Graphene-reinforced carbon-coated sodium titanium manganese phosphate microsphere electrode material and preparation method and application thereof

A technology of carbon-coated titanium manganese sodium phosphate and electrode materials, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of reduced material ion diffusion rate, effective conductive network surface area, graphene agglomeration, uneven coating, etc., and achieves excellent electrochemical performance. properties, enhanced conductivity, and reduced dissolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Add 10mmol citric acid powder, 5mmol manganese acetate powder, 15mmol sodium dihydrogen phosphate powder, 5mmol bis(2-hydroxypropionic acid) diammonium dihydroxide titanium into 100mL deionized water in turn, stir at room temperature for 30min to dissolve , add 0.01g graphene oxide and ultrasonically disperse for 30min;

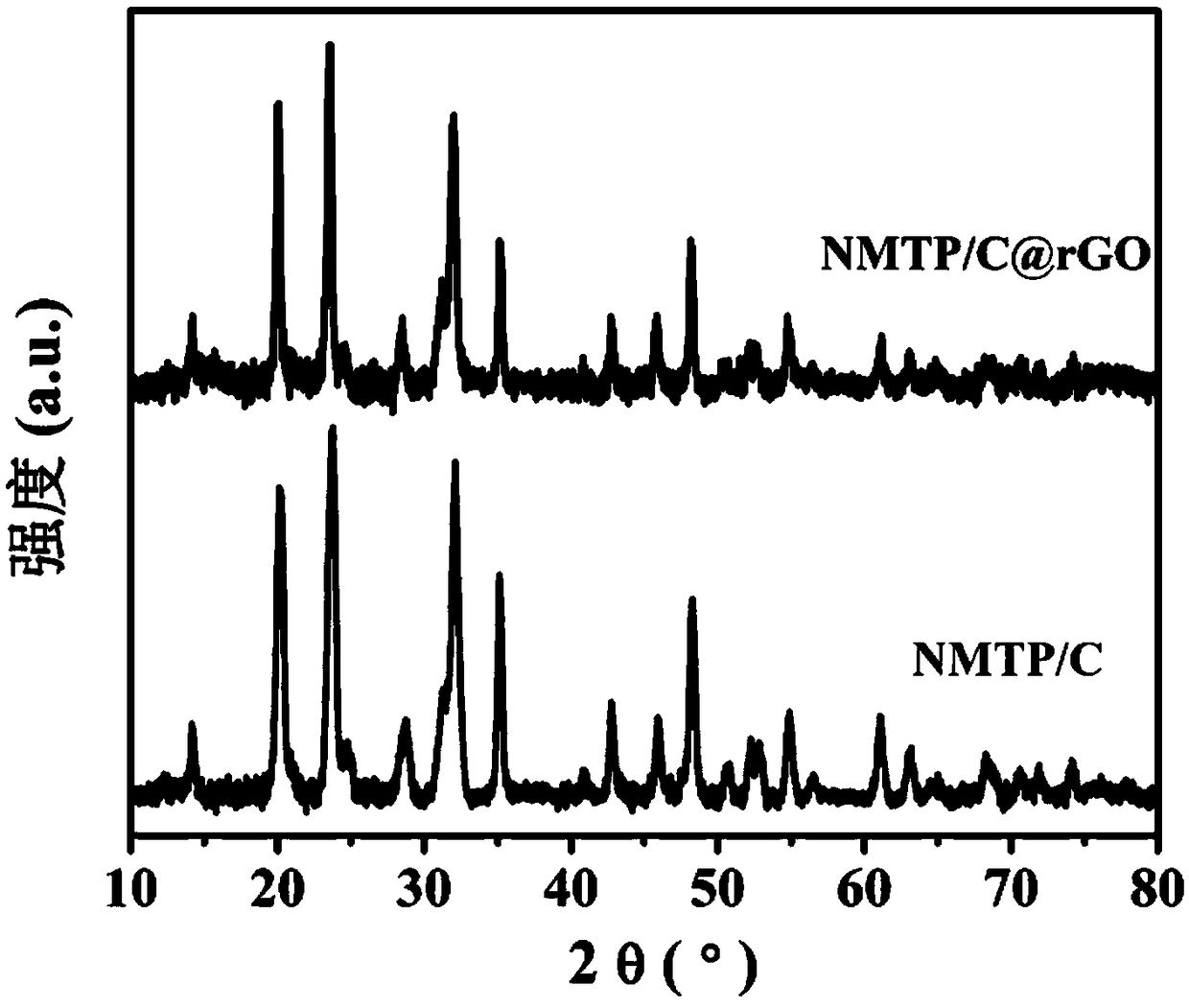

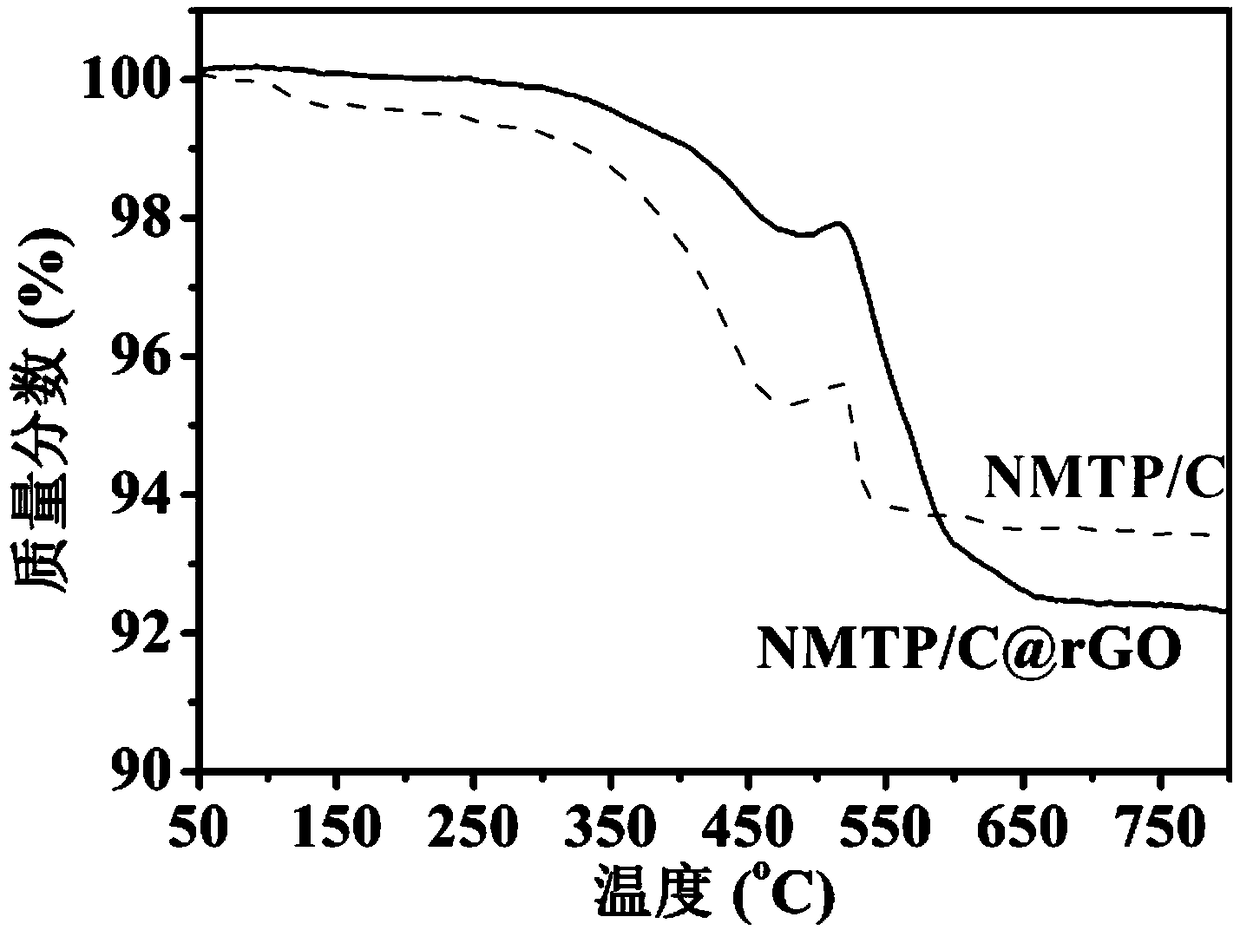

[0028] 2) The solution obtained in step 1) is spray-dried. The spray-drying temperature is 160° C., the circulating air flow is 90%, and the sampling pump is 5%. The resulting product is put into a tube furnace for calcination. The calcination temperature is 600° C., and the calcination time is 4 hours, the calcination atmosphere is argon, and the heating rate is 3°C / min. The final calcined product is Na 3 MnTi(PO 4 ) 3 / C@rGO(600℃) microspheres;

[0029] 3) Graphene oxide is not added in 1), and other steps remain unchanged to obtain Na 3 MnTi(PO 4 ) 3 / C (600°C) microspheres.

[0030] With the product Na of this experiment invention 3 MnT...

Embodiment 2

[0035] 1) Add 10mmol of citric acid powder, 5mmol of manganese acetate powder, 15mmol of sodium dihydrogen phosphate powder, and 5mmol of bis(2-hydroxypropionic acid)diammonium dihydroxide titanium into 100mL of deionized water in sequence, and stir at room temperature for 30min to dissolve , add 0.01g graphene oxide and ultrasonically disperse for 30min.

[0036] 2) The solution obtained in step 1) is spray-dried, the spray-drying temperature is 160°C, the circulating air flow is 90%, the sampling pump is 5%, and the resulting product is put into a tube furnace for calcination, the calcination temperature is 600°C, and the calcination time is 4 hours, the calcination atmosphere is argon, and the heating rate is 3°C / min. The final calcined product is Na 3 MnTi(PO 4 ) 3 / C@rGO (600°C) microspheres.

[0037] 3) Adjust the calcination temperature in 2) to 550°C, and keep the other steps unchanged to obtain Na 3 MnTi(PO 4 ) 3 / C@rGO (550°C) microspheres.

[0038] With the ...

Embodiment 3

[0042]1) Add 10mmol citric acid powder, 5mmol manganese acetate powder, 15mmol sodium dihydrogen phosphate powder, 5mmol bis(2-hydroxypropionic acid) diammonium dihydroxide titanium into 100mL deionized water in turn, stir at room temperature for 30min to dissolve , add 0.05g graphene oxide and ultrasonically disperse for 30min.

[0043] 2) The solution obtained in step 1) is spray-dried, the spray-drying temperature is 200°C, the circulating air flow is 90%, the sampling pump is 5%, and the resulting product is put into a tube furnace for calcination, the calcination temperature is 600°C, and the calcination time is 4 hours, the calcination atmosphere is argon, and the heating rate is 3°C / min. The final calcined product is Na 3 MnTi(PO 4 ) 3 @C (600°C) microspheres.

[0044] With the product Na of this experiment invention 3 MnTi(PO 4 ) 3 / C@rGO (600°C) microspheres as an example, after the electrochemical performance test, the constant current charge and discharge tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com