Wrapping formed inspection well prepared from plastic in environmental protection, and method of preparation

An environmentally friendly plastic winding molding technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems that affect project quality, pollute the environment, increase project cost and manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

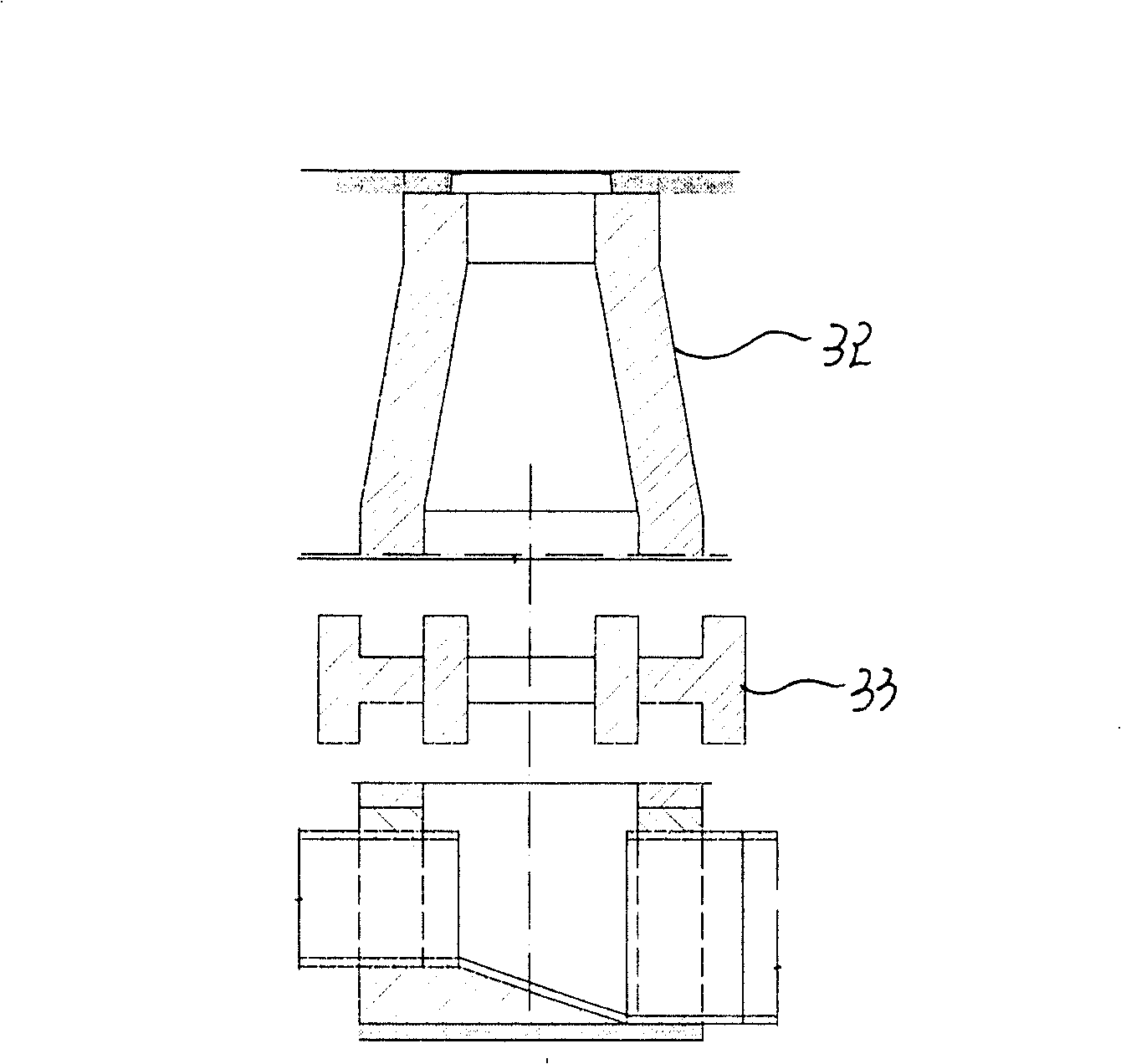

[0035] An environmentally friendly plastic inspection well formed by winding, the strip-shaped or linear plastic or plastic composite material 1 is spirally wound and melt-bonded at 360 degrees around the central axis, and the strip-shaped or linear plastic or plastic composite materials are mutually fused There are spiral reinforcement ribs at the glued joints. The strip-shaped or linear plastic or plastic composite material is helically wound and melt-bonded at 360 degrees around the central axis to form the inspection well body 32 . The strip-shaped or linear plastic or plastic composite material is spirally wound 360 degrees around the central axis to form the inspection well parts, and each part is snap-fitted to form the inspection well, or a plastic sealing sleeve or rubber ring 33 connect. The cross-section of the strip-shaped or linear plastic or plastic composite material is circular or rectangular. The diameter of the strip-shaped or wire-shaped plastic or plastic...

Embodiment 2

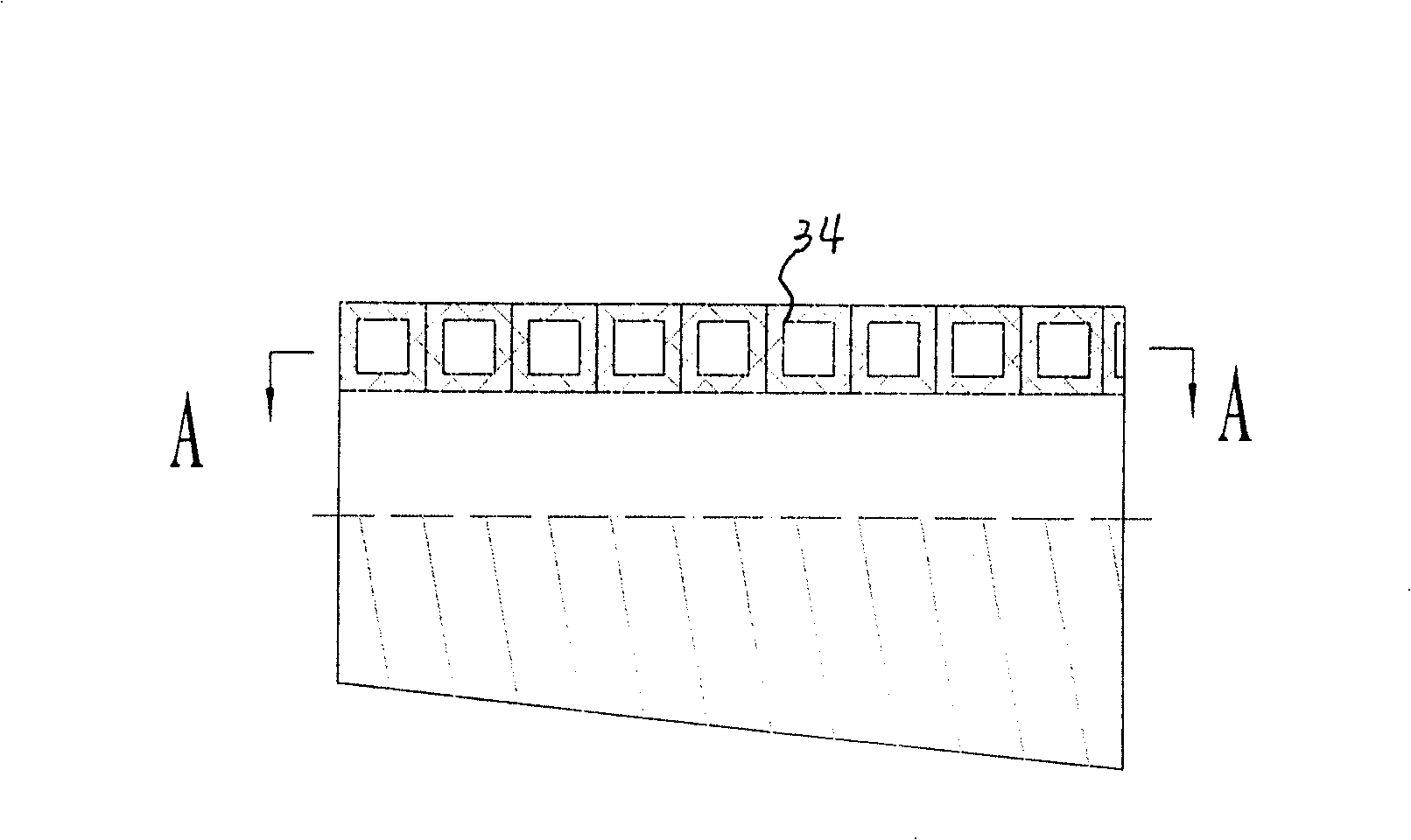

[0037] Check whether the upper well body 32 is equal diameter or unequal diameter or axis offset. The unequal-diameter axis-offset well body is mainly used in inspection wells of large-diameter main well bodies (above 1200mm), which is beneficial to the setting of climbing devices and the up and down of maintenance workers. The partial section of the 360-degree spiral-shaped plastic inspection well wall is as follows image 3 shown.

[0038] In the plastic inspection well with the above structure, the reinforcing rib and its basic profile structure can adopt different structures according to the application field or purpose. For example, from the shape of the well wall section 34, a rectangular sheet can be used, or a hollow rectangular bar, pipe, bar, etc. can be used, plastic can be used completely, or composite materials such as plastic and steel or aluminum or fiberglass can be used. Said plastics include polyvinyl chloride, polyethylene, polypropylene or other modified ...

Embodiment 3

[0043] A method for manufacturing an environmentally friendly plastic inspection well body by winding. The environmentally friendly plastic inspection well body is manufactured according to the following steps: a. The granular plastic is passed from the first extrusion molding equipment and the matching mold and includes cooling, Auxiliary equipment including traction is made into strip-shaped or linear plastic profiles with a diameter of 50 mm; or granular plastics are melted by the first extrusion equipment and steel or aluminum or glass is added to the mold during the molding process The fiber is made into a strip-shaped or linear plastic composite material with a diameter of 50 mm; the temperature of the feed section of the extrusion equipment is 160 ° C, and the temperature of the exit section of the extrusion equipment is 180 ° C; b. The plastic profile or plastic composite material is wound on the plastic pipe winding molding machine, and the molten material extruded by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com