Multilayer chip ZnO varistor prepared by nano material and manufacturing method

A varistor and nanomaterial technology, applied in varistor core, resistor manufacturing, varistor and other directions, can solve the problem of reducing the nonlinear coefficient of varistor, increasing the leakage current of varistor, Resistance performance deterioration and other problems, to achieve the effect of saving production steps, reducing usage, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

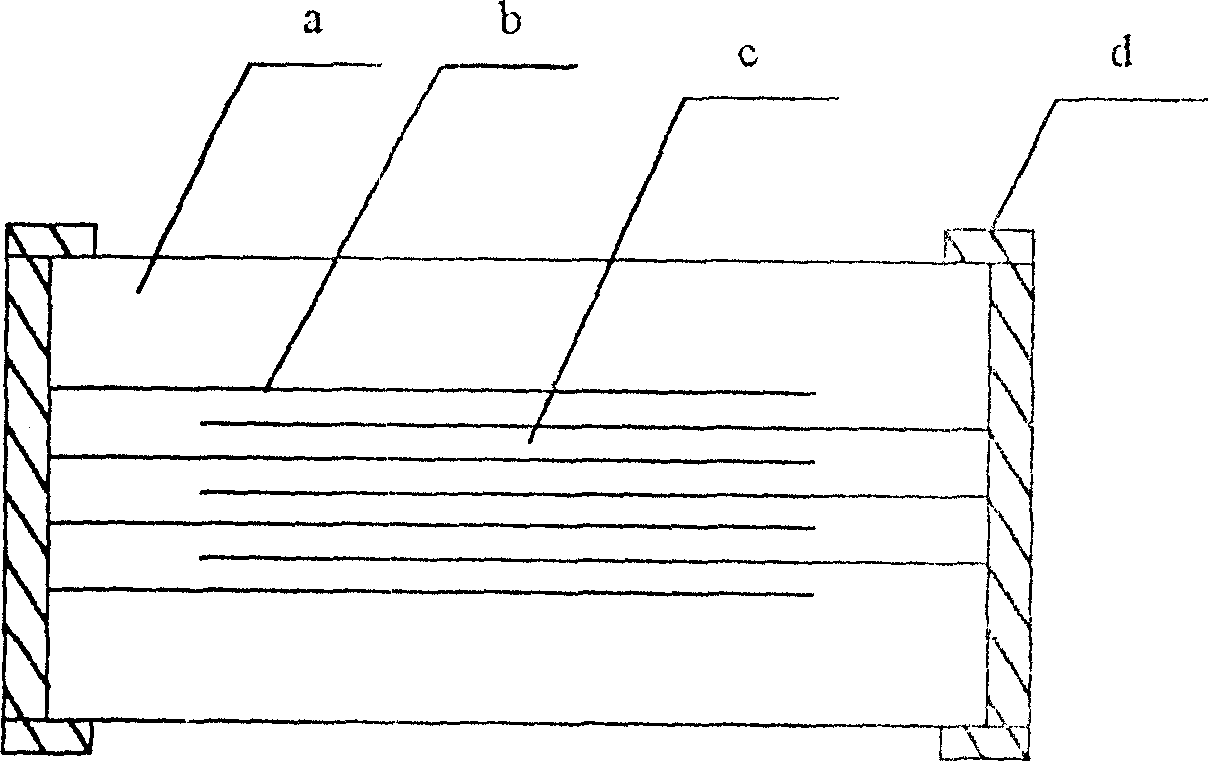

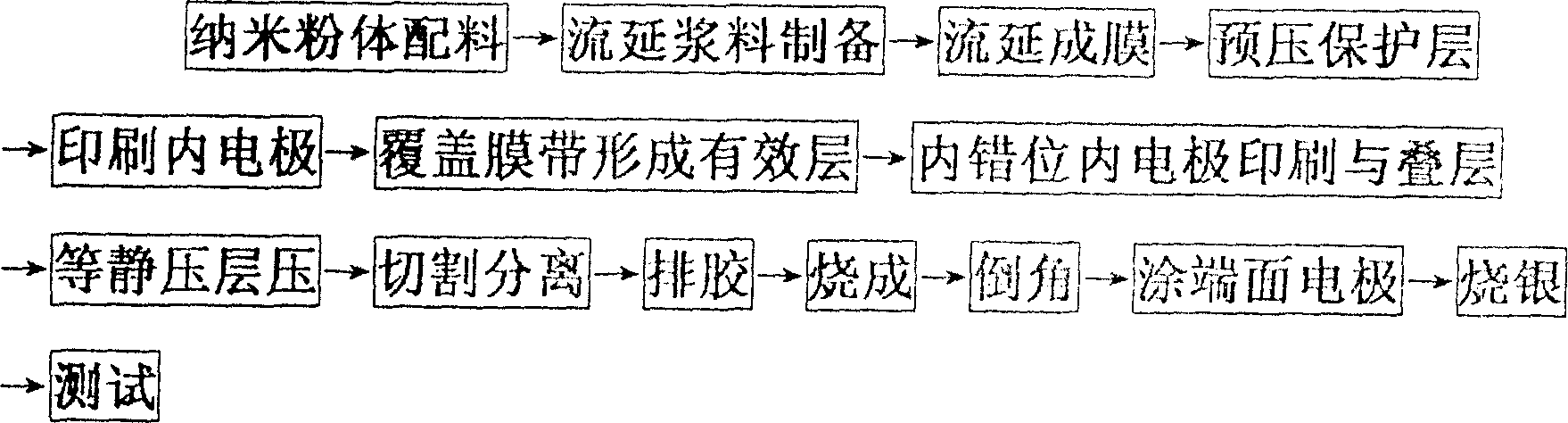

[0038] Such as figure 1 structure shown, figure 2 The manufacturing method process shown, and according to formula table 1, accurately weigh the oxides of the nano-ZnO powder that the average particle diameter is 99nm and the various nano-powder additives that the average particle diameter is 99nm, put the weighed material into Add appropriate amount of xylene, binder, dispersant and zirconium balls to the ball mill, mill for 12 hours to obtain casting slurry, and then cast a ceramic film tape with a thickness of 25 microns, and press the ten-layer ceramic film tape slightly A film with a thickness of about 250 microns is obtained, and an alloy internal electrode b with a weight ratio of 75% silver and 25% palladium is printed on the film with a protective layer a, and another layer of internal electrodes is printed in a misplaced manner after lamination until The effective layer c is 8 layers. After isostatic pressure, the sintered green body with a size of 1.0×0.5mm is cut...

Embodiment 2

[0041] Such as figure 1 structure shown, figure 2 The manufacturing method process shown, and according to the formula table two, accurately weigh the oxides of the nano-ZnO powder with an average particle diameter of 1nm and various nano-powder additives with an average particle diameter of 1nm, and put the weighed materials into Add appropriate amount of xylene, binder, dispersant and zirconium balls to the ball mill, mill for 12 hours to obtain casting slurry, and then cast a ceramic film tape with a thickness of 25 microns, and press the ten-layer ceramic film tape slightly A film with a thickness of about 250 microns is obtained. On the film with a protective layer a, an alloy internal electrode b with a weight ratio of 89% silver and 11% palladium is printed, and another layer of internal electrodes is printed in a misplaced manner after lamination until The effective layer c is 8 layers. After isostatic pressure, the sintered green body with a size of 1.0×0.5mm is cut...

Embodiment 3

[0044] Such as figure 1 structure shown, figure 2 According to the manufacturing method flow shown, accurately weigh the composite nano-particles containing Zn and Bi, Sb, Mn, Si, Cr, Co, Ni, Al and other elements with an average particle size of 40nm according to the formula table three. Oxide powder, put the weighed material into a ball mill and add an appropriate amount of xylene, binder, dispersant and zirconium balls, ball mill for 12 hours to obtain a cast slurry, and then cast a 25 micron thick Ceramic membrane strips, ten layers of ceramic membrane strips are slightly pressed to obtain a membrane strip protective layer a with a thickness of about 250 microns, and an alloy internal electrode b with a weight ratio of 85% silver and 15% palladium is printed on the film strip protective layer a, and the laminated After one layer, another layer of internal electrodes is printed in dislocation until the effective layer c is 8 layers. After isostatic pressure, the sintered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com