Electrode for lithium rechargeable battery and lithium rechargeable battery comprising same

A rechargeable battery and electrode technology, applied in non-aqueous electrolyte battery electrodes, battery electrodes, lithium batteries, etc., can solve problems such as unsatisfactory battery performance in operability, and achieve good rate characteristics, high rate characteristics, and good life. Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

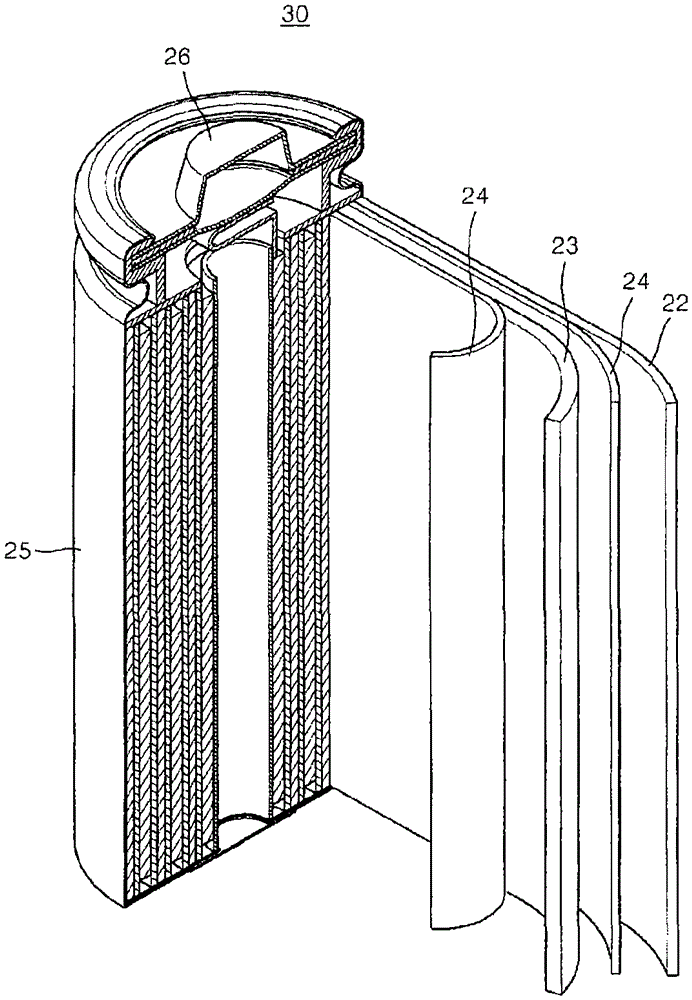

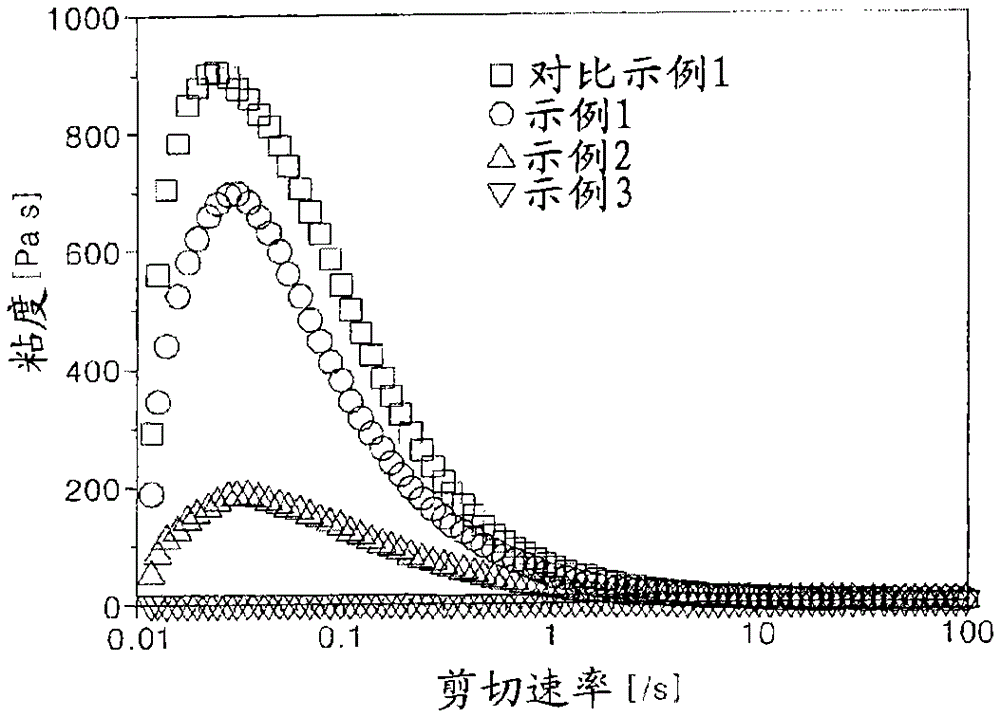

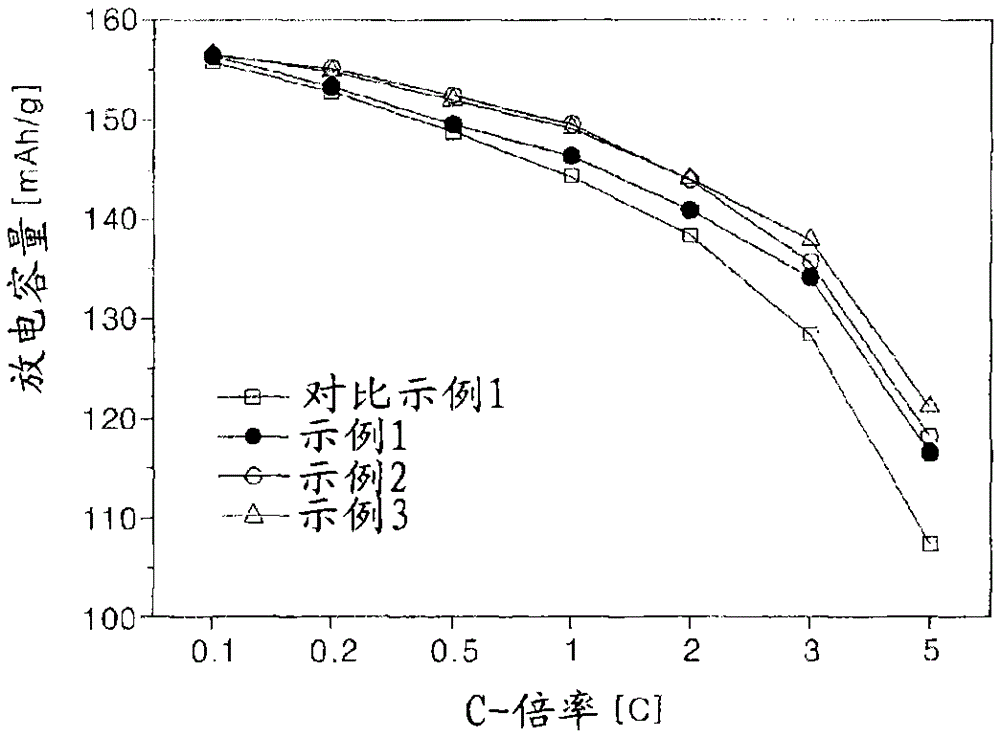

[0102] Example 1: Preparation of positive electrode and lithium secondary battery including the positive electrode

[0103] 36 g of LiFePO as the positive electrode active material 4 , 0.15g polyvinylidene fluoride substituted with carboxyl group (the amount of carboxyl group: about 1.2×10 -4 mol / g), 2 g of polyvinylidene fluoride, 2 g of carbon black, and 0.2 g of a polyurethane-based compound represented by formula 1 (x=30, y=15, z=10) (weight average molecular weight: approx. 10000) was dispersed in 60 g of N-methylpyrrolidone to prepare a composition for forming a positive electrode active material layer.

[0104] The composition for forming a cathode active material layer was coated on an aluminum foil to form a film having a thickness of 60 μm, thereby preparing a thin electrode plate. Then, the thin electrode plate was dried at a temperature of 135° C. for at least 3 hours, and then pressed, thereby completing the positive electrode.

[0105] Separately, an anode was...

example 2

[0108] Example 2: Preparation of positive electrode and lithium secondary battery including the positive electrode

[0109] A lithium secondary battery was fabricated as in Example 1 except that the amount of the polyurethane-based compound represented by Formula 1 was 0.4 g.

example 3

[0110] Example 3: Preparation of positive electrode and lithium secondary battery including the positive electrode

[0111] A lithium secondary battery was fabricated as in Example 1 except that the amount of the polyurethane-based compound represented by Formula 1 was 0.6 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com