Transmission belt base rubber and preparation method thereof

A transmission belt and primer technology, applied in the field of transmission belts, can solve the problem of easy breakage of the transmission belt primer, and achieve the effects of enhancing lateral rigidity, facilitating production, processing and work efficiency, good hardness and self-adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

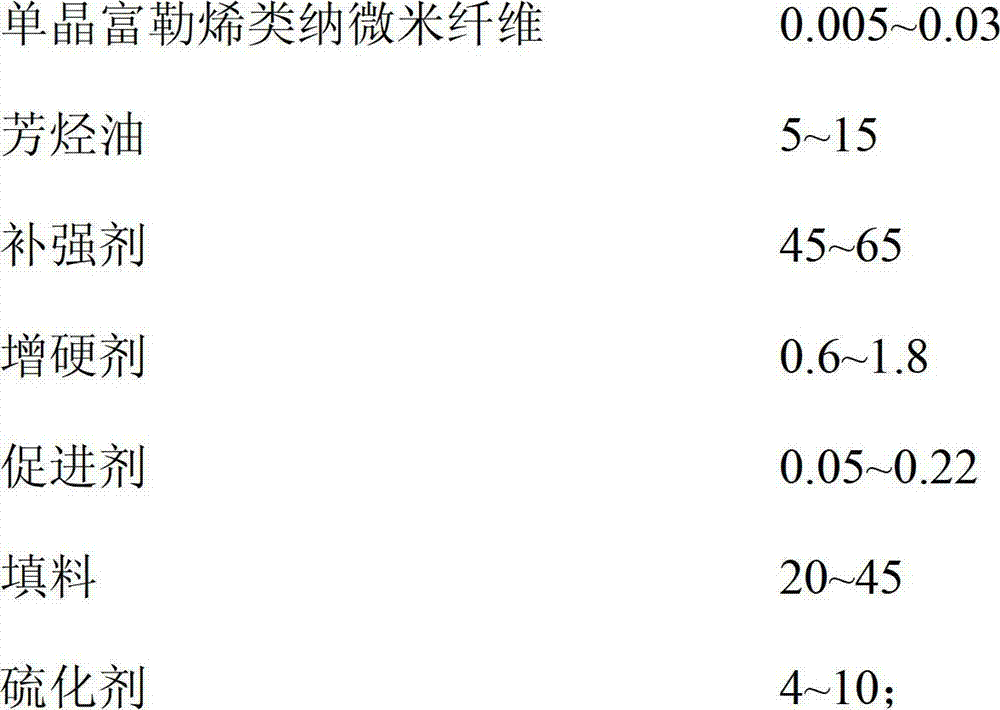

[0077] A kind of drive belt primer comprises by mass parts:

[0078]

[0079]

[0080] The preparation method of above-mentioned transmission belt primer is as follows:

[0081] (1) Add the EPDM rubber and chloroprene rubber in the formula amount into the open mill respectively, thin and pass 6 times, and roll down after wrapping and rolling for use;

[0082] (2) Mix the single-crystal fullerene-based nano-microfibers in the formulation amount with 20% of the formulation amount of aromatic oil, carbon black N770 and white carbon black to obtain a blend a, and mix the remaining substances according to the formulation amount to obtain blend b;

[0083] (3) After banburying the EPDM rubber obtained in step (1) in a 110L internal mixer for 20s, add blend a, continue banburying for 50s, and cut the obtained film into 8cm in length and width small pieces;

[0084] (4) Mix the chloroprene rubber obtained in step (1) in a 110L internal mixer for 30 seconds, then add the film ...

Embodiment 2

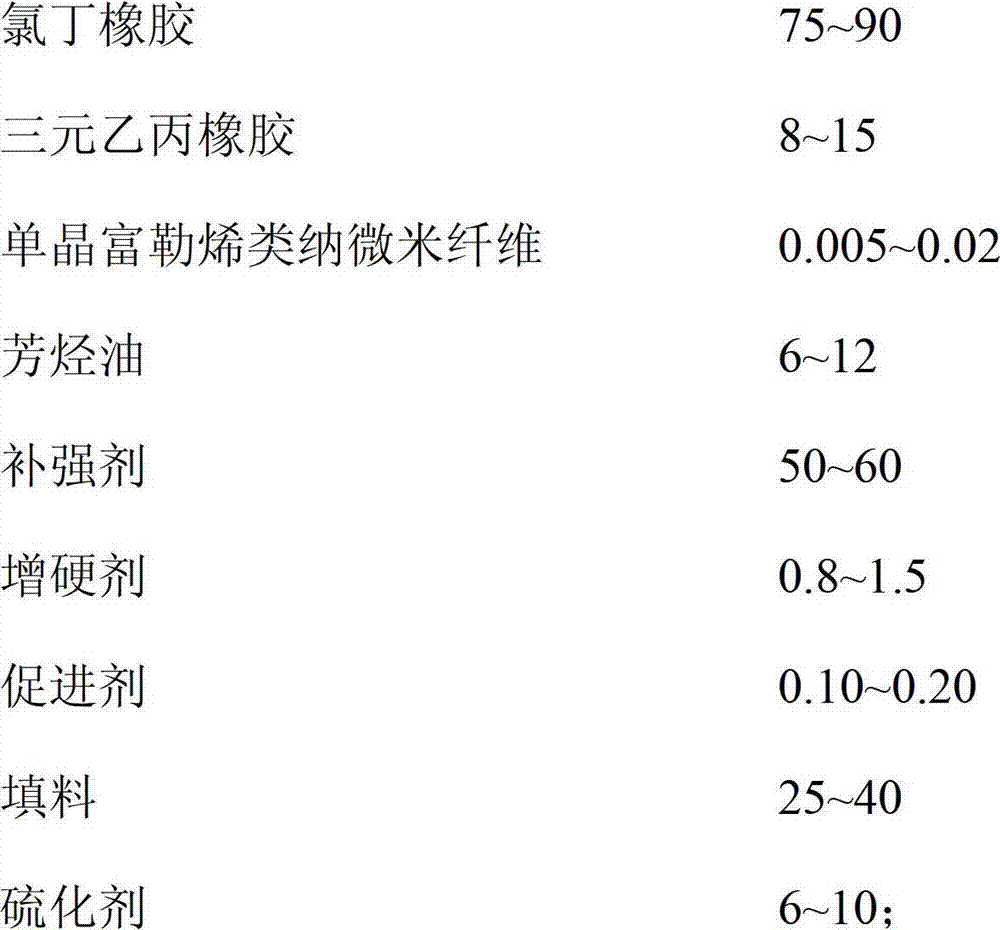

[0088] A kind of drive belt primer comprises by mass parts:

[0089]

[0090]

[0091] The preparation method of above-mentioned transmission belt primer is as follows:

[0092] (1) Add the EPDM rubber and chloroprene rubber in the formula amount into the open mill respectively, thin and pass 6 times, and roll down after wrapping and rolling for use;

[0093] (2) Mix the single-crystal fullerene-based nano-microfibers in the formulation amount with 20% of the formulation amount of aromatic oil, carbon black N770 and white carbon black to obtain a blend a, and mix the remaining substances according to the formulation amount to obtain blend b;

[0094] (3) After banburying the EPDM rubber obtained in step (1) in a 110L internal mixer for 40s, add blend a, continue banburying for 70s, and cut the obtained film into 8cm in length and width small pieces;

[0095] (4) Mix the chloroprene rubber obtained in step (1) in a 110L internal mixer for 50 seconds, then add the film ...

Embodiment 3

[0099] A kind of drive belt primer comprises by mass parts:

[0100]

[0101] The preparation method of above-mentioned transmission belt primer is as follows:

[0102] (1) Add the EPDM rubber and chloroprene rubber in the formula amount into the open mill respectively, thin and pass 6 times, and roll down after wrapping and rolling for use;

[0103] (2) Mix the single-crystal fullerene-based nano-microfibers in the formulation amount with 20% of the formulation amount of aromatic oil, carbon black N770 and white carbon black to obtain a blend a, and mix the remaining substances according to the formulation amount to obtain blend b;

[0104] (3) After banburying the EPDM rubber obtained in step (1) in a 110L internal mixer for 30s, add blend a, continue banburying for 60s, and cut the obtained film into 8cm in length and width small pieces;

[0105] (4) Mix the chloroprene rubber obtained in step (1) in a 110L internal mixer for 40 seconds, then add the film and blend b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com