Flexible heat-resistant ultraviolet-aging-resistant high-efficiency light-emitting high polymer material and preparation method thereof

A polymer material and UV-resistant technology, applied in the field of polymer materials, can solve problems such as material aging, chemical bond destruction, and material performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

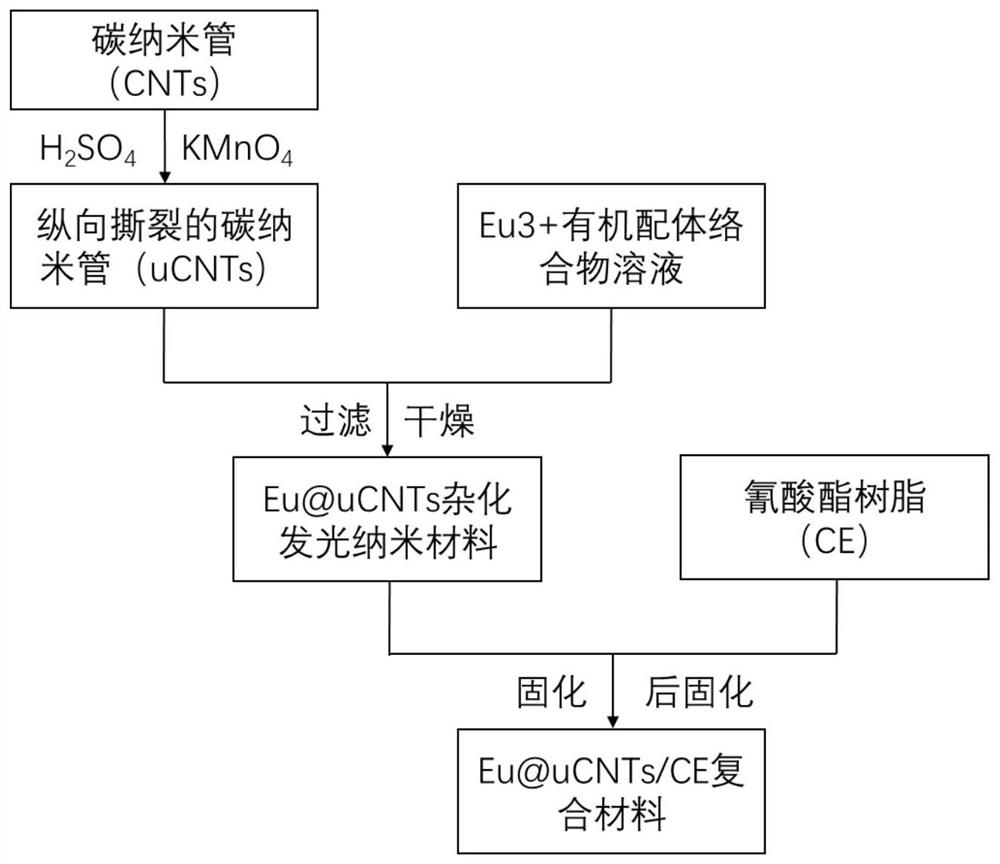

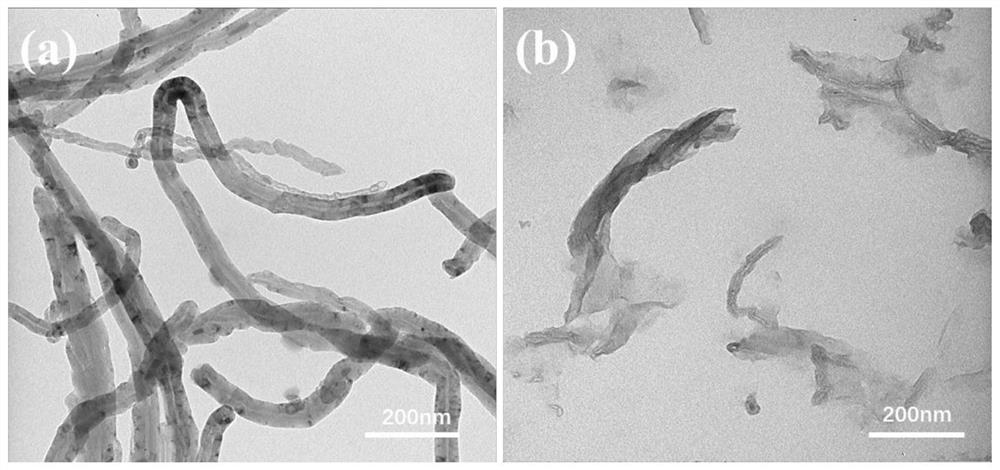

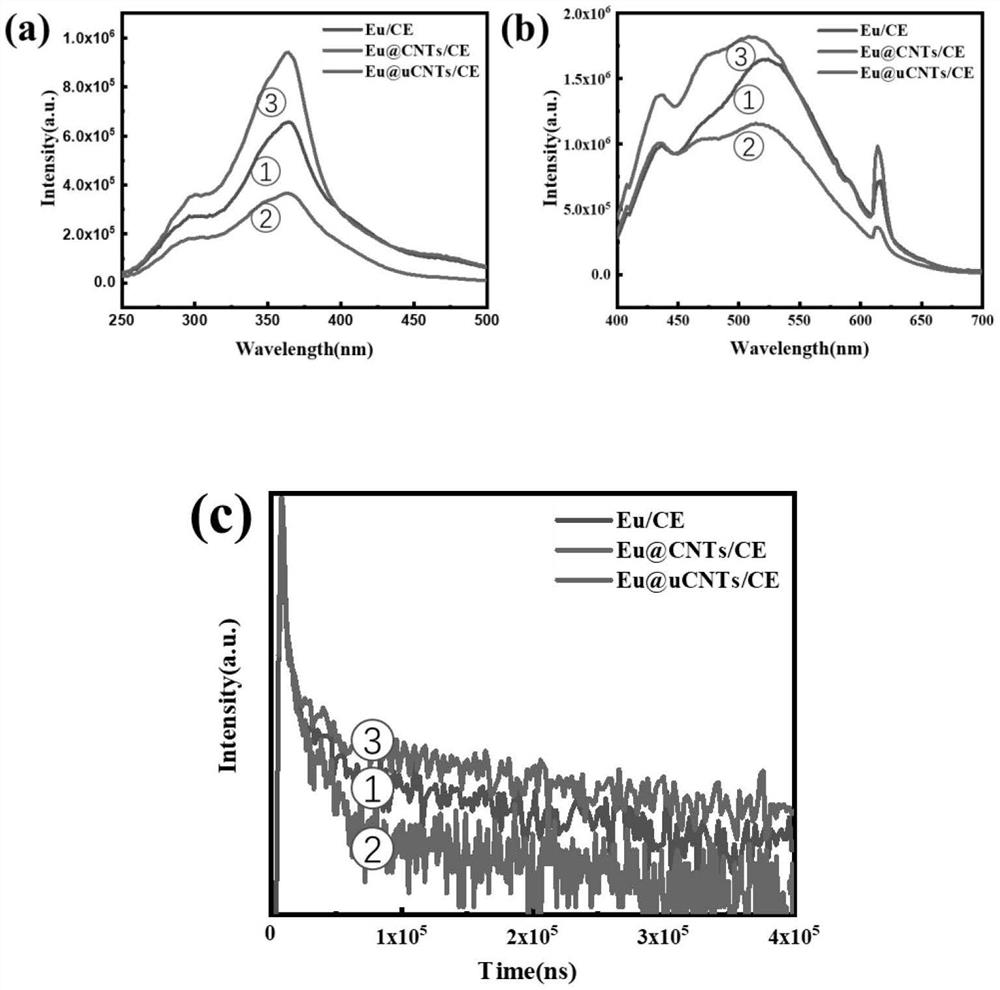

[0024] Disperse 0.2g of carbon nanotubes (CNTs) in 35ml of concentrated sulfuric acid, and sonicate for 10-20 hours. Then add potassium permanganate (KMnO 4 ), 0.20g each time, stirring at intervals of 10min each time. The mixed solution was heated to 50° C. in a water bath, kept warm and stirred for 1 h. Prepare 0.3% hydrogen peroxide aqueous solution and freeze into ice cubes. Pour the insulated mixed solution into a beaker filled with ice cubes of hydrogen peroxide. If gas occurs, add 0.2ml of 30% hydrogen peroxide solution again, and repeat this process until no bubbles appear. Obtain uCNTs dispersion. The uCNTs dispersion was centrifuged and washed with distilled water until the pH value was 4-7, and then dried to obtain unzipped carbon nanotubes (uCNTs).

[0025] Disperse 10mg uCNTs in 20ml ethanol at 50°C, add 400μL 0.1mol / L phen solution, 400μL 0.1mol / L EuCl3 solution and 400μL 0.3mol / L TTA solution, then adjust the pH value to 6-7 with dilute ammonia , stirred fo...

Embodiment 2

[0029] Disperse 10mg of CNTs in 20ml of ethanol at 50°C, add 400μL of 0.1mol / L phen solution, 400μL of 0.1mol / L EuCl3 solution and 400μL of 0.3mol / L TTA solution, and then adjust the pH value to 6-7 with dilute ammonia water , stirred for 2h. After filtration, washing and drying, the luminescent nanomaterial Eu@CNTs was obtained.

[0030]Firstly, 0.01 g of luminescent nanomaterial Eu@CNTs was dispersed in 10 ml of acetone solution, and then 10 g of cyanate resin monomer was added and mixed and stirred at 100 °C until completely dissolved to obtain a uniformly mixed Eu@CNTs / CE solution. The mass ratio of the luminescent nanometer material in the cyanate resin is 0.1%. Pour the mixture into a shallow dish lined with release paper, dry for 24 hours, and remove embedded air bubbles in a vacuum oven at 130°C for 30 minutes. Then the mixture is poured into the mold, cured at 160°C / 2h+180°C / 2h+200°C / 2h and post-cured above 200°C. Finally, the cured resin was demolded and coded as ...

Embodiment 3

[0032] In 20ml ethanol solution, add 1ml 0.1mol / L Phen solution respectively, then add 1ml 0.1mol / LEuCl 3 solution and 1ml 0.3mol / L TTA solution, stirred for 2h, then filtered, washed and dried to obtain Eu complex powder.

[0033] First, disperse 0.01g of fluorescent nanomaterial Eu complex in 10ml of acetone solution, then add 10g of cyanate resin monomer and mix thoroughly at 100°C until completely dissolved to obtain a uniformly mixed Eu / CE solution. The mass ratio of the luminescent nanometer material in the cyanate resin is 0.1%. Pour the mixture into a shallow pan lined with release paper, dry in an oven at 80°C for 24 hours to remove the solvent, and dry in a vacuum oven at 130°C for 30 minutes to remove embedded air bubbles. Then the mixture is poured into the mold, cured at 160°C / 2h+180°C / 2h+200°C / 2h and post-cured above 200°C. Finally, the cured resin is demolded to obtain a hybrid material of Eu complex and cyanate resin. The Eu complex / CE hybrid material sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com