Preparation method of single-layer graphene

A graphene and monolayer technology, applied in the field of monolayer graphene preparation, can solve problems such as difficulty in preparing large-sized graphene, high price of SiC wafers, unfavorable large-scale application, etc., and achieve low cost of raw materials and production steps. Less and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

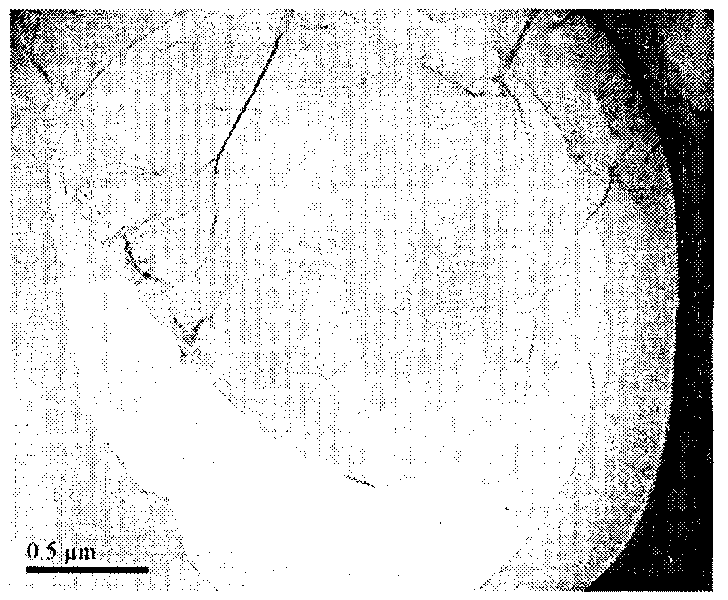

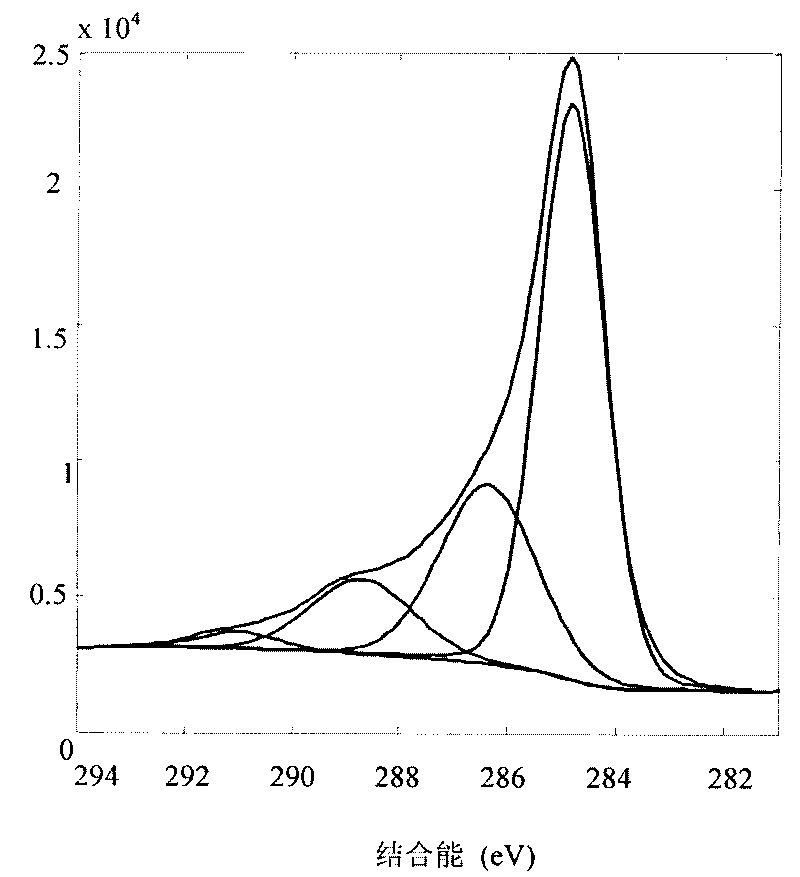

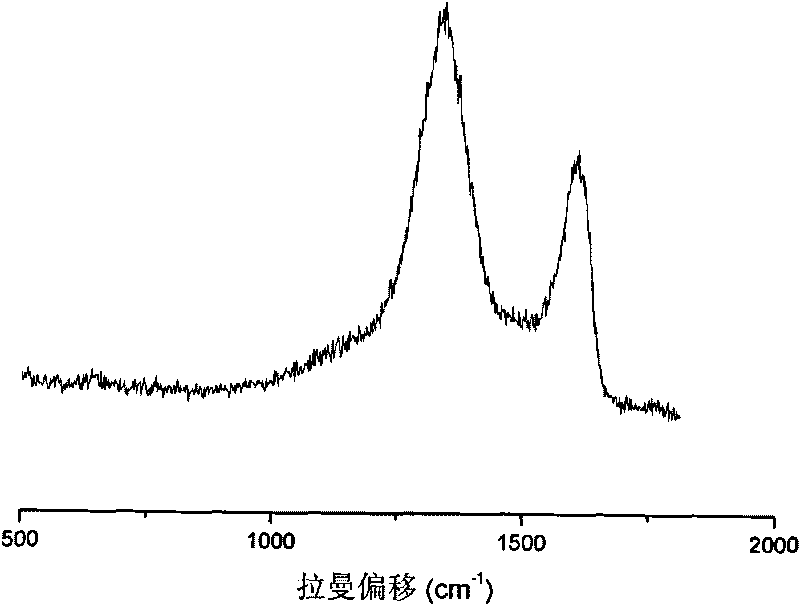

[0013] First prepare graphene oxide: take 20g of 325 mesh natural flake graphite particles and 460mL of concentrated H with a mass concentration of 98%. 2 SO 4 Place in a three-necked flask, slowly add 60g KMnO in a water bath at 0°C 4 , the control temperature cannot be higher than 20°C. Add 920mL of deionized water into the three-necked flask, and keep the reaction at 35±3°C for 2h. Finally, add 2.8L of deionized water and 50mL of H 2 o 2 , the mixture changed from tan to bright yellow, and the reaction was terminated after 15 min. Wash and filter the above reaction product with 5 L of 1:10 HCl solution to remove some metal ions. Put the graphite oxide washed with dilute hydrochloric acid into a dialysis bag, and perform dialysis in deionized water. 2 Solution inspection filtrate without SO 4 2- , and with AgNO 3 Solution test without Cl - until. Filter and dry to obtain graphite oxide. Take this graphite oxide and prepare a 1 mg / mL graphite oxide aqueous dispers...

Embodiment 2

[0016] Graphene oxide preparation method is identical with embodiment example 1.

[0017] Take 20 mL of the 1 mg / mL graphene oxide aqueous dispersion prepared in Example 1, place it in a conical flask, add 54 g of deionized water, then place the conical flask in an ice-water bath, and slowly dropwise add a mass fraction of 98% 100mL of concentrated sulfuric acid was prepared into a reaction solution with a sulfuric acid mass concentration of 70%. After the dropwise addition, the triangular flask was placed in a constant temperature blast drying oven at 80°C and reacted at a constant temperature for 24 hours. After the reaction was completed, the reaction mixture was slowly poured into 1 L of deionized water, and cooled to room temperature. Filter with a solvent filter, wash the filter cake 3 times with 500 mL of deionized water, and finally wash with BaCl 2 No white precipitate was formed in the solution test filtrate. The obtained filter cake was transferred to a vacuum ove...

Embodiment 3

[0019] Graphene oxide preparation method is identical with embodiment example 1.

[0020] Get 16 mL of the 1 mg / mL graphene oxide aqueous dispersion prepared in Example 1, place it in an Erlenmeyer flask, place the Erlenmeyer flask in an ice-water bath, slowly add 100 mL of concentrated sulfuric acid with a mass fraction of 98%, and prepare The sulfuric acid mass concentration is 90% reaction liquid, after dropwise addition, this triangular flask is put into 60 ℃ constant temperature blast drying box, constant temperature reaction 24 hours. After the reaction was completed, the reaction mixture was slowly poured into 1 L of deionized water and cooled to room temperature. Filter with a solvent filter, wash the filter cake 4 times with 500 mL of deionized water, and finally wash with BaCl 2 No white precipitate was formed in the solution test filtrate. The obtained filter cake was transferred to a vacuum oven, and dried at 75° C. for 8 hours to obtain a black graphene film. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com