Novel cigarette for heating non-combustible tobacco

A heat-not-burn, tobacco stick technology, applied in applications, tobacco, smoke oil filter elements, etc., can solve the problems of increasing processing costs and steps, increasing processing costs, and difficult control of processing and manufacturing, so as to reduce the complexity of production processes and materials cost, reduce production equipment cost, and release smoke quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

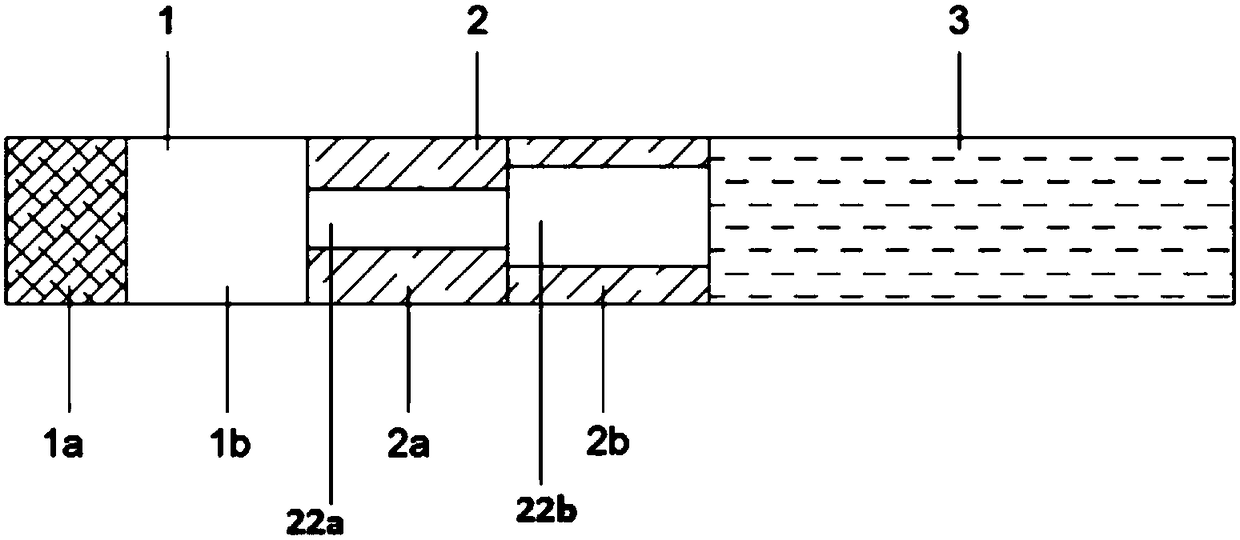

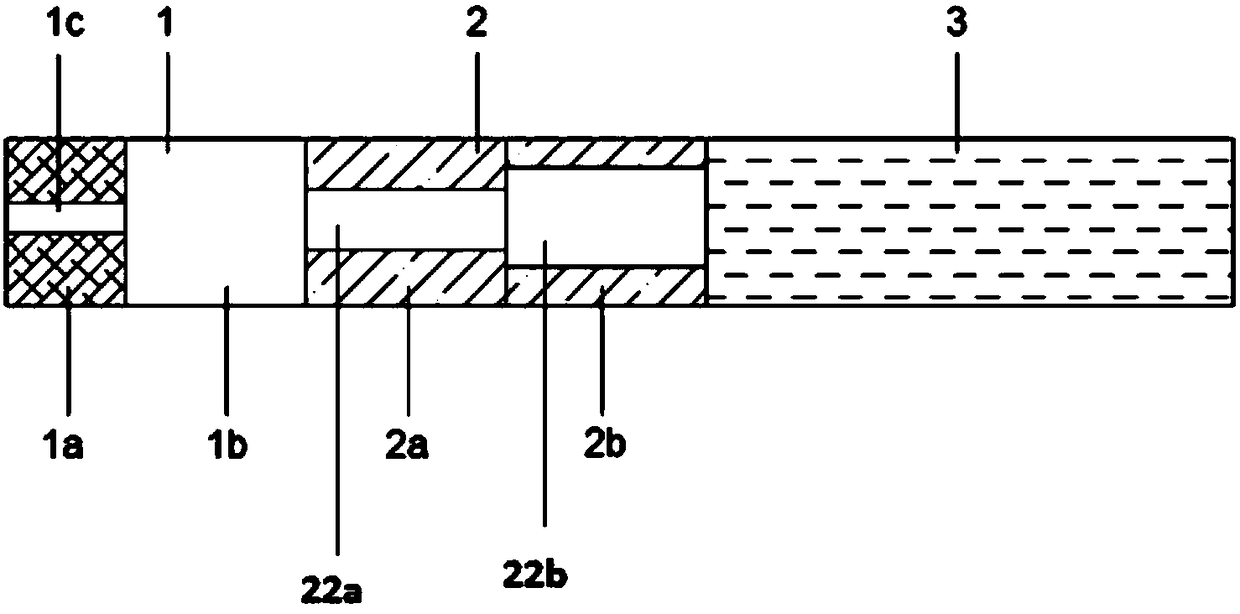

[0023] An axial micro-cavity (1c) is added to the filter section (1a) in the countersunk head filter rod (1), and the shape can be polygonal, preferably circular. The flue gas temperature can be lowered again, wherein the material used in the filter section (1a) can be a high molecular polymer such as acetate fiber, polylactic acid, metal fiber, preferably a combination of acetate fiber and polylactic acid. See image 3 .

Embodiment 2

[0025] In the axial microcavity (1c) of the filter segment (1a) in the reverse countersunk head filter rod (1), increase the first fragrance-enhancing gel (1d), the taste that this flavor-enhancing gel has can be Tobacco, mint, wine aroma, food aroma, etc. are liquid substances that are not limited to the form of aroma. When inhaling, the pressure can be used to explode it to increase the aroma of the smoke. See Figure 4 .

Embodiment 3

[0027] In the axial microcavities (1c) and the first axial cavities (22a) in the filter section (1a), respectively add the first scented gel 1d) and the second scented gel (2c), the two The flavors of the scent-increasing gel can be tobacco, peppermint, wine, food and other liquid substances that are not limited to the form of fragrance. Among them, the fragrance of the first fragrance-enhancing gel (1d) and the second fragrance-enhancing gel (2c) can be consistent or inconsistent. The two are extruded by external pressure, and finally exploded, so that the fragrance itself is released, and the fragrance of the smoke is further increased. . See Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com