Method for synergistically improving arc ablation performance of CuW contact material

A technology of arc ablation and contact material, which is applied in the direction of contacts, circuits, electric switches, etc., can solve the problems of unfavorable high-voltage circuit breakers and the decline of electrical properties of contact materials, so as to improve the performance of arc ablation resistance and mechanical strength. Performance, the effect of improving the protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The method of the present embodiment comprises the following steps:

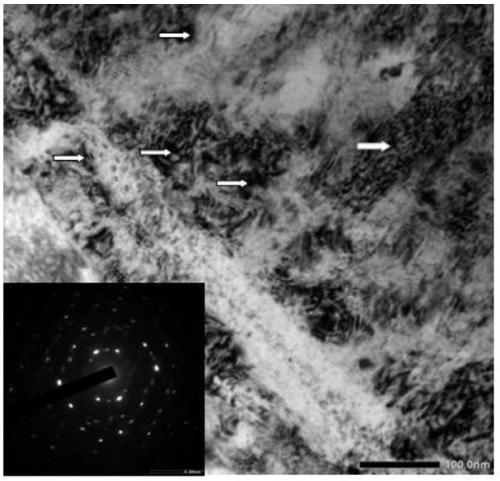

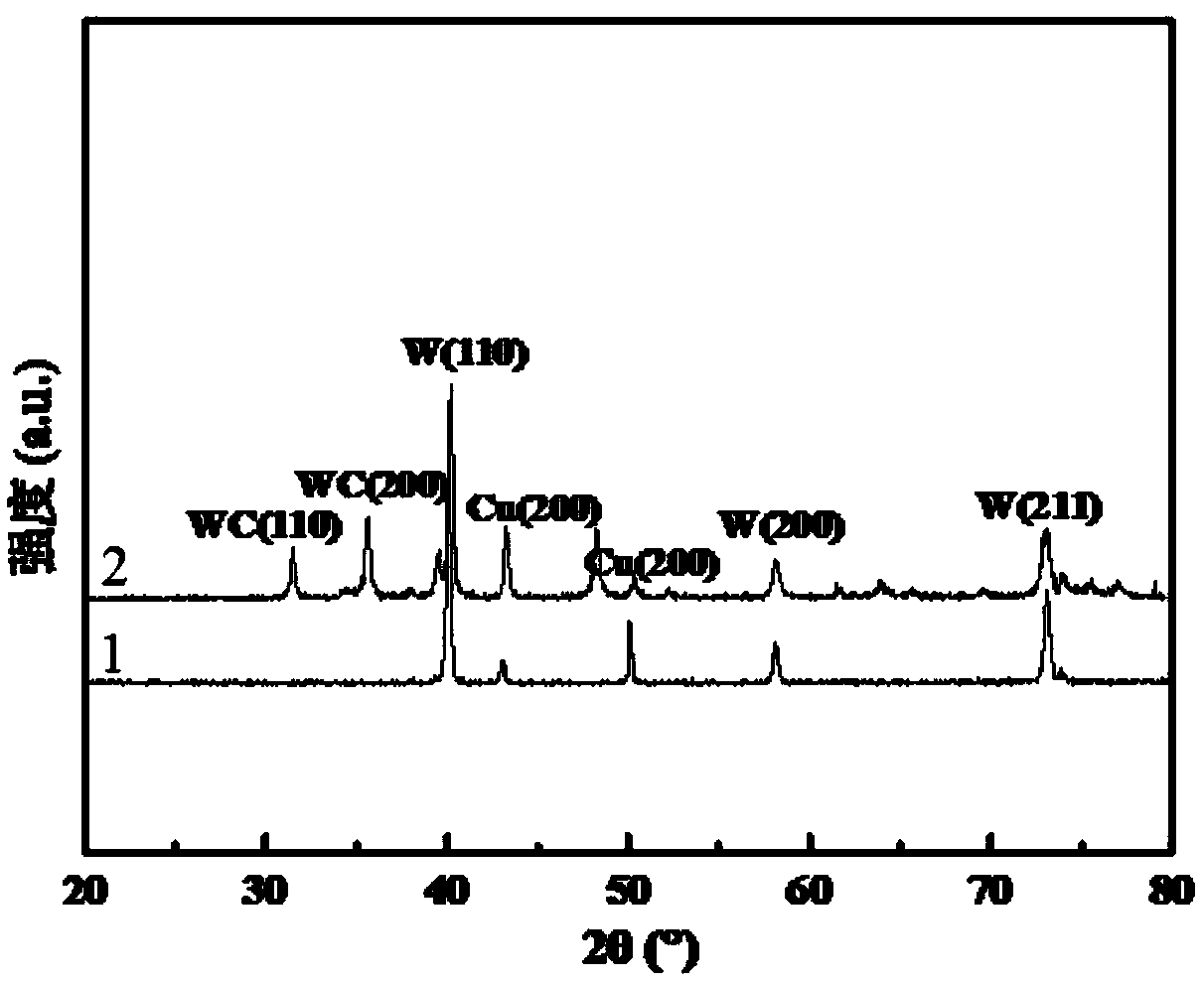

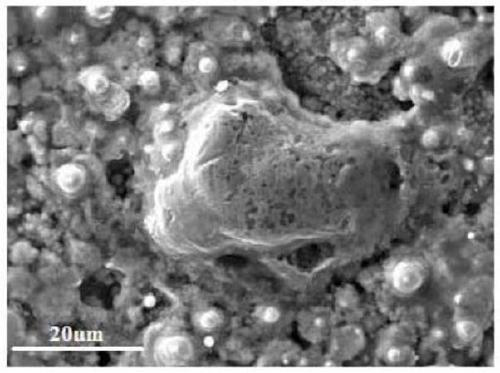

[0043] Step 1. Preparation of tungsten-copper modified mixed powder: Put 50g of spherical electrolytic copper powder with a particle size of 48 μm into a planetary high-energy ball mill and grind it into flakes, then add 50 g of reduced tungsten powder with a particle size of 7 μm for ball milling and mix evenly. Obtain tungsten-copper modified mixed powder; the rotating speed of the ball mill is 400rpm, the time of ball milling is 10h, and the grinding balls adopted in the process of the ball mill are large balls with a diameter of 8mm, medium balls with a diameter of 3mm and small balls with a diameter of 1mm , the total mass of the large ball, the total mass of the medium ball and the total mass of the small ball are respectively 250g, 150g and 100g;

[0044] Step 2, preparing graphene oxide: 300-mesh expanded graphite is sequentially subjected to low-temperature, medium-temperature and high-temper...

Embodiment 2

[0066] The method of the present embodiment comprises the following steps:

[0067] Step 1. Preparation of tungsten-copper modified mixed powder: Put 30g of spherical electrolytic copper powder with a particle size of 48 μm into a planetary high-energy ball mill and grind it into flakes, then add 70g of reduced tungsten powder with a particle size of 7 μm for ball milling and mix evenly. Obtain tungsten-copper modified mixed powder; the rotating speed of the ball mill is 500rpm, the time of ball milling is 8h, and the grinding balls adopted in the process of the ball mill are large balls with a diameter of 8mm, medium balls with a diameter of 3mm and small balls with a diameter of 1mm , the total mass of the large ball, the total mass of the medium ball and the total mass of the small ball are respectively 250g, 150g and 100g;

[0068] Step 2, preparing graphene oxide: 300-mesh expanded graphite is sequentially subjected to low-temperature, medium-temperature and high-temperat...

Embodiment 3

[0078] The method of the present embodiment comprises the following steps:

[0079] Step 1. Preparation of tungsten-copper modified mixed powder: Put 10g of spherical electrolytic copper powder with a particle size of 48 μm into a planetary high-energy ball mill and grind it into flakes, then add 90 g of reduced tungsten powder with a particle size of 7 μm for ball milling and mix evenly. Obtain tungsten-copper modified mixed powder; the rotating speed of the ball mill is 600rpm, the time of ball milling is 5h, and the grinding balls adopted in the process of the ball mill are large balls with a diameter of 8mm, medium balls with a diameter of 3mm and small balls with a diameter of 1mm , the total mass of the large ball, the total mass of the medium ball and the total mass of the small ball are respectively 250g, 150g and 100g;

[0080] Step 2, preparing graphene oxide: 300-mesh expanded graphite is sequentially subjected to low-temperature, medium-temperature and high-tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com