 2, and the polyethylene film layer 3 are bonded by heat and pressure, and the specific composite method is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com