Preparing method of thermoplastic resin matrix carbon fiber-titanium/titanium alloy laminate plate

A thermoplastic resin, titanium alloy technology, applied in the coating and other directions, can solve the problems of poor bonding effect, etc., to achieve the effect of less volatilization, less harm to human body and environment, and difficult to decompose production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

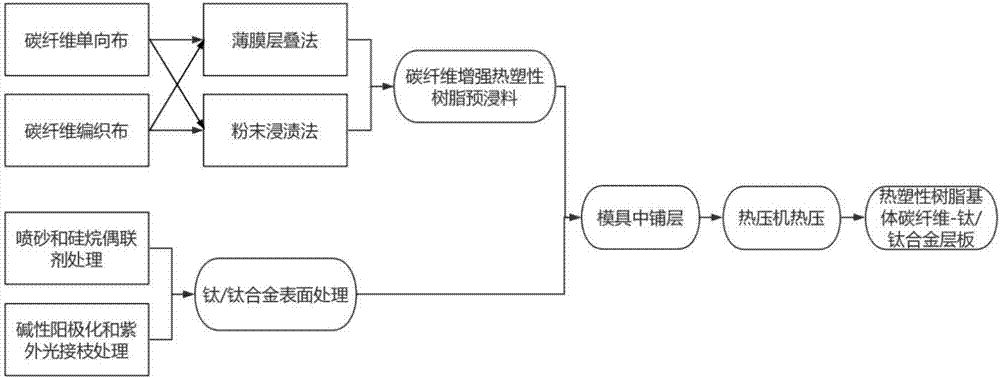

[0024] Embodiment 1: A method for preparing a thermoplastic resin matrix carbon fiber-titanium / titanium alloy laminate in this embodiment includes the following steps:

[0025] 1) Using a film lamination method or a powder impregnation method to impregnate a carbon fiber unidirectional fabric or a carbon fiber woven fabric with a thermoplastic resin to prepare a carbon fiber reinforced thermoplastic resin prepreg;

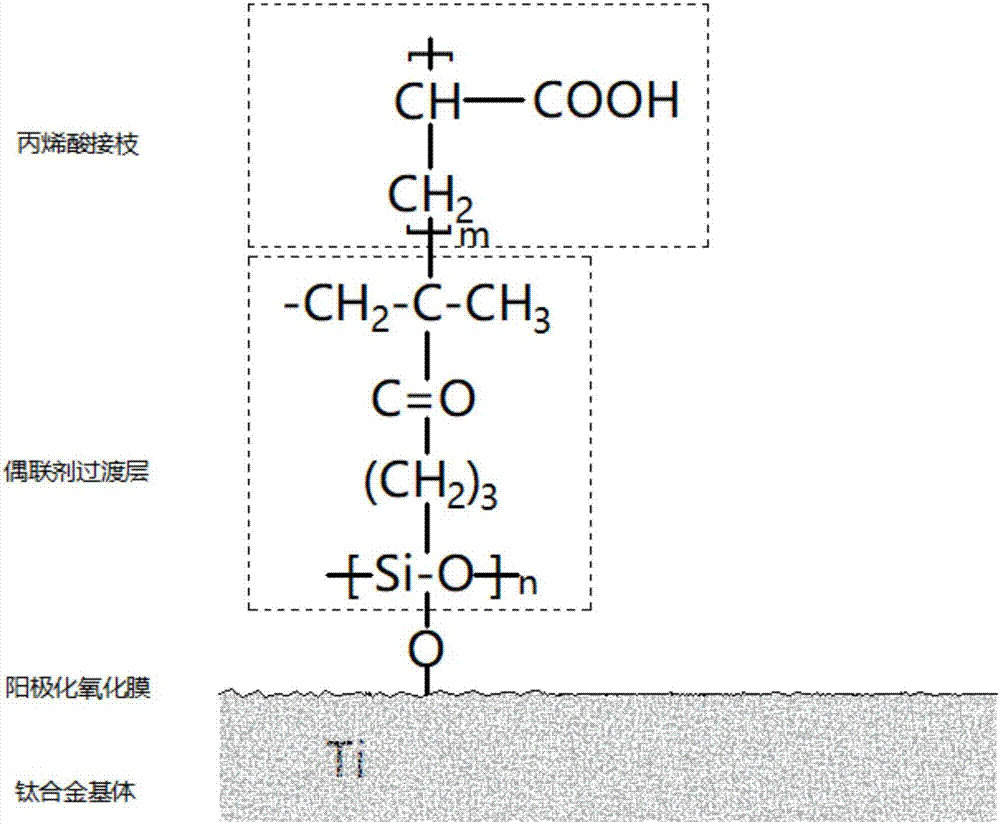

[0026] 2) The surface of the titanium / titanium alloy with a thickness of 0.3-0.5 mm is subjected to combined treatment of sandblasting and silane coupling agent or combined treatment of alkaline anodization and ultraviolet light grafting;

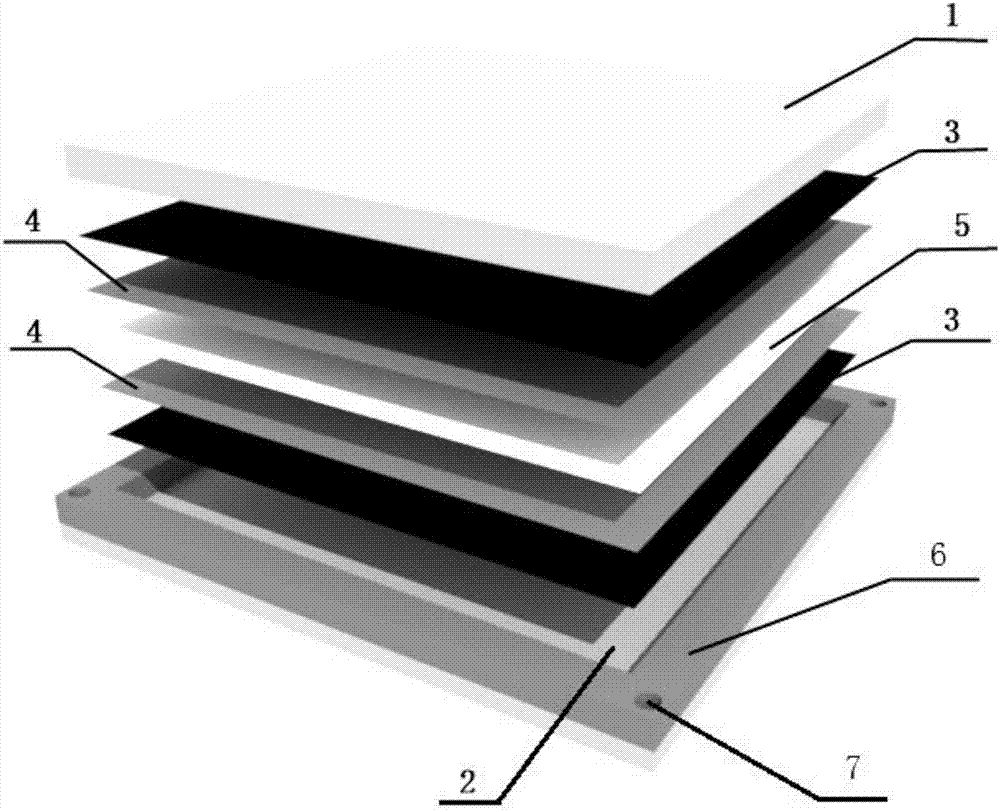

[0027] 3) Brush the release agent evenly on the inner side of the mold, lay up the titanium / titanium alloy and carbon fiber reinforced thermoplastic resin prepreg obtained by surface treatment in the mold according to the laying rules, and lay the titanium / titanium alloy and prepreg on each layer Place a thermoplastic resin film...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the process of preparing carbon fiber reinforced thermoplastic resin prepreg by film lamination method in step 1) is: single-layer carbon fiber unidirectional cloth or carbon fiber woven cloth with a thickness of 0.05-0.1mm thermoplastic resin film is superimposed, under the condition of temperature 250-370℃ and pressure 0.5-5MPa, it is hot-pressed by vulcanizer, and the rubber content is 50-60% and the thickness is 0.1-0.2mm. Prepreg. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030]Specific embodiment three: the difference between this embodiment and specific embodiment one is: the process of preparing carbon fiber reinforced thermoplastic resin prepreg by powder impregnation method in step 1) is: single-layer carbon fiber unidirectional cloth or carbon fiber woven cloth is dispersed The roller enters the electrostatic chamber in which thermoplastic resin powder with a particle size of 5-15 μm is suspended, and is fully mixed. According to the standard of prepreg glue content of 50-60% and thickness of 0.1-0.2mm, the single-layer carbon fiber unidirectional cloth or The carbon fiber woven cloth is supplemented with resin powder from top to bottom and placed in a vulcanizer. Under the conditions of temperature of 250-370°C and pressure of 0.5-5MPa, it is hot-pressed to obtain a prepreg. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com