Biosynthesis method of nano Ag

A biosynthesis and nanotechnology, applied in the nano field, can solve the problems that will affect the purity and application range of nano-Ag, complex method conditions, impure products, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Take green tea and ultrapure water at a mass ratio of 1:80, add green tea to ultrapure water at 90°C for 30 minutes, filter, and cool to obtain a green tea extract;

[0019] 2) Take AgNO 3 Crystals were added to ultrapure water to prepare AgNO with a concentration of 0.02mol / L 3 solution, keep it in a dark place for use;

[0020] 3) Mix green tea extract with AgNO 3 The solution was mixed at a volume ratio of 1:30, and magnetically stirred at room temperature to obtain a nano-Ag colloidal solution;

[0021] 4) The nano-Ag colloid solution is centrifuged in a centrifuge at 10000 r / min, the obtained precipitate is repeatedly washed with ultrapure water for 3 to 4 times, and dried at 150° C. for 6 hours to obtain nano-Ag particles.

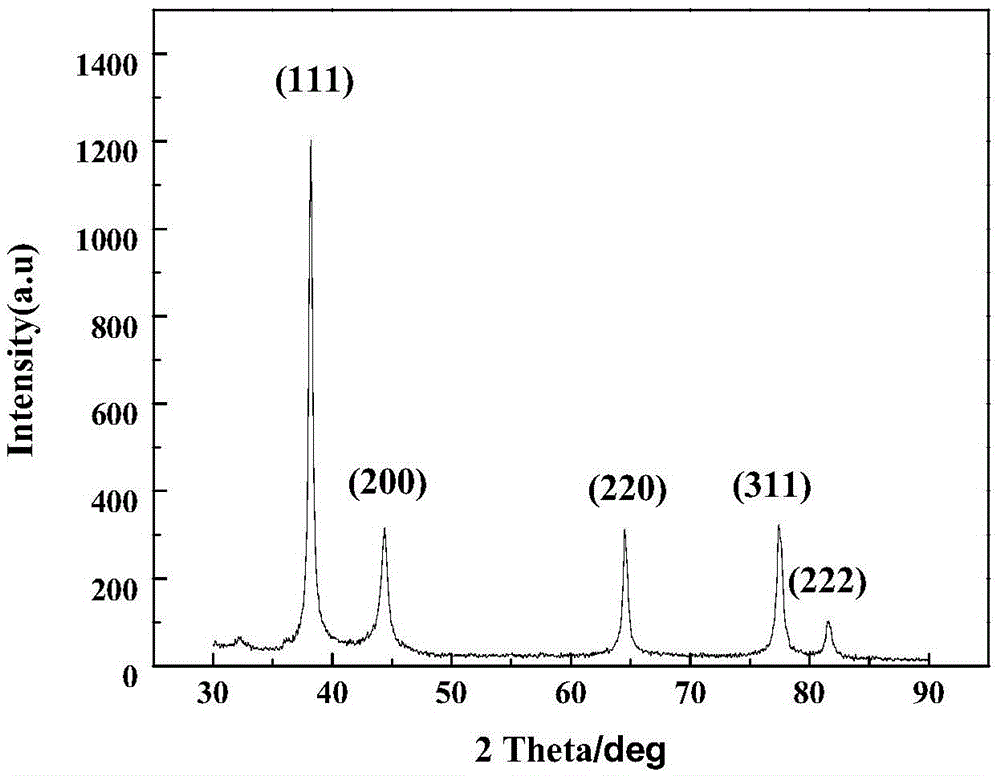

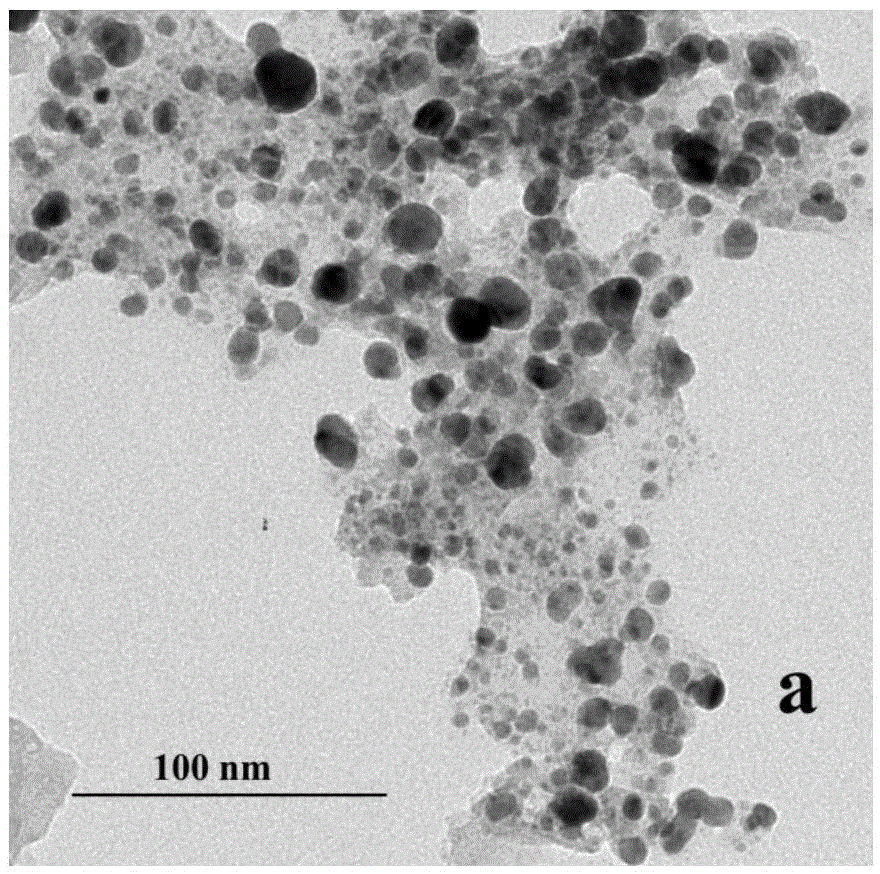

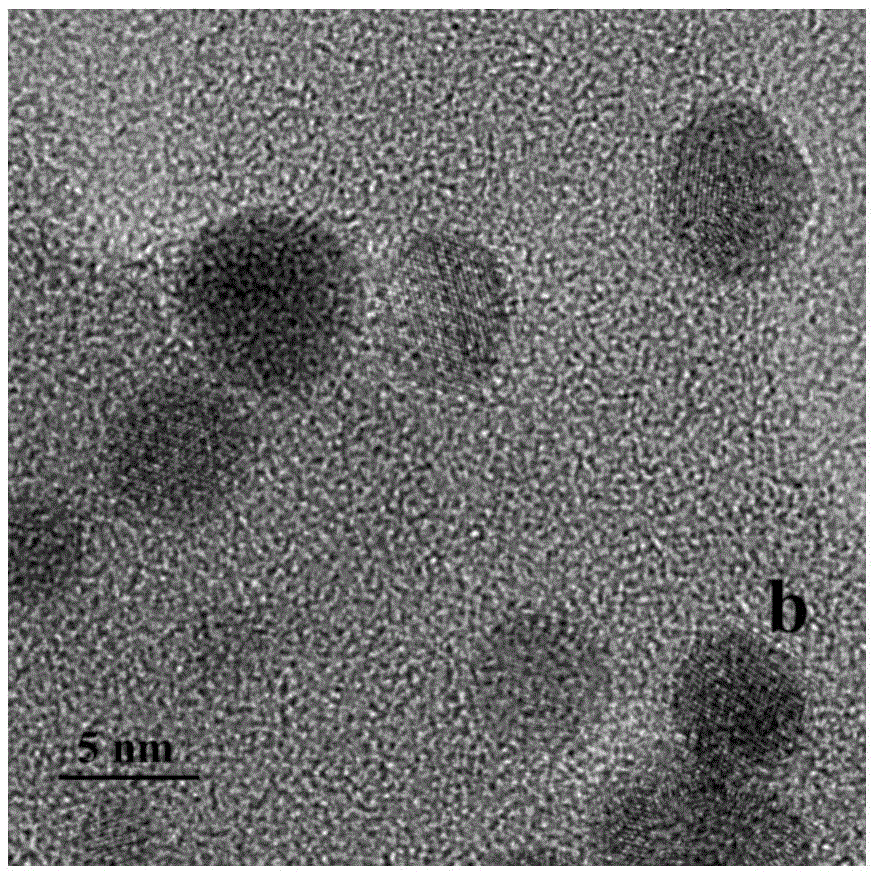

[0022] figure 1 It is the XRD diffraction pattern of the nano-Ag prepared in this embodiment, as can be seen from the figure at (111), (200), (220), (311) and (222) at 2θ=38.118, 44.304, 64.450, 77.407, 81.550 five places These five crys...

Embodiment 2

[0025] 1) Take green tea and ultrapure water according to the mass ratio of 1:60, add green tea into ultrapure water at 100°C for 10 minutes, filter and cool to obtain green tea extract;

[0026] 2) Take AgNO 3 Crystals were added to ultrapure water to prepare AgNO with a concentration of 0.06mol / L 3 solution, keep it in a dark place for use;

[0027] 3) Mix green tea extract with AgNO 3 The solution was mixed at a volume ratio of 1:20, and magnetically stirred at room temperature to obtain a nano-Ag colloidal solution;

[0028] 4) The nano-Ag colloid solution is centrifuged in a centrifuge at 8000r / min, the obtained precipitate is repeatedly washed with ultrapure water for 3-4 times, and dried at 80° C. for 12 hours to obtain nano-Ag particles.

Embodiment 3

[0030] 1) Take green tea and ultrapure water according to the mass ratio of 1:40, add green tea into ultrapure water at 80°C for 40 minutes, filter and cool to obtain green tea extract;

[0031] 2) Take AgNO 3 Crystals were added to ultrapure water to prepare AgNO with a concentration of 0.08mol / L 3 solution, keep it in a dark place for use;

[0032] 3) Mix green tea extract with AgNO 3 The solution was mixed at a volume ratio of 1:40, and magnetically stirred at room temperature to obtain a nano-Ag colloidal solution;

[0033] 4) The nano-Ag colloid solution is centrifuged in a centrifuge at 5000r / min, the obtained precipitate is repeatedly washed with ultrapure water for 3-4 times, and dried at 100° C. for 8 hours to obtain nano-Ag particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com