Primer for aluminum plate curtain wall, preparation method of primer, composite paint vehicle for aluminum plate curtain wall and preparation method of aluminum plate curtain wall

A composite paint and aluminum plate technology, which is applied in primers, anti-corrosion coatings, and devices for coating liquid on the surface, etc., can solve problems such as high cost, primer migration, and affecting the coating effect of aluminum curtain walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

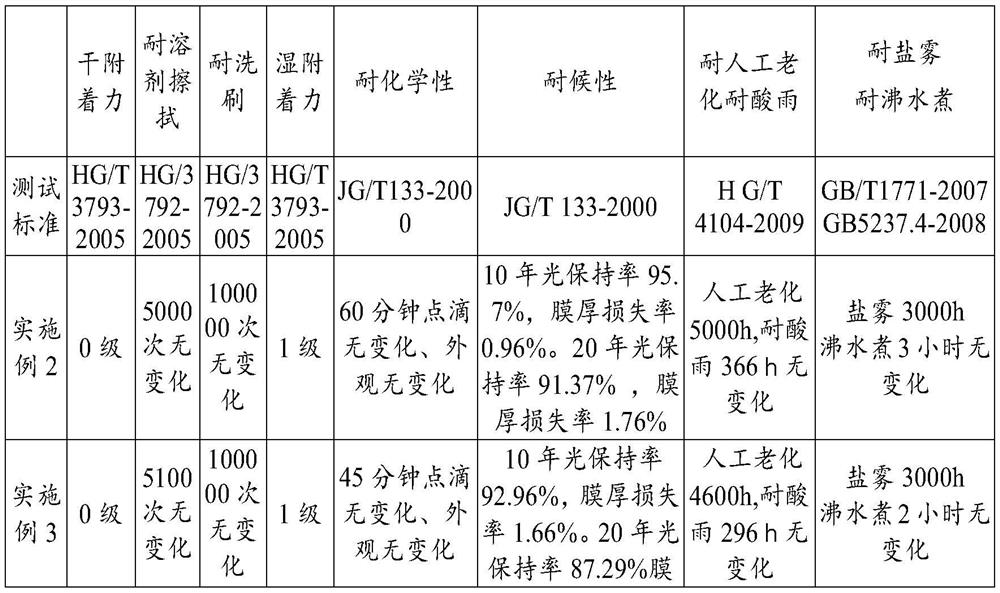

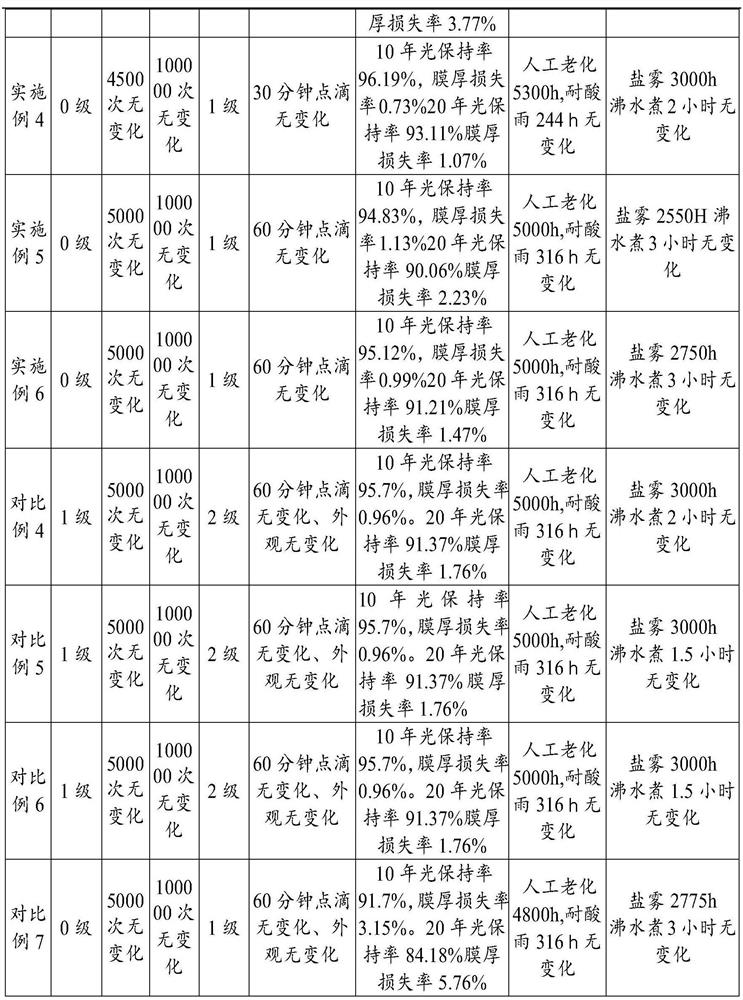

Examples

preparation example Construction

[0054] The present invention also provides a preparation method for the aluminum curtain wall primer described in the above technical solution, comprising the following steps:

[0055] Water-based hydroxyl acrylic emulsion HD-8102, neutralizer, deionized water, cosolvent PNB, part of cosolvent DPM, dispersant 760W, 024 defoamer, 346 wetting agent, 902 defoamer, 4100 wetting agent and 706 titanium dioxide is mixed and ground to obtain emulsion pre-pulp;

[0056] Mix FB12 aliphatic isocyanate water-based blocked curing agent, allnex 303 amino resin and the remaining co-solvent DPM to obtain a curing agent mixture;

[0057] After mixing the emulsion pre-pulp and the curing agent mixture, add King's 3525 acid drier, 105A thickener and 53L thickener in sequence to obtain the primer for the aluminum curtain wall.

[0058] In the present invention, water-based hydroxyl acrylic emulsion HD-8102, neutralizer, deionized water, cosolvent PNB, part of cosolvent DPM 2.0%, dispersant 760W,...

Embodiment 1

[0125] A primer for aluminum curtain wall, comprising the following components in mass percentage:

[0126] Water-based hydroxyl acrylic emulsion HD-8102 50%, neutralizer DMEA 0.3%, deionized water 8.4%, co-solvent PNB 2.0%, co-solvent DPM 5.0%, dispersant 760W 0.6%, 024 defoamer 0.3%, 346 wetting Wetting agent 0.3%, 902 defoamer 0.2%, 4100 wetting agent 0.2%, 706 titanium dioxide 22%, King’s 3525 acid drier 0.3%, 105A thickener 0.20%, 53L thickener 0.2%, FB12 Aliphatic isocyanate water-based blocked curing agent 3.0%, allnex 303 amino resin 7.0%;

[0127] The solid content of the aqueous hydroxyacrylic acid emulsion HD-8102 is 43wt%;

[0128] The hydroxyl value of the aqueous hydroxyl acrylic emulsion HD-8102 is 85 mg / mol.

[0129] The preparation method comprises the following steps:

[0130] Water-based hydroxyl acrylic emulsion HD-8102 50%, neutralizer DMEA 0.3%, deionized water 8.4%, cosolvent PNB 2.0%, cosolvent DPM 2.0%, dispersant 760W 0.6%, 024 defoamer 0.3%, 346 ...

Embodiment 2

[0144] A composite paint for aluminum curtain wall: comprising the primer and aminofluorocarbon topcoat for aluminum curtain wall described in Example 1;

[0145] The aminofluorocarbon topcoat includes the following components in mass percentage:

[0146] 30.6% water-based fluorocarbon emulsion resin 827;

[0147] 25.4% water-based fluorocarbon emulsion resin M15A;

[0148] 0.1% net taste neutralizer AMP-95;

[0149] 3.0% ethylene glycol tert-butyl ether;

[0150] 1.5% isopropanol;

[0151] 0.7% dispersant 181;

[0152] 0.2% wetting agent 4100;

[0153] 0.2% defoamer 902w;

[0154] 2.0% coalescence aid DPNB;

[0155] 0.2% light stabilizer 5400WB;

[0156] 18.2% titanium dioxide 996;

[0157] 8.2% water-based amino resin 303;

[0158] 3.0% Nano Zirconia Z3103;

[0159] 4.5% modified nano-zirconia Z3100 dispersion (the nano-zirconia Z3100 dispersion with a solid content of 40% and silicon dioxide are mixed at a mass ratio of 95:5 and wrapped at 200°C for 30 minutes); ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com