A kind of flame retardant pet composite material and preparation method thereof

A composite material and feeding port technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, single-component polyester rayon, etc., can solve the problems of many by-products, low decomposition temperature, unfavorable industrial production, etc. Less, the effect of improving the thermal stability of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 5g of CMSs in a quartz boat, place the quartz boat in a closed tubular muffle furnace, and first pass nitrogen for 10 minutes to displace and drive off the air in the muffle furnace. Keeping the nitrogen flow rate at 150ml / min, the muffle furnace was heated to 800°C at a heating rate of 10°C / min, and the constant temperature was maintained for 2h. After the reaction, the temperature was naturally cooled to room temperature under a nitrogen atmosphere, and the product was collected to obtain annealed CMSs (ie, TCMSs).

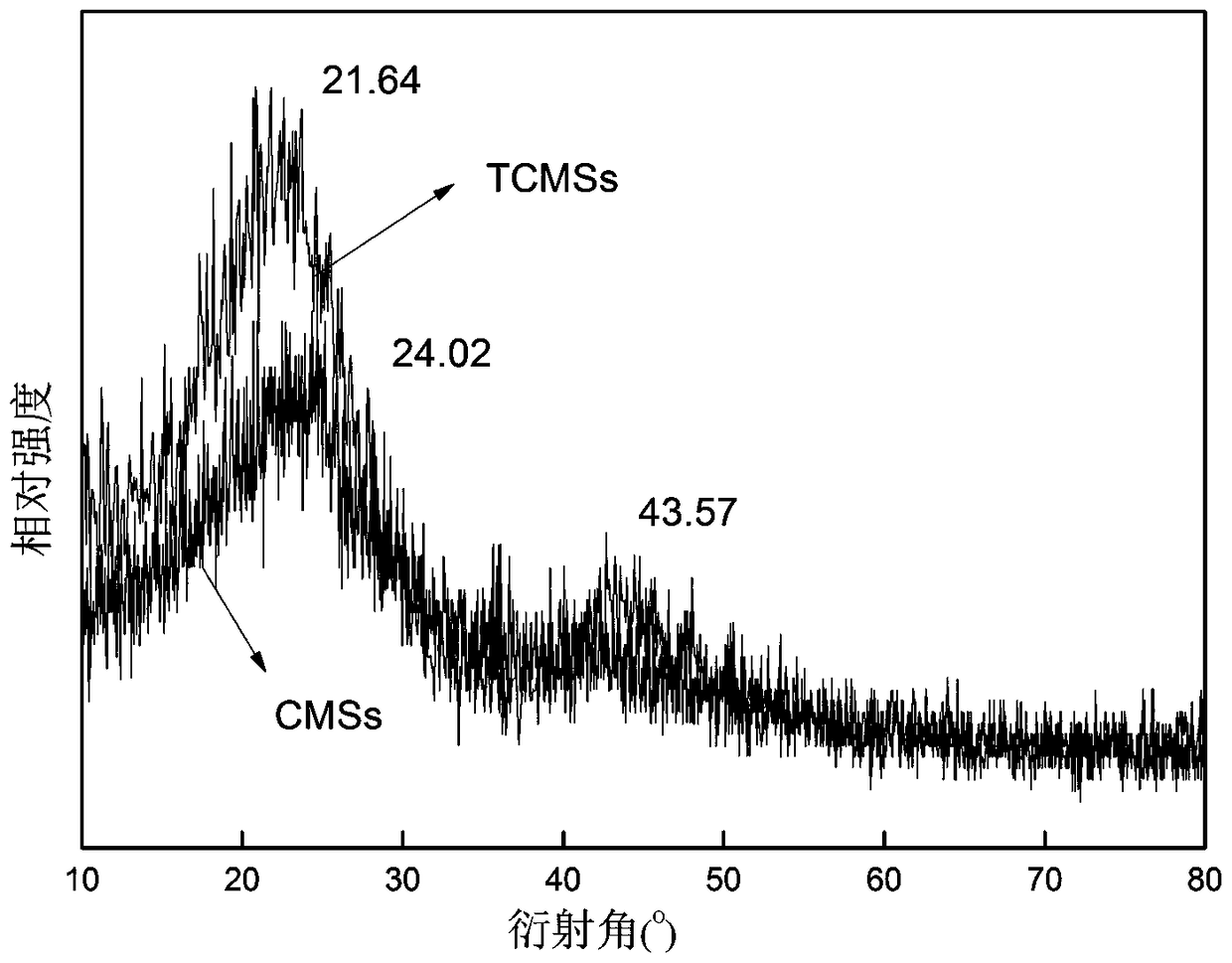

[0029] figure 1 The XRD patterns of raw CMSs and TCMSs obtained by annealing are given respectively. It can be seen from the figure that CMSs have a broad diffraction peak at 22.83°, indicating that CMSs mainly exist in the form of amorphous carbon. The diffraction peak of annealed TCMSs at 21.64° is narrowed and another diffraction peak appears at 43.57°. Both are characteristic peaks of graphitic carbon. The relative intensity and peak width of...

Embodiment 2

[0042] Weigh 5g of CMSs in a quartz boat, place the quartz boat in a closed tubular muffle furnace, and first pass nitrogen gas for 20 minutes to displace and drive off the air in the muffle furnace. Keeping the nitrogen flow rate at 200ml / min, the muffle furnace was heated to 600°C at a heating rate of 20°C / min, and the constant temperature was maintained for 5h. After the reaction, the temperature was naturally cooled to room temperature under nitrogen atmosphere, and the products were collected to obtain annealed CMSs (ie, TCMSs).

[0043] Weigh 1kg of PET chips and vacuum dry them at 130°C for 8 hours, so that the moisture content of the chips reaches 28ppm. 10 g of TCMSs were weighed and dried under vacuum at 130 °C for 5 h. The dried PET chips are added to the main feeding port of the twin-screw extruder with a frequency of 10 Hz, 10 g of TCMSs are added to the side feeding port of a frequency of 7 Hz, heated to 265 ° C for melt blending, wire drawing and pelletizing to...

Embodiment 3

[0046] Weigh 10 g of CMSs into a quartz boat, place the quartz boat in a closed tubular muffle furnace, and first introduce nitrogen for 20 min to displace and drive off the air in the muffle furnace. Keeping the nitrogen flow rate at 200ml / min, the muffle furnace was heated to 700°C at a heating rate of 50°C / min, and the constant temperature was maintained for 3h. After the reaction, the temperature was naturally cooled to room temperature under a nitrogen atmosphere, and the products were collected to obtain annealed CMSs (ie, TCMSs).

[0047] Weigh 1kg of PET chips and vacuum dry at 130°C for 8 hours to make the moisture content of the chips reach 28ppm. Weigh 20 g of TCMSs, and also vacuum dry at 130 °C for 8 h. The dried PET chips are added to the main feeding port of the twin-screw extruder with a frequency of 13 Hz, and 20 g of TCMSs are added to the side feeding port of a frequency of 9 Hz, heated to 275 ° C for melt blending, wire drawing and pelletizing to obtain T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com