Flame-resistant PET composite and preparation method thereof

A composite material and feeding port technology, applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyester artificial filaments, etc., can solve the problems of many by-products, low decomposition temperature, unfavorable industrial production, etc., and achieve by-product Less, the effect of improving the thermal stability of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 5g of CMSs into a quartz boat, place the quartz boat in a closed tubular muffle furnace, and first pass nitrogen gas for 10 minutes to replace and drive off the air in the muffle furnace. Keep the nitrogen flow rate at 150ml / min, raise the temperature of the muffle furnace to 800°C at a heating rate of 10°C / min, and keep the constant temperature for 2h. After the reaction, the temperature was naturally lowered to room temperature under a nitrogen atmosphere, and the product was collected to obtain annealed CMSs (ie, TCMSs).

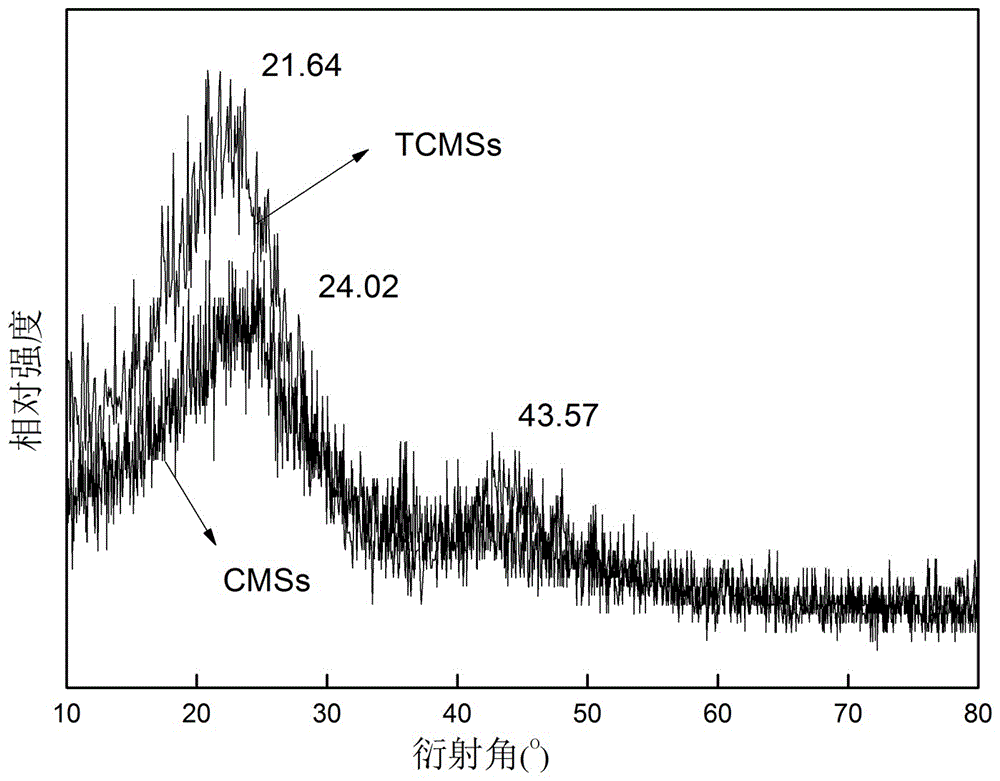

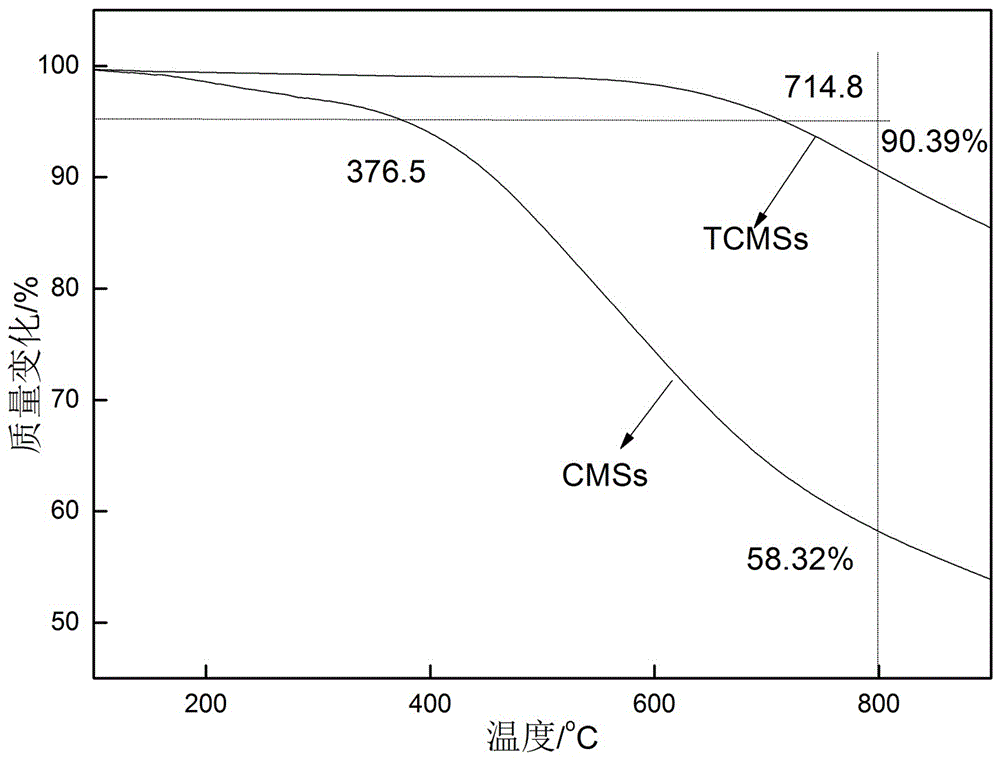

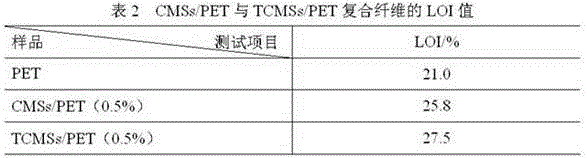

[0029] figure 1 The XRD patterns of the raw CMSs and the annealed TCMSs are given respectively. It can be seen from the figure that CMSs has a broad diffraction peak at 22.83°, indicating that CMSs mainly exists in the form of amorphous carbon. After annealing, the diffraction peak of TCMSs at 21.64° narrows, and another diffraction peak appears at 43.57°. Both are characteristic peaks of graphitic carbon. The relative intensity and peak w...

Embodiment 2

[0042] Weigh 5g of CMSs into a quartz boat, place the quartz boat in a closed tubular muffle furnace, and first pass nitrogen gas for 20 minutes to replace and drive off the air in the muffle furnace. Keep the nitrogen flow rate at 200ml / min, raise the temperature of the muffle furnace to 600°C at a heating rate of 20°C / min, and keep the constant temperature for 5h. After the reaction, the temperature was naturally cooled to room temperature under a nitrogen atmosphere, and the product was collected to obtain annealed CMSs (ie, TCMSs).

[0043] Weigh 1 kg of PET slices, and dry them under vacuum at 130° C. for 8 hours, so that the moisture content of the slices reaches 28 ppm. Weigh 10 g of TCMSs, and also dry it under vacuum at 130° C. for 5 h. Add the dried PET slices to the main feed port of the twin-screw extruder with a frequency of 10Hz, add 10g TCMSs to the side feed port with a frequency of 7Hz, heat to 265°C for melt blending, wire drawing and pelletizing, and obtain...

Embodiment 3

[0046] Weigh 10 g of CMSs into a quartz boat, place the quartz boat in a closed tubular muffle furnace, and first pass nitrogen gas for 20 minutes to replace and remove the air in the muffle furnace. Keep the nitrogen flow rate at 200ml / min, raise the temperature of the muffle furnace to 700°C at a heating rate of 50°C / min, and keep the constant temperature for 3h. After the reaction, the temperature was naturally cooled to room temperature under a nitrogen atmosphere, and the product was collected to obtain annealed CMSs (ie, TCMSs).

[0047] Weigh 1 kg of PET slices, and dry them under vacuum at 130° C. for 8 hours, so that the moisture content of the slices reaches 28 ppm. Weigh 20g of TCMSs, and also dry it in vacuum at 130°C for 8h. Add the dried PET chips to the main feed port of the twin-screw extruder with a frequency of 13Hz, add 20g TCMSs to the side feed port with a frequency of 9Hz, heat to 275°C for melt blending, wire drawing and pelletizing, and obtain TCMSs / P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com