Water varnish for protection of printable aluminum foil for drug packing and preparation method of water varnish

A water-based, aluminum foil technology, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of pungent odor of small molecule butanol, high environmental humidity requirements, affecting the speed of the drug packaging machine, etc. The surface printing has the advantages of strong adaptability, simple operation and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

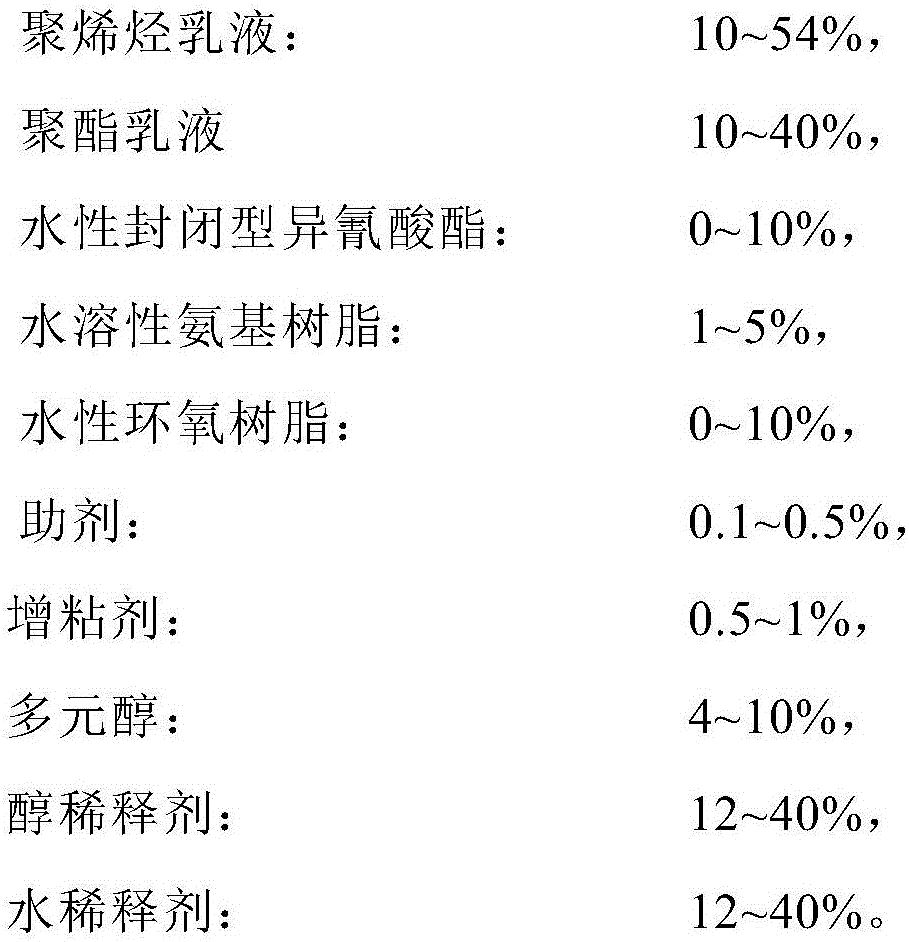

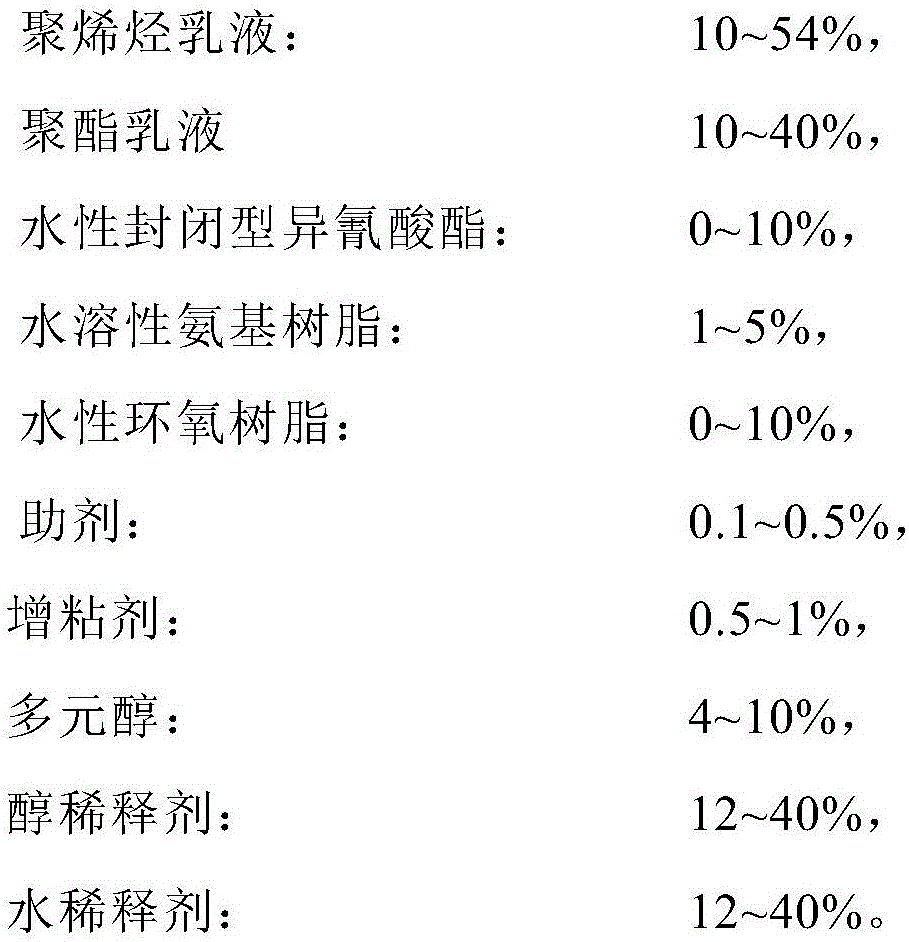

Method used

Image

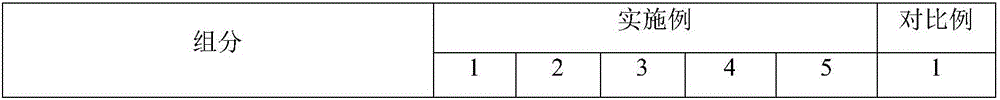

Examples

Embodiment 1

[0038] A kind of printing that this embodiment relates to is used for the preparation method of protective water-based varnish of pharmaceutical packaging aluminum foil, and the method comprises the following process steps:

[0039] (1) All the emulsions, i.e. 40Kg of polyolefin emulsion, 20Kg of polyester emulsion, 2Kg of water-soluble amino resin, and 9Kg of water-based epoxy are added to the reaction kettle successively, and kept stirring;

[0040] (2) After pre-mixing all the solvents, namely 12Kg of water, 12Kg of diluent alcohol, and 4.3Kg of polyols, slowly add the solvent to the reaction kettle while keeping stirring, and stir for about 1 hour;

[0041] (3) After stirring evenly, slowly add 0.2Kg of additives and 0.5Kg of tackifier, and keep stirring at high speed for about 30 minutes;

[0042] (4) When all the components are mixed evenly, stop the machine and mature for more than 12 hours;

[0043] (5) Measure the solid content and adjust to 25%;

[0044] (6) Stir s...

Embodiment 2

[0046] This embodiment relates to a method for preparing a water-based varnish that can be printed on the surface of a PTP aluminum foil for pharmaceutical blister packaging. The method includes the following process steps:

[0047] (1) First all the emulsions, i.e. polyolefin emulsion 50Kg, polyester emulsion 10Kg, water-based blocked isocyanate 5Kg, water-soluble amino resin 2Kg are added in the reactor successively, and keep stirring;

[0048] (2) After premixing all the solvents, namely 13Kg of water, 13Kg of diluent alcohol, and 6Kg of polyol, slowly add the solvent into the reaction kettle while keeping stirring, and stir for about 1 hour;

[0049] (3) After stirring evenly, slowly add 0.5Kg of additives and 0.5Kg of tackifier, and keep stirring at high speed for about 30 minutes;

[0050] (4) When all the components are mixed evenly, stop the machine and mature for more than 12 hours;

[0051] (5) Measure the solid content and adjust to 25%;

[0052] (6) Stir slowly f...

Embodiment 3

[0054] This embodiment relates to a method for preparing a water-based varnish that can be printed on the surface of a PTP aluminum foil for pharmaceutical blister packaging. The method includes the following process steps:

[0055] (1) First all the emulsions, i.e. polyolefin emulsion 45Kg, polyester emulsion 15Kg, water-based blocked isocyanate 3Kg, water-soluble amino resin 5Kg, water-based epoxy resin emulsion 3Kg are added in the reactor successively, and keep stirring;

[0056] (2) After premixing all the solvents, namely 12.4Kg of water, 12Kg of diluent alcohol, and 4Kg of polyols, slowly add the solvent to the reaction kettle while keeping stirring, and stir for about 1 hour;

[0057] (3) After stirring evenly, slowly add 0.1Kg of additives and 0.5Kg of tackifier, and keep stirring at high speed for about 30 minutes;

[0058] (4) When all the components are mixed evenly, stop the machine and mature for more than 12 hours;

[0059] (5) Measure the solid content and adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com