Preparation method of graphene

A graphene, graphene solution technology, applied in graphene, nano-carbon and other directions, can solve the problems of long reaction time and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

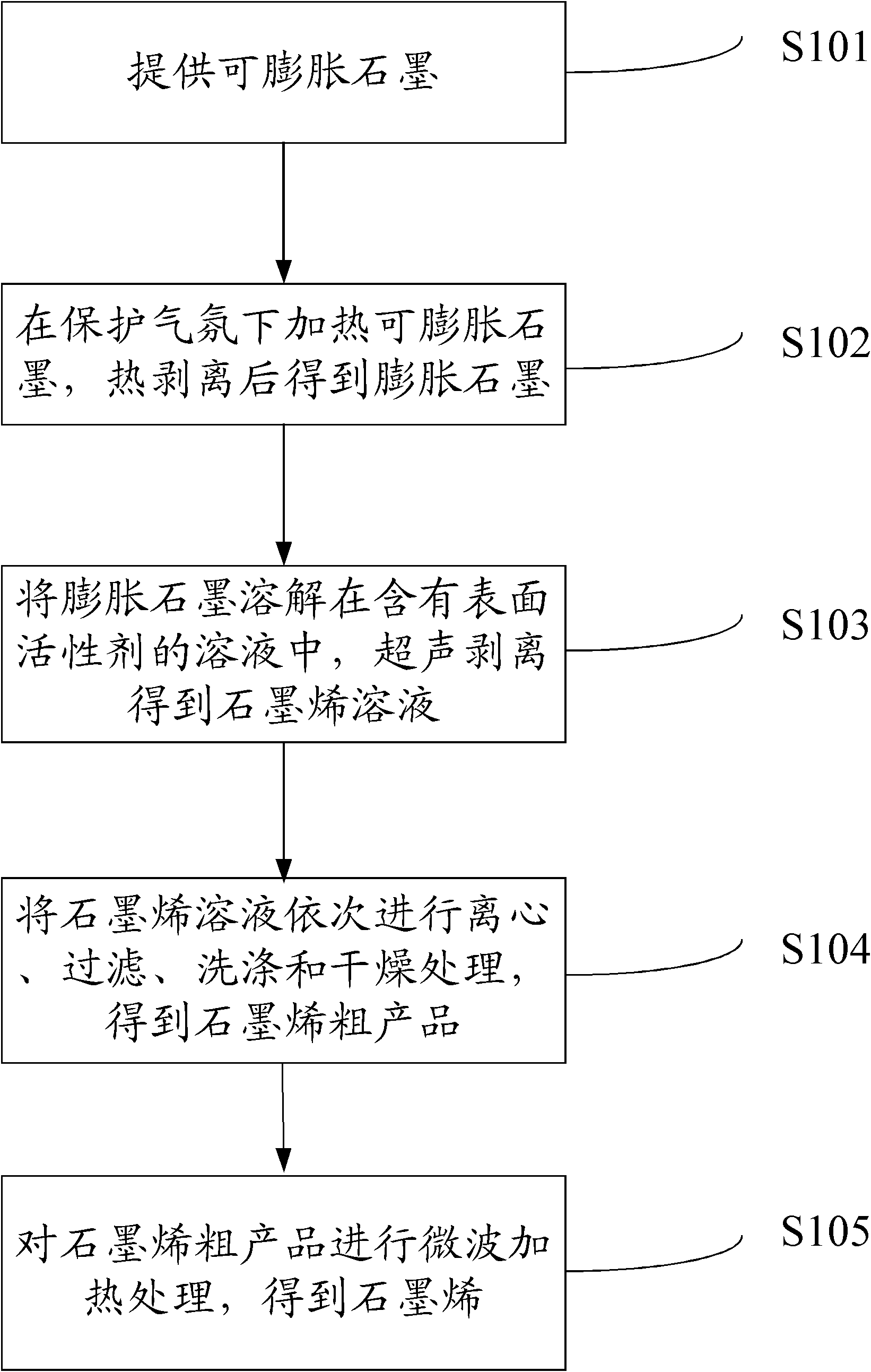

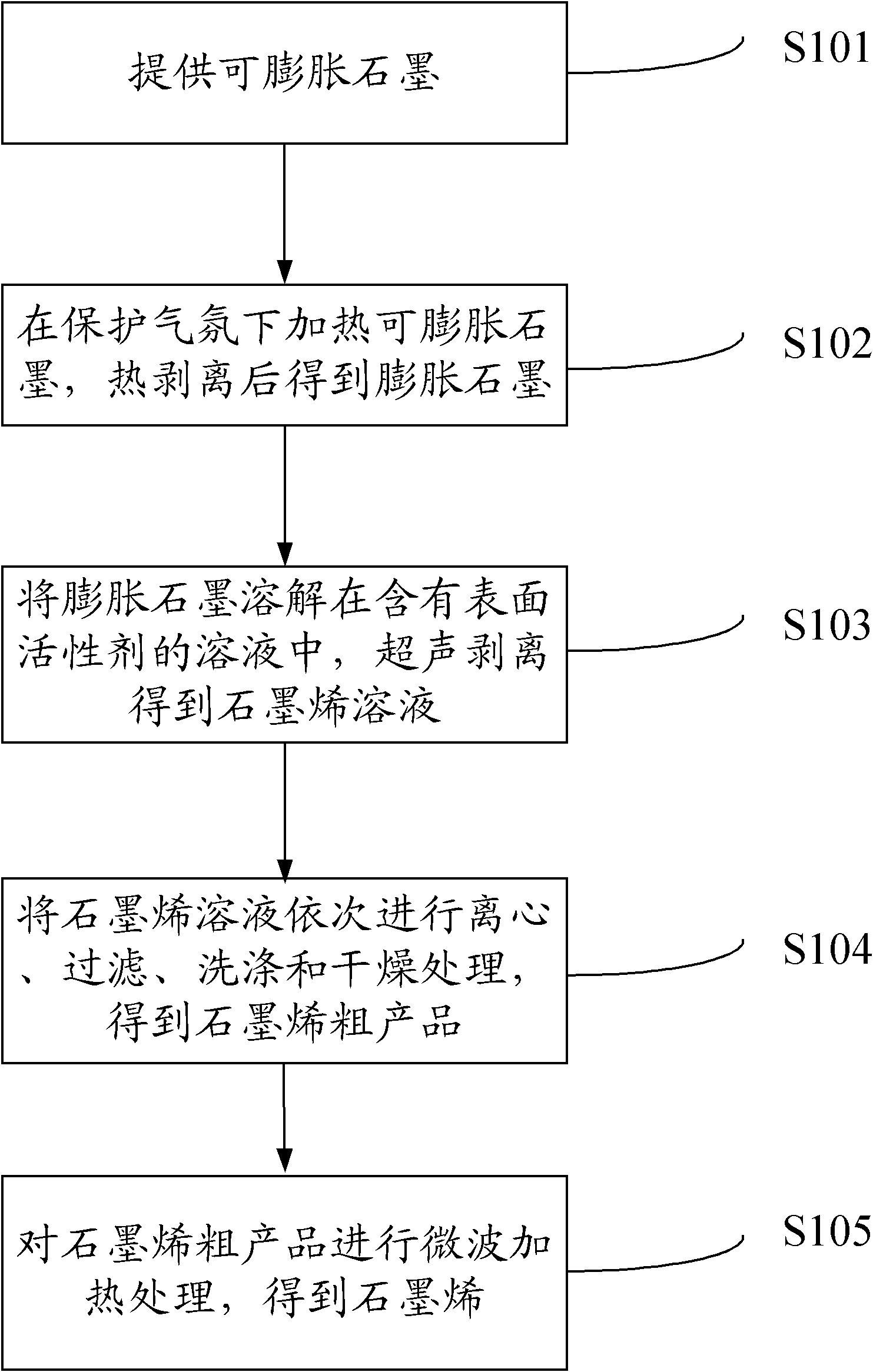

[0019] see figure 1 , the preparation method of the graphene of an embodiment comprises the steps:

[0020] Step S101, providing expandable graphite. The expandable graphite is expandable graphite that complies with the national standard GB / T 10698-1989, and generally refers to natural crystalline graphite that can instantly expand into a worm-like shape when exposed to high temperature after special treatment. The expandable graphite used in this embodiment has an average diameter of 300-500 μm and a purity of 99-99.5%.

[0021] Step S102, heating the expandable graphite under a protective atmosphere to obtain expanded graphite after thermal exfoliation. In this embodiment, the expandable graphite is mixed with protective gas (2%~7%H 2 and 93% to 98% Ar), heated to 800°C to 1200°C for 10s to 60s (seconds) to expand the expandable graphite, and then perform thermal exfoliation to obtain expanded graphite. Of course, N 2 and other protective gases. In addition, the expand...

Embodiment 1

[0030] A kind of preparation method of high-purity graphene, its technological process is as follows:

[0031] (1) Provide expandable graphite with an average diameter of 300 μm and a purity of 99%;

[0032] (2) The expandable graphite is passed into a mixed protective gas (5% H 2 and 95% Ar), heated to 800°C for 60s, and formed expanded graphite after thermal exfoliation;

[0033] (3) The expanded graphite (25mg) in (2) is joined in 250ml, and concentration is in the sodium dodecylbenzene sulfonate solution of 5mg / ml, after ultrasonic 30min, leave standstill 12h, ultrasonic stripping forms graphene solution;

[0034] (4) Centrifuge the graphene solution in (3) for 30 minutes, collect the supernatant, filter, wash repeatedly with deionized water and ethanol, and finally dry in a vacuum oven at 80°C for 2 hours to obtain graphene crude product.

[0035] (5) Put the crude graphene product in (4) into a 1500W microwave reactor and heat for 60s to remove water molecules and sur...

Embodiment 2

[0037] A kind of preparation method of high-purity graphene, its technological process is as follows:

[0038] (1) Provide expandable graphite with an average diameter of 400 μm and a purity of 99.5%;

[0039] (2) The expandable graphite is fed into the mixed gas (5%H 2 and 95% Ar), heated to 1200°C for 10s to form expanded graphite;

[0040] (3) Add the expanded graphite (25mg) in (2) to 500ml, in the cetyltrimethylammonium bromide solution with a concentration of 50mg / ml, after ultrasonic for 30min, let it stand for 24h, and ultrasonically exfoliate to form graphene solution;

[0041] (4) The graphene solution in (3) is centrifuged for 30min, the supernatant is collected, filtered, washed repeatedly with deionized water and ethanol, and finally dried at 80°C for 2h in a vacuum oven to obtain graphene crude product.

[0042] (5) Repeat the operations of (3) to (4) for the centrifuged precipitate to increase the yield of the crude graphene product.

[0043] (6) Put the crud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com