Stiffener cage for use in opening of anchor block for direct-buried heat supply pipelines

A technology for heating pipes and fixed piers, which is applied in the direction of pipe supports, pipe laying and maintenance, pipes/pipe joints/pipe fittings, etc. Effectively prevent problems such as damage to fixed piers, and achieve the effect of improving the overall ability to withstand external forces and increasing the reinforcement strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

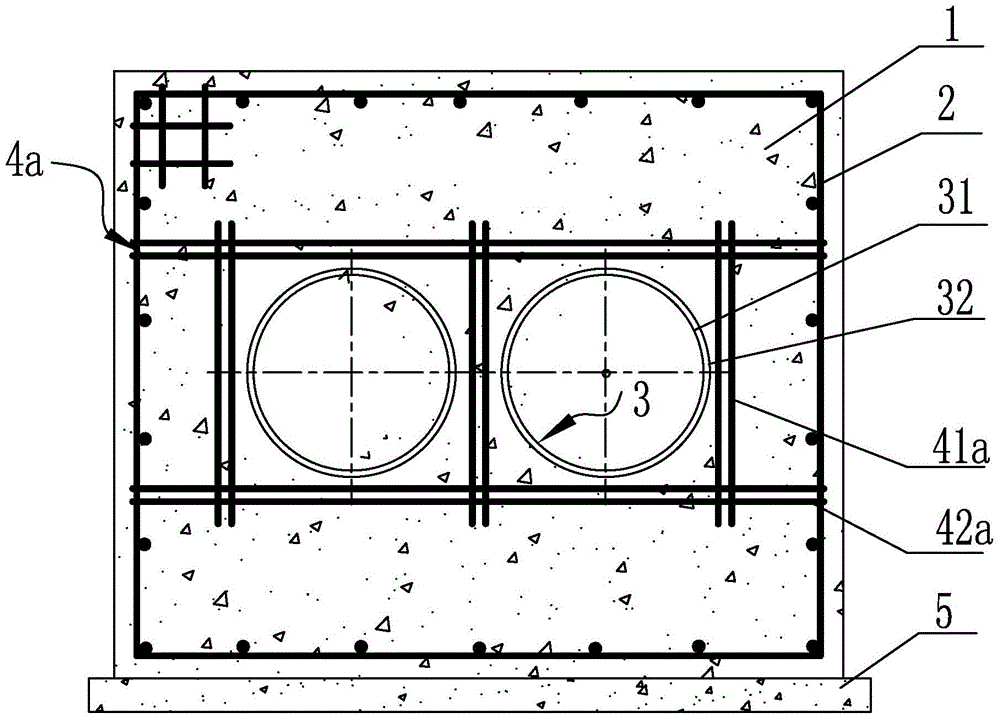

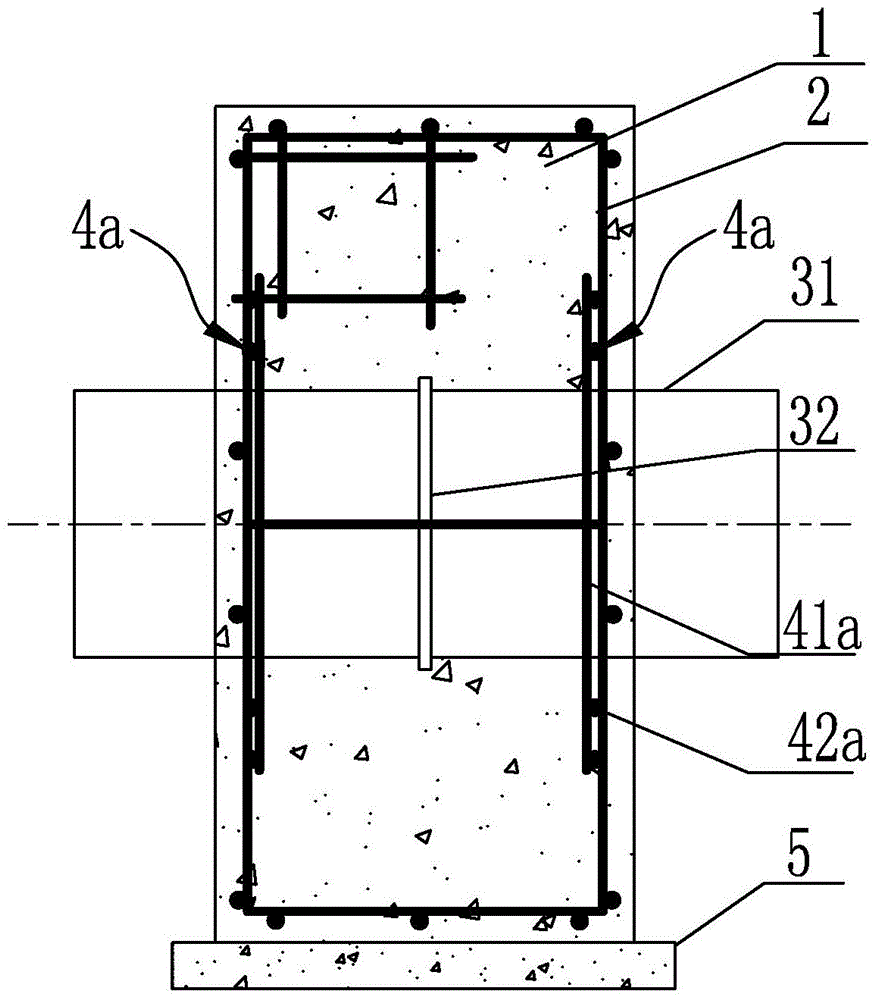

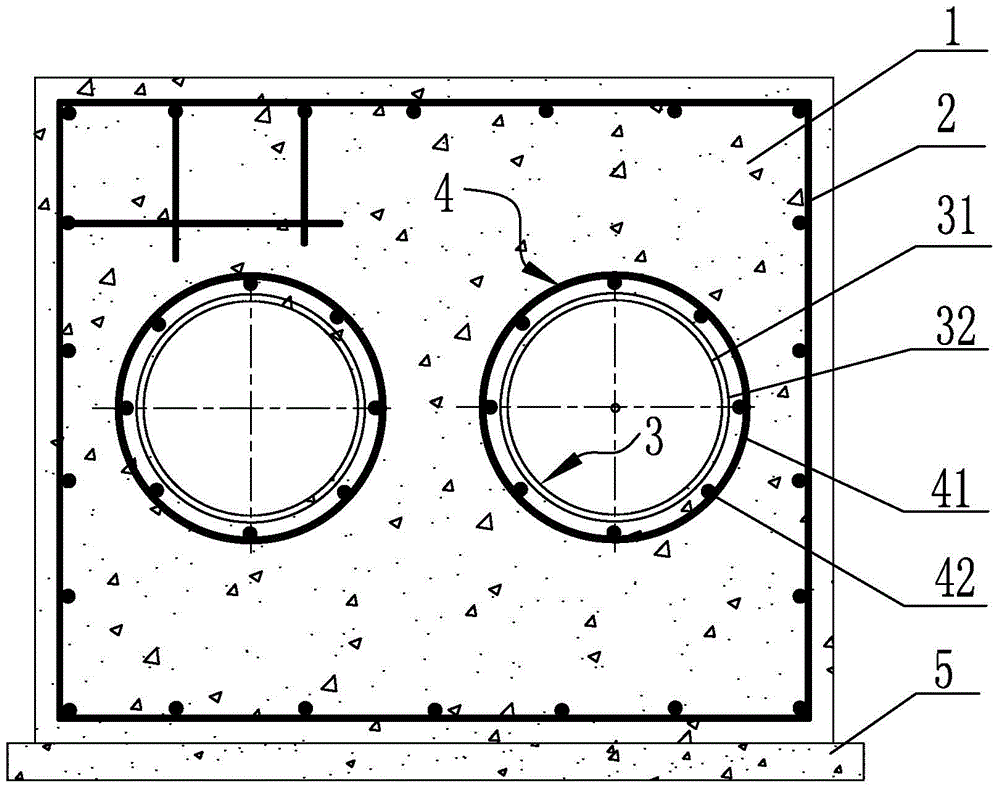

[0014] Figure 3-Figure 4 It shows a cage-type reinforcing rib for the opening of a fixed pier of a direct-buried heating pipeline. The fixed pier is formed by two parallel fixed joints 3, a steel mesh 2, and the reinforcing ribs of the hole connected to the steel mesh pass through the base plate. 5. Pouring concrete 1 to form a reinforced concrete integral connector, where the base plate is a concrete base plate. The fixed joint 3 is a connecting pipe 31 with an annular flange 32 on the outside and two ends extending across the holes on the front and rear sides of the fixed pier. The connecting pipe 31 is used to connect the laid heating pipeline. The steel mesh 2 is lined with In the interior close to the external surface of the fixed pier, in this embodiment, the fixed pier is a square body, and the steel mesh is laid on the interior close to the side surfaces of the square body.

[0015] The feature of the present invention is that the reinforcing rib 4 is composed of a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com