V2O5 hollow micron wire ball with nano wire three-dimensional winding structure and preparation method and application thereof

A nanowire and three-dimensional technology, applied in the field of V2O5 hollow micro-wire sphere and its preparation, can solve the problems of agglomeration and low tap density, and achieve the effects of improving tap density, mild reaction conditions and shortening diffusion distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] V with nanowire three-dimensional winding structure 2 o 5 The preparation method of hollow micron wire ball, it comprises the steps:

[0038] 1) Measure 0.5mmol of V 2 o 5 Sol and add deionized water to dilute to 10mL;

[0039] 2) In the solution obtained in step 1), add 50 mL of isopropanol as a solvent;

[0040] 3) Add 2.0 g of tris to the solution obtained in step 2), and sonicate for 30 minutes;

[0041] 4) Transfer the reactants obtained in step 3) into a reactor for hydrothermal reaction at 200°C for 2 hours, take out the reactor, and cool naturally to room temperature;

[0042] 5) Centrifugally filter the product obtained in step 4), wash with absolute ethanol for 3-5 times, and dry in an oven to obtain a blue precursor powder;

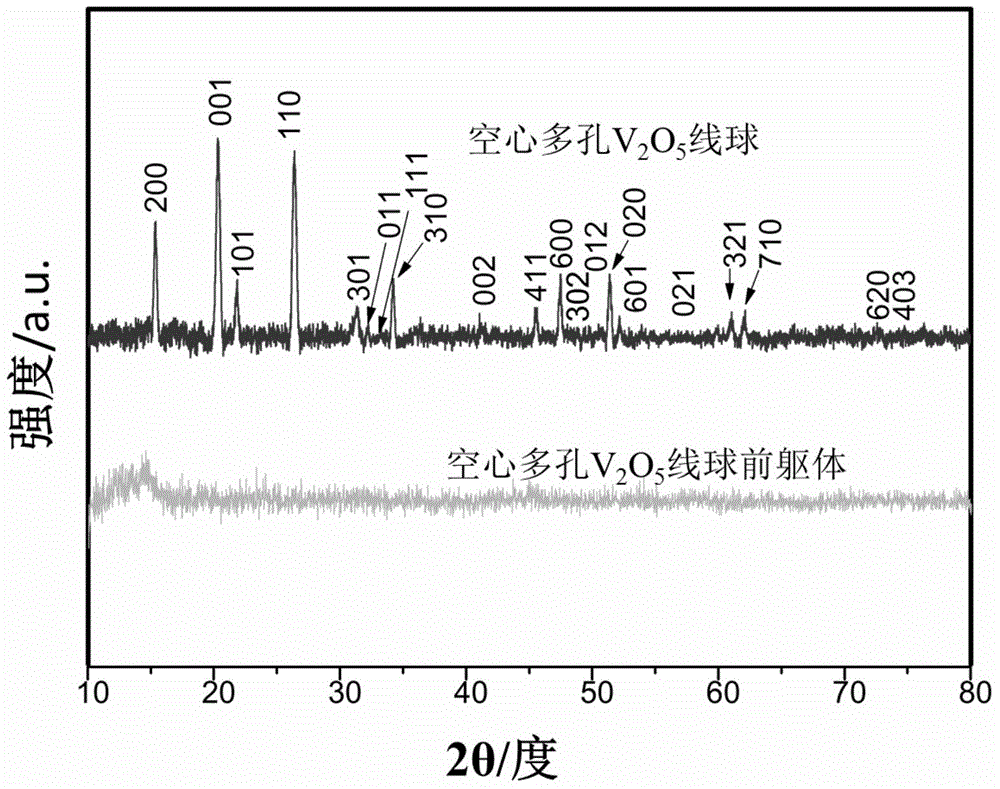

[0043] 6) Put the product obtained in step 5) in a muffle furnace for calcination at 400°C for 5 hours to obtain V 2 o 5 Hollow micron wire balls.

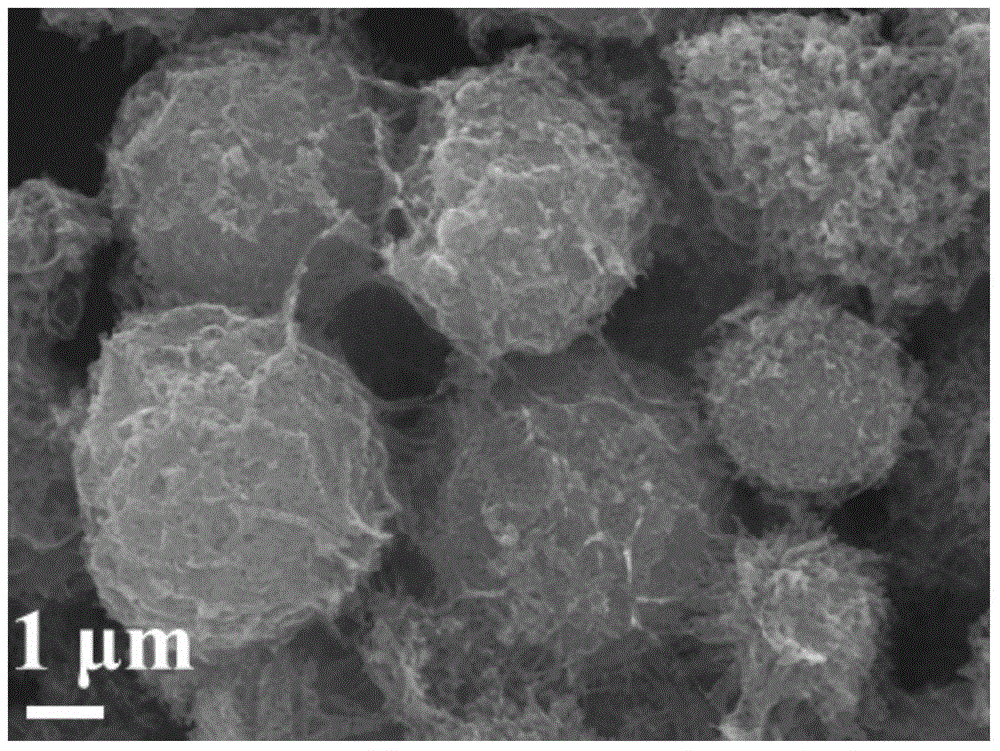

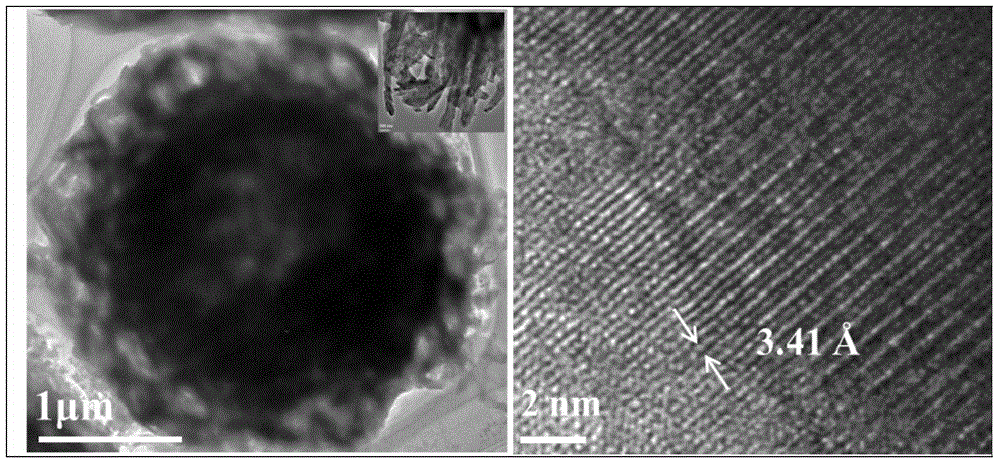

[0044] Such as Figure 4As shown, the synthesis mechanism of the present inven...

Embodiment 2

[0049] V with nanowire three-dimensional winding structure 2 o 5 The preparation method of hollow micron wire ball, it comprises the steps:

[0050] 1) Measure 0.3mmol of V 2 o 5 Sol and add deionized water to dilute to 10mL;

[0051] 2) In the solution obtained in step 1), add 50 mL of isopropanol as a solvent;

[0052] 3) Add 1.0 g of tris to the solution obtained in step 2), and sonicate for 30 minutes;

[0053] 4) Transfer the reactants obtained in step 3) into a reactor for hydrothermal reaction at 200°C for 24 hours, take out the reactor, and cool to room temperature naturally;

[0054] 5) Centrifugally filter the product obtained in step 4), wash with absolute ethanol for 3-5 times, and dry in an oven to obtain a blue precursor powder;

[0055] 6) Put the product obtained in step 5) in a muffle furnace for calcination at 400°C for 5 hours to obtain V 2 o 5 Hollow micron wire balls.

[0056] With the V 2 o 5 Hollow micron wire balls are taken as an example. Wh...

Embodiment 3

[0058] V with nanowire three-dimensional winding structure 2 o 5 The preparation method of hollow micron wire ball, it comprises the steps:

[0059] 1) Measure 0.5mmol of V 2 o 5 Sol and add deionized water to dilute to 10mL;

[0060] 2) In the solution obtained in step 1), add 40 mL of isopropanol as a solvent;

[0061] 3) Add 2.0 g of tris to the solution obtained in step 2), and sonicate for 30 minutes;

[0062] 4) Transfer the reactants obtained in step 3) into a reactor for hydrothermal reaction at 220°C for 1 hour, take out the reactor, and cool naturally to room temperature;

[0063] 5) Centrifugally filter the product obtained in step 4), wash with absolute ethanol for 3-5 times, and dry in an oven to obtain a blue precursor powder;

[0064] 6) The product obtained in step 5) is placed in a muffle furnace and calcined at 425°C for 3 hours to obtain a V 2 o 5 Hollow micron wire balls.

[0065] With the V 2 o 5 Hollow micron wire balls are taken as an example....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com