Waterborne coating

A water-based paint and raw material technology, applied in the field of building decoration materials, can solve the problems of poor weather resistance and scrub resistance, failure to meet market demand, high price, etc., achieve excellent anti-fading and decolorization effects, and good color development effect , good effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

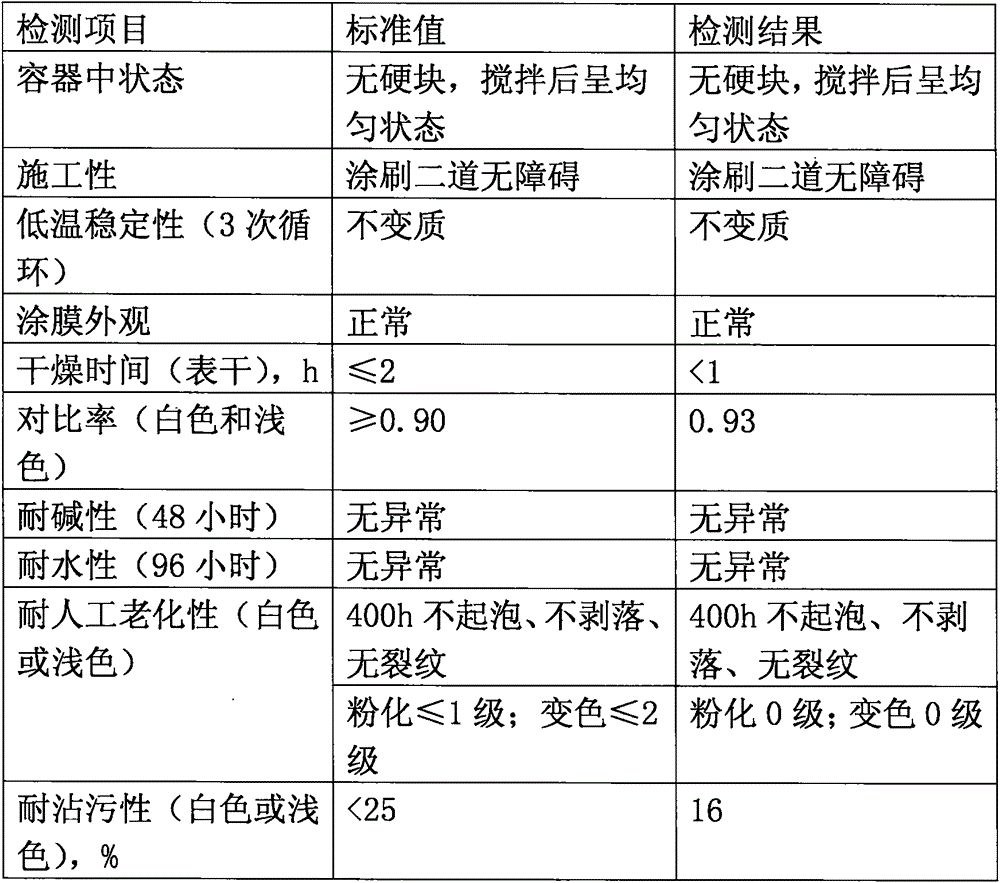

Examples

Embodiment 1

[0034] serial number Variety material Recipe dosage 1 Deionized water 153 2 Cellulose 2 3 Dispersant 7 4 D 1.5 5 Ethylene glycol 15 6 Multifunctional additive 1.5 7 Defoamer 1.5 8 Nano attapulgite 3 9 Rutile Titanium Dioxide 150 10 800 mesh talcum powder 75 11 1250 mesh heavy calcium carbonate 175 12 RS-3989 Emulsion 400 13 C-12 film-forming aid 6 14 Defoamer 1 15 fungicide 1.5 16 TRM-105 thickener 1.5 17 TRM-272 Thickener 1 18 TRM-112 thickener 1.5

[0035] The manufacturing steps of this embodiment are as follows:

[0036] Step 1. Add water into the dispersing kettle according to the required amount, start the high-speed dispersing machine at a speed of 1440r / min; slowly add cellulose, and then add dispersant, wetting agent, ethylene glycol, multifunctional additives and disinfectant Foaming agent, disperse for 30 minutes after adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com