Transparent super-hydrophobic coating for preventing calligraphy and painting from being polluted as well as preparation method and application thereof

A super-hydrophobic coating and anti-fouling technology, applied in the field of coatings, can solve the problems of losing the meaning of protection, affecting the appearance of calligraphy and painting, high anti-fouling performance and high temperature resistance of super-hydrophobic coatings, and achieving strong pollution ability and good transparency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

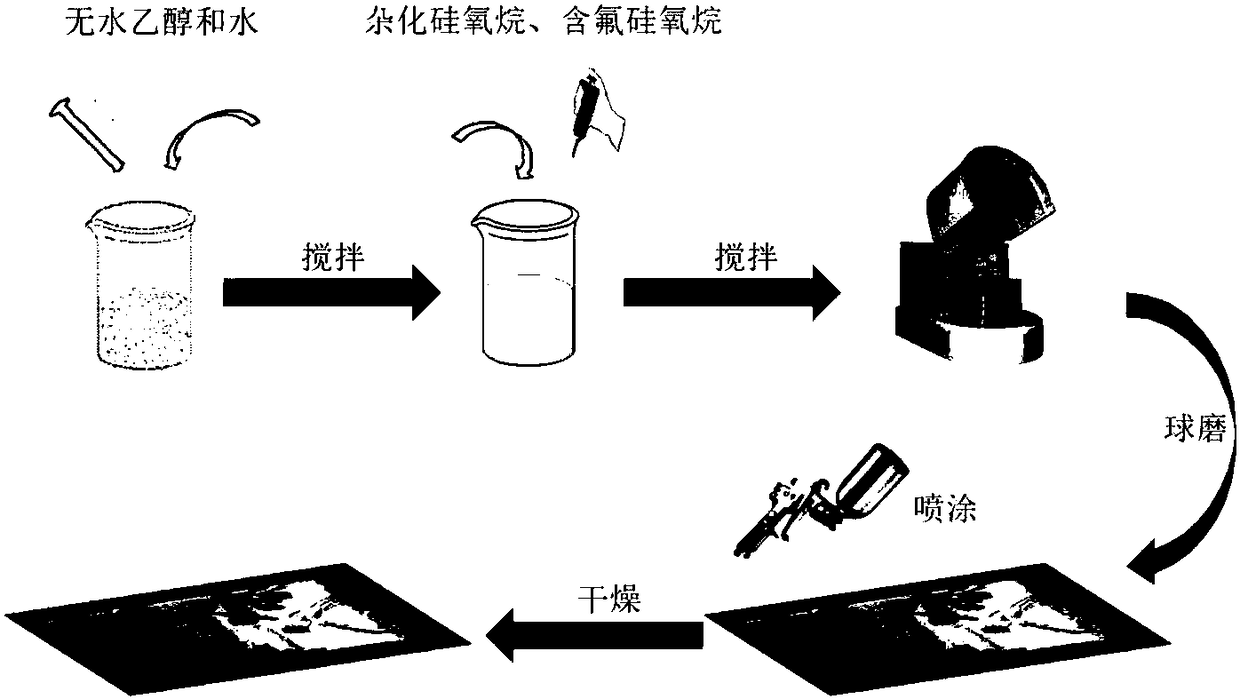

[0033] Add 2g SiO to the mixture of 75mL ethanol and 75mL water 2 (Zhejiang Wanjing New Material Co., Ltd., SP-30 type, the same below), stirred for 10 minutes, and then added 2mL KH560 (Shanghai Aladdin Biochemical Co., Ltd.), 2mL FAS-17 (Quanzhou Sikang New Material Co., Ltd.) company), continue to stir and react at room temperature for 20 minutes, and then ball mill in a ball mill for 4 hours to obtain a superhydrophobic coating.

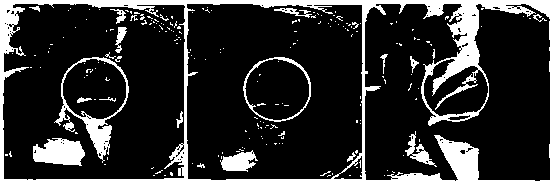

[0034] After spraying the paint on the surface of calligraphy and painting for 3 times, bake it at 120°C for 40min ( figure 1 ), to obtain a superhydrophobic coating ( figure 2 ), see the specific reaction mechanism image 3 ( image 3 d shows the mechanism for the reaction of amine groups with epoxy groups). In the colored area of calligraphy and painting, the static contact angle is 154.0°, and the rolling angle is 8.8°. In the calligraphy and painting area without ink and pigment, the static contact angle is 154.2°, and the rolling angl...

Embodiment 2

[0039] The ethanol / water mixing ratio in Example 1 is adjusted to only add 150mL of ethanol, and the others are the same as in Example 1 to obtain a super-hydrophobic coating.

[0040] After spraying the coating on the surface of calligraphy and painting for 3 times, bake it at 120°C for 40 minutes to obtain a super-hydrophobic coating. The static contact angle in the colored area of calligraphy and painting is 151.7°, and the rolling angle is 9.0°. The static contact angle in the non-ink and pigment area of calligraphy and painting is 152.0°, and the rolling angle is 9.0°.

Embodiment 3

[0042] The ethanol / water mixing ratio in Example 1 is adjusted to ethanol / water=30:120, and the others are the same as in Example 1 to obtain a super-hydrophobic coating.

[0043] After spraying the coating on the surface of calligraphy and painting for 3 times, bake it at 120°C for 40 minutes to obtain a super-hydrophobic coating. The static contact angle in the colored area of calligraphy and painting is 150.5°, and the rolling angle is 9.3°. The static contact angle in the ink and pigment-free area of calligraphy and painting is 150.5°, and the rolling angle is 9.2°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com