Split-type sealing ring

A sealing ring, split-half technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of short service life of the sealing ring, reduce the production efficiency of the enterprise, and troublesome operation of the sealing ring, so as to improve production efficiency, Simple structure and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

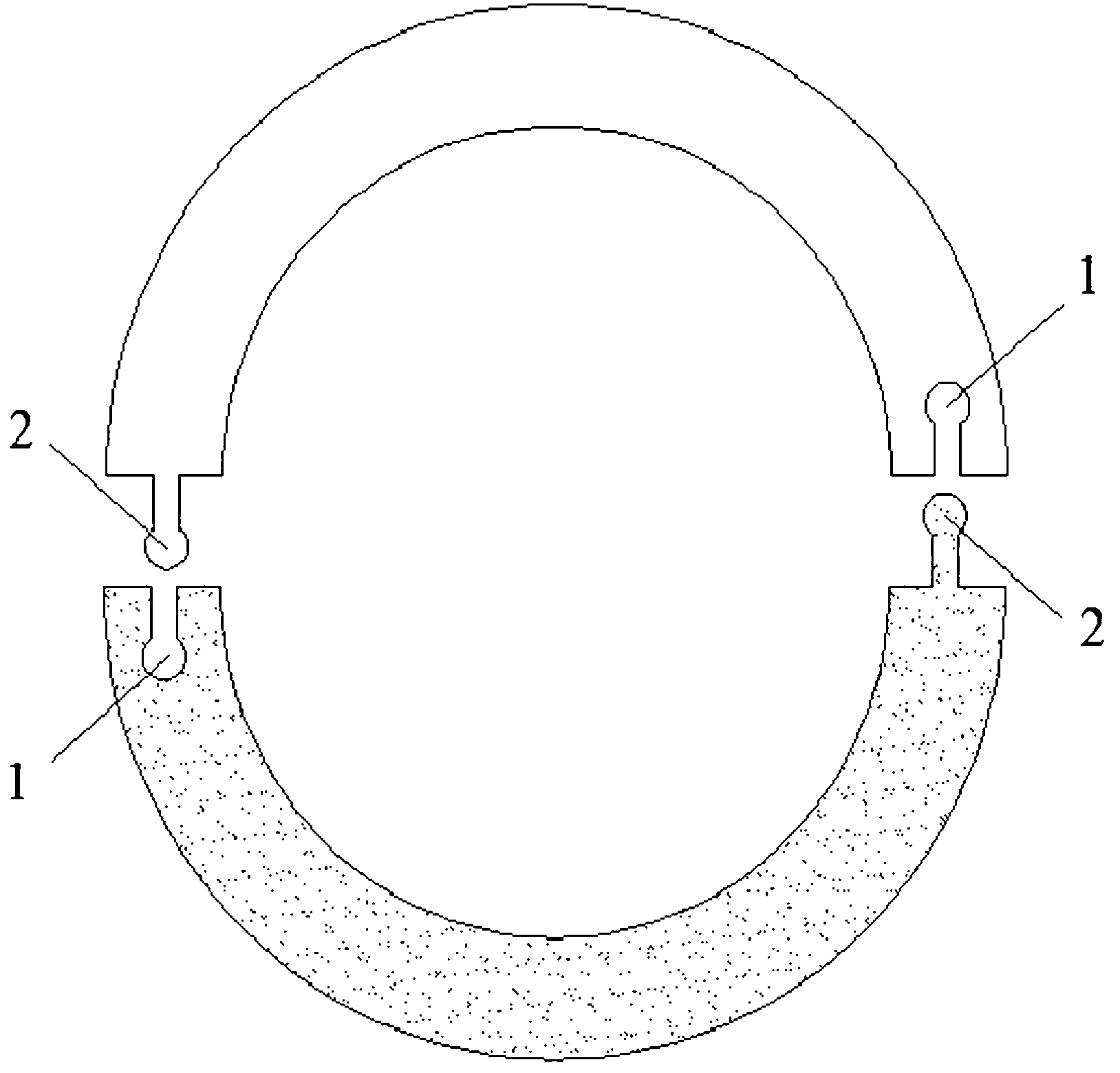

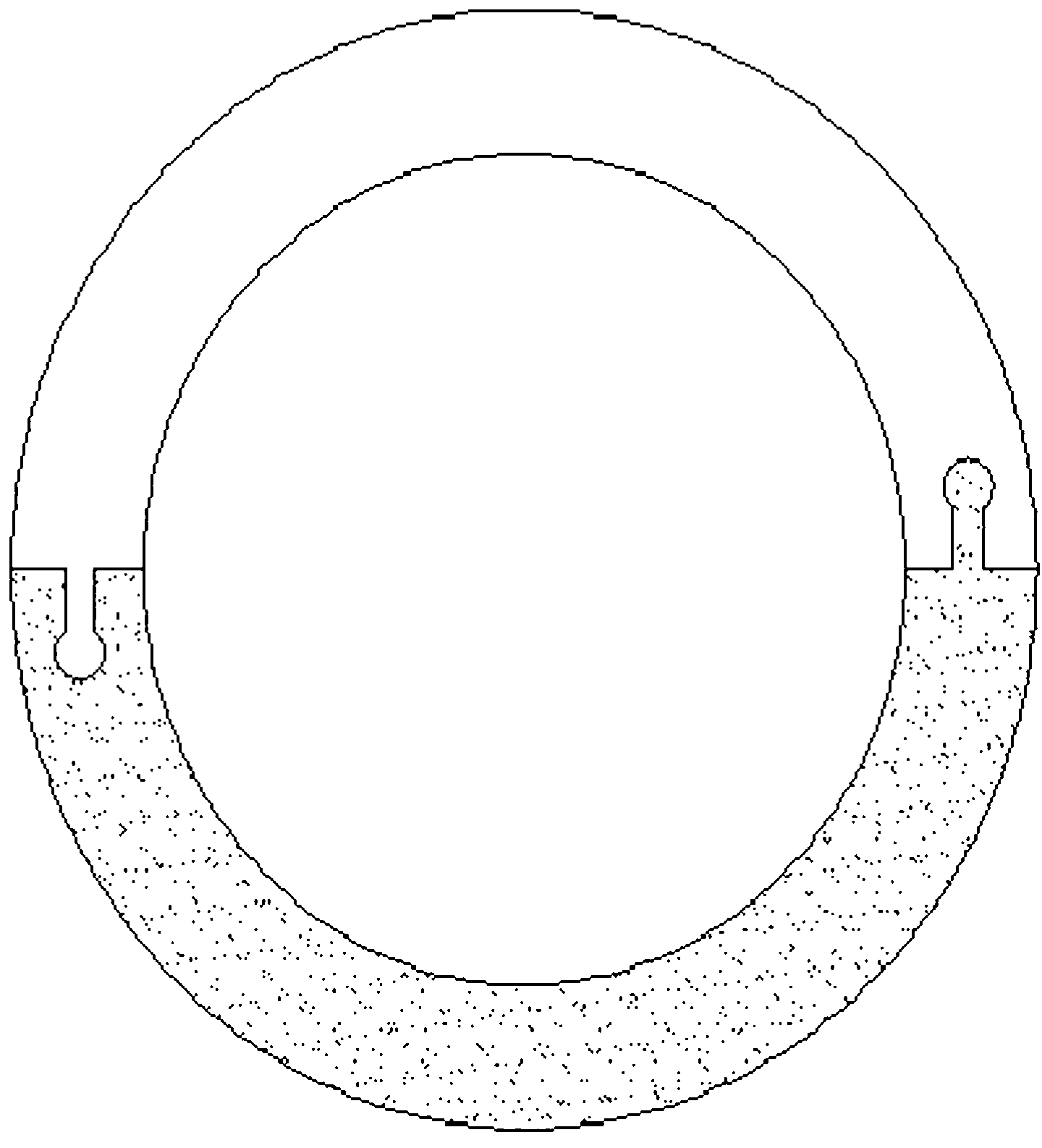

[0017] refer to figure 1 and figure 2 , taking the O-shaped sealing ring as an example, the split-half sealing ring of the present invention is composed of two separate halves that are spliced and inserted, that is, two semicircles are butted and then spliced and combined to form a complete circle.

[0018] As a preferred solution, the above two separated halves are assembled into a complete sealing ring through the interfitting joint slot 1 and the limit rod 2 . The shape of spelling slot 1 and limit rod 2 is not limited to figure 1 and figure 2 As shown, it can also be trapezoidal, fan-shaped, etc., which will not be repeated here.

[0019] More preferably, the splicing slot 1 and the limit rod 2 are formed on the abutting surface of the sealing ring. Since the sealing ring needs to be coated with lubricating oil on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com