Preparation method of single-layer MoS2/grapheme combined electrode of lithium ion battery

A graphene composite and composite electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of long time, large consumption of organic solvents, high sensitivity, etc., and achieve a simple process and high electrochemical lithium storage capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

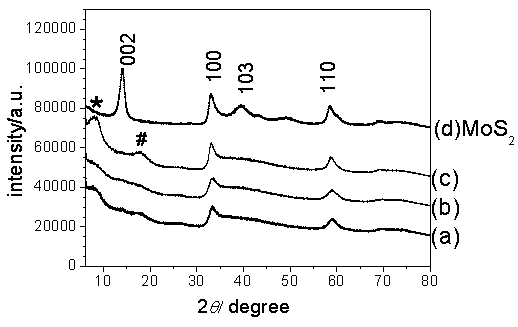

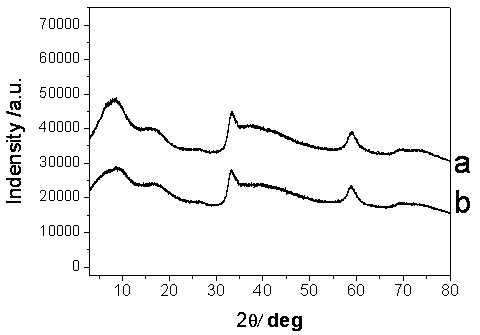

[0020] Example 1 1) Ultrasonic disperse 10.76mmol graphene oxide in 200mL deionized water, add 0.01mol cetyltrimethylammonium bromide cationic surfactant (concentration 0.05M), and stir well; 2) Then Add 1.4g (5.38mmol) ammonium thiomolybdate into it, stir well, slowly add 20mL of hydrazine hydrate dropwise under stirring, continue stirring and heating to 95°C, and react for 5h under constant stirring and reflux conditions, Simultaneous and separate reduction of ammonium thiomolybdate and graphene oxide to MoS 2 and graphene, the solid product was collected by centrifugation, fully washed with deionization, and then vacuum-dried at 100°C; 3) The obtained solid product was heat-treated at 800°C for 2h in a nitrogen / hydrogen mixed atmosphere, and the hydrogen in the mixed gas The volume ratio is 10%, and the monolayer MoS is prepared after heat treatment 2 Composite nanomaterials with graphene. The final product obtained after heat treatment was characterized by XRD, SEM and H...

Embodiment 2

[0027] Example 2 1) Ultrasonic disperse 10.76mmol of graphene oxide in 200mL of deionized water, add 0.004mol of cetyltrimethylammonium bromide cationic surfactant (concentration 0.02M), and stir well; 2) Then Add 1.4g (5.38mmol) ammonium thiomolybdate into it, stir well, slowly add 20mL of hydrazine hydrate dropwise under stirring, continue to stir and heat to 95°C, and react for 6h under constant stirring and reflux conditions, Simultaneous and separate reduction of ammonium thiomolybdate and graphene oxide to MoS 2 and graphene, the solid product was collected by centrifugation, fully washed with deionization, and then vacuum-dried at 100°C; 3) The obtained solid product was heat-treated at 800°C for 2h in a nitrogen / hydrogen mixed atmosphere, and the hydrogen in the mixed gas The volume ratio is 10%, and the monolayer MoS is prepared after heat treatment 2 Composite nanomaterials with graphene. The final product obtained after heat treatment was characterized by XRD, SEM...

Embodiment 3

[0031] Example 3 1) Ultrasonic disperse 10.76mmol graphene oxide in 200mL deionized water, add 0.004mol dodecyltrimethylammonium bromide cationic surfactant (concentration 0.02M), and stir well; 2) Then Add 1.4g (5.38mmol) ammonium thiomolybdate into it, stir well, slowly add 20mL of hydrazine hydrate dropwise under stirring, continuously stir and heat to 95°C, react under constant stirring and reflux for 8h, Simultaneous and separate reduction of ammonium thiomolybdate and graphene oxide to MoS 2 and graphene, the solid product was collected by centrifugation, fully washed with deionization, and then vacuum-dried at 100°C; 3) The obtained solid product was heat-treated at 800°C for 2h in a nitrogen / hydrogen mixed atmosphere, and the hydrogen in the mixed gas The volume ratio is 10%, and the monolayer MoS is prepared after heat treatment 2 Composite nanomaterials with graphene. The final product obtained after heat treatment was characterized by XRD, SEM and HRTEM, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com