Permeation type face-beautifying and nourishing cosmetic and preparation method

A technology for beautifying and beautifying skin, applied in the field of permeable beautifying and beautifying cosmetics and its preparation, can solve the problems of difficulty in effectively exerting activity, low dissolution and absorption rate, immature technology, etc., and achieves easy absorption, accelerated penetration and absorption, and excellent penetration promotion. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

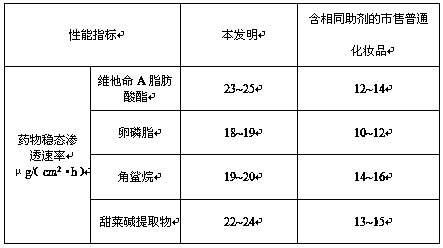

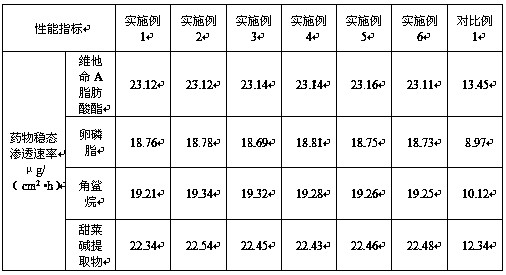

Examples

Embodiment 1

[0033] (1) Add microcrystalline cellulose to sulfuric acid aqueous solution first, then heat up and stir for hydrolysis, filter, then wash with distilled water to pH=7 to obtain hydrolyzed microcrystalline cellulose; the mass concentration of sulfuric acid aqueous solution is 25%; hydrolysis The temperature is 46°C, and the time is 70 minutes;

[0034] (2) First mix the hydrolyzed microcrystalline cellulose obtained in step (1) with water, and then perform high-pressure homogenization treatment to obtain a nanocrystalline cellulose aqueous dispersion; the pressure of the homogenization treatment is 11MPa, and the time is 26h; water dispersion In the liquid, 32 parts by weight of hydrolyzed microcrystalline cellulose, 68 parts by weight of water;

[0035] (3) Adding functional additives to the aqueous dispersion in step (2), and freeze-drying, so that the nanocrystalline cellulose forms an airgel and fixes the functional additives in the network; the functional additives are co...

Embodiment 2

[0039] (1) Add microcrystalline cellulose to sulfuric acid aqueous solution first, then heat up and stir for hydrolysis, filter, then wash with distilled water to pH=7 to obtain hydrolyzed microcrystalline cellulose; the mass concentration of sulfuric acid aqueous solution is 20%; hydrolysis The temperature is 40°C, and the time is 90 minutes;

[0040] (2) First mix the hydrolyzed microcrystalline cellulose obtained in step (1) with water, and then perform high-pressure homogenization treatment to obtain a nanocrystalline cellulose aqueous dispersion; the pressure of the homogenization treatment is 8MPa, and the time is 30h; water dispersion In the liquid, 20 parts by weight of hydrolyzed microcrystalline cellulose, 80 parts by weight of water;

[0041](3) Adding functional additives to the aqueous dispersion in step (2), and freeze-drying, so that the nanocrystalline cellulose forms an airgel and fixes the functional additives in the network; the functional additives are comp...

Embodiment 3

[0045] (1) Add microcrystalline cellulose to sulfuric acid aqueous solution first, then heat up and stir for hydrolysis, filter, then wash with distilled water to pH=7 to obtain hydrolyzed microcrystalline cellulose; the mass concentration of sulfuric acid aqueous solution is 20%; hydrolysis The temperature is 42°C, and the time is 80 minutes;

[0046] (2) First mix the hydrolyzed microcrystalline cellulose obtained in step (1) with water, and then perform high-pressure homogenization treatment to obtain a nanocrystalline cellulose aqueous dispersion; the pressure of the homogenization treatment is 9MPa, and the time is 28h; water dispersion In the liquid, 25 parts by weight of hydrolyzed microcrystalline cellulose, 75 parts by weight of water;

[0047] (3) Adding functional additives to the aqueous dispersion in step (2), and freeze-drying, so that the nanocrystalline cellulose forms an airgel and fixes the functional additives in the network; the functional additives are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com