Strawberry-shaped super-hydrophobic composite microsphere and application thereof

A composite microsphere and super-hydrophobic technology, which is applied in the direction of microsphere preparation, microcapsule preparation, coating, etc., can solve the problems of limited use and poor durability, and achieve improved binding force, good durability, and strong durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

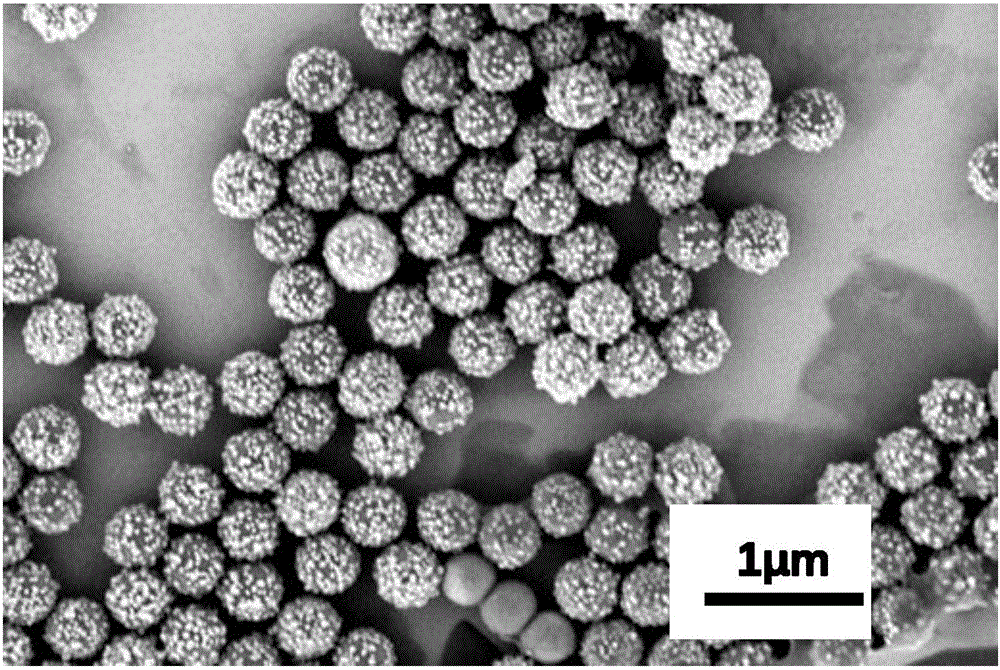

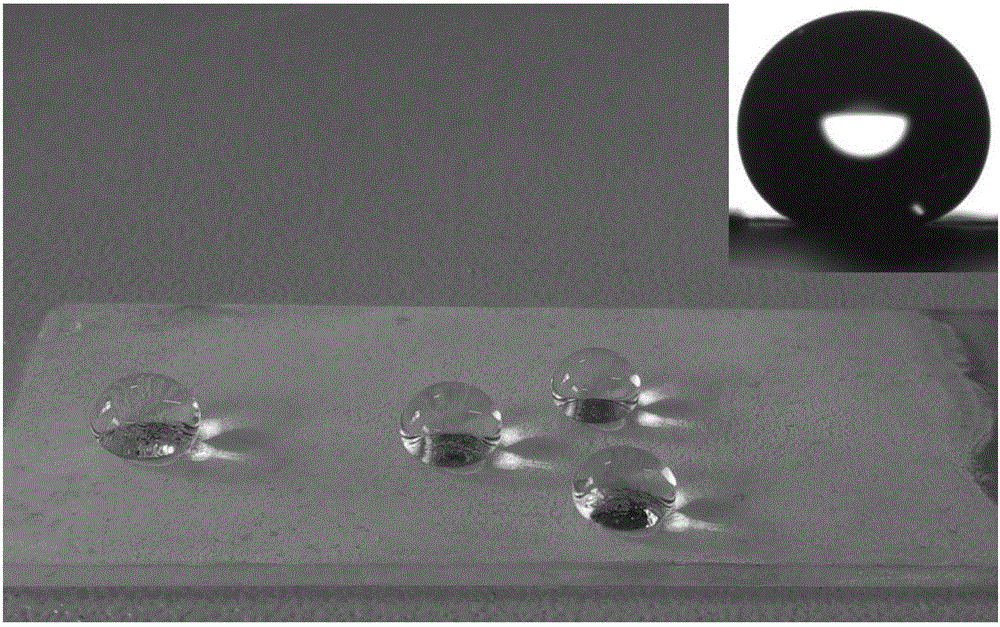

[0029] (1) Preparation of strawberry-like superhydrophobic composite microspheres

[0030] Put 1g of linear aminopolystyrene microspheres (500nm) into the reactor, add 100mL (78.93g) of ethanol, stir until the aminopolystyrene microspheres are evenly dispersed, then add 20g of tetraethyl orthosilicate (TEOS) and 20g of Put distilled water into the reactor and react at room temperature for 24 hours to obtain a strawberry-like composite microsphere dispersion. The product was washed with ethanol three times and vacuum-dried to obtain a strawberry-like PS / SiO 2 Composite microsphere powder. Take 1g strawberry-like PS / SiO 2 Add the composite microsphere powder into the reactor, and then add 100mL (78.93g) of dispersion ethanol. After the system temperature reaches 80°C, add 300μL (0.42g) of perfluorooctyltrimethoxysilane to modify the reaction for 12h, centrifuge Finally, strawberry-like superhydrophobic composite microspheres were obtained.

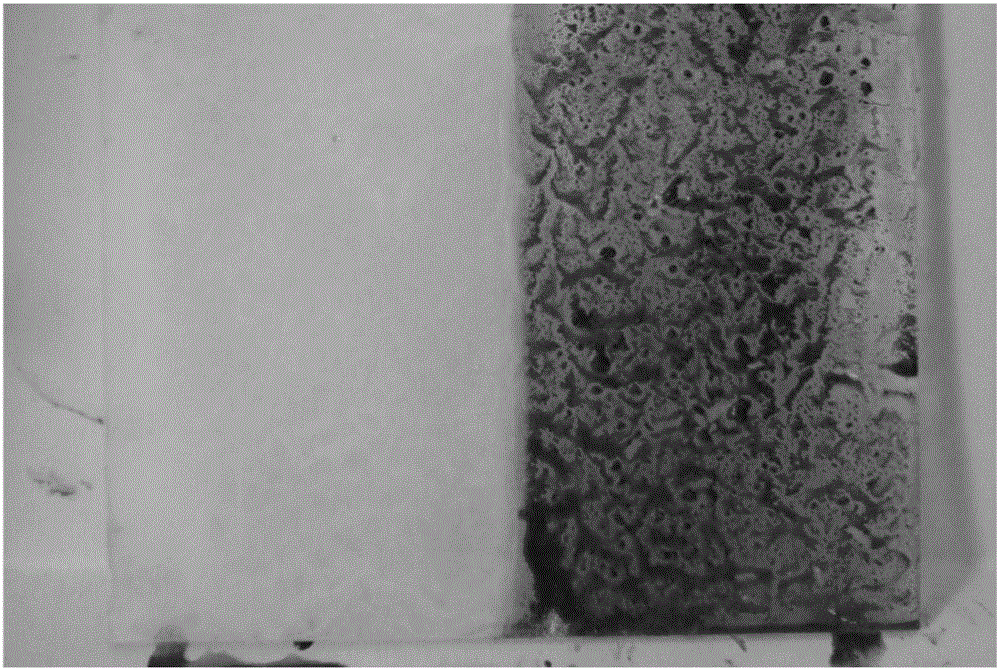

[0031] (2) Strawberry-like superhy...

Embodiment 2

[0038] (1) Preparation of strawberry-like superhydrophobic composite microspheres

[0039] Put 1 g of amino polystyrene microspheres (600 nm) with a cross-linking degree of 30% into the reactor, add 100 mL (78.93 g) of ethanol, stir until the amino polystyrene microspheres are uniformly dispersed, and then add 20 g of ethyl orthosilicate Ester (TEOS) and 20g of distilled water were put into the reactor, and reacted at room temperature for 24h to obtain a strawberry-like composite microsphere dispersion. The product was washed with ethanol three times, and after vacuum drying, the strawberry-like PS@SiO 2 Composite microsphere powder. Take 1g strawberry PS@SiO 2 Add the composite microsphere powder into the reactor, and then add 100mL (78.93g) of ethanol as the dispersion liquid. After the system temperature reaches 80°C, add 300μL (0.46g) of perfluorodecyltrimethoxysilane to modify the reaction for 10h, centrifuge Finally, strawberry-like superhydrophobic composite microsphe...

Embodiment 3

[0046] (1) Preparation of strawberry-like superhydrophobic composite microspheres

[0047] Put 1 g of amino polystyrene microspheres (500 nm) with a cross-linking degree of 40% into the reactor, add 100 mL (78.93 g) of ethanol, stir until the amino polystyrene microspheres are uniformly dispersed, and then add 20 g of ethyl orthosilicate Ester (TEOS) and 20 g of distilled water were put into the reactor, and reacted at room temperature for 24 hours to obtain a strawberry-like composite microsphere dispersion. The product was washed with ethanol three times, and after vacuum drying, a strawberry-like PS / SiO 2 Composite microsphere powder. Take 1g strawberry PS@SiO 2 Add the composite microsphere powder into the reactor, then add 100mL (78.93g) of ethanol as the dispersion, and add 300μL (0.27g) of hexadecyltrimethoxysilane to modify the reaction for 12h after the system temperature reaches 80°C. After centrifugation, strawberry-like superhydrophobic composite microspheres wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com