Patents

Literature

32results about How to "Improve the ability to withstand external forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass fiber reinforced and hydrolysis-resistant nylon PA (Polyethylene) 6/PA66 composite material and preparation method thereof

ActiveCN103113737AImprove bending strengthImprove the ability to withstand external forcesCoatingsGlass fiberAlkali free

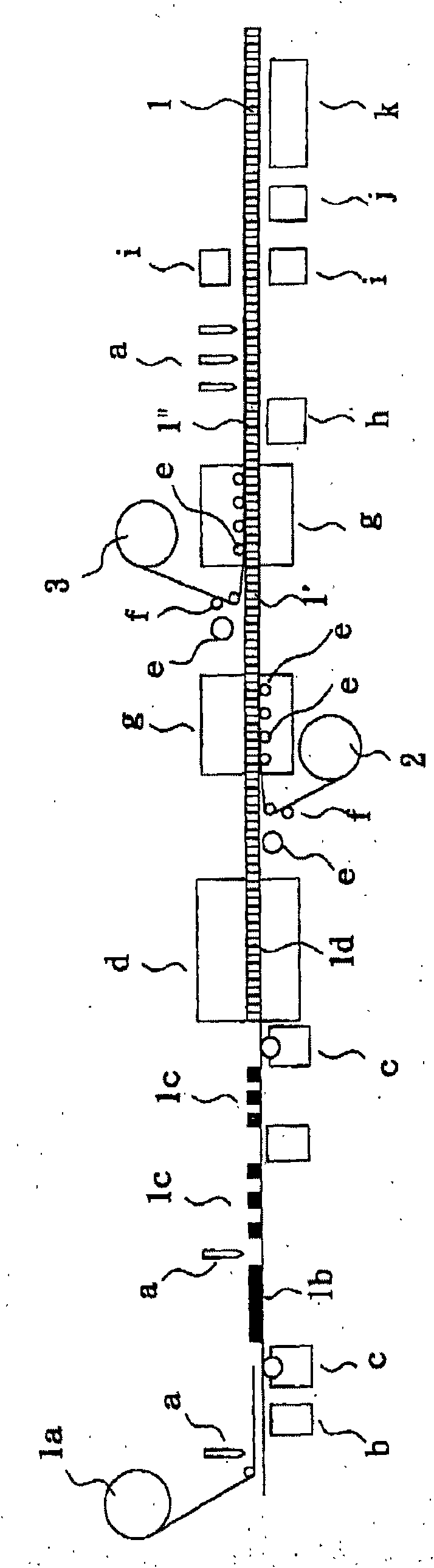

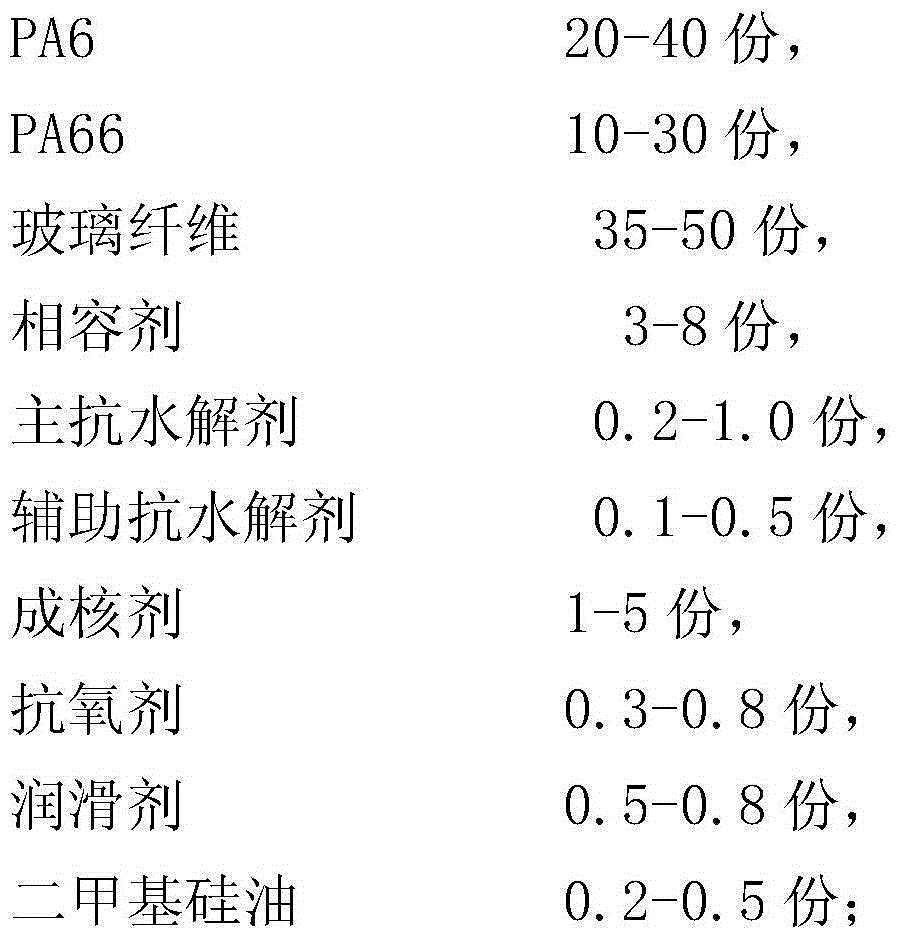

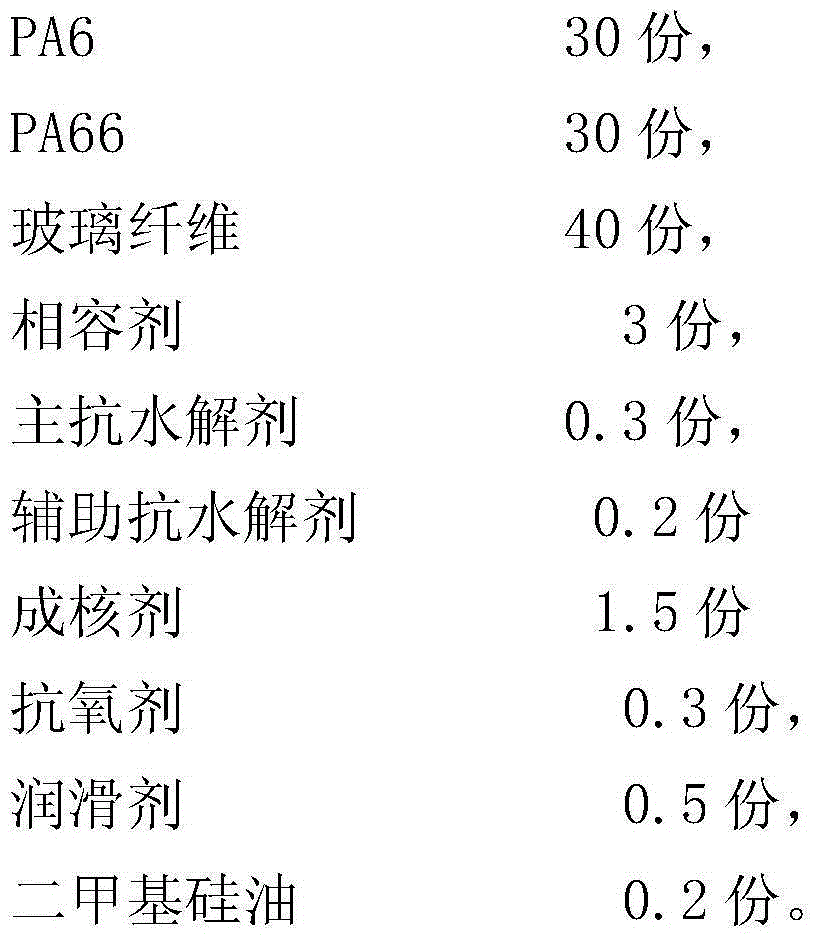

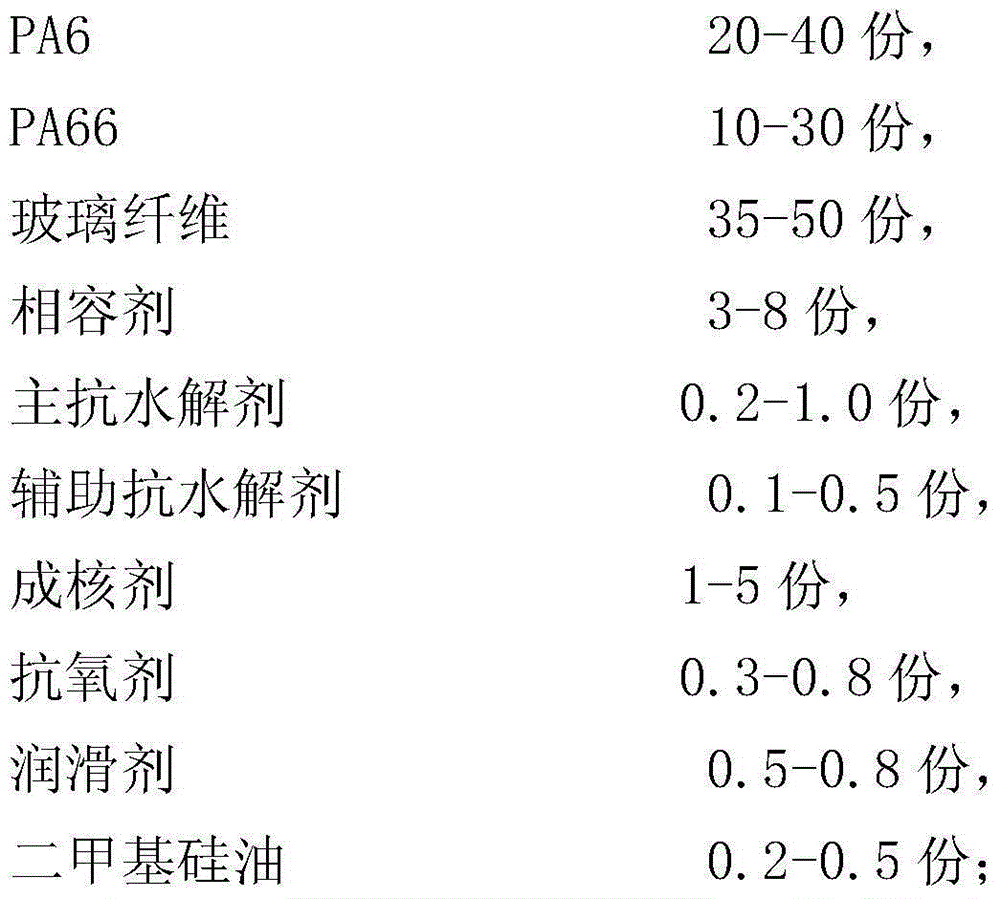

The invention relates to a glass fiber reinforced and hydrolysis-resistant nylon PA (Polyethylene) 6 / PA66 composite material and a preparation method thereof. The composite material comprises the following components: PA6, PA66, hydrolysis-resistant alkali-free glass fibers, a compatilizer, a main hydrolysis resisting agent, an epoxide assistant hydrolysis resisting agent, a nucleating agent, an antioxidant that is the 1010 and 168 compounded antioxidant, a lubricant and simethicone. The preparation method comprises the following steps: placing the PA6, the PA66, the compatilizer and the simethicone into a high-speed mixer to mix according to the formula mass; adding each assistant mentioned above; mixing by the high-speed mixer; transferring into a twin-screen extruder; and molting, extruding, blanking and drying the materials, so as to obtain the composite material. The glass fiber reinforced and hydrolysis-resistant nylon PA6 / PA66 composite material has the advantages of being high in bending strength, excellent in toughness and hydrolysis resistance and wide in applicable scope, is mainly applicable to components of controllers of electric bicycle, and can meet the requirement of the performance of the materials.

Owner:天津万塑新材料科技有限公司

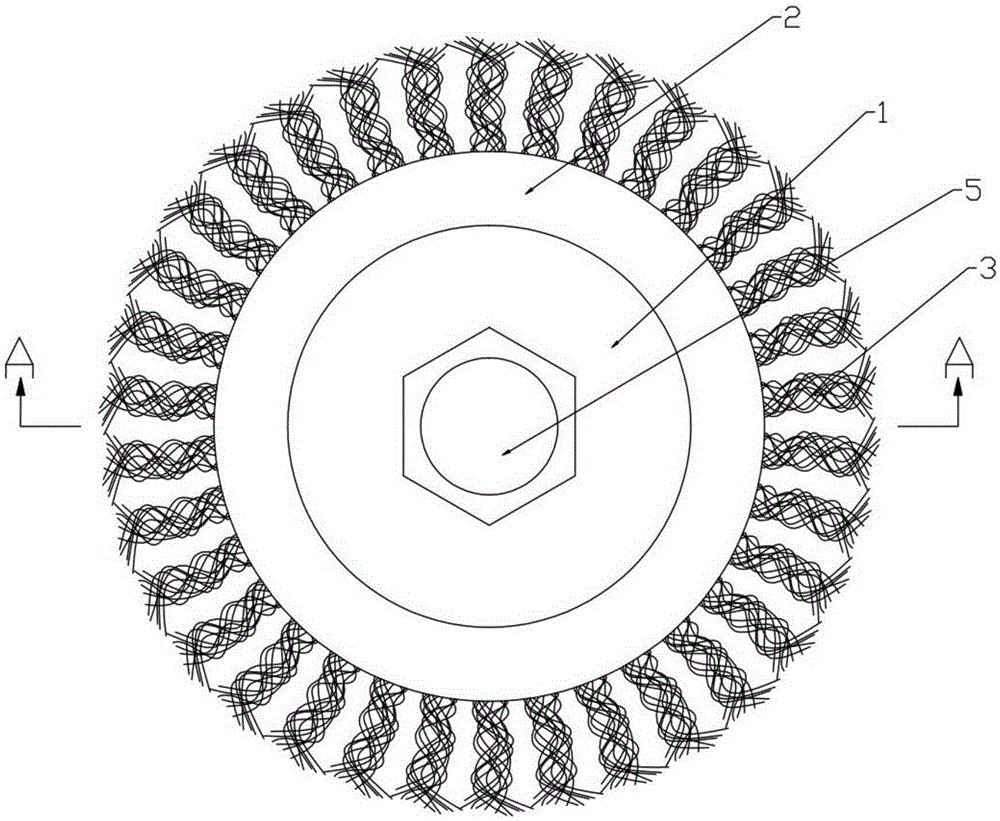

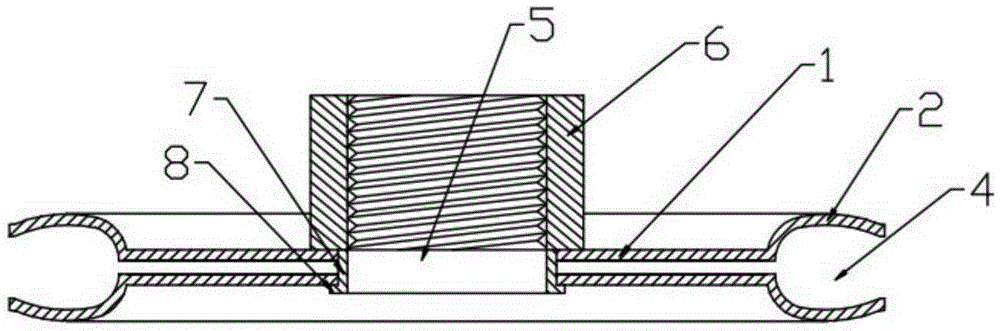

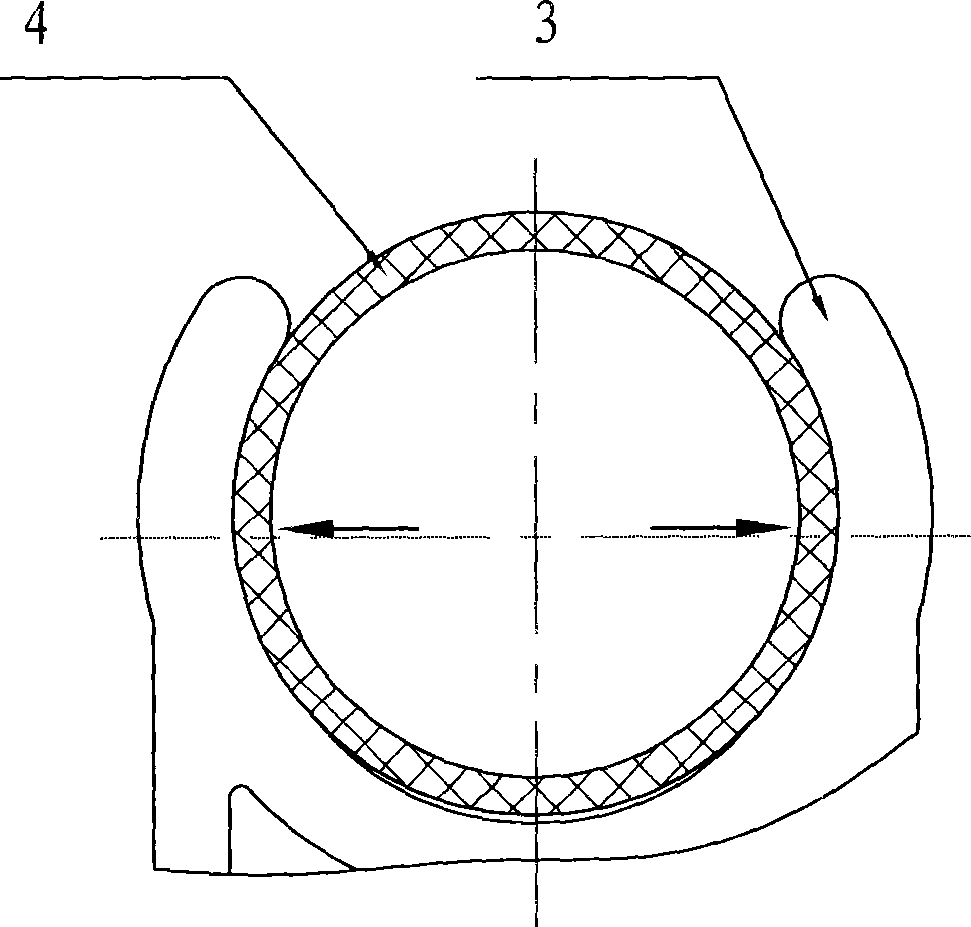

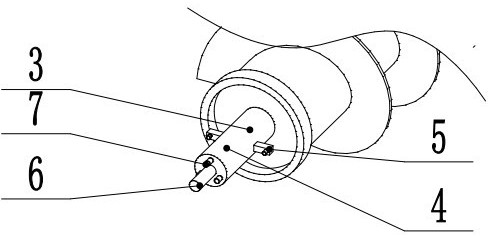

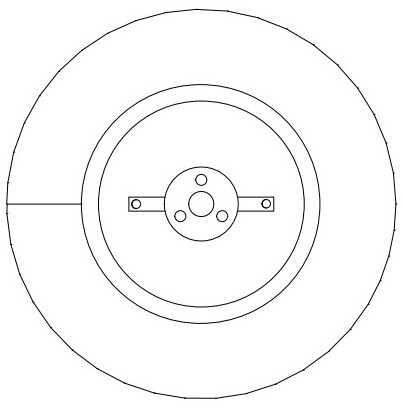

Metal wire polishing wheel

InactiveCN105415212ALight in massReduce quality problemsFlexible-parts wheelsMetallic material coating processesAlloy substrateEngineering

The invention provides a metal wire polishing wheel. The metal wire polishing wheel comprises an upper clamping plate and a lower clamping plate. A plurality of metal wire beams are installed between the edge parts of the upper clamping plate and the lower clamping plate in a central symmetrical mode. A fastener is installed between through holes of the upper clamping plate and the lower clamping plate. A longitudinal installation hole is formed in the middle of the fastener and internally provided with an internal thread. Both the upper clamping plate and the lower clamping plate are divided into the annular sunk parts in the middles and the annular protruding parts at the edges. The annular protruding part of the upper clamping plate and the annular protruding part of the lower clamping plate are symmetrical and form an annular installation groove of the metal wire beams. The metal wire beams are formed by twisting a plurality of metal wires made from an aluminum alloy composite material. The aluminum alloy composite material comprises an aluminum alloy substrate and a ceramic layer arranged on the surface of the aluminum alloy substrate through laser cladding. The metal wire polishing wheel is compact and firm in structure, convenient to install and use and good in thermal conductivity, heat dispersion, mechanical property and usability.

Owner:NINGBO DAHUA GRINDING WHEEL

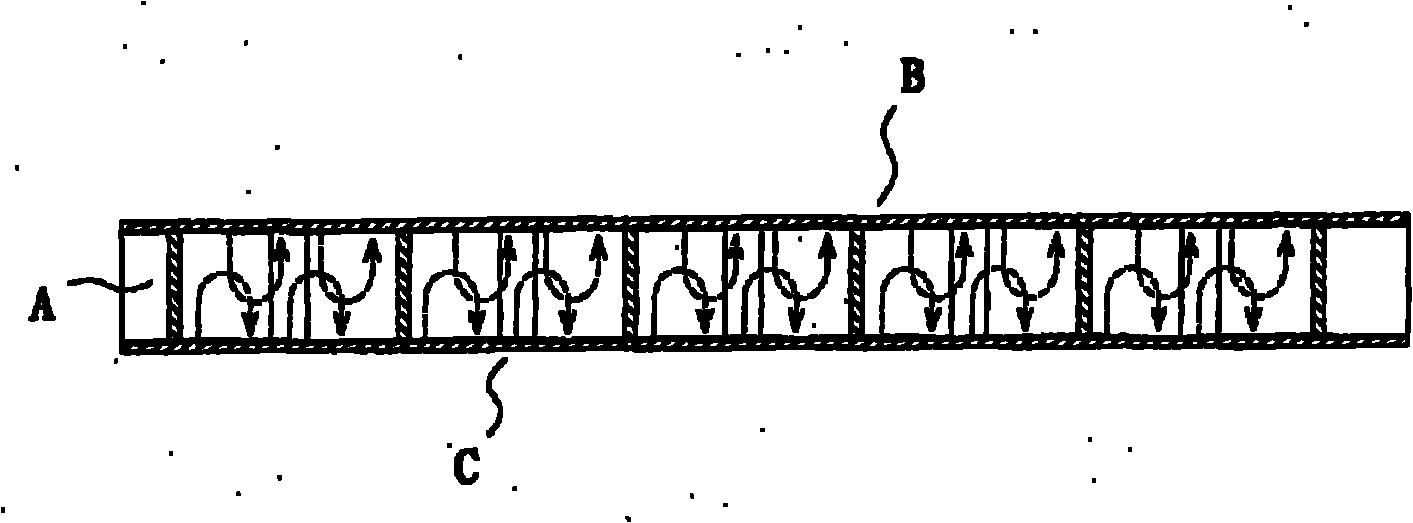

Membrane for flexible solid super capacitor and preparation method thereof

InactiveCN102360950AReduce weightImprove the ability to withstand external forcesSolid electrolytic capacitorsCapacitor electrolytes/absorbentsPolymer chemistryElectrolyte

The invention relates to a membrane for a flexible solid super capacitor and a preparation method thereof. The membrane comprises a fiber support body and a polymer electrolyte, wherein the polymer electrolyte comprises a polymer matrix, an electrolyte and an additive. The preparation method is characterized by comprising the following steps: evenly mixing the polymer matrix, the electrolyte with the additive according to mass ratio to prepare polymer electrolyte slurry; coating the polymer electrolyte slurry onto a fiber sheet by utilizing a blade coating method, and drying to obtain the membrane for the flexible solid super capacitor, wherein the thickness of the membrane is 30-120mum. As the support body, the fiber sheet forms a structure and function integrated membrane with the attached polymer electrolyte, thus, the weight of an energy storage unit is reduced; the strength of the flexible solid super capacitor can be improved; the membrane for the flexible solid super capacitor is beneficial to the integrated design of automobile interior trim parts; current-carrying ions are provided by the polymer electrolyte; the energy storage function of the device is met; new energy automobile assembly space are saved; and the membrane for the flexible solid super capacitor is safe and environmentally friendly.

Owner:CHINA FIRST AUTOMOBILE

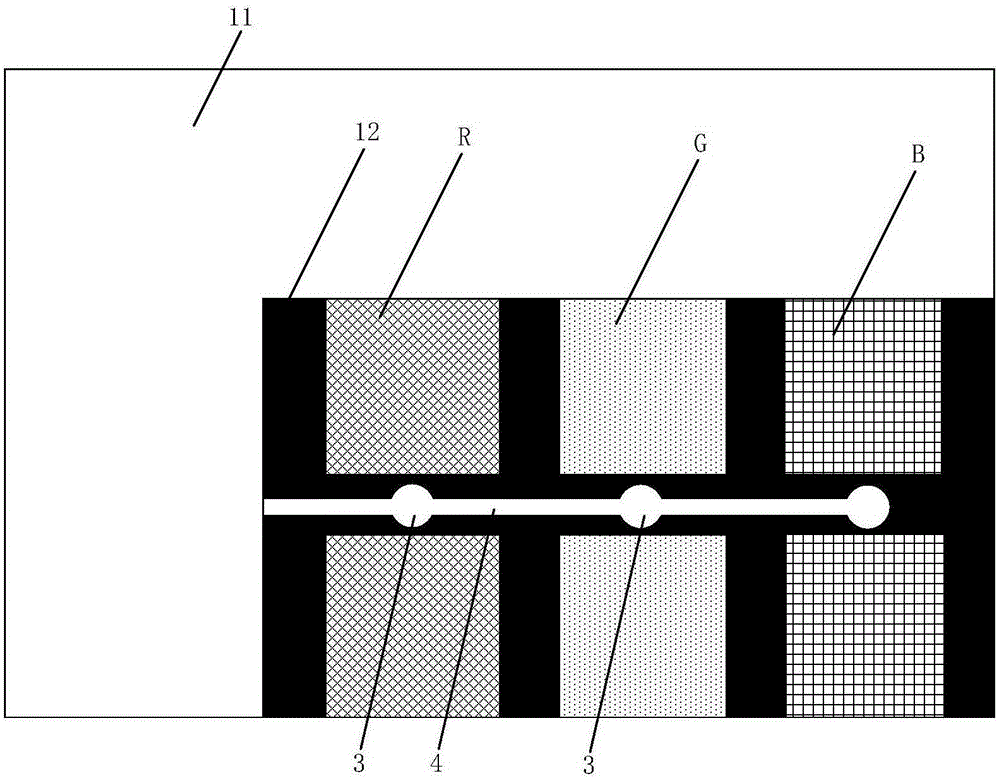

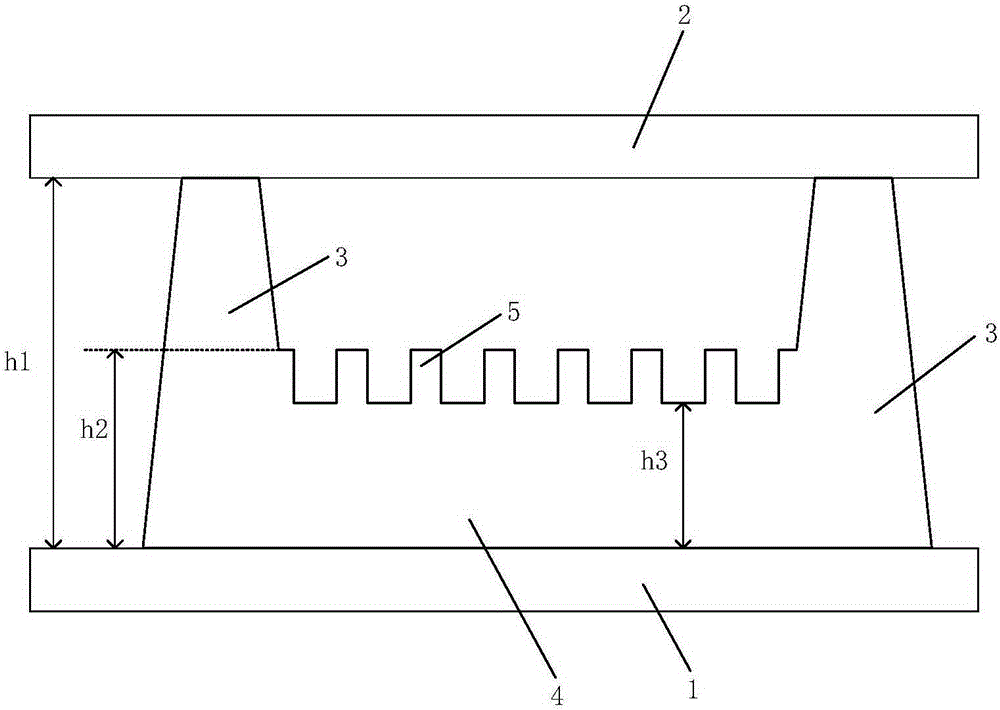

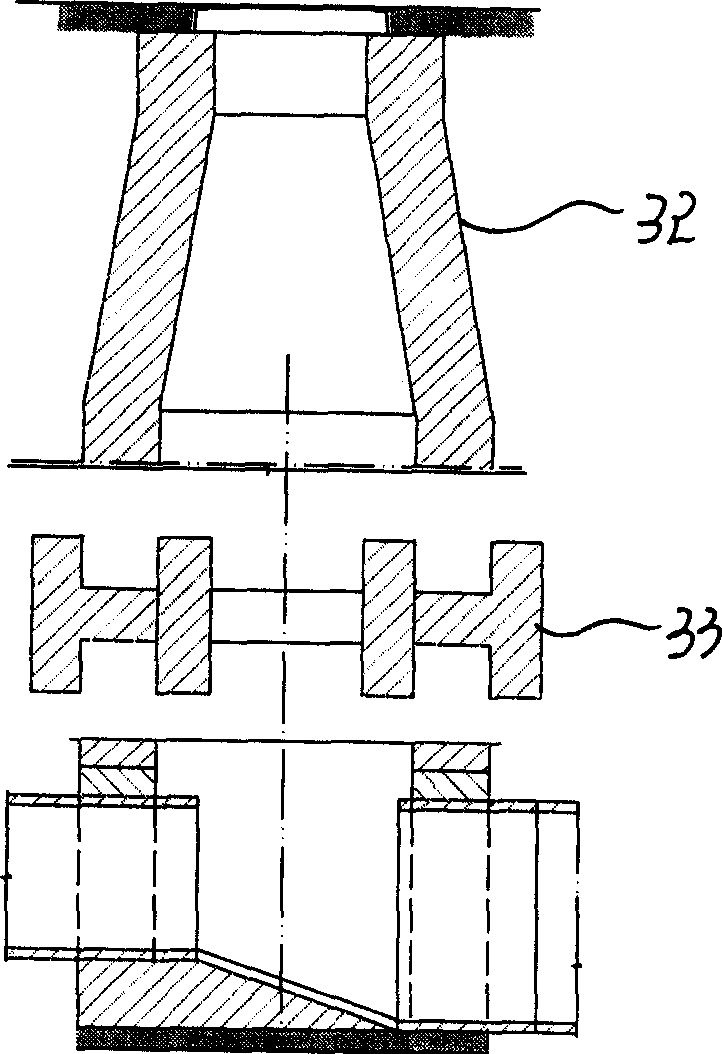

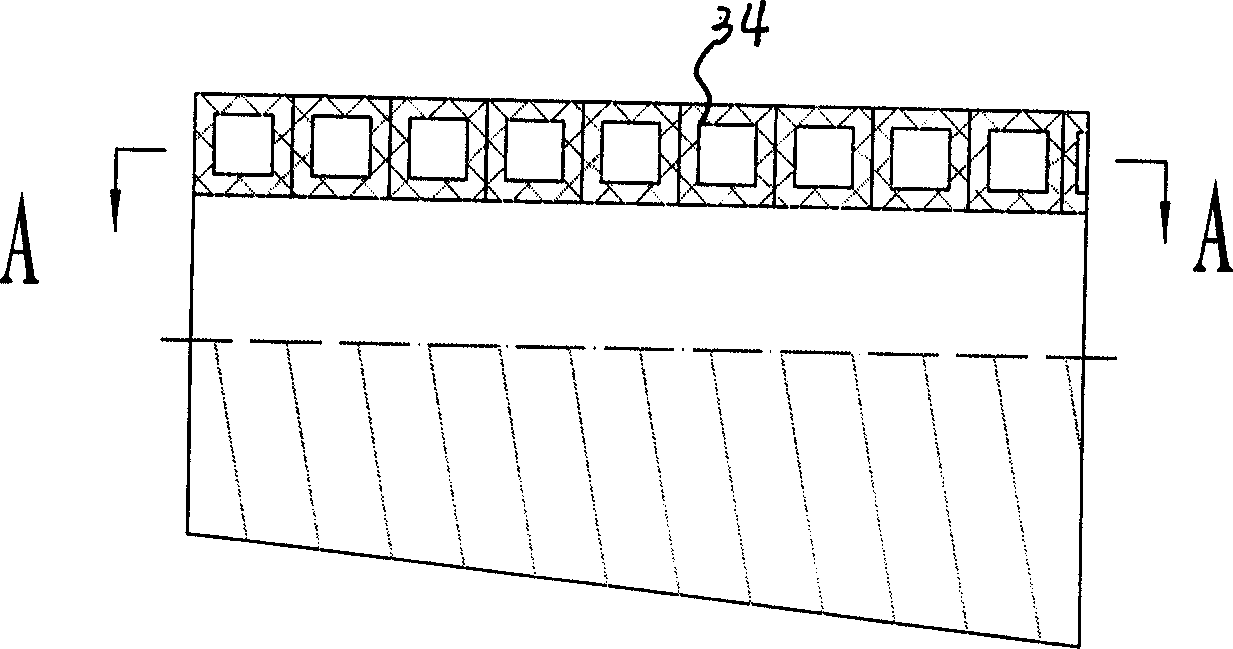

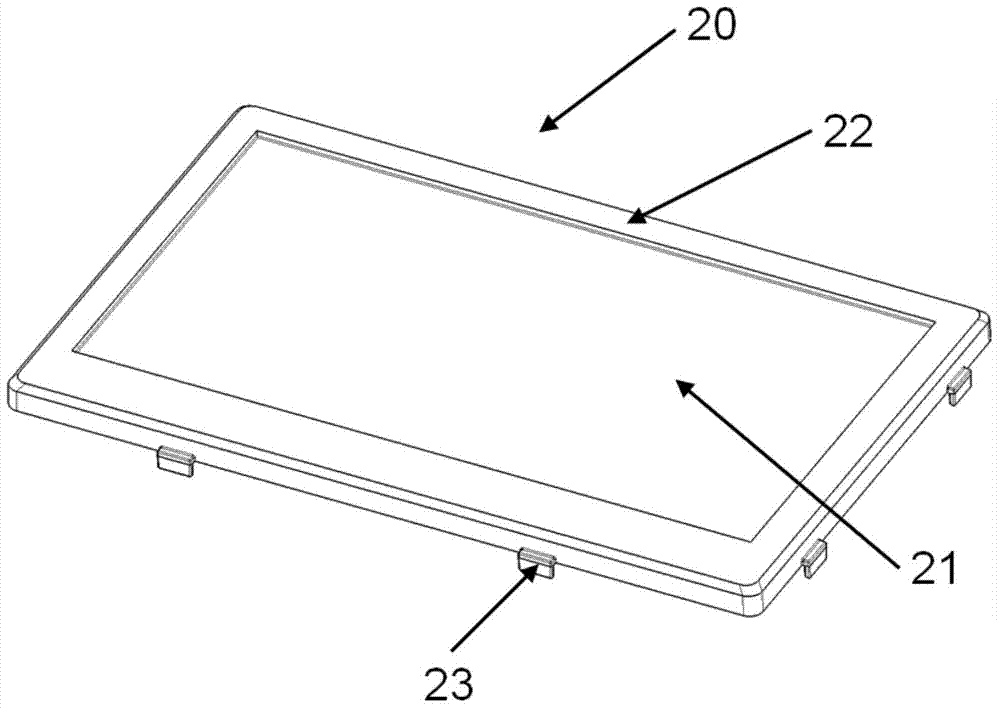

Isolation pad, display panel, method for manufacturing display panel, and display device

InactiveCN105182627AImprove the ability to withstand external forcesImprove the display effectNon-linear opticsInput/output processes for data processingDisplay deviceBearing capacity

The invention discloses an isolation pad, a display panel, a method for manufacturing the display panel, and a display device. The isolation pad comprises main isolation pad bodies and connecting parts, wherein the main isolation pad bodies and the connecting parts are located on a first substrate, and the connecting parts are located between the main isolation pad bodies and used for connecting the main isolation pad bodies. By arranging the connecting parts between the main isolation pad bodies, the external force bearing capacity of the isolation pad is improved, the contact area between the isolation pad and the first substrate is increased, the situation that the isolation pad breaks and falls off from the first substrate is avoided, and then poor display of the display panel is avoided and the display quality of the display panel is improved.

Owner:BOE TECH GRP CO LTD +1

Nanometer level regenerated spider silk fiber and its preparation method

InactiveCN1670272ALower requirementStable structureWet spinning methodsSpinning solutions preparationEngineeringNonwoven fabric

The invention discloses a manufacturing method for nm grade regeneration spider silk fiber. It includes the following steps: dissolving the egg covering silk or dragging silk in hex-fluorin isopropyl alcohol, and putting under room temperature for 5 hours, the regeneration spider silk solution would be available after filtrating and the consistence is 1.0%-4.5%; processing the solution by the method of static electrical filature and using the conduct metal net as receive screen, the voltage is from 7-29KV, the distance from the silk spraying outlet to the receiving screen is 8-20cm, and temperature is 20-30 degree centigrade, the nm grade regeneration spider silk nonwoven fabric would be available after spinning; taking after process to the nonwoven fabric by wood alcohol or acetone for 0.5-1.5 hour, the nm grade regeneration spider silk fiber would be available. The invention could improve stability and the mechanical property of the products structure and color.

Owner:SUZHOU LONGJIE SPECIAL FIBER

Hot working method for smelting molybdenum rhenium alloy casting ingot by suspending

InactiveCN101269383AReduce the amount of dislocation movementFine grainTemperature control deviceMetal rolling arrangementsRheniumDislocation

The invention discloses a thermal processing method for suspension electron beam melting molybdenum-rhenium alloy ingot. The method obtains rod-shaped ingot by melting a molybdenum-rhenium alloy sintered bar through suspension electron beam. The high temperature rolling is carried out by the first fire, the parallel ingot is axially fed, with a rolling speed ranging from 300 to 400mm / min, the temperature is kept for 1 hour; the ingot is rolled to the set thickness through rolling for three times and heated at high temperature for the second time, the temperature is kept for 1 hour, with a rolling speed ranging from 300 to 400mm / min; the ingot is rolled to the set thickness after inverting the direction; the ingot is heated at high temperature for the third time, the temperature is kept for half an hour; the ingot is rolled to the set thickness through 3 rolling for three times and is carried for cold rolling after annealing. The thermal processing method provided by the invention reduces the dislocation movement for single sliding and the speed of the dislocation movement, controls the direction of the dislocation movement, avoids the cracking at crystal boundary owing to the accumulation of the dislocation; besides, the thermal processing method ensures cogging of the ingot but not cracking, and ensures heating processing to go on smoothly. By the thermal processing method, accepted plank stuff characterized by fine crystal particles and uniform sizes can be made, with purity over 99.99 percent.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Wrapping formed inspection well prepared from plastic in environmental protection, and method of preparation

InactiveCN1727582AImprove the ability to withstand external forcesImprove sealingArtificial islandsUnderwater structuresEnvironmental engineeringMechanical engineering

An environmental protection type plastic manhole is made up of the plastic band (or strips) and reinforcing ribs through preparing the plastic band (or strips) through extruding and cooling, winding them on a mould while extruding out the fused plastic onto the plastic band (or strips) for playing the roles of adhesive and reinforcing rib.

Owner:四川天鑫塑胶管业有限公司

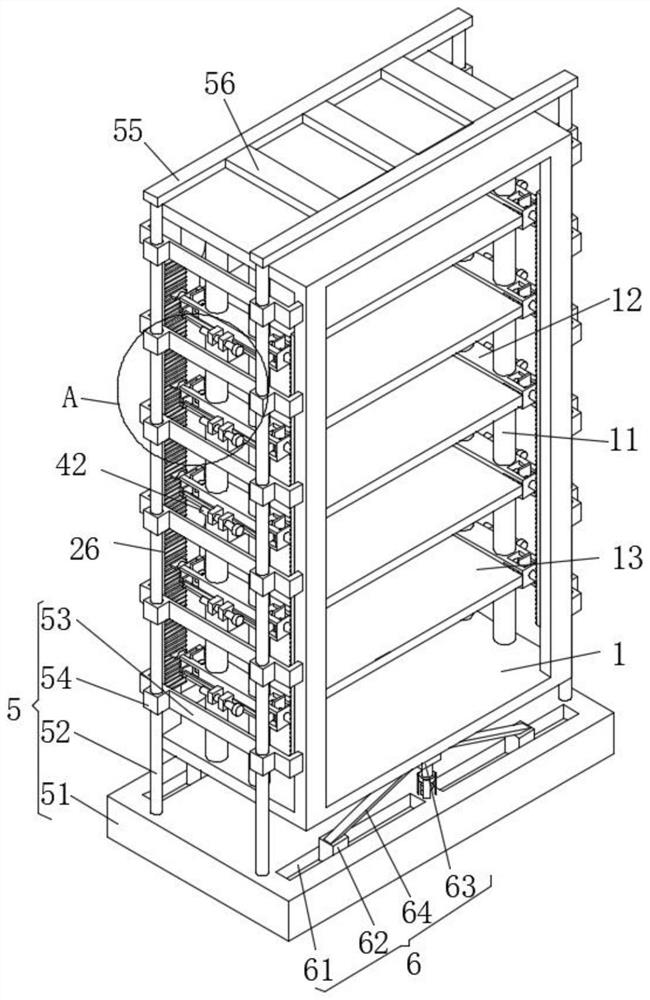

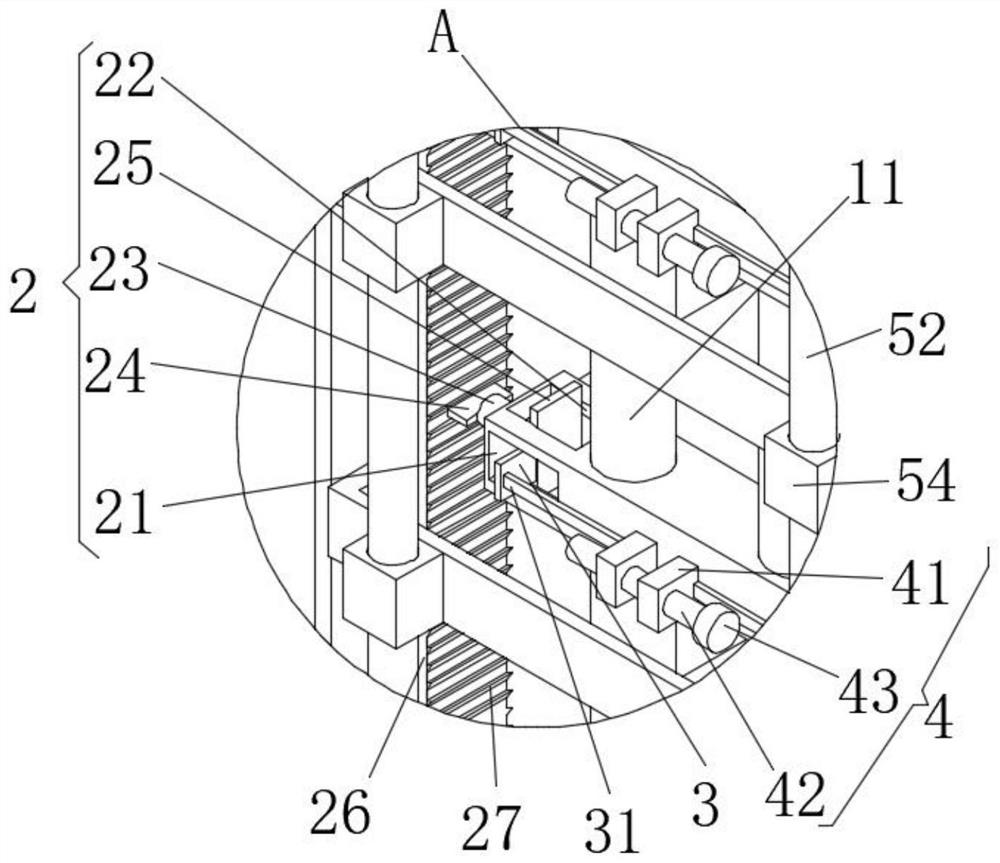

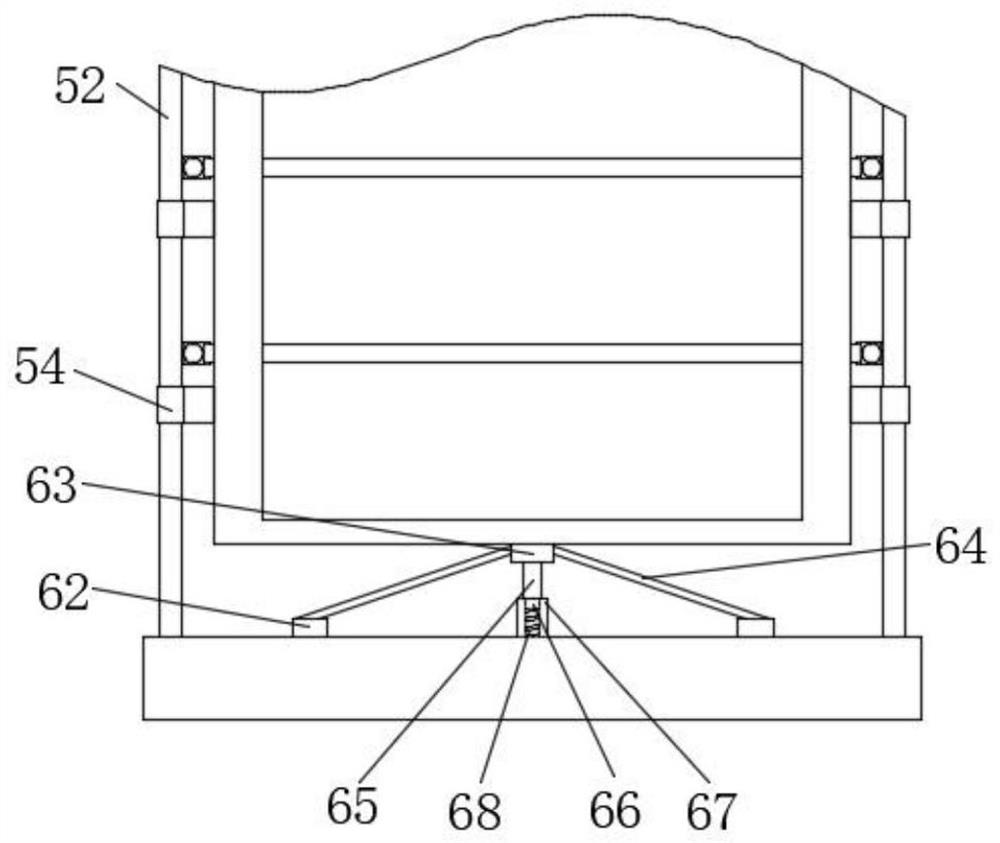

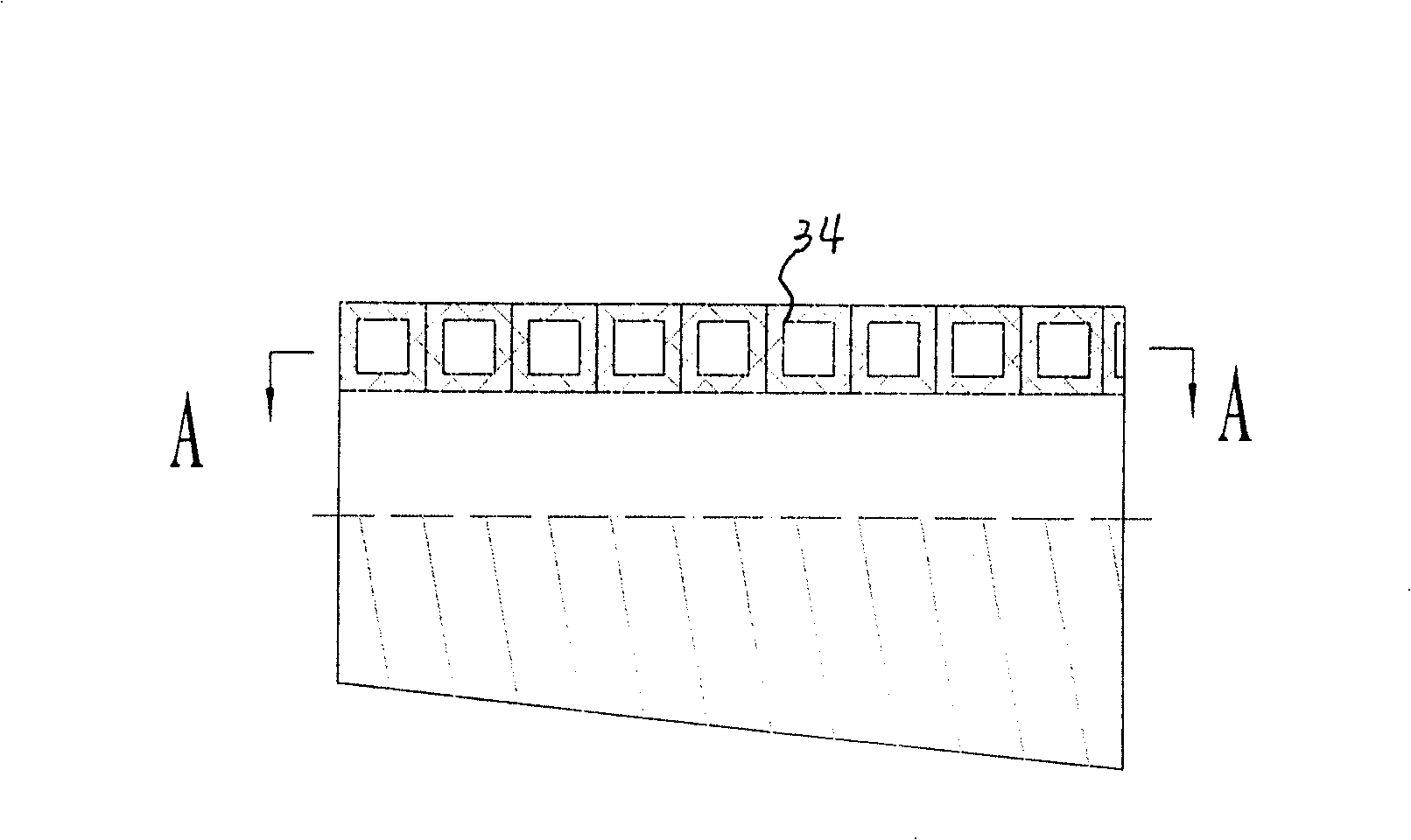

High-strength multilayer switch cabinet

PendingCN112003149AHigh strengthAchieve fixationSubstation/switching arrangement casingsAnti-seismic devicesEngineeringStructural engineering

The invention discloses a high-strength multi-layer switch cabinet which comprises a cabinet body and a limiting assembly. Guide rods are symmetrically arranged on the two sides of the cabinet body, movable blocks are movably connected to the guide rods in a sleeving mode, and a layer plate is arranged between the corresponding movable blocks on the two sides. The limiting assembly comprises mounting grooves, a guide groove, a limiting rod, a limiting plate and a baffle. The number of the mounting grooves is two. Two mounting grooves are symmetrically formed in the two ends of the movable block. The guide groove penetrates through the upper and lower surfaces of the mounting groove. One end of the limiting rod penetrates through the side surface of the mounting groove and extends out of the mounting groove. The limiting plate is arranged at one end, outside the mounting groove, of the limiting rod. The baffle is arranged at the end, located in the mounting groove, of the limiting rod.The upper end and the lower end of the baffle are in sliding fit with side faces of the upper side and the lower side of the guide groove correspondingly. A control assembly is arranged on the limiting assembly. According to the high-strength multi-layer switch cabinet, flexible adjustment of the distance between the layers can be achieved according to needs, the strength and the shock resistanceof the cabinet body are improved, and the high-strength multi-layer switch cabinet is high in practicability.

Owner:江苏中顺电气有限公司

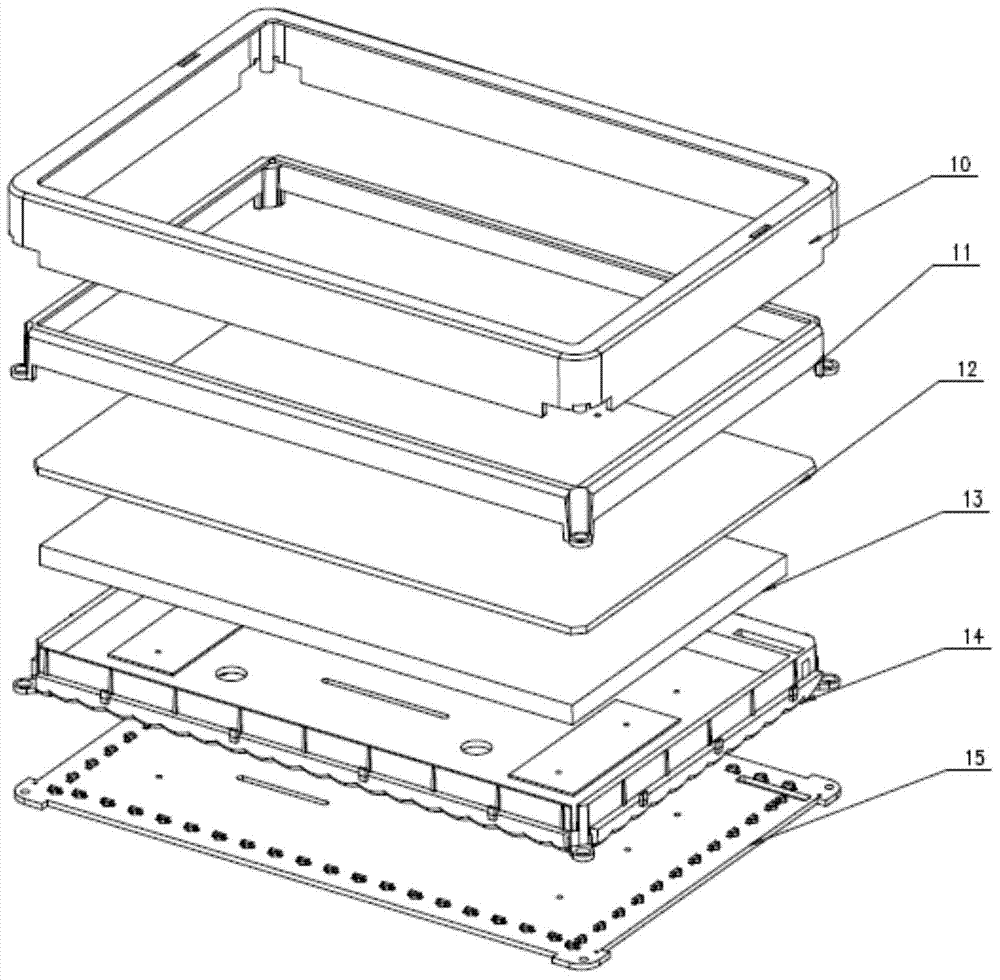

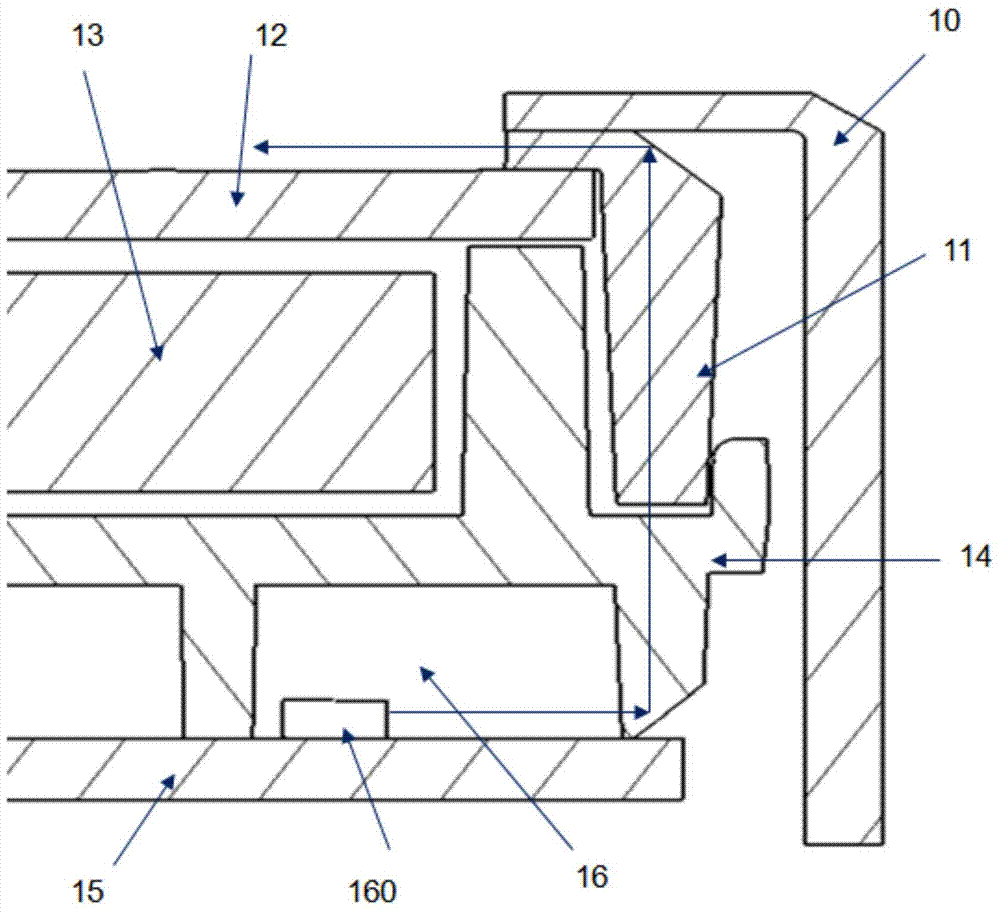

Infrared touch screen and touch panel thereof

InactiveCN104516593ASimple structureImprove the ability to withstand external forcesInput/output processes for data processingTouch panelEngineering

A touch panel of an infrared touch screen is provided, which comprises a touch portion and a light guide element, wherein the light guide element is formed integrally with the touch portion. The touch panel of the invention, due to its touch portion and its light guide element being integrally formed, has a simple structure and an improved ability of enduring an external force and is not easy to be deformed by the external force. In this way, a precise light transmission path can be ensured, a touch point can be precisely positioned into a location on the touch panel, and mis-operation can be avoided. The infrared touch screen with the touch panel according to the invention provides advantages including a simple structure, better endurance and enabling precise operation.

Owner:BOSCH AUTOMOTIVE PROD SUZHOU

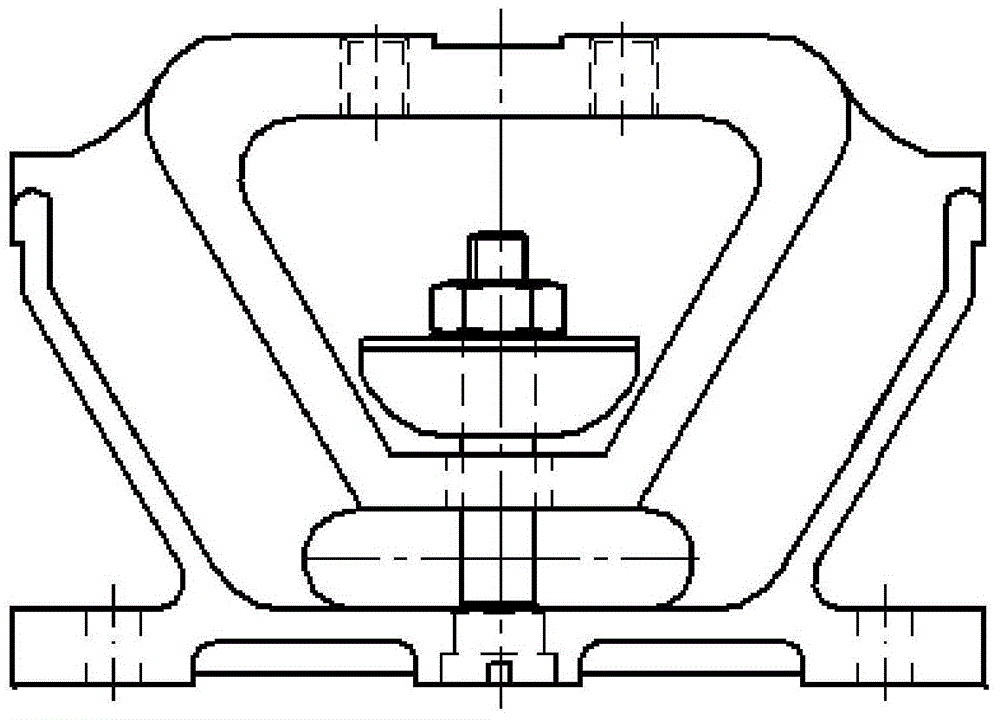

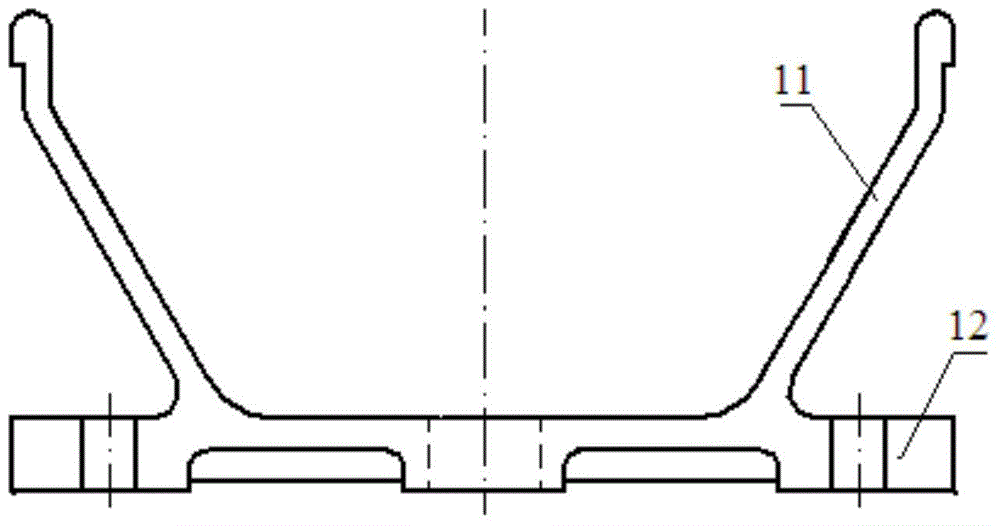

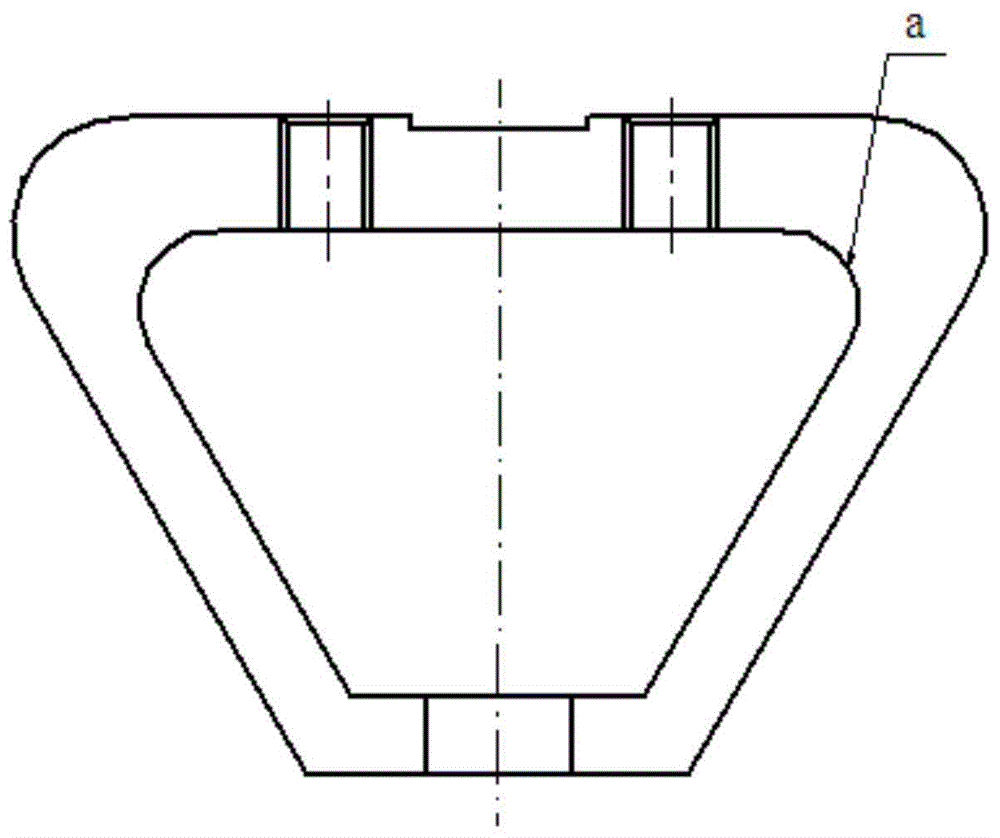

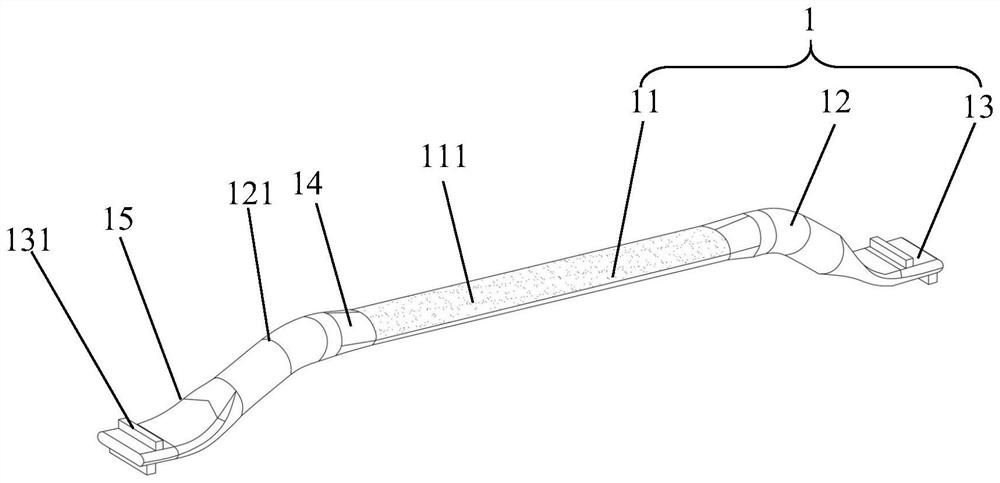

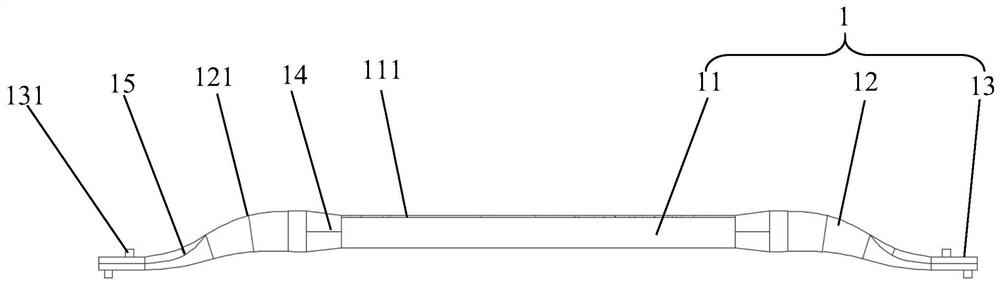

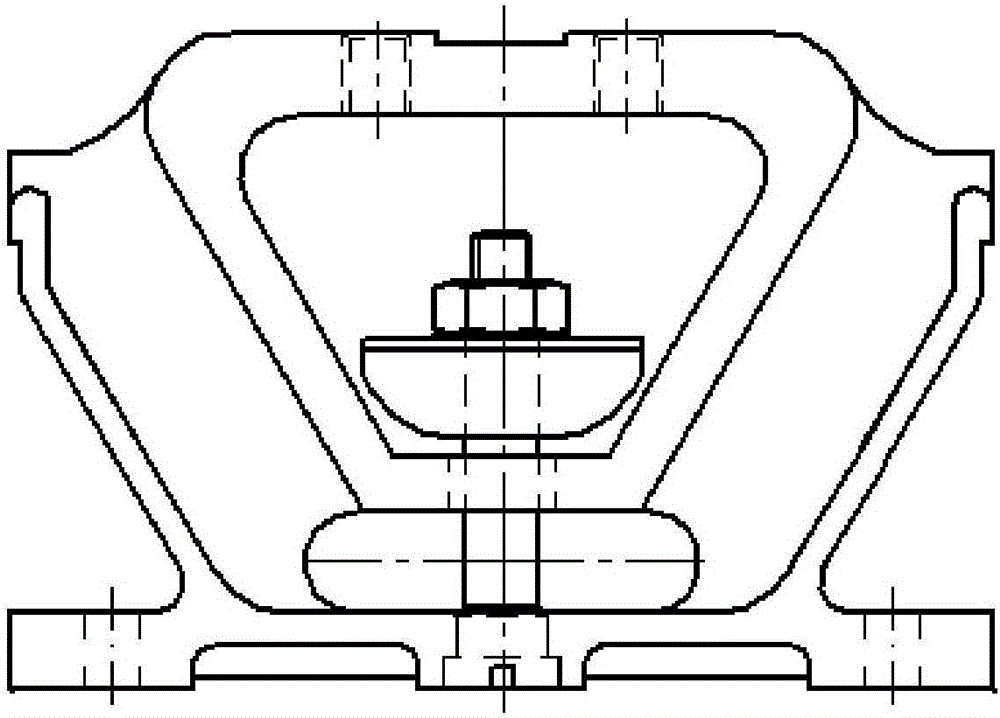

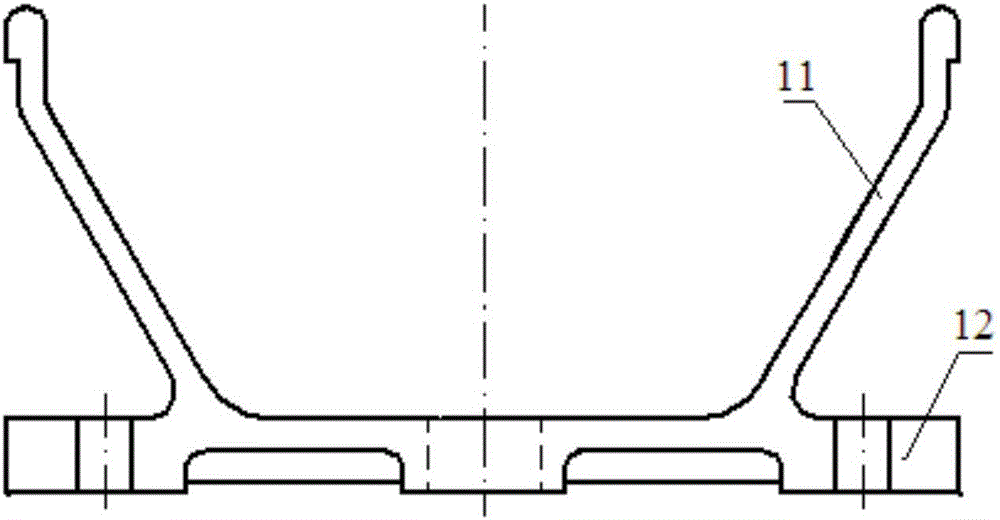

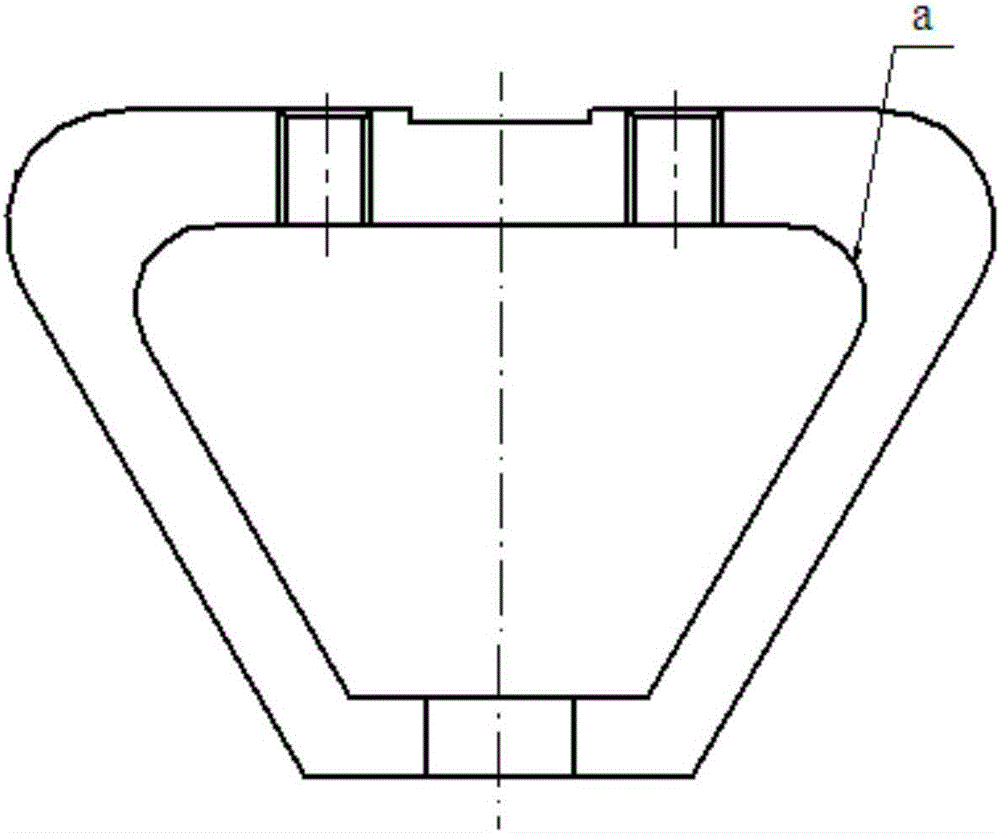

Rear-mounted rubber mat assembly

ActiveCN104896006AImprove the ability to withstand external forcesNot prone to crackingSpringsNon-rotating vibration suppressionEngineeringRubber mat

The invention discloses a rear-mounted rubber mat assembly. A rubber mat base comprises two half bases, a rubber mat supporting space is formed between the two half bases, each half base comprises a soleplate, an oblique supporting plate and an auxiliary supporting plate, one end of the auxiliary supporting plate is fixed on the soleplate, the other end of the auxiliary supporting plate is fixed on the oblique supporting plate, and a preset angle is formed between the outer wall of the auxiliary supporting plate and the oblique supporting plate; a rubber mat pressure block comprises a pressure block body with an upper installation surface and a rubber mat adhesion surface, supporting ribs are fixed inside the pressure block body, lightening holes are formed in two sides of each supporting rib, and each lightening hole is formed by encircling the inner wall of the pressure block body and the supporting rib; the rubber mat comprises two rubber mat bodies which are fixedly connected with each other, each rubber mat body comprises at least two superimposed bodies as well as a liner plate which is fixed between two adjacent bodies, and two opposite surfaces of the liner plate are respectively fit to the oblique surfaces of the two bodies. The rubber mat base and the rubber mat pressure block in the rear-mounted rubber mat assembly are unlikely to fracture, and the rubber mat is unlikely to fracture.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Nanometer level regenerated spider silk fiber and its preparation method

InactiveCN100351437CLower requirementStable structureMonocomponent fibroin artificial filamentWet spinning methodsEngineeringNonwoven fabric

The invention discloses a manufacturing method for nm grade regeneration spider silk fiber. It includes the following steps: dissolving the egg covering silk or dragging silk in hex-fluorin isopropyl alcohol, and putting under room temperature for 5 hours, the regeneration spider silk solution would be available after filtrating and the consistence is 1.0%-4.5%; processing the solution by the method of static electrical filature and using the conduct metal net as receive screen, the voltage is from 7-29KV, the distance from the silk spraying outlet to the receiving screen is 8-20cm, and temperature is 20-30 degree centigrade, the nm grade regeneration spider silk nonwoven fabric would be available after spinning; taking after process to the nonwoven fabric by wood alcohol or acetone for 0.5-1.5 hour, the nm grade regeneration spider silk fiber would be available. The invention could improve stability and the mechanical property of the products structure and color.

Owner:SUZHOU LONGJIE SPECIAL FIBER

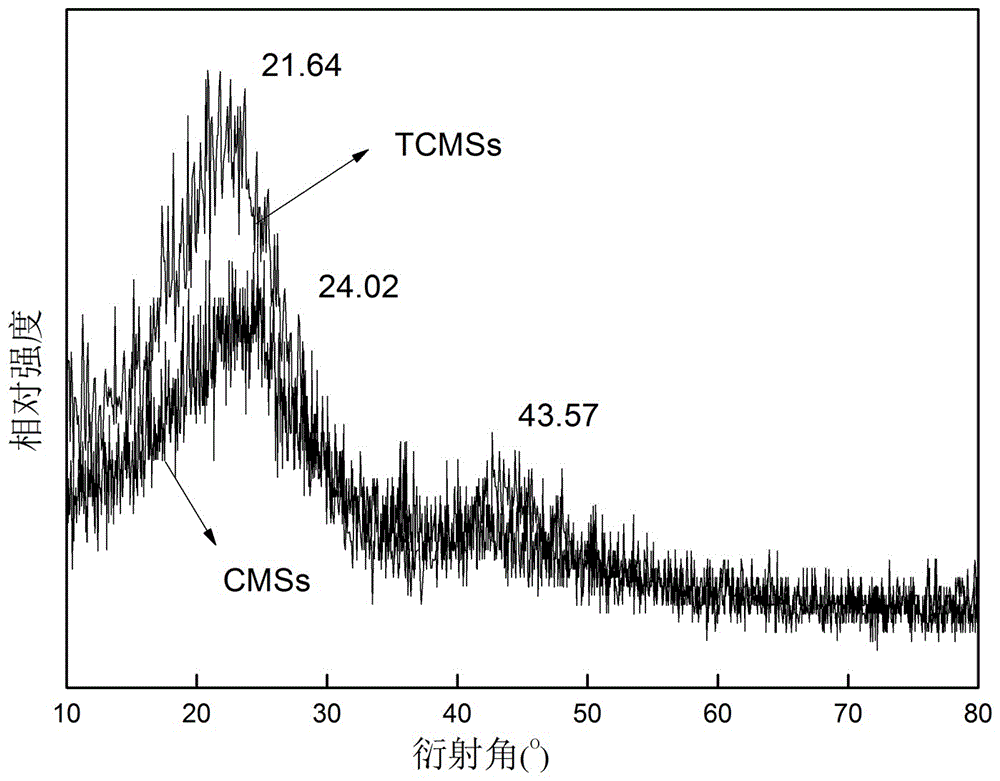

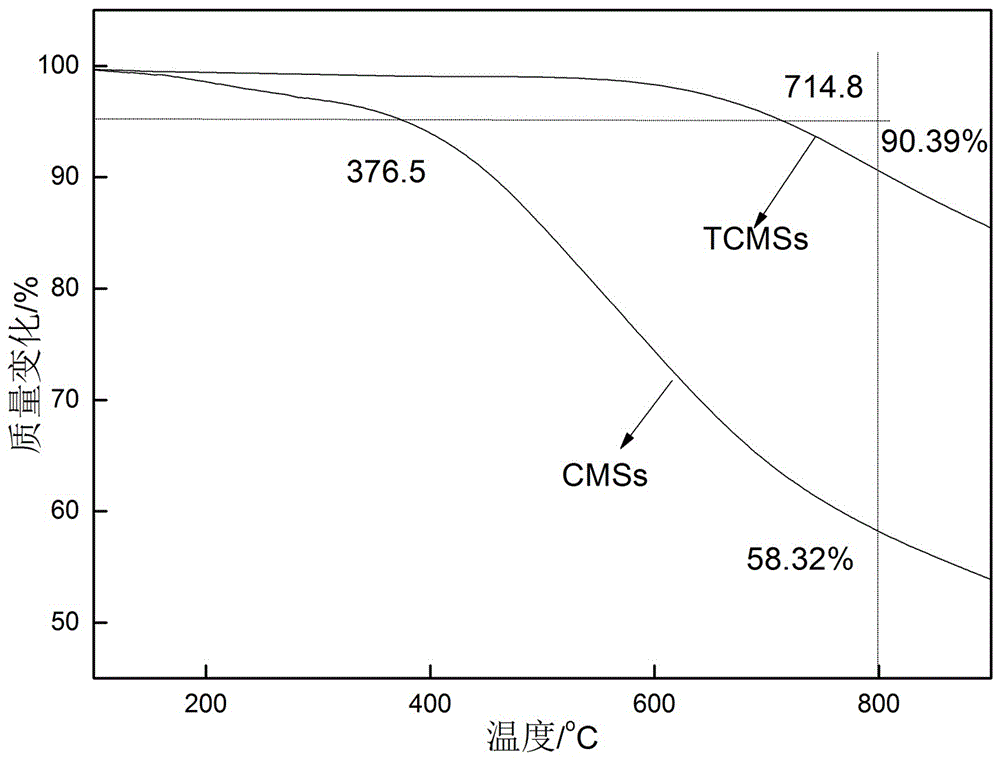

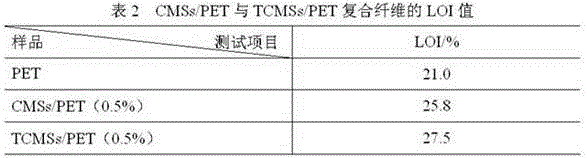

Flame-resistant PET composite and preparation method thereof

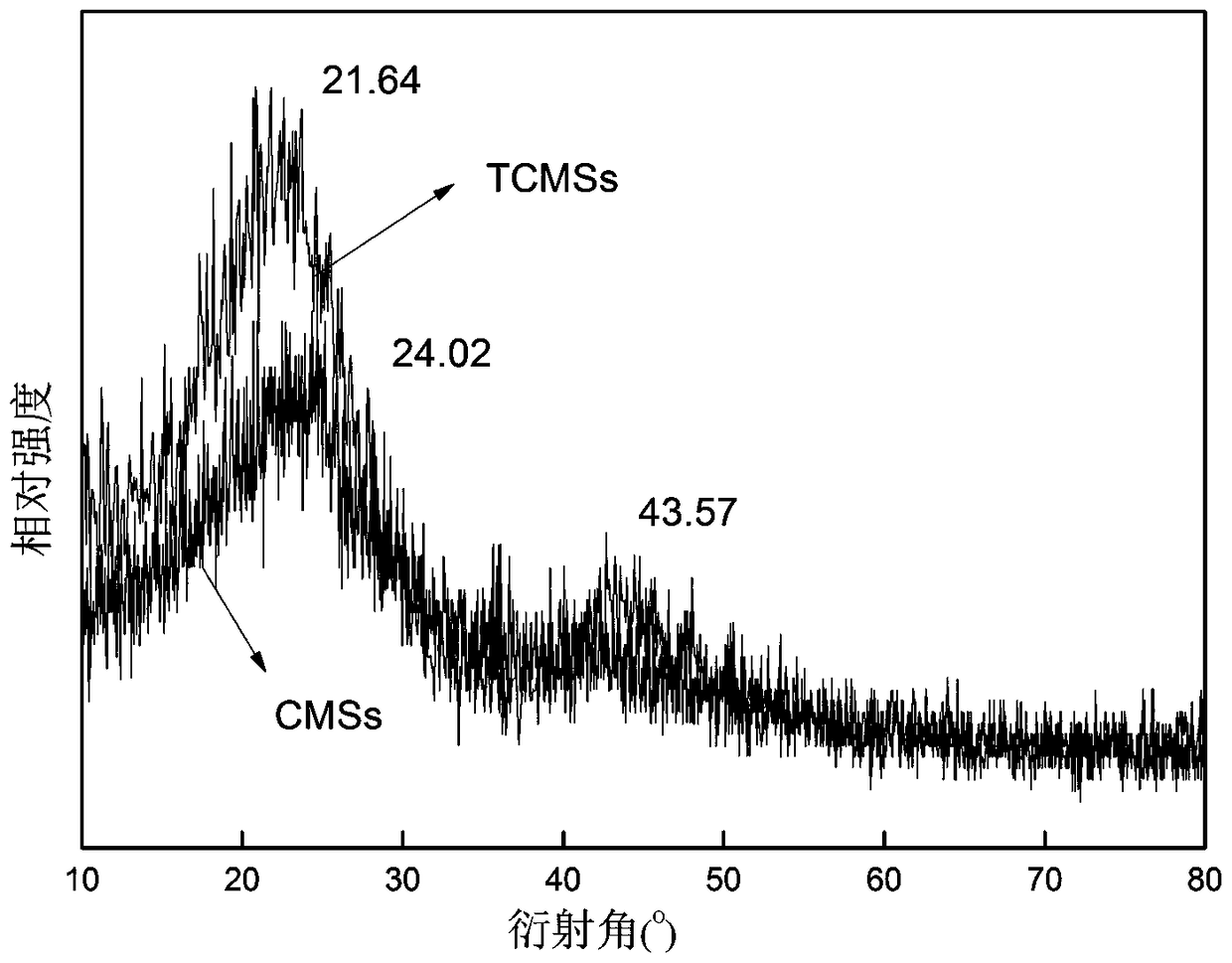

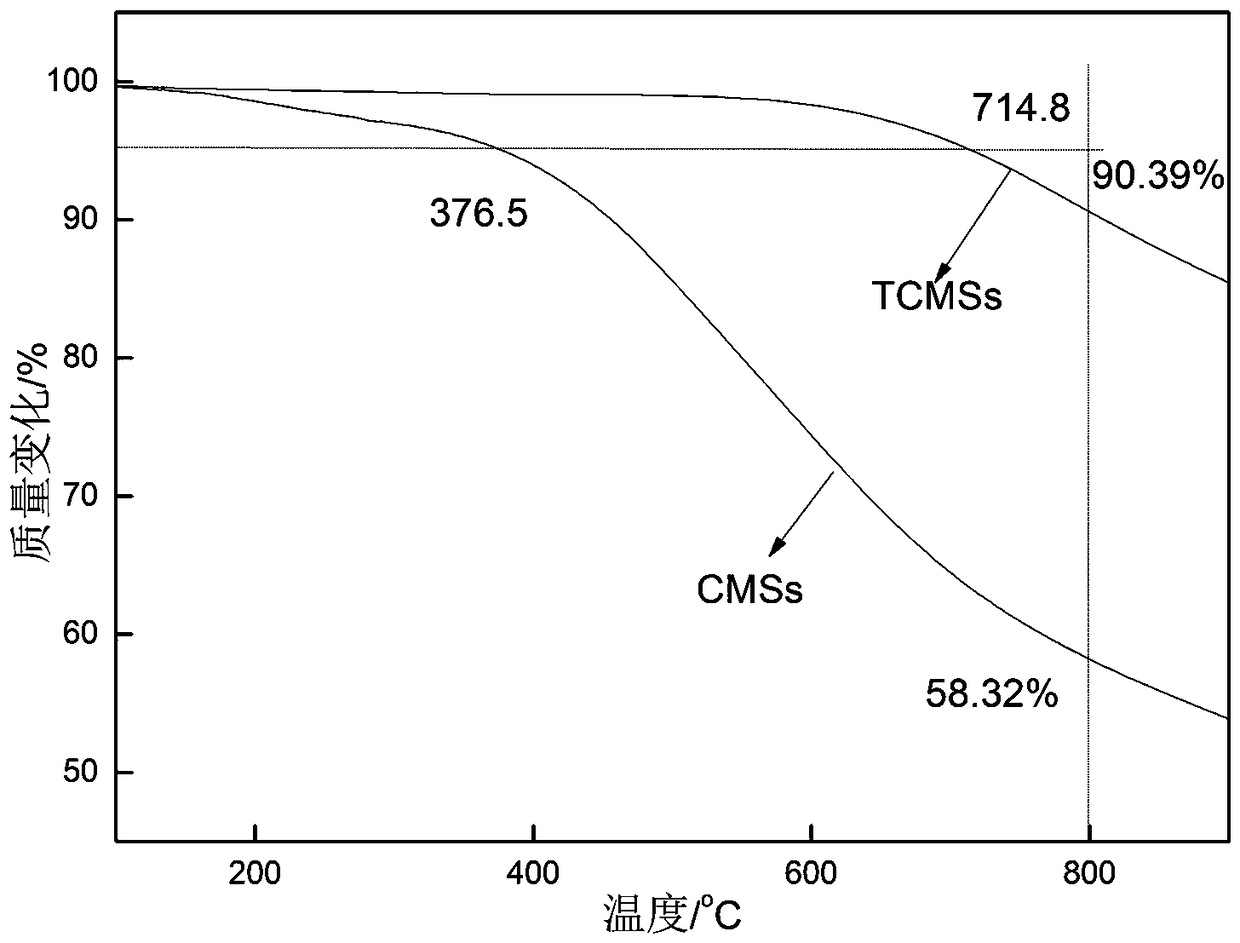

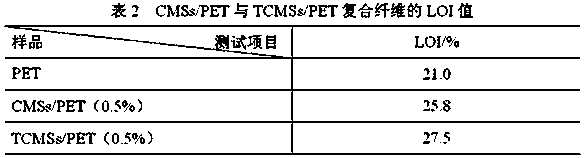

ActiveCN106674920AMeet the process requirementsImprove thermal stabilityFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberFlame resistance

The invention discloses a flame-resistant PET composite. The flame-resistant PET composite is prepared according to the following steps: adding TCMSs to a PET basal body for melting, blending, wire drawing and slicing so as to obtain TCMSs / PET slices containing the TCMSs of which the percentage by mass is 0.2-2%, wherein the TCMSs is a material obtained by heating CMSs under inert atmosphere to 600-800 DEG C and then performing annealing treatment for 30-120min, and can be used for preparing flame-resistant PET fibers. The composite disclosed by the invention can be added to the PET basal body for preparing the flame-resistant PET fibers, so that the fire resistance of the PET fibers can be improved, and the condition that the tensile strength of the PET fibers is reduced due to the addition of the CMSs is also obviously improved.

Owner:TAIYUAN UNIV OF TECH

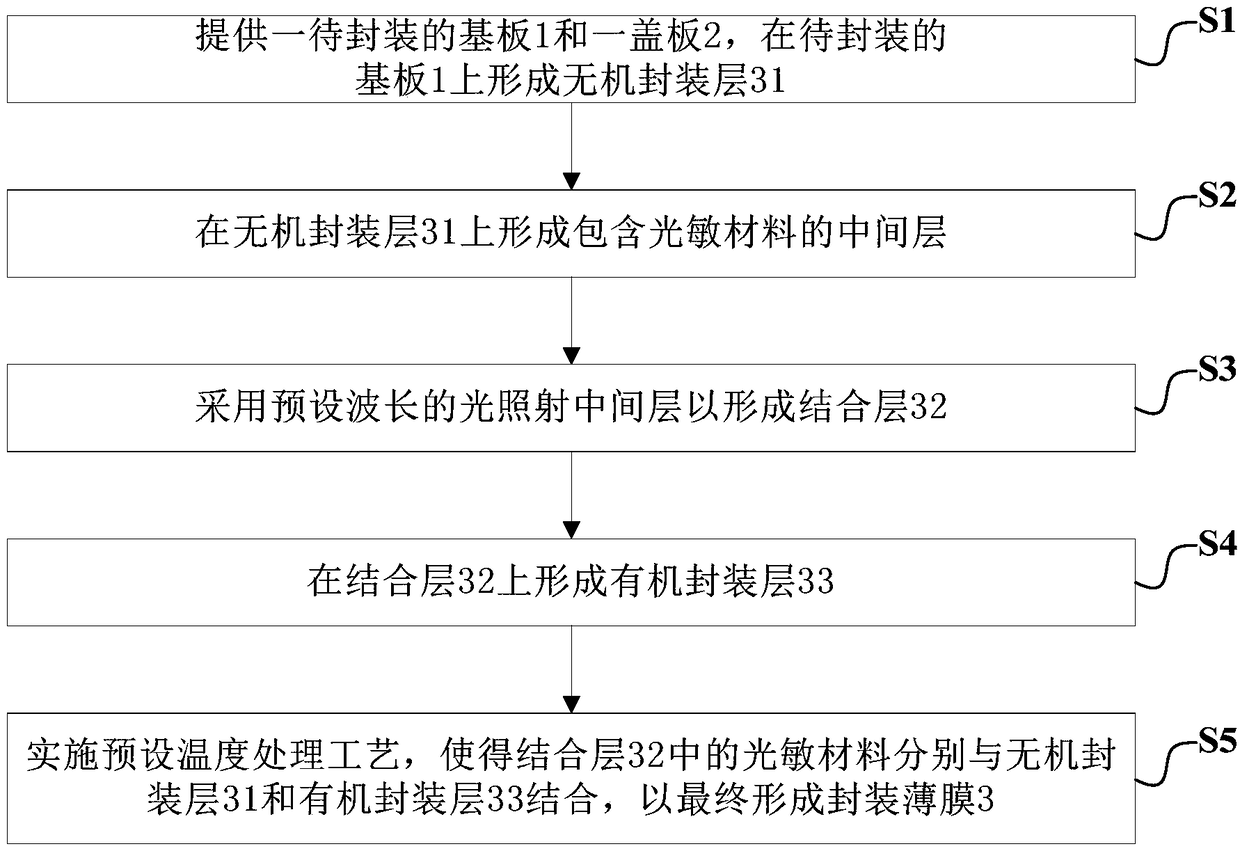

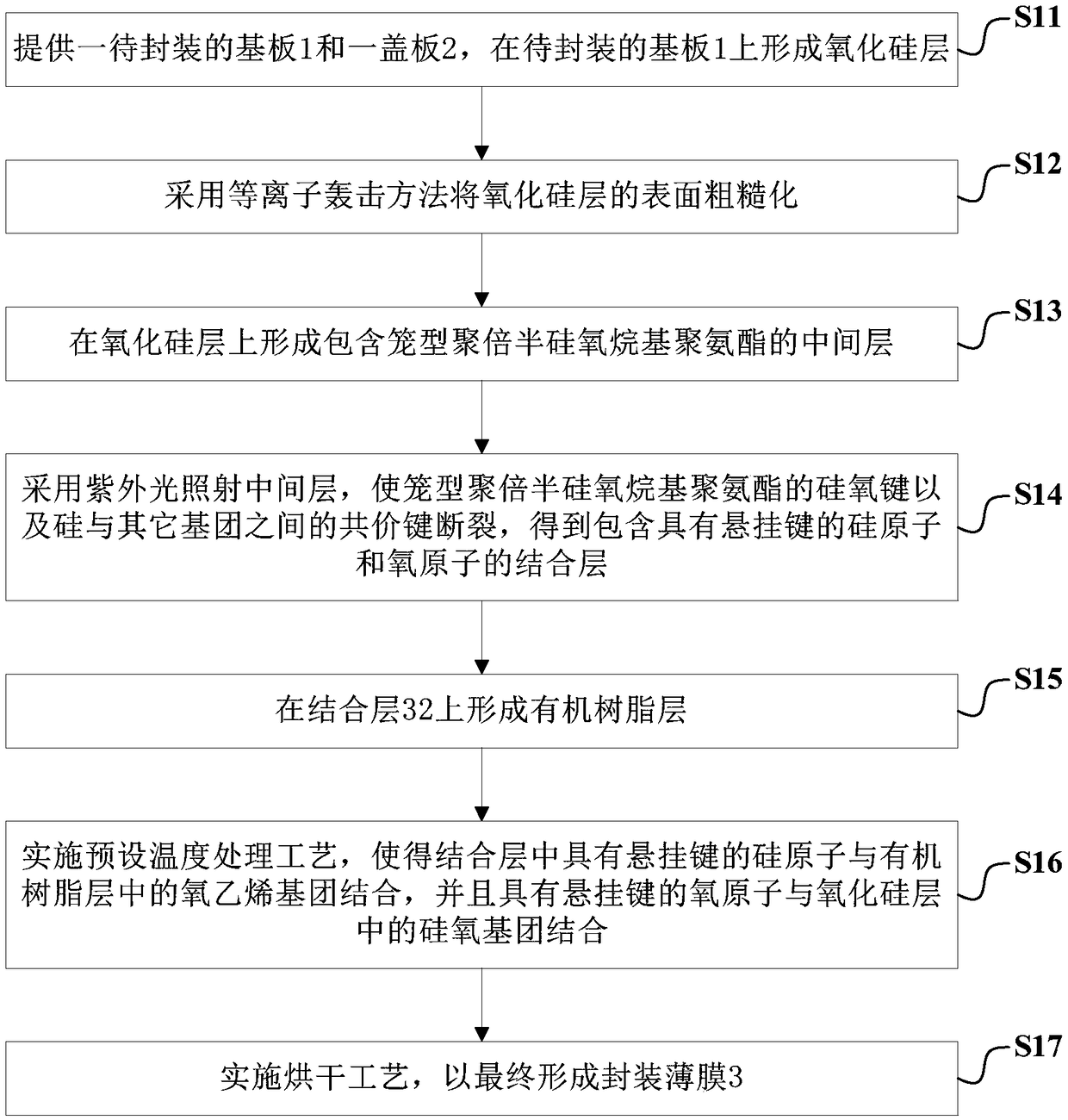

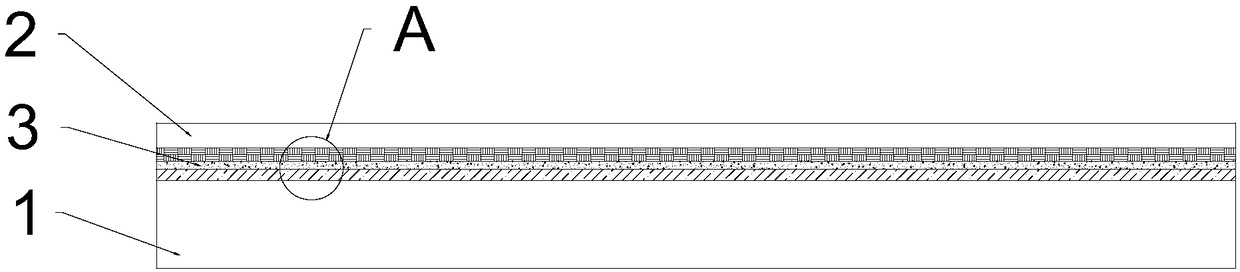

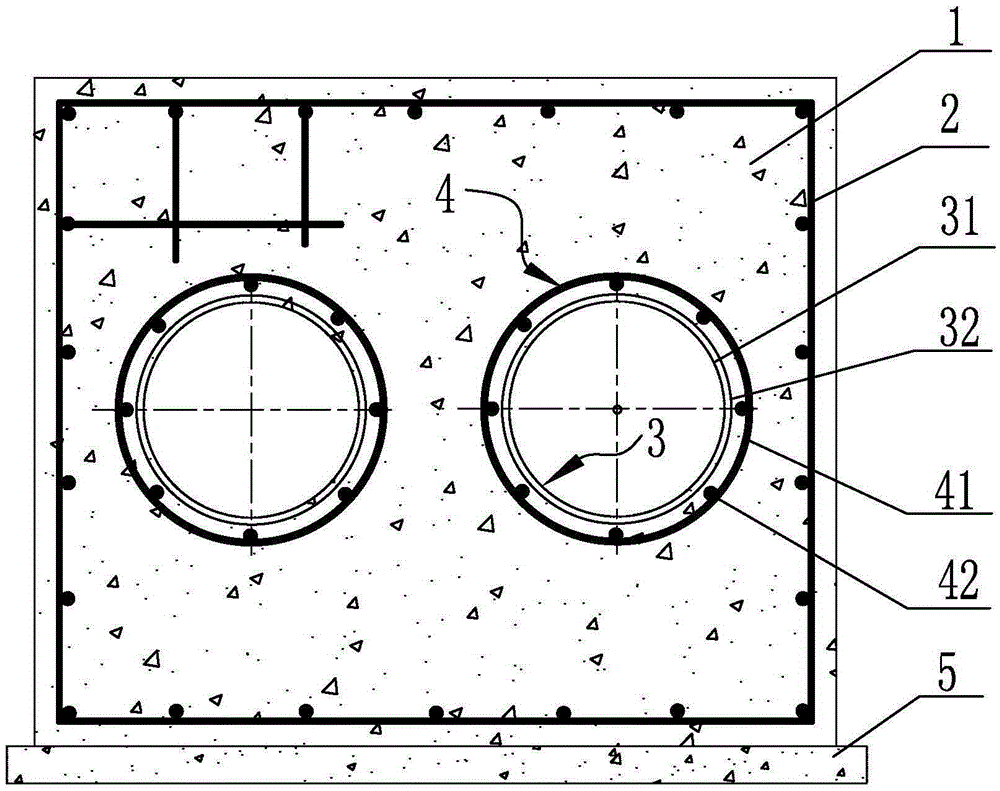

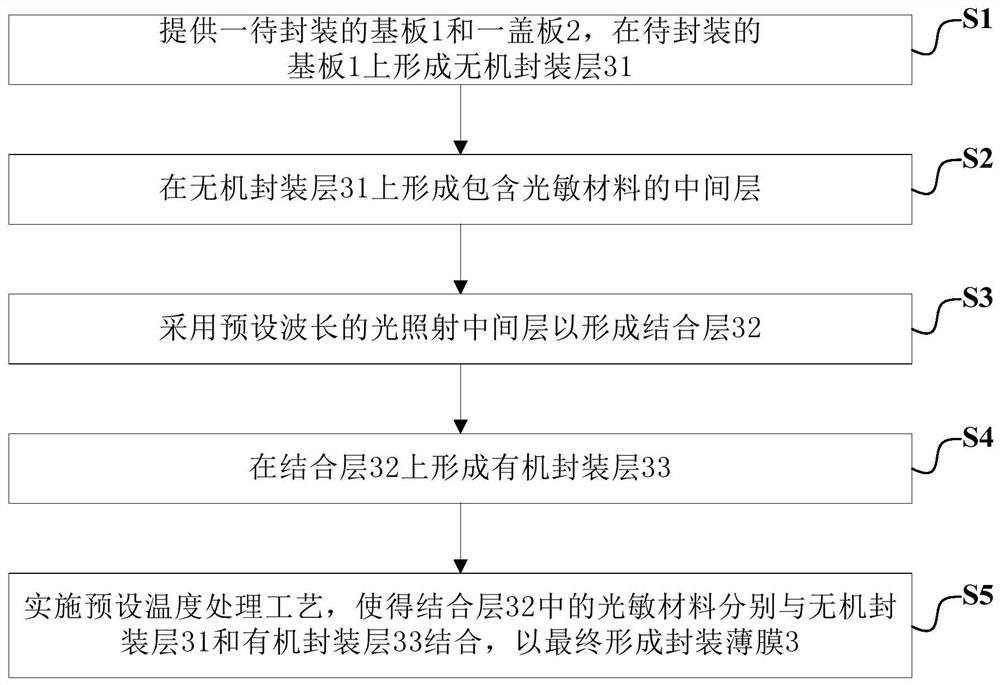

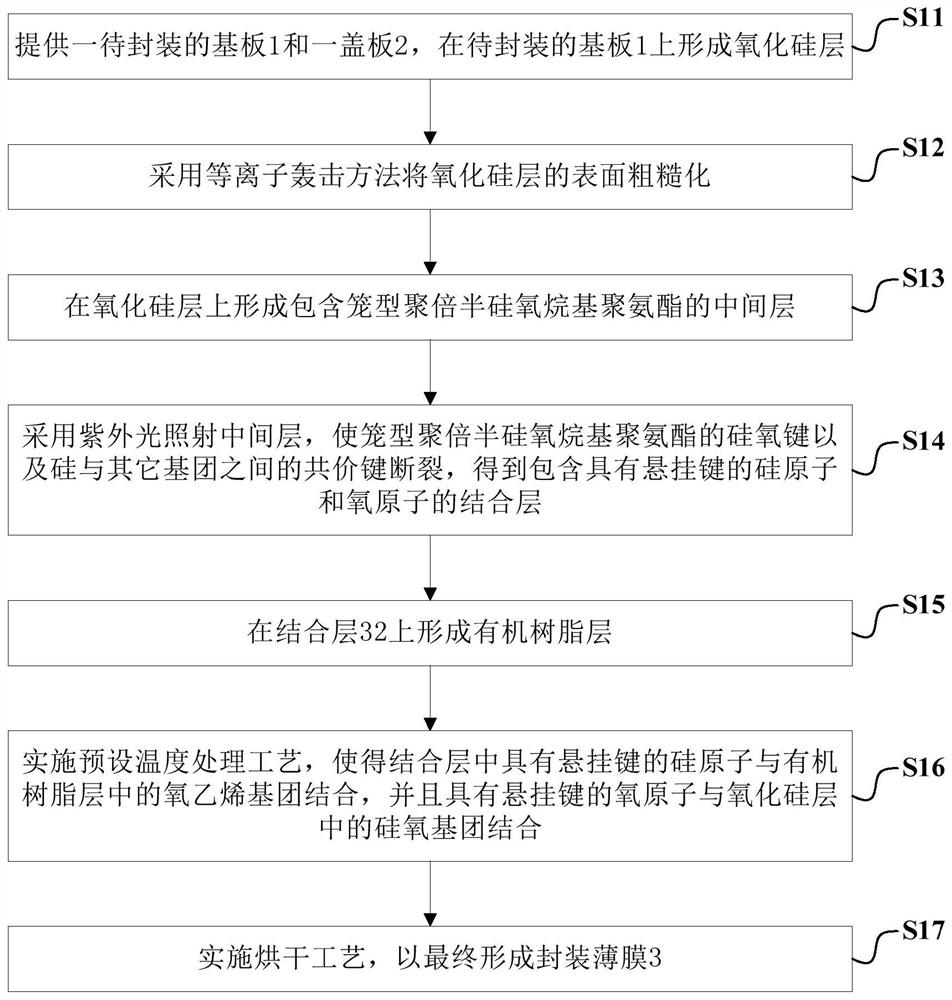

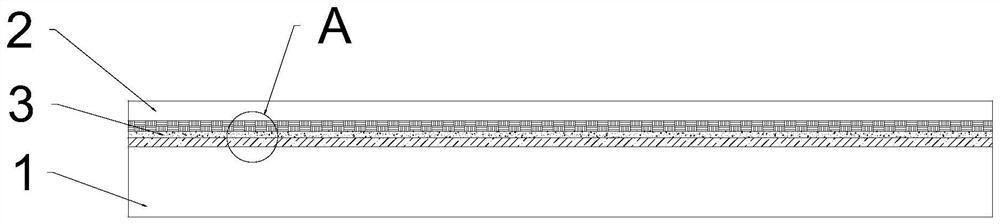

Encapsulation method and display panel

ActiveCN109037479AImprove the ability to withstand external forcesImprove barrier propertiesSolid-state devicesSemiconductor/solid-state device manufacturingInter layerBlock effect

An embodiment of the present application provides an encapsulation method and a display panel. The encapsulation method includes: providing a substrate to be encapsulated and a cover plate; forming aninorganic encapsulation layer on the substrate to be encapsulated; forming an intermediate layer containing a photosensitive material on the inorganic encapsulation layer, and irradiating the intermediate layer with light of a preset wavelength to form a bonding layer; forming an organic encapsulation layer on the bonding layer; implementing a preset temperature treatment process, so that a photosensitive material in the bonding layer is bonded with the inorganic encapsulation layer and the organic encapsulation layer respectively to finally form an encapsulation film. The bonding layer allows the inorganic encapsulation layer and the organic encapsulation layer to be bonded more closely, the capability of the encapsulation film of withstanding external force is improved, the invention reduces the probability of a stripping phenomenon of the interface between the inorganic encapsulation layer and the organic encapsulation layer, and further improves the blocking effect of the encapsulation film. The encapsulation film is formed on the substrate in the display panel by adopting the encapsulation method, so that moisture and oxygen can be effectively prevented from contact with thesubstrate, and corrosion damage to the substrate can be avoided.

Owner:BOE TECH GRP CO LTD

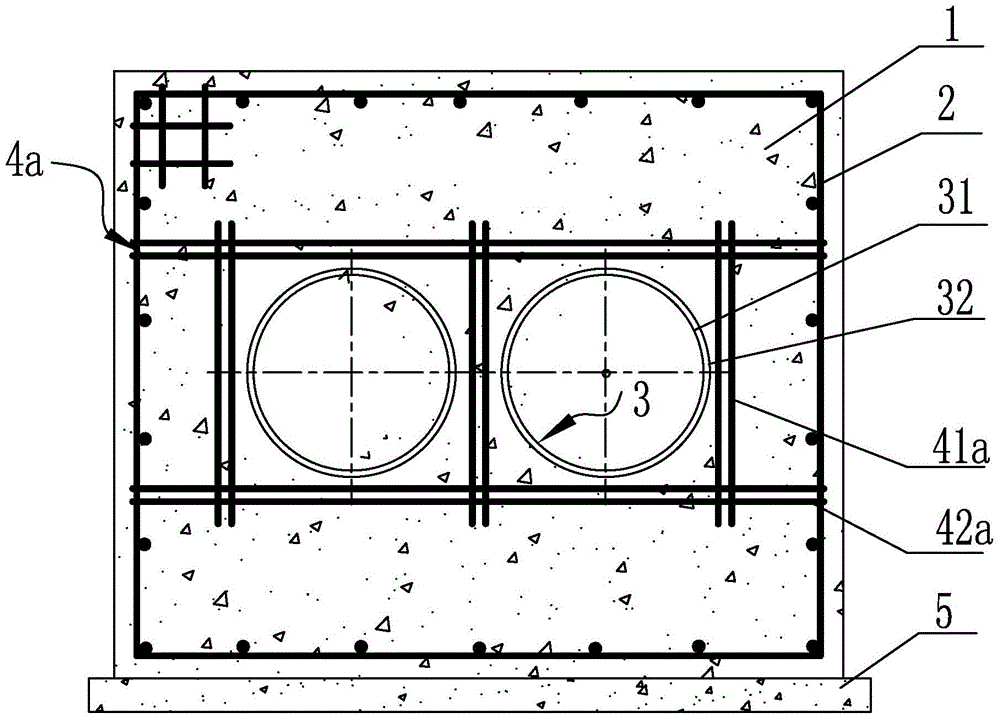

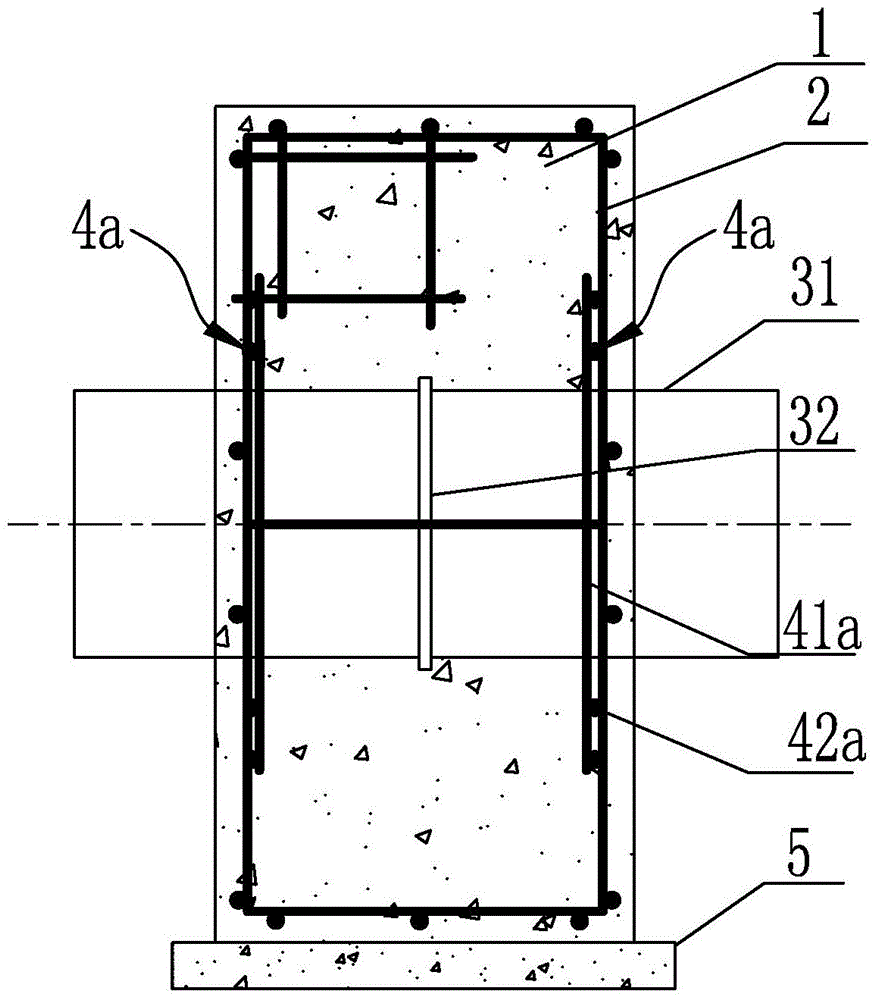

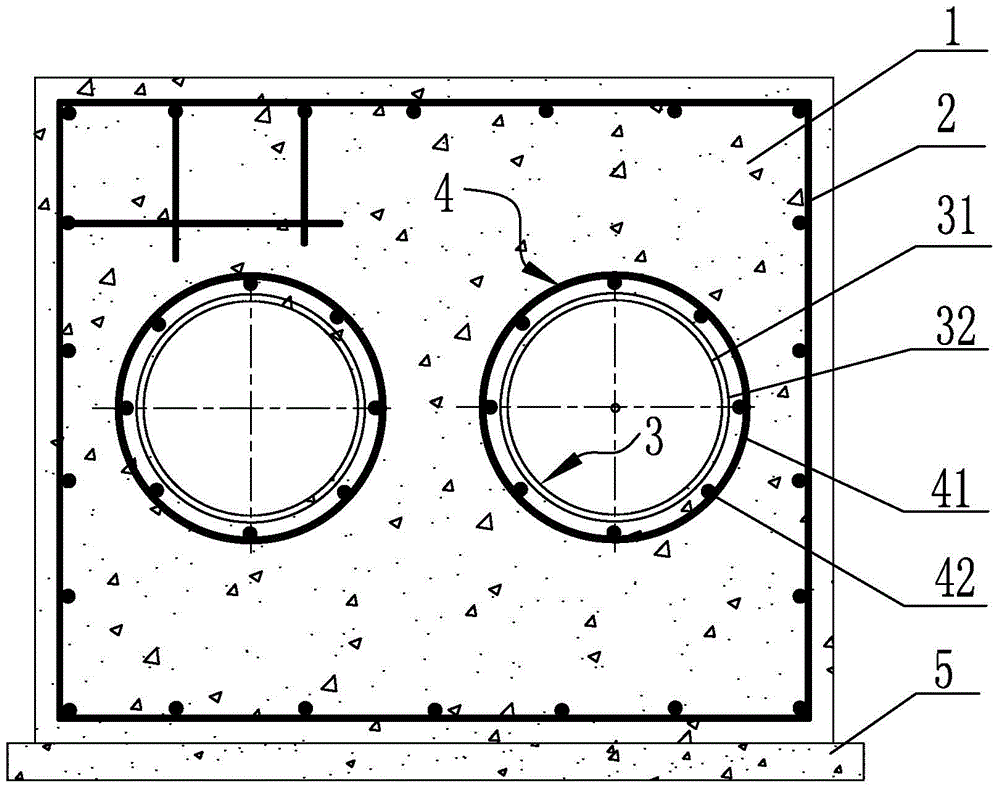

Stiffener cage for use in opening of anchor block for direct-buried heat supply pipelines

ActiveCN104154328AImprove the overall ability to withstand external forcesImprove reinforcement strengthPipe supportsPipe laying and repairRebarReinforced concrete

The invention relates to a stiffener cage for use in an opening of an anchor block for direct-buried heat supply pipelines. The anchor block is a reinforced concrete integrated connector made by subjecting two fixing segments arranged in parallel, a reinforcement fabric and opening stiffeners connected with the reinforcement fabric, to concreting on a base plate. Each fixing segment is a connecting pipe; the outside of the connecting pipe is provided with a circular flange; two ends of each connecting pipe horizontally penetrate one opening of the anchor block; the reinforcement fabric is arranged inside close to the outer surface of the anchor block by lining. The stiffener cage is characterized by comprising a plurality of circular bars and a plurality of longitudinal bars; the circular bars surround the fixing segments in the anchor block and evenly and parallelly arranged axially along the connecting pipes; the longitudinal bars surround the circular bars and are fixedly connected to the circular bars axially along the connecting pipes; the stiffener cage is fixed outside the fixing segments in such a manner that two ends of every longitudinal bar are fixedly connected to the reinforcement fabrics arranged on the front and rear sides of the openings. The stiffener cage has the advantages that overall strength of the anchor block is improved, and the anchor block is protected from damage.

Owner:TIANJIN THERMAL POWER DESIGNING INST

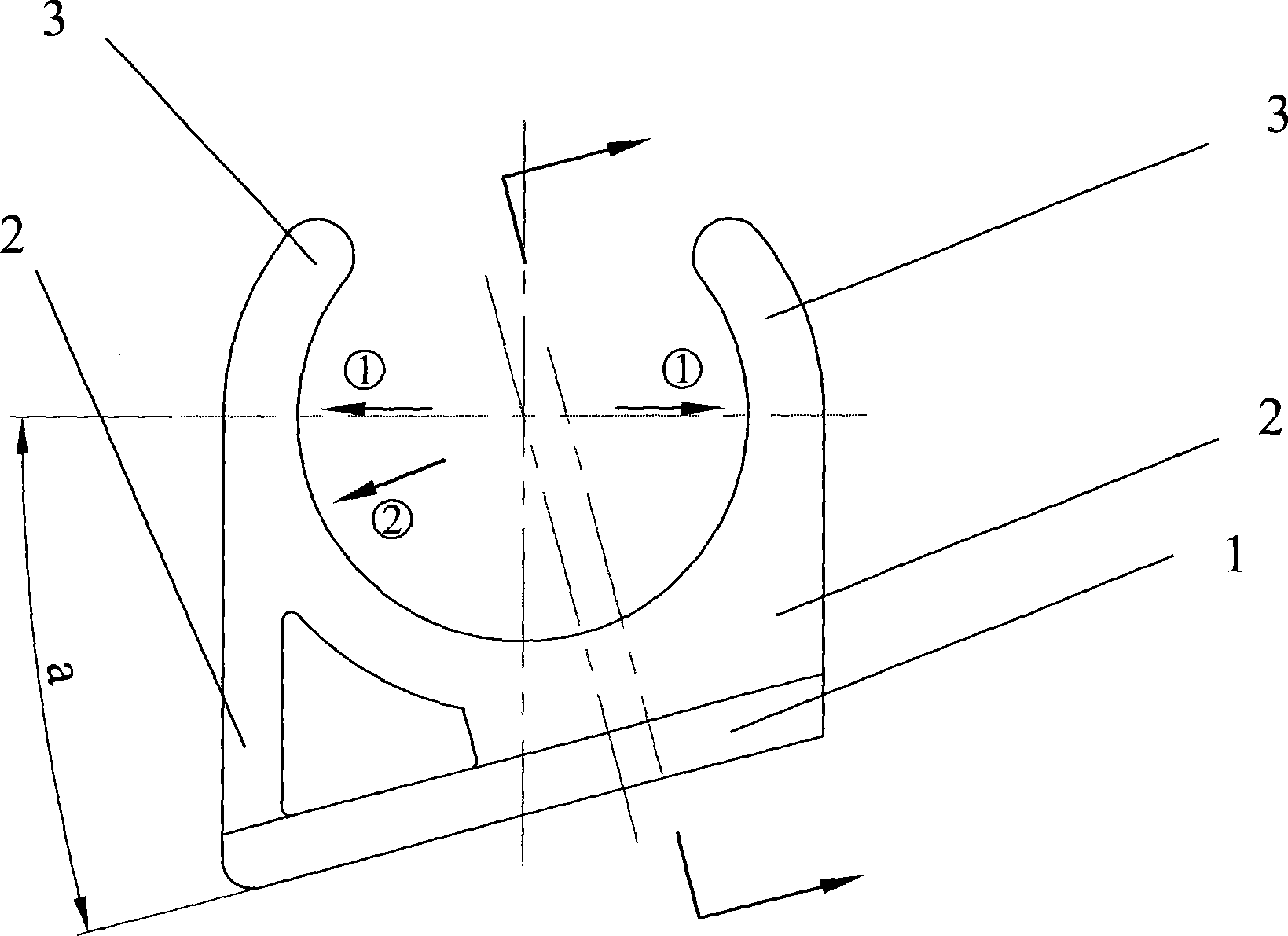

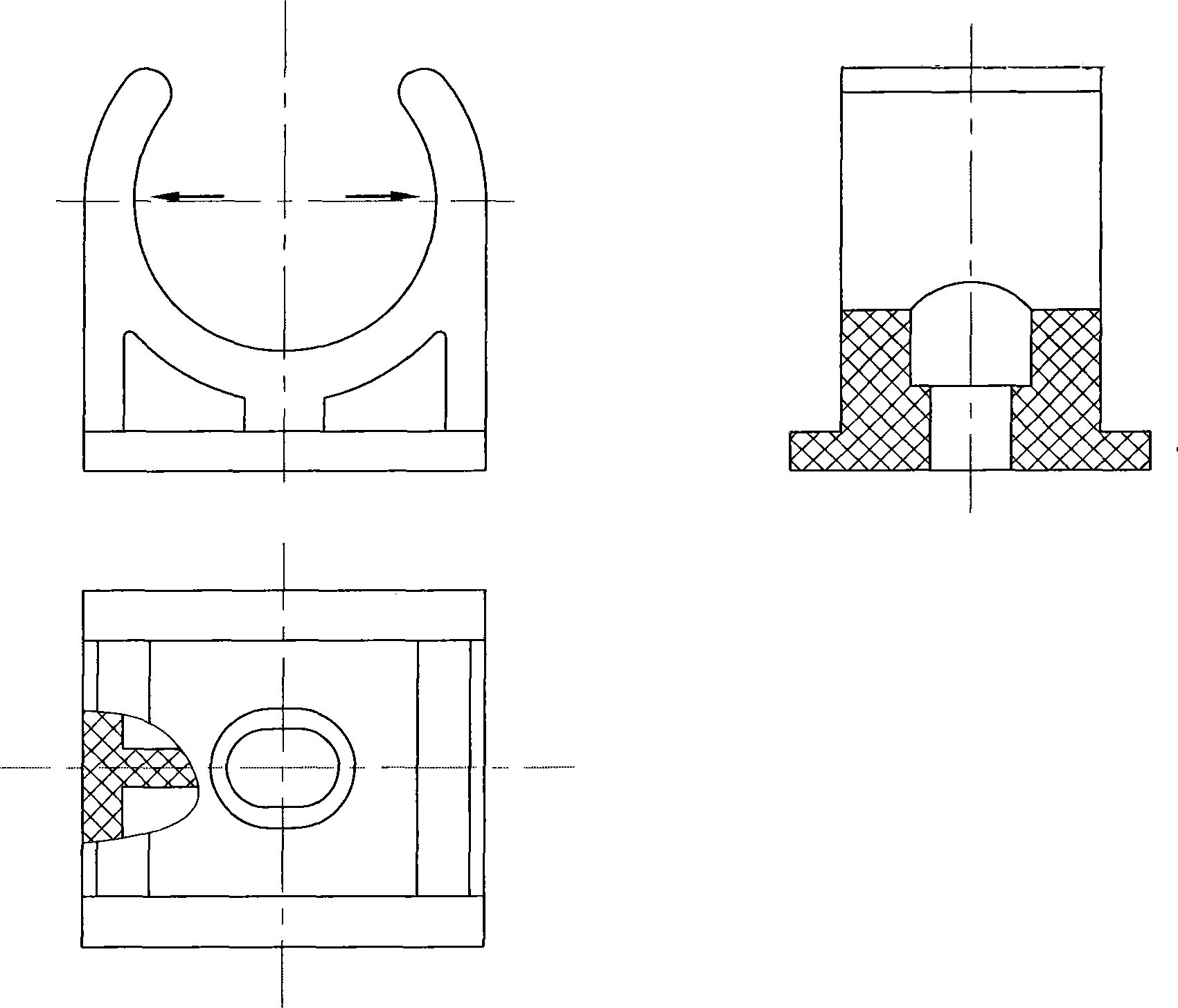

Pipe clamp structure

The invention provides a pipe clamp structure which comprises a connecting base, a supporting part and a pipe retainer, wherein one side of the connecting base is abreast and clings a wall when mounted, the other side of the connecting base is provided with the supporting part, the pipe retainer is arranged on the supporting part, and the geometrical center symmetric line of the pipe retainer forms a sharp angle with the flush side of the connecting base. The pipe clamp structure enables the largest force distortion direction and the external force gravity direction to form a certain included angle, which allows more uniform force distribution and effectively prolongs the service life.

Owner:GUANGDONG LIANSU TECH INDAL

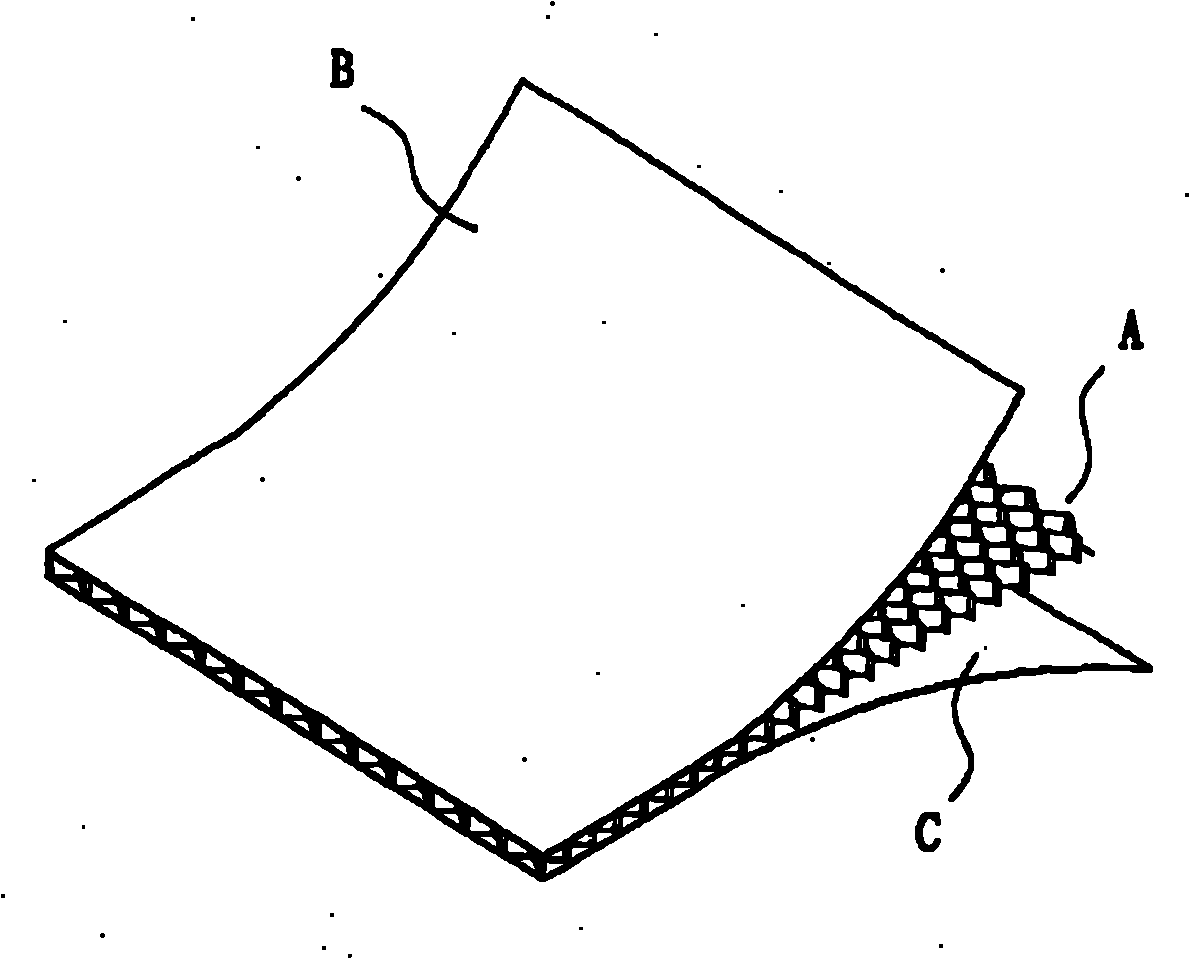

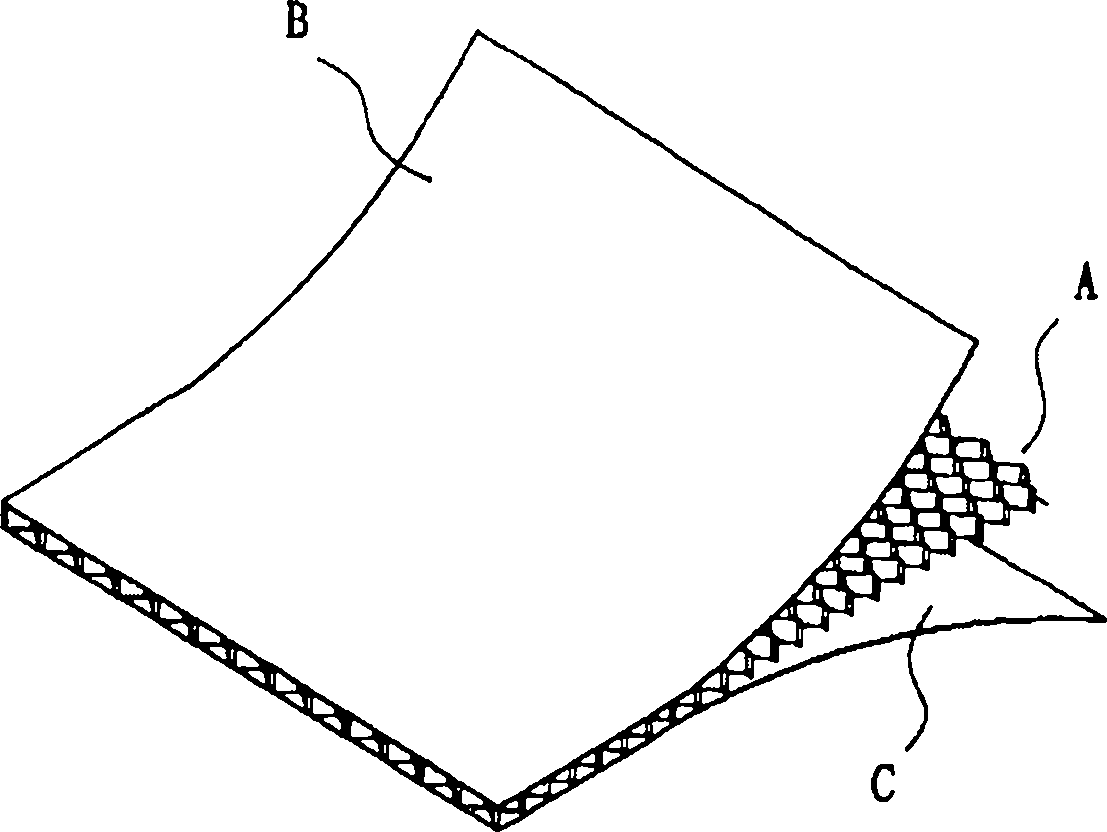

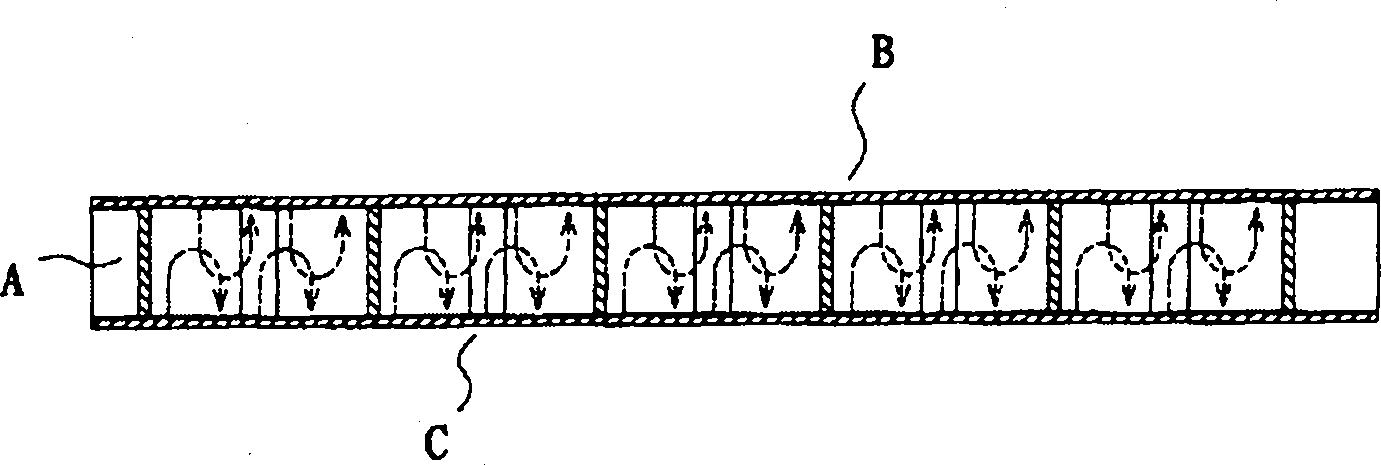

Method for manufacturing pressure-resistant plate

ActiveCN101774292AFast evaporative emissionImprove efficiencyLamination ancillary operationsLaminationAdhesiveEngineering

The invention discloses a method for manufacturing a pressure-resistant plate. The method comprises the following steps of: single-sided molding, namely coating an adhesive on the lower surface of a large-area pressure-resistant body, and pressing and positioning the lower surface of the pressure-resistant body onto a bottom plate and drying the adhesive; double-sided molding, namely coating the adhesive on the upper surface of the large-area pressure-resistant body, and pressing and positioning the upper surface onto a top plate; trimming, namely trimming after the double-sided molding; and cutting, namely cutting required pressure-resistant plates of each predetermined length. In the processes of adhering the top plate and the bottom plate to the upper surface and the lower surface of the large-area pressure-resistant body from the lower surface to the upper surface respectively and orderly, the contained moisture can be rapidly evaporated and discharged and the total drying time is shortened, so that the manufactured pressure-resistant plate has stronger and harder structure strengthening effect after being dried completely and the capacity of bearing an external force is improved.

Owner:龙廷实业股份有限公司

Glass fiber reinforced hydrolysis-resistant nylon pa6/pa66 composite material and preparation method thereof

ActiveCN103113737BImprove bending strengthEnhance the ability to withstand external forcesCoatingsAlkali freeAntioxidant

The invention relates to a glass fiber reinforced and hydrolysis-resistant nylon PA (Polyethylene) 6 / PA66 composite material and a preparation method thereof. The composite material comprises the following components: PA6, PA66, hydrolysis-resistant alkali-free glass fibers, a compatilizer, a main hydrolysis resisting agent, an epoxide assistant hydrolysis resisting agent, a nucleating agent, an antioxidant that is the 1010 and 168 compounded antioxidant, a lubricant and simethicone. The preparation method comprises the following steps: placing the PA6, the PA66, the compatilizer and the simethicone into a high-speed mixer to mix according to the formula mass; adding each assistant mentioned above; mixing by the high-speed mixer; transferring into a twin-screen extruder; and molting, extruding, blanking and drying the materials, so as to obtain the composite material. The glass fiber reinforced and hydrolysis-resistant nylon PA6 / PA66 composite material has the advantages of being high in bending strength, excellent in toughness and hydrolysis resistance and wide in applicable scope, is mainly applicable to components of controllers of electric bicycle, and can meet the requirement of the performance of the materials.

Owner:天津万塑新材料科技有限公司

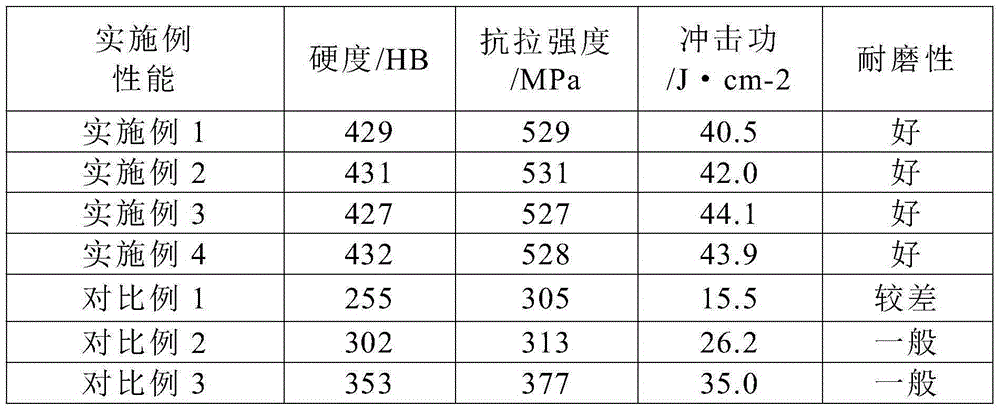

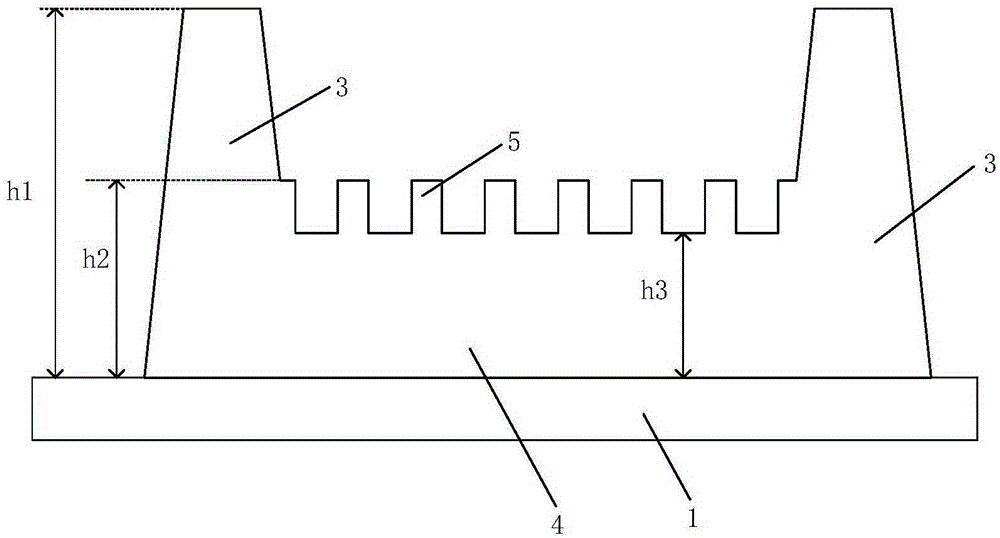

Variable-cross-section multi-anchoring-section special steel fiber structure

PendingCN112609900AGuaranteed tensile strengthHigh tensile strengthBuilding reinforcementsStructural engineeringUltimate tensile strength

The invention discloses a variable-cross-section multi-anchoring-section special steel fiber structure. The variable-cross-section multi-anchoring-section special steel fiber structure comprises a steel fiber body, the middle section of the steel fiber body is a flat and straight first anchoring section, hook-shaped second anchoring sections are arranged on the two end sides of the first anchoring section, the cross sections of the second anchoring sections are round, main anchoring points are arranged on the second anchoring sections, third anchoring sections are arranged at the side ends, away from the first anchoring section, of the second anchoring sections, and the cross sections of the third anchoring sections are oval and flat. The middle section of the steel fiber body is the flat and straight first anchoring section, so that the tensile strength of a steel fiber body is guaranteed; the hook-shaped second anchoring sections are provided with the main anchoring points so that the anchoring range of the steel fiber and concrete can be enlarged, and therefore the bonding strength of the steel fiber is improved, and the anchoring capacity is improved; the structure of an anchoring protruding part enables the bonding area of the steel fibers and the concrete to be increased, so that the bonding strength of the concrete and the steel fibers is improved, and then the tensile strength of the concrete is improved; and the anchoring protruding parts can carry out limitation on the steel fiber, so that the steel fiber is not to be pulled out or moves easily.

Owner:武汉新途工程新材料科技有限公司

Method for manufacturing pressure-resistant plate

ActiveCN101774292BFast evaporative emissionImprove efficiencyLamination ancillary operationsLaminationAdhesiveEngineering

The invention discloses a method for manufacturing a pressure-resistant plate. The method comprises the following steps of: single-sided molding, namely coating an adhesive on the lower surface of a large-area pressure-resistant body, and pressing and positioning the lower surface of the pressure-resistant body onto a bottom plate and drying the adhesive; double-sided molding, namely coating the adhesive on the upper surface of the large-area pressure-resistant body, and pressing and positioning the upper surface onto a top plate; trimming, namely trimming after the double-sided molding; and cutting, namely cutting required pressure-resistant plates of each predetermined length. In the processes of adhering the top plate and the bottom plate to the upper surface and the lower surface of the large-area pressure-resistant body from the lower surface to the upper surface respectively and orderly, the contained moisture can be rapidly evaporated and discharged and the total drying time is shortened, so that the manufactured pressure-resistant plate has stronger and harder structure strengthening effect after being dried completely and the capacity of bearing an external force is improved.

Owner:龙廷实业股份有限公司

A diaphragm for flexible solid supercapacitor and preparation method thereof

InactiveCN102360950BSave assembly spaceImprove the ability to withstand external forcesSolid electrolytic capacitorsCapacitor electrolytes/absorbentsFiberPolymer science

The invention relates to a membrane for a flexible solid super capacitor and a preparation method thereof. The membrane comprises a fiber support body and a polymer electrolyte, wherein the polymer electrolyte comprises a polymer matrix, an electrolyte and an additive. The preparation method is characterized by comprising the following steps: evenly mixing the polymer matrix, the electrolyte with the additive according to mass ratio to prepare polymer electrolyte slurry; coating the polymer electrolyte slurry onto a fiber sheet by utilizing a blade coating method, and drying to obtain the membrane for the flexible solid super capacitor, wherein the thickness of the membrane is 30-120mum. As the support body, the fiber sheet forms a structure and function integrated membrane with the attached polymer electrolyte, thus, the weight of an energy storage unit is reduced; the strength of the flexible solid super capacitor can be improved; the membrane for the flexible solid super capacitor is beneficial to the integrated design of automobile interior trim parts; current-carrying ions are provided by the polymer electrolyte; the energy storage function of the device is met; new energy automobile assembly space are saved; and the membrane for the flexible solid super capacitor is safe and environmentally friendly.

Owner:CHINA FIRST AUTOMOBILE

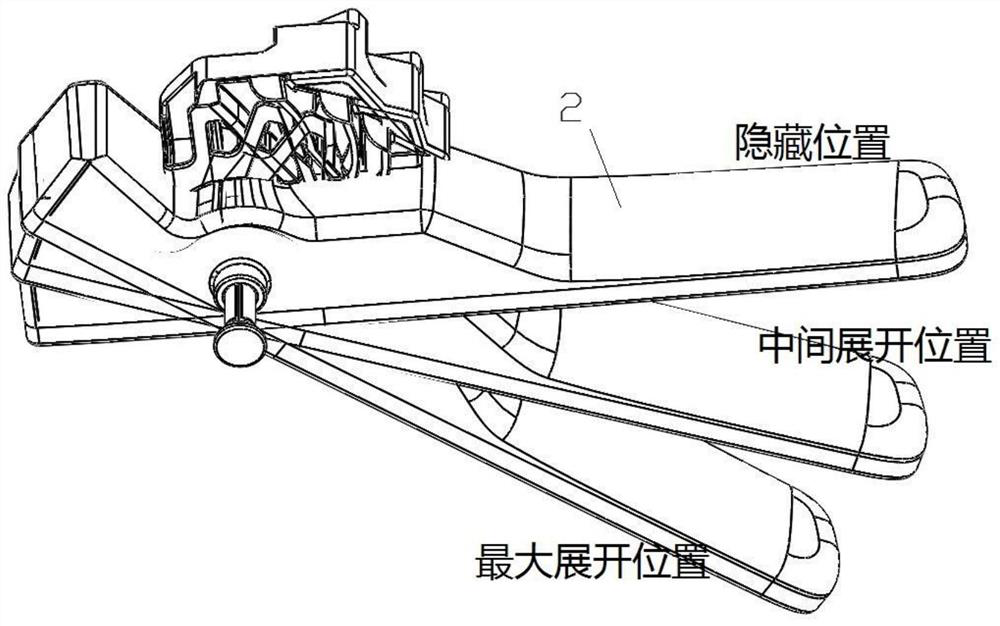

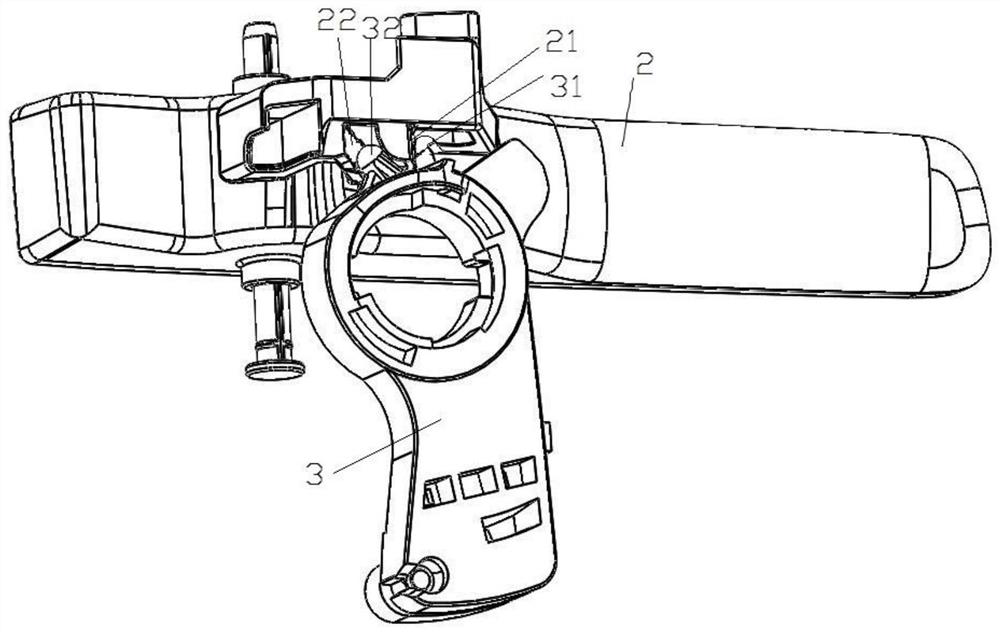

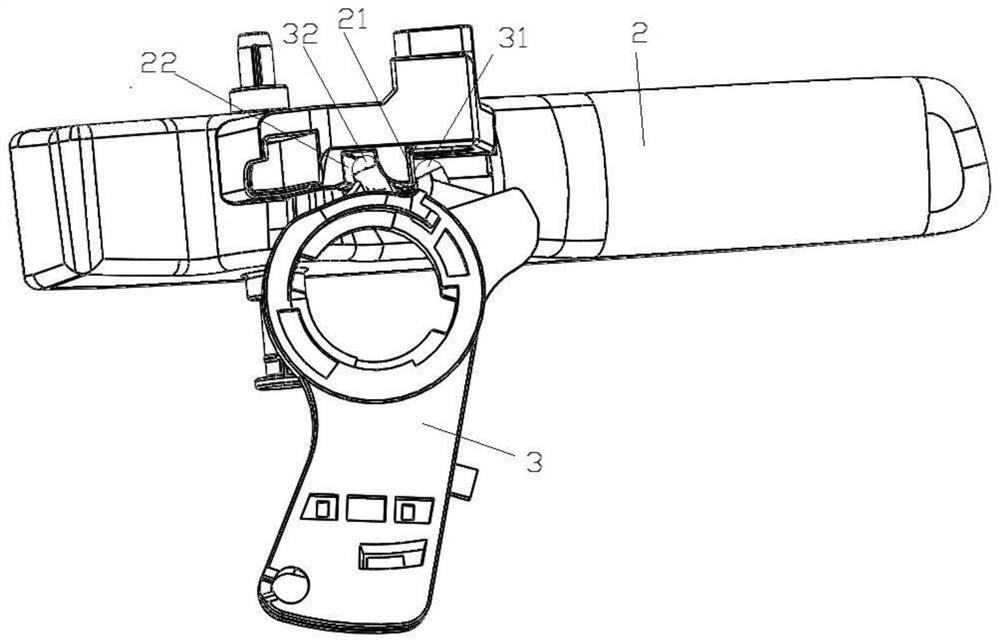

Automobile door handle transmission mechanism and working method thereof

The invention relates to the technical field of automobile parts, in particular to an automobile door handle transmission mechanism. The automobile door handle transmission mechanism comprises a base, a handle and a swing arm are rotationally connected to the base, the positions of the handle at least comprise a hidden position, a middle unfolding position and a maximum unfolding position, at least one tooth is arranged on the swing arm, a transmission guide face correspondingly matched with the tooth is arranged on the handle, and the transmission guide face is a cam face. According to the automobile door handle transmission mechanism, the teeth are matched with the transmission guide face, the occupied space of the handle in the thickness direction can be saved, the transmission guide face can be the cam face, and the transmission process is more stable.

Owner:伟速达(中国)汽车安全系统有限公司

A kind of flame retardant pet composite material and preparation method thereof

ActiveCN106674920BMeet the process requirementsImprove thermal stabilityFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberFire resistance

The invention discloses a flame-resistant PET composite. The flame-resistant PET composite is prepared according to the following steps: adding TCMSs to a PET basal body for melting, blending, wire drawing and slicing so as to obtain TCMSs / PET slices containing the TCMSs of which the percentage by mass is 0.2-2%, wherein the TCMSs is a material obtained by heating CMSs under inert atmosphere to 600-800 DEG C and then performing annealing treatment for 30-120min, and can be used for preparing flame-resistant PET fibers. The composite disclosed by the invention can be added to the PET basal body for preparing the flame-resistant PET fibers, so that the fire resistance of the PET fibers can be improved, and the condition that the tensile strength of the PET fibers is reduced due to the addition of the CMSs is also obviously improved.

Owner:TAIYUAN UNIV OF TECH

Wrapping formed inspection well prepared from plastic in environmental protection, and method of preparation

InactiveCN100441783CImprove the ability to withstand external forcesImprove sealingArtificial islandsUnderwater structuresPlastic materialsMolding machine

The invention discloses an environmentally friendly plastic inspection well formed by winding and a preparation method thereof. The environmentally friendly plastic inspection well formed by winding is formed by 360-degree spiral winding and fusion bonding of strip-shaped or linear plastic or plastic composite materials around the central axis, and the strip-shaped or linear plastic or plastic composite materials are melt-bonded and connected to each other. There are spiral reinforcement ribs. Its manufacturing method is to make plastic profiles by the first extrusion equipment, matched molds and auxiliary equipment including cooling and traction; winding plastic profiles or plastic composite materials in the form of strips or wires on plastic pipes Winding is carried out on the machine, and at the same time, the molten material extruded by the second extrusion equipment is melted and bonded with the plastic material or plastic composite material being wound. In the present invention, the inner and outer walls of the plastic inspection well are flat, and the molten material in the well wall of this structure becomes the reinforcing rib, which enhances the ability of the well body to withstand external forces.

Owner:四川天鑫塑胶管业有限公司

A cage-type reinforcing rib for fixed pier openings of direct-buried heating pipelines

ActiveCN104154328BImprove the ability to withstand external forcesImprove reinforcement strengthPipe supportsPipe laying and repairReinforced concreteEngineering

The invention relates to a stiffener cage for use in an opening of an anchor block for direct-buried heat supply pipelines. The anchor block is a reinforced concrete integrated connector made by subjecting two fixing segments arranged in parallel, a reinforcement fabric and opening stiffeners connected with the reinforcement fabric, to concreting on a base plate. Each fixing segment is a connecting pipe; the outside of the connecting pipe is provided with a circular flange; two ends of each connecting pipe horizontally penetrate one opening of the anchor block; the reinforcement fabric is arranged inside close to the outer surface of the anchor block by lining. The stiffener cage is characterized by comprising a plurality of circular bars and a plurality of longitudinal bars; the circular bars surround the fixing segments in the anchor block and evenly and parallelly arranged axially along the connecting pipes; the longitudinal bars surround the circular bars and are fixedly connected to the circular bars axially along the connecting pipes; the stiffener cage is fixed outside the fixing segments in such a manner that two ends of every longitudinal bar are fixedly connected to the reinforcement fabrics arranged on the front and rear sides of the openings. The stiffener cage has the advantages that overall strength of the anchor block is improved, and the anchor block is protected from damage.

Owner:TIANJIN THERMAL POWER DESIGNING INST

Packaging method and display panel

ActiveCN109037479BImprove the ability to withstand external forcesImprove barrier propertiesSolid-state devicesSemiconductor/solid-state device manufacturingPhoto irradiationThin membrane

Embodiments of the present application provide a packaging method and a display panel. The packaging method includes: providing a substrate to be packaged and a cover plate; forming an inorganic packaging layer on the substrate to be packaged; forming an inorganic packaging layer containing a photosensitive material on the inorganic packaging layer. The intermediate layer is irradiated with light of a preset wavelength to form a bonding layer; an organic encapsulation layer is formed on the bonding layer; a preset temperature treatment process is implemented so that the photosensitive material in the bonding layer is respectively combined with the inorganic encapsulation layer and the organic encapsulation layer combined to form an encapsulation film. The bonding layer makes the inorganic encapsulation layer and the organic encapsulation layer more tightly combined, improves the ability of the encapsulation film to withstand external forces, reduces the probability of peeling at the interface between the inorganic encapsulation layer and the organic encapsulation layer, and improves the barrier of the encapsulation film As a result, the encapsulation method is used to form the encapsulation film on the substrate in the display panel, which can effectively prevent water vapor and oxygen from contacting the substrate, and prevent the substrate from being corroded and damaged.

Owner:BOE TECH GRP CO LTD

Hot working method for smelting molybdenum rhenium alloy casting ingot by suspending

InactiveCN100574908CImprove the ability to withstand external forcesFlexible size controlTemperature control deviceMetal rolling arrangementsRheniumIngot casting

The invention discloses a thermal processing method for suspension electron beam melting molybdenum-rhenium alloy ingot. The method obtains rod-shaped ingot by melting a molybdenum-rhenium alloy sintered bar through suspension electron beam. The high temperature rolling is carried out by the first fire, the parallel ingot is axially fed, with a rolling speed ranging from 300 to 400mm / min, the temperature is kept for 1 hour; the ingot is rolled to the set thickness through rolling for three times and heated at high temperature for the second time, the temperature is kept for 1 hour, with a rolling speed ranging from 300 to 400mm / min; the ingot is rolled to the set thickness after inverting the direction; the ingot is heated at high temperature for the third time, the temperature is kept for half an hour; the ingot is rolled to the set thickness through 3 rolling for three times and is carried for cold rolling after annealing. The thermal processing method provided by the invention reduces the dislocation movement for single sliding and the speed of the dislocation movement, controls the direction of the dislocation movement, avoids the cracking at crystal boundary owing to the accumulation of the dislocation; besides, the thermal processing method ensures cogging of the ingot but not cracking, and ensures heating processing to go on smoothly. By the thermal processing method, accepted plank stuff characterized by fine crystal particles and uniform sizes can be made, with purity over 99.99 percent.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

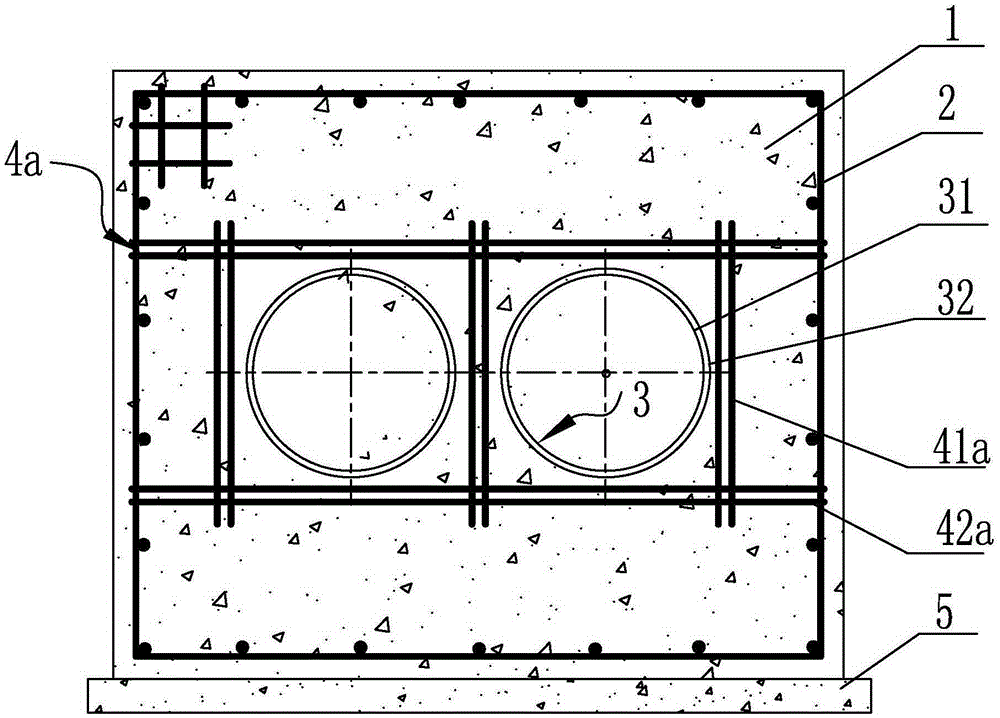

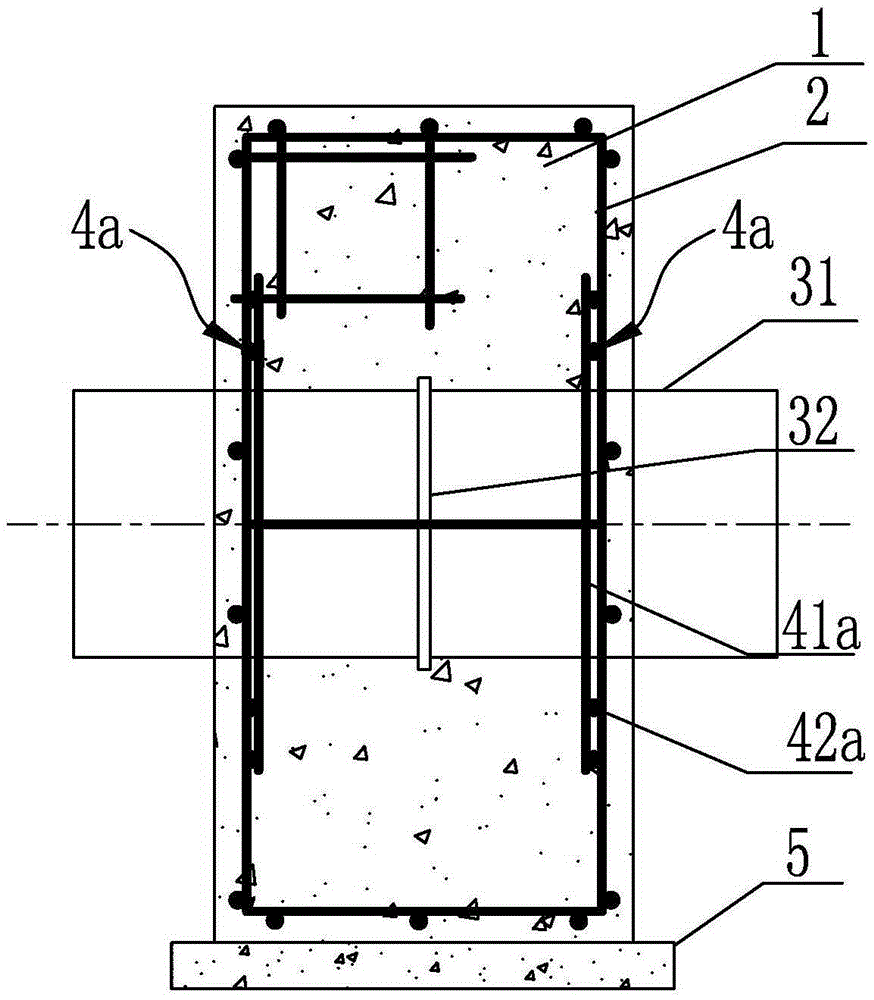

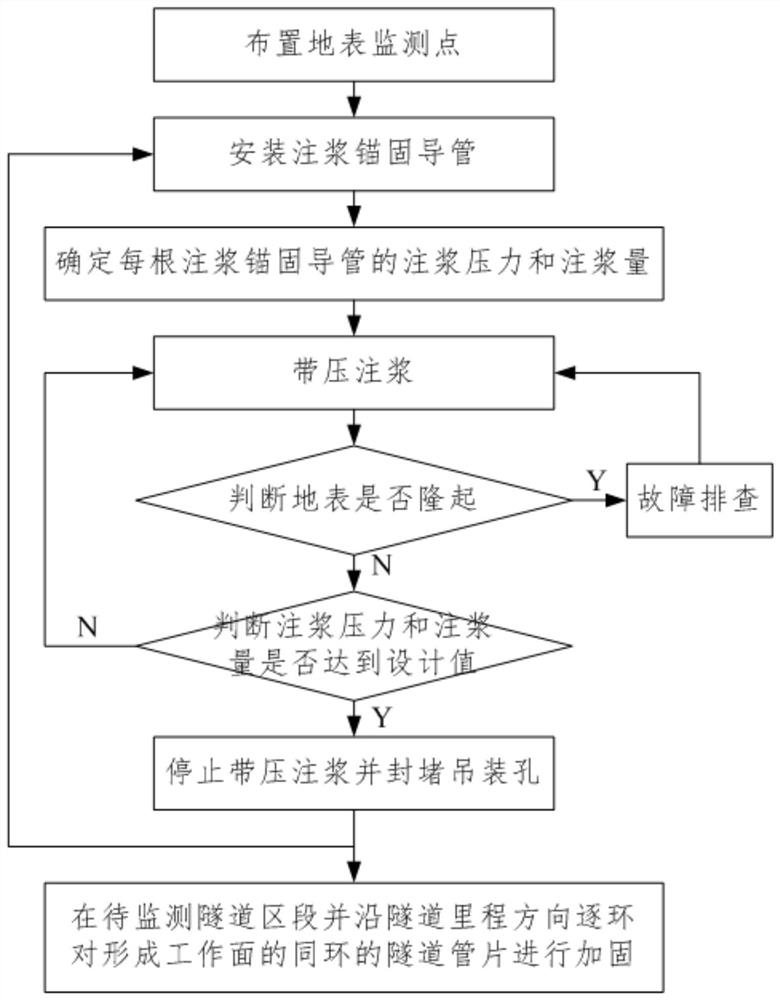

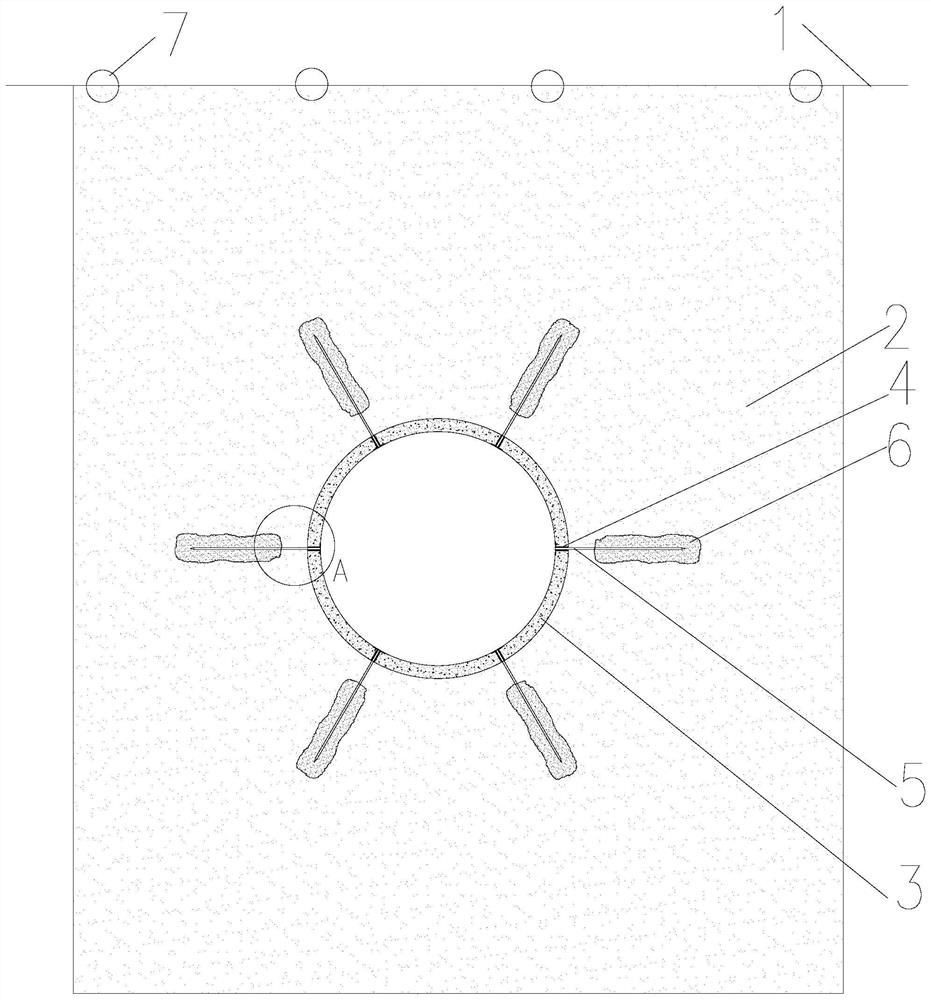

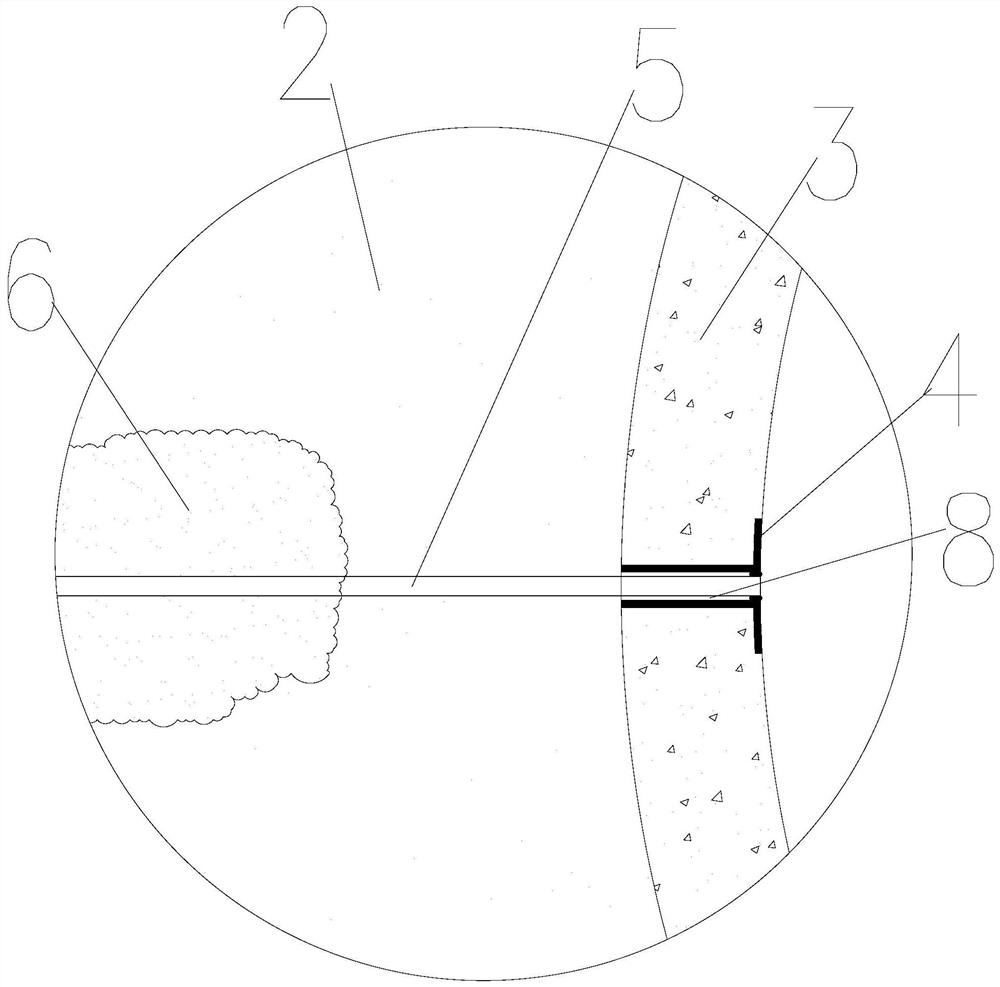

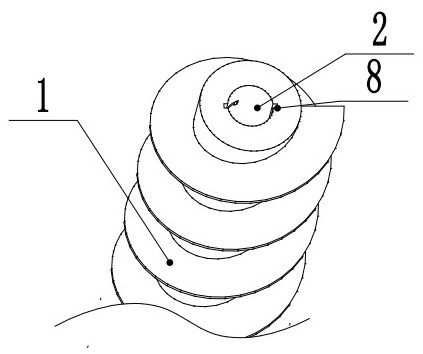

A Construction Method for Preventing Instability of Shield Tunneling in Highly Sensitive Stratum Conditions

ActiveCN110924978BImprove stabilityNot pollutedUnderground chambersTunnel liningArchitectural engineeringStructural engineering

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

High-toughness large-drift-diameter wide-fin spiral drill rod

PendingCN111734323AEasy to useImprove the ability to withstand external forcesDrilling rodsDrilling casingsStructural engineeringDrill pipe

The invention relates to the technical field of mining equipment, in particular to a high-toughness large-drift-diameter wide-fin spiral drill rod. The high-toughness large-drift-diameter wide-fin spiral drill rod comprises a drill rod body, wherein a mounting groove is formed in the top of the drill rod body, a mounting head is arranged at the bottom of the drill rod body, the mounting head comprises protruding blocks, a plurality of clamping blocks and a fixing part, the protruding block is arranged at the bottom of the drill rod body, the clamping blocks are arranged in the middle of the protruding block, the fixing part is arranged at the bottom of the protruding block, the fixing part comprises a fixed rod and a plurality of limiting rods, clamping grooves are formed in the mounting groove, the clamping blocks are arranged in the clamping grooves, limiting grooves are formed in the clamping grooves, and elastic blocks are arranged on the clamping blocks and are arranged in the limiting grooves.

Owner:ZOUCHENG YANKUANG TAIDE IND & TRADE CO LTD

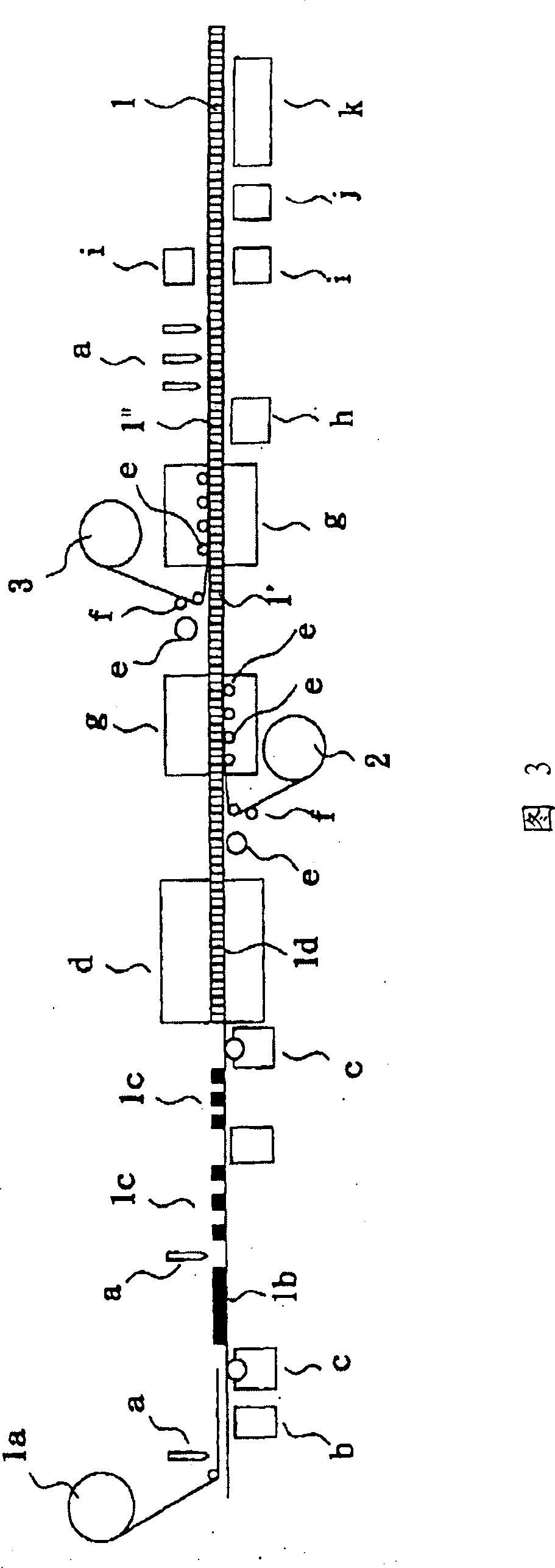

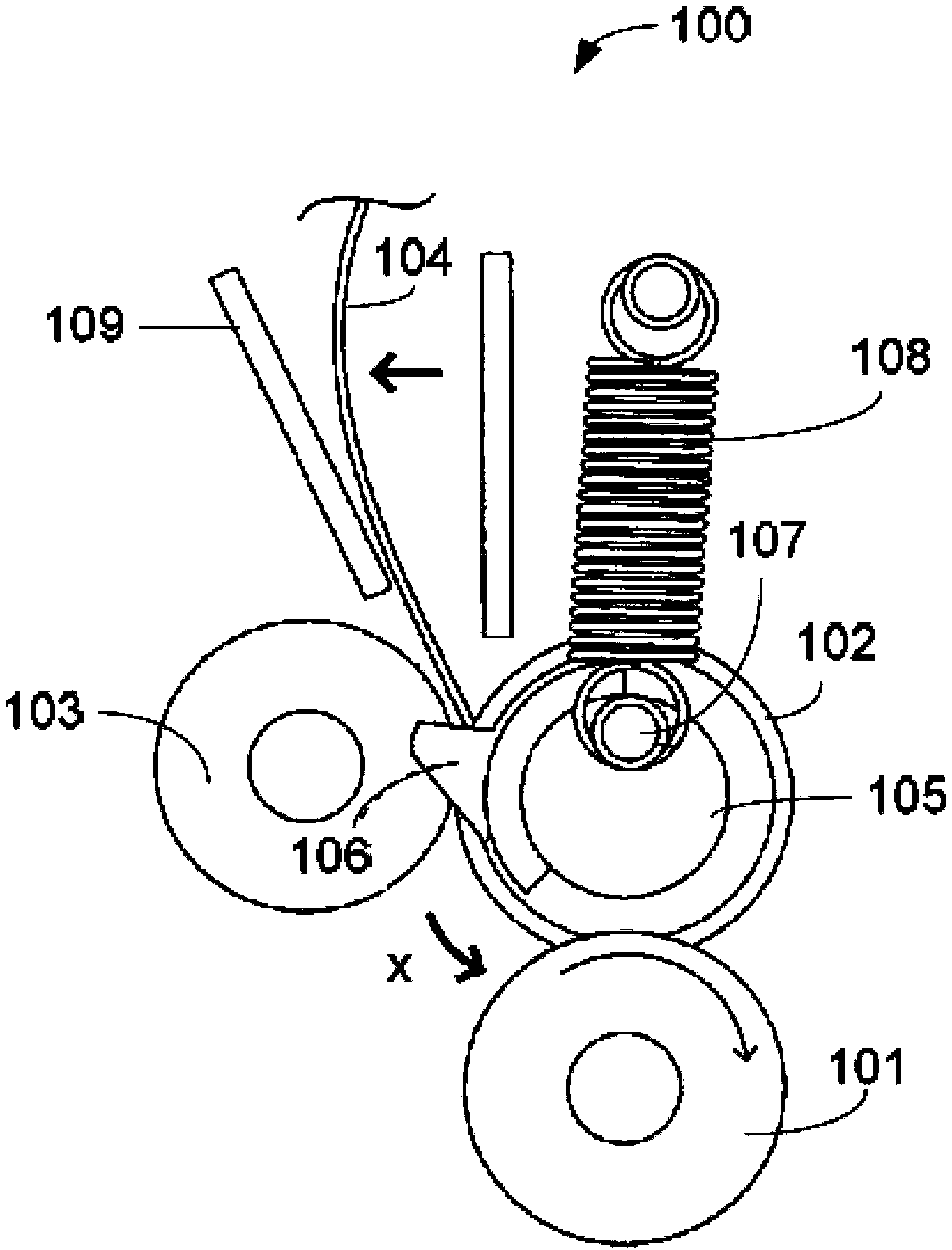

Conveyor Straightening Unit

InactiveCN102826356BImprove stabilityImprove the ability to withstand external forcesConveyorsRollersEngineeringMechanical engineering

Owner:昆山特力伯传动科技有限公司

Rear suspension rubber pad assembly

ActiveCN104896006BImprove the ability to withstand external forcesNot prone to crackingSpringsNon-rotating vibration suppressionEngineeringRubber mat

The invention discloses a rear-mounted rubber mat assembly. A rubber mat base comprises two half bases, a rubber mat supporting space is formed between the two half bases, each half base comprises a soleplate, an oblique supporting plate and an auxiliary supporting plate, one end of the auxiliary supporting plate is fixed on the soleplate, the other end of the auxiliary supporting plate is fixed on the oblique supporting plate, and a preset angle is formed between the outer wall of the auxiliary supporting plate and the oblique supporting plate; a rubber mat pressure block comprises a pressure block body with an upper installation surface and a rubber mat adhesion surface, supporting ribs are fixed inside the pressure block body, lightening holes are formed in two sides of each supporting rib, and each lightening hole is formed by encircling the inner wall of the pressure block body and the supporting rib; the rubber mat comprises two rubber mat bodies which are fixedly connected with each other, each rubber mat body comprises at least two superimposed bodies as well as a liner plate which is fixed between two adjacent bodies, and two opposite surfaces of the liner plate are respectively fit to the oblique surfaces of the two bodies. The rubber mat base and the rubber mat pressure block in the rear-mounted rubber mat assembly are unlikely to fracture, and the rubber mat is unlikely to fracture.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com