Modified cyanate ester resin surface film and preparation method thereof

A technology of cyanate ester resin and surface film, applied in the direction of coating, etc., can solve the problems of low long-term use temperature, inconsistent curing temperature, poor matching of prepreg, etc., to increase resin toughness, interface bonding and adhesion The effect of increasing the junction strength and increasing the ability to resist microcrack propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

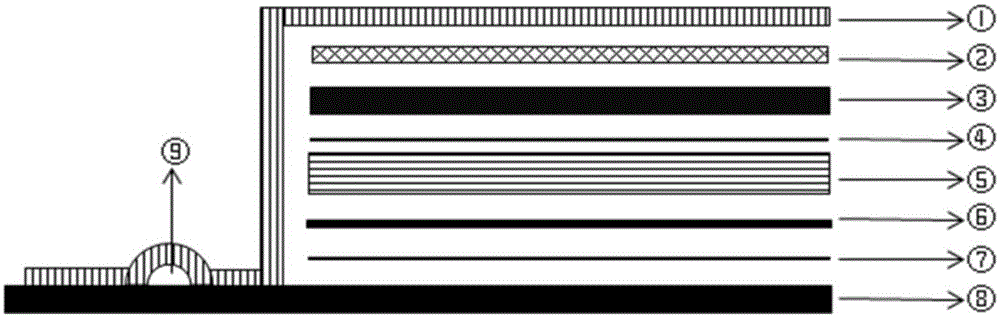

Image

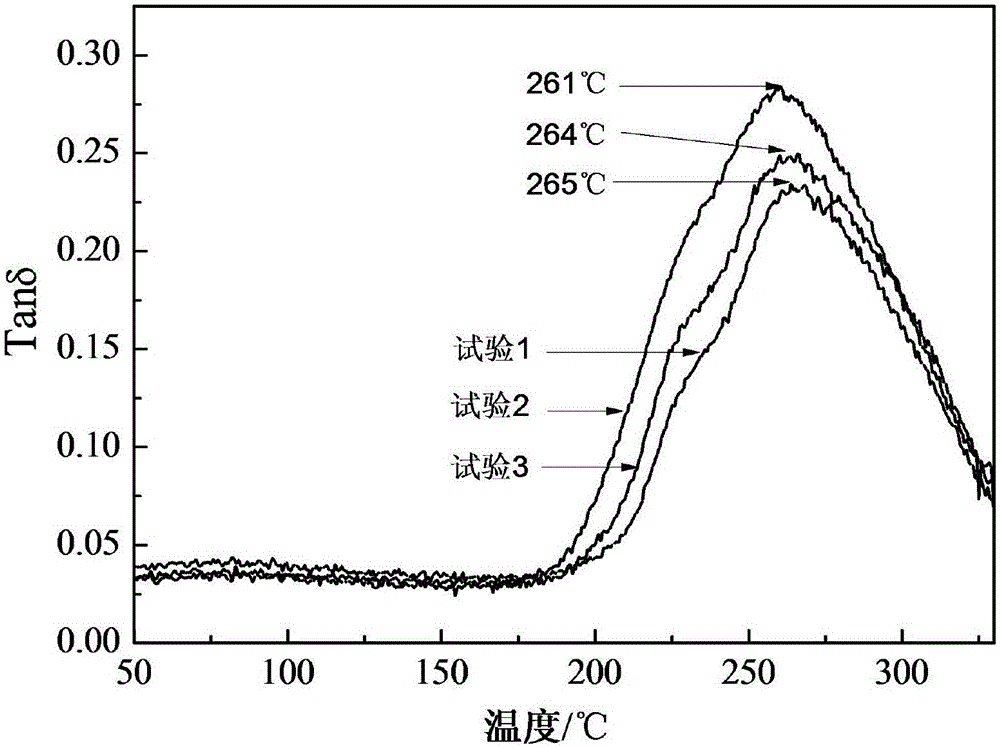

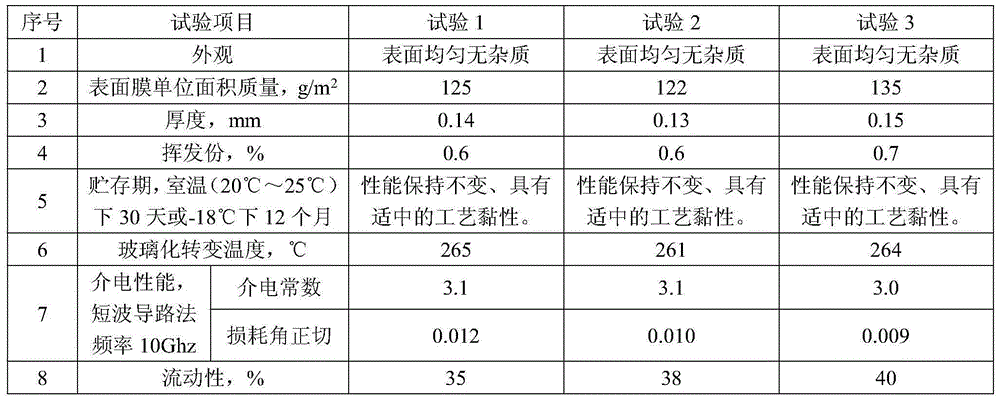

Examples

specific Embodiment approach 1

[0020] Specific implementation mode one: a modified cyanate ester resin surface film according to the present embodiment, which is composed of 75 to 100 parts of cyanate resin, 25 to 40 parts of copolymerization process modifier, 10 to 25 parts by weight. It consists of 1-4 parts of toughening modifier, 2-4 parts of curing accelerator, 1-3 parts of coupling agent, 1-4 parts of inorganic filler, 1-5 parts of UV stabilizer and carrier.

specific Embodiment approach 2

[0021] Specific embodiment two: this embodiment is different from specific embodiment one: cyanate resin is made of bisphenol A type cyanate resin, novolac type cyanate resin and bisphenol F type cyanate resin by mass ratio Composed in a ratio of 5:3:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the copolymerization process modifier is modified by diallyl bisphenol S bismaleimide resin and diallyl bisphenol A modified bismaleimide resin is composed of a mass ratio of 2:1. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com