Square lithium ion battery with prestress structure

A pre-stressed structure, lithium-ion battery technology, applied in secondary batteries, structural parts, battery pack parts, etc., can solve the problems of low battery shell strength, reduced shell strength, battery shell deformation, etc., to reduce the phenomenon of bulging shells , improve safety and reliability, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

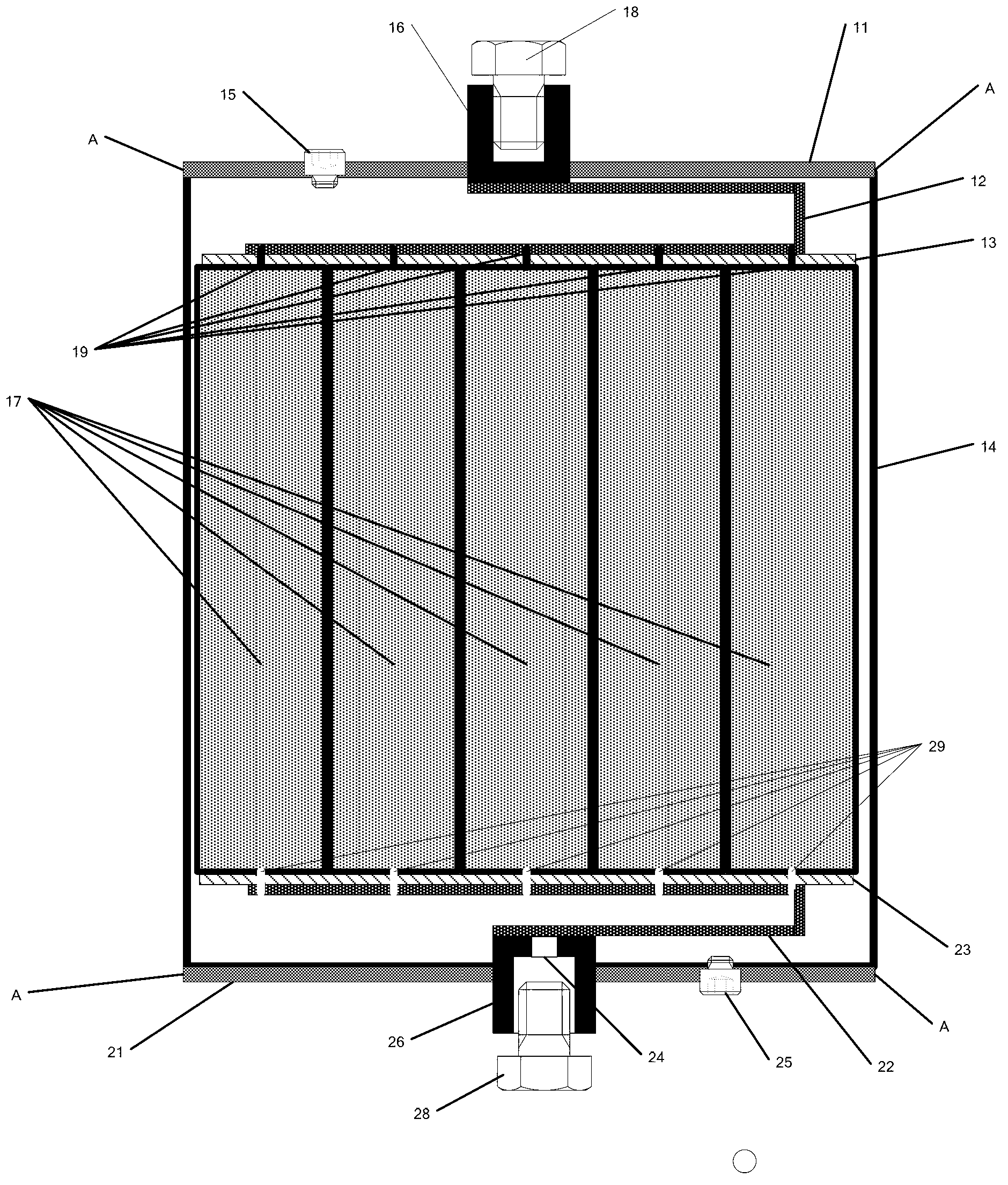

[0039] The prismatic lithium-ion battery structure of the described prestressed structure can refer to figure 1 , its preparation method comprises the following steps:

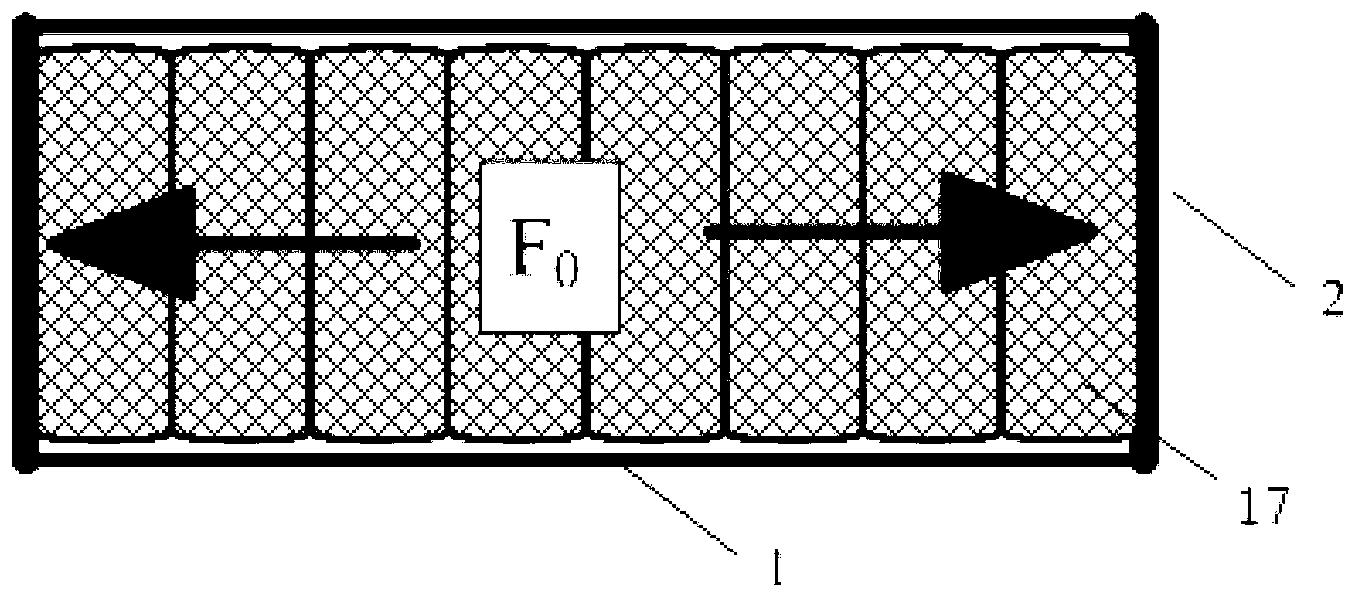

[0040] 1) Use the square winding method to wind the small winding core 17, and when winding, the positive pole tab 19 and the negative pole tab 29 each face one side;

[0041] 2) The positive pole tab 19 and the negative pole tab 29 are welded to the drain strips 12 and 22 respectively;

[0042] 3) The positive drain strip 12 and the negative drain strip 22 are welded to the battery positive cap 11 and the negative cap 21 respectively;

[0043] 4) The positive electrode cap 11 and the negative electrode cap 21 are sealed by laser welding with the square casing of unequal thickness.

[0044] 5) If the plastic shell is used, it shall be sealed by heat welding

[0045] 6) After vacuum drying, liquid injection and aging, chemical formation and volumetric screening are carried out to obtain qualified battery pro...

Embodiment 1

[0048] A square lithium-ion battery with a prestressed structure, the lithium-ion battery structure can refer to figure 1 , The designed battery capacity is 50Ah. The shell size is 102mm×52mm×130mm, the wall thickness of the battery’s long side shell is 1mm, and the short side shell’s wall thickness is 2mm. Each large battery is designed to be composed of 10 square winding cells connected in parallel. The size of the square winding cells is 9.9mm×49mm×114mm. The design capacity of each square winding cell is 5Ah and the thickness is 9.9mm.

[0049] The performance indicators of the assembled battery are shown in Table 1:

[0050] Table 1

[0051]

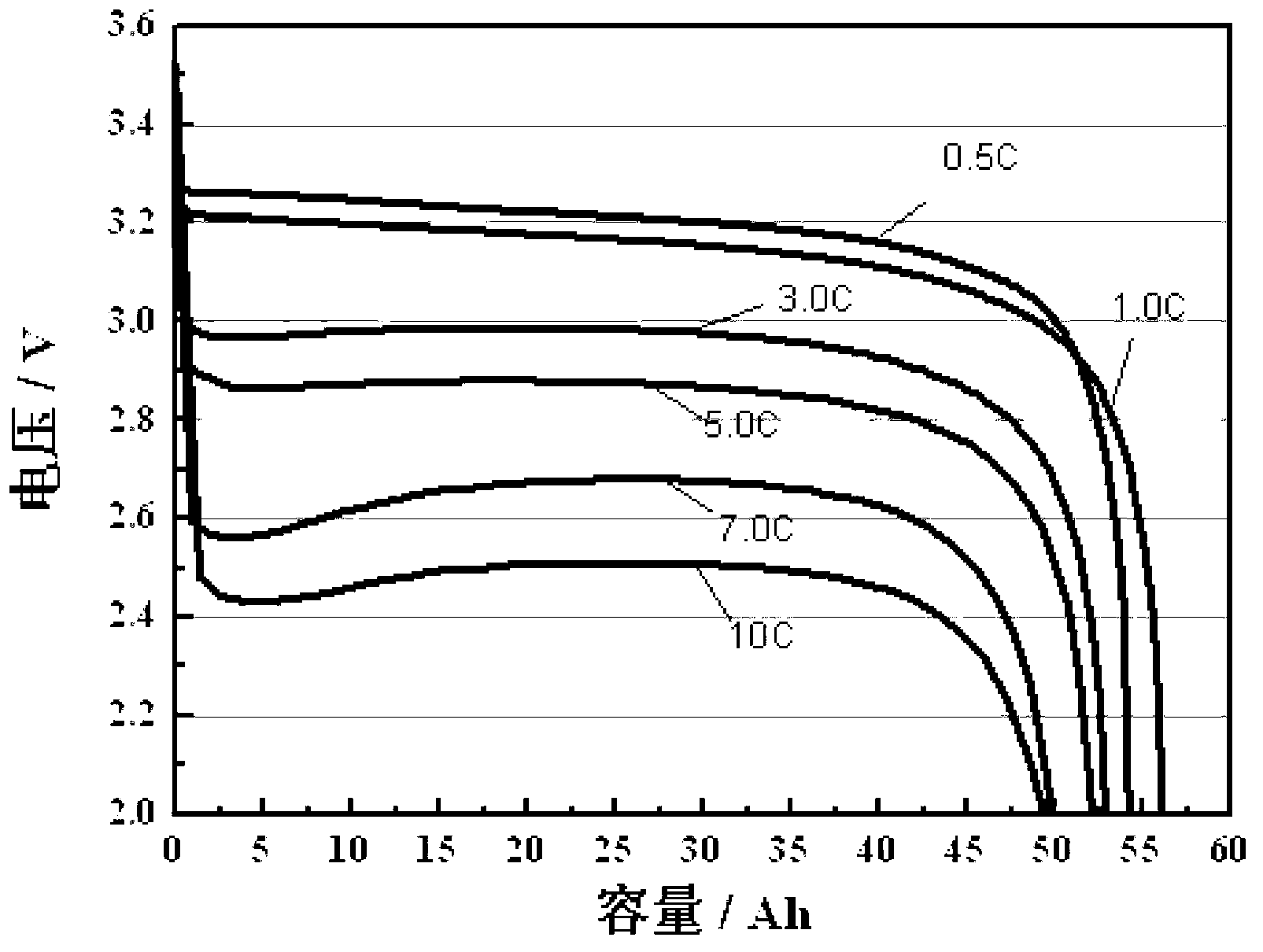

[0052] The performance index of the designed 50Ah prestressed square lithium-ion battery has obvious advantages compared with conventional square batteries in terms of internal resistance, discharge platform voltage, specific energy density, cycle life, high-rate discharge characteristics, and low-temperature performance. , it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com