Reflecting film and manufacturing method thereof, and use of the reflecting film

A technology of reflective film and aluminum film, applied in chemical instruments and methods, devices for coating liquid on the surface, lamination, etc., can solve the problems of low reflective rate, no reflective property, easy to fall off, etc., and achieve strong weather resistance, Easy to paste, strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

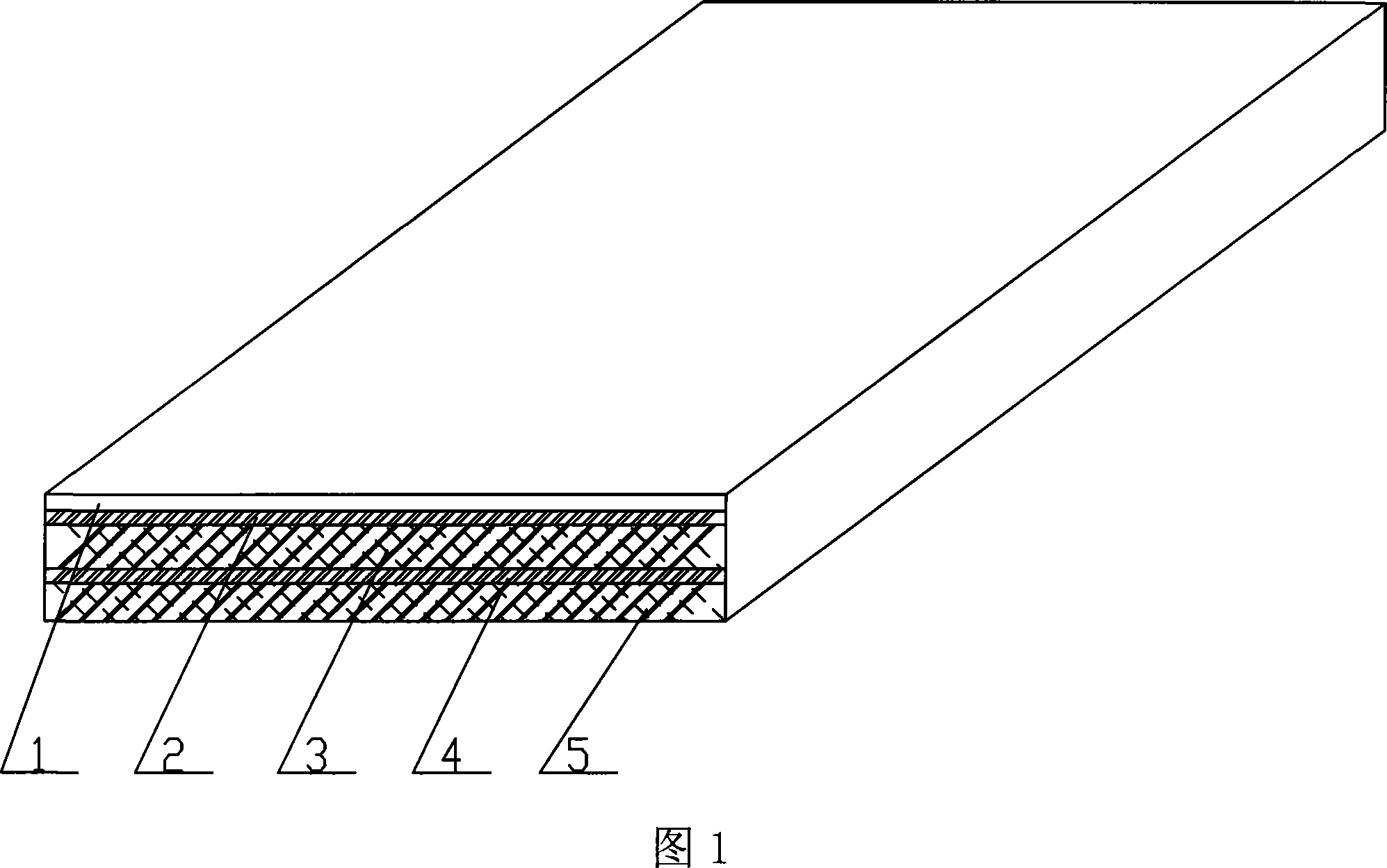

[0010] With reference to accompanying drawing, reflective film of the present invention comprises base material 3, base material 3 adopts PET high-transparency plastic film, all is coated with aluminum film 2,4 at base material 3 both sides, a surface of base material 3 is coated with aluminum film 4 Combined with the base surface 5 with an oily pressure-sensitive adhesive, the other surface of the substrate 3 coated with the aluminum film 2 is evenly coated with a layer of organic silicon glass resin coating 1 .

[0011] The production method is: choose 4-5 wire thick PET high-transparency plastic film as the substrate, use a vacuum coating machine to use high-purity aluminum wire as the raw material to vacuum-plate aluminum on both sides of the substrate, and coat one of the substrates with aluminum. The surface of the film is coated with an oily pressure-sensitive adhesive with a solid content of 35wt%, and the amount of glue used is 80 grams per square meter. Paste the back...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com