Method for producing thermoplastic elastic fibers

A thermoplastic elasticity, thermoplastic elastomer technology, applied in fiber processing, melting of filament raw materials, textiles and papermaking, etc., can solve the problems of low temperature resistance of fibers, low fiber competitiveness, long process flow, etc. Short, wear-resistant and breathable, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

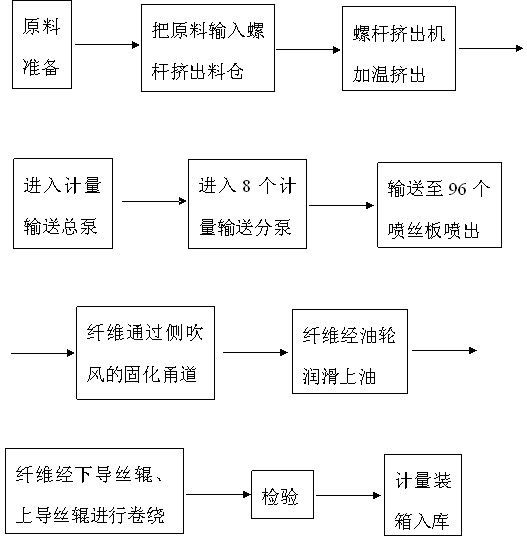

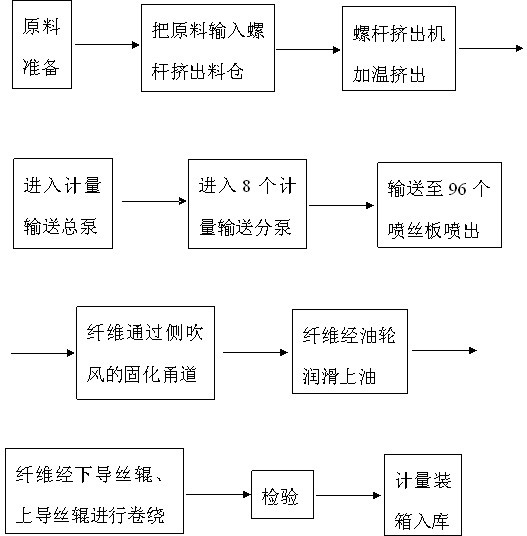

[0014] Embodiment 1 (compared with attached figure 1 , to produce thermoplastic elastic fibers)

[0015] 1. Raw material preparation: Take 100 kg of thermoplastic elastomer particles, and input the raw material into the silo of the screw extruder;

[0016] 2. Input the raw materials into the silo of the screw extruder;

[0017] 3. The raw materials in the silo of the screw extruder extrude the melt material through 4 different heating temperature zones in the screw extruder. The temperatures of the 4 different heating temperature zones are: 130°C, 230°C, 235°C, 240°C;

[0018] 4. The extruded melt material enters the metering and conveying master pump through the pipeline in the spinning box for metering and conveying, and then enters 8 spinning metering and conveying sub-pumps through the pipeline for metering and conveying. The 8 spinning metering and conveying sub-pumps are metered and conveyed. pump, each spinning metering delivery sub-pump corresponds to 12 spinnerets,...

Embodiment 2

[0022] Embodiment 2 (production thermoplastic elastomer)

[0023] 1. Raw material preparation: Take 5 parts of polyolefin (POE), 88 parts of propylene-based elastomer, 3 parts of polypropylene (PP), and 4 parts of polyethylene (PE);

[0024] 2. Mix the raw materials evenly and send them to the silo of the twin-screw reaction extruder;

[0025] 3. The raw materials in the twin-screw reaction extruder are sequentially melted, mixed and extruded through 12 different heating temperature zones. The 12 different heating temperature zones are 140°C, 150°C, 160°C, 170°C, 180°C , 190°C, 200°C, 210°C, 215°C, 220°C, 230°C, 240°C;

[0026] 4. The material extruded by melting and mixing is drawn by the pelletizer through the cooling channel, the traction speed is 4m / min, and the material is solidified into filaments. The traction of the pelletizer is through the wire guide wheel in front of the pelletizer Traction, after traction, the pelletizing knife cuts the pellets; the water tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com